How to insulate the ceiling in the bath: modern materials and work technology. How to insulate the ceiling in a bath with a cold roof? Attic insulation in a bath with a cold roof

Each bath room requires the organization of high-quality insulation of the ceiling. This is necessary to prevent the loss of warm air, which will inevitably tend to the top. If the ceiling does not delay it, then the process of heating the bath and maintaining a constant elevated temperature inside will require an increased consumption of heat carriers and time.

Another possible problem is condensation in uninsulated rooms. Cold drops flowing here and there will significantly reduce the degree of comfort. And the moisture that will rise up along with heat flows will gradually destroy the ceiling ceilings and structural elements of the roof. In order to avoid condensation, it is necessary to put a heat-insulating “pie” on the ceiling during the manufacture of the bath, which will protect wooden structures in the attic of a bathhouse with a cold roof.

Insulation selection criteria

Expert advice on the requirements for heat insulators for a Russian bath:

Expert opinion

Konstantin Alexandrovich

Ask an expertIf the material you have chosen for thermal insulation meets all the criteria listed above, then it will be safe, warm and comfortable to be inside the dressing room and the steam room itself.

Bath ceiling insulation with mineral wool

Mineral wool is more often found on sale packed in rolls, their thickness is from 5 to 10 centimeters. It is not difficult to work with such material, you just need to unwind the roll, measure the fragment required along the length and, cutting it with an ordinary knife, lay the insulation where necessary. Thicker material, over 10 centimeters thick, is sold in the form of slabs or mats, which are placed at a distance between the structural elements of the batten, rafters or log from the attic side. Often this method of fastening does not need additional fastening. Experienced builders are advised to choose basalt wool for thermal insulation of the steam room.

In other cases, elements of the insulation material will need to be fixed. Fixing methods may vary in each case and depend on the density of the material and the gaps between the structural elements of the attic or roof.

In addition to fixing by surprise, there are other ways of fastening:

ATTENTION! Getting started with mineral wool, be sure to prepare means to protect the organs of vision, breathing and hands - goggles, a respirator and gloves. Ideally, you should use a protective suit to protect the body.

The procedure for thermal insulation of the ceiling space in the bath

Thermal insulation of the bath ceiling with expanded clay

Expanded clay is a very budgetary and fairly common insulation for floors and ceilings. You can easily fill it yourself with a minimum of effort. In fact, expanded clay is clay granules. large size that have been baked at a high temperature. Its texture resembles a stone with many pores. Such a heater is not afraid of the effects of harmful insects; bacteria and other pests of buildings do not develop in it. It is non-biodegradable. The insulation is absolutely harmless to human health, since it does not emit hazardous substances. In addition, it is completely non-flammable. The algorithm for thermal insulation of the ceiling space using expanded clay varies depending on the material for arranging the floors - wooden or concrete. First, familiarize yourself with the sequence of insulation of concrete floors.

The procedure for insulating the ceiling in the bath with expanded clay will be slightly different depending on whether the ceiling is concrete or wooden elements were used to equip it. First, you are invited to familiarize yourself with the procedure for insulating concrete floors. Detailed information about each technological stage isolation.

Thermal insulation of floors made of concrete and expanded clay

Insulation of concrete floors with expanded clay does not create any special problems.

ATTENTION! Despite the fact that expanded clay has a porous structure and belongs to light materials, its thirty-centimeter layer will have a fairly considerable weight. Insulation of wood floors with this material is possible only if the ceiling is strong enough. In the case of internal filing of the ceiling with OSB boards, it will be necessary to provide additional fastening to the boards. It is produced by mounting the crate, which is attached to the beams with the help of special studs.

Thermal insulation of the floor of a wooden bath with the help of expanded clay do-it-yourself

The installation of the insulating "pie" on this can be considered completed. Further order actions will be carried out according to the wishes of the owner of the premises. Most often, finishing flooring is laid either along the beams themselves, or on top of the logs specially laid for this purpose. This is advisable in the event that a residential attic will be equipped.

Thermal insulation of the ceiling using ecowool

Ecological wool is considered a completely safe material of natural origin. It has a long service life and quite effectively copes with the function of keeping the heat in the room. The material is free-flowing, therefore, for its transportation and storage, it is subject to pressing and packing into consumer containers - briquettes. For direct use, ecowool is released from packaging and fluffed up, after which it increases in volume several times. Professionals for applying ecowool prefer to use equipment specially designed for this. First, the material is slightly moistened and sprayed onto the insulated plane. After that, the crate is blown with dry material, which is pumped with a powerful compressor. This fact is the most significant disadvantage of using ecowool, since the purchase or rental of equipment is not cheap. At the same time, if it is planned to insulate a not too large area, for example, the ceiling space of a small bathhouse, it is quite possible to carry out the work manually. The process will take a lot of time and increase the degree of consumption of the insulation, but the thermal insulation will still turn out to be of high quality and will not cost too much.

The list of tips for arranging the sheathing and layers of insulation against moisture and steam is the same as for mineral wool, so it makes no sense to repeat them again. But it is worth considering that in the industrial application of ecowool, hydro and vapor barriers are usually not used. With manual application, it is not worth refusing them for greater reliability.

REFERENCE. In order to achieve maximum quality indicators with manual insulation with ecowool, it is important to correctly assess the required weight of the building material.

It is calculated using a simple formula:

m (ecowool weight) = S (cell area where the insulation will be placed) * L (thermal insulation layer thickness) * P (standard insulation density, for horizontal surfaces - 45 kg / m3).

After the crate space is filled with insulation, waterproofing and sheathing material are arranged on top of it.

Insulation of the ceiling of the bath with polypropylene foam

Foamed polypropylene, also called penofol, or foamed polyethylene - all these types of insulation materials are similar in structure, and they are installed in a similar way. The heat insulators under consideration are very easy to install, but their thermal insulation performance is often insufficient. Because of this feature, polypropylene foam and similar materials are best used in combination with other types of insulation, such as mineral wool.

Such a tandem can provide the most efficient heat conservation in the finished room.

Scheme of ceiling insulation in a bath with foamed polypropylene

A mixture of cement and sawdust

Such material for insulation has long been known and belongs to the traditional ones, which were used even before the era of modern materials for thermal insulation. Cement is successfully replaced in such compositions with clay, and straw can be taken instead of sawdust. The mixture is made by mixing the dry ingredients with water. The proportion is as follows: for 10 shares of sawdust, you need to add 1 share of cement and the same amount of lime. The resulting dry mass is poured with 1.5 parts of water and thoroughly mixed until a thick mixture of a homogeneous texture is obtained. The mass is laid out on a warmed surface and evenly distributed.

ATTENTION! Sawdust for the preparation of the mixture must be thoroughly dried, ideally - about one year.

Such an insulating material is characterized by minimal cost and environmental friendliness. But its thermal insulation qualities are inferior to those of mineral wool or expanded clay. The process of preparing and laying the mixture requires significant labor costs, and upon completion of the laying, it will be necessary to repair the inevitable cracks.

Finally

The thermal insulation of the ceiling in the bathhouse in the country is very important. If you want to save on heating the steam room, then this cannot be achieved without thermal insulation. With limited funds, you can give preference to budget options proper insulation, which will allow you to make a ceiling inexpensively and enjoy bathing in a bathhouse and not think about the cold that the ceiling radiates.

Video about the insulation of the ceiling in the bath with sawdust and cement

Greetings, dear readers, the topic of today's article is how to insulate the ceiling of the bath and how it is better to do it. In the last article, we chose the optimal height of the ceiling, now let's go directly to the installation and insulation of the bath ceiling.

A bit of theory. We all know that warm air is lighter than cold air and rises to the ceiling. And imagine the situation - hot steam has risen up, and the ceiling is cold. What will happen? That's right, condensation will fall. You soar with brooms in the bath, and the rain drips on you :). Let's see how improper insulation of the ceiling and the lack of vapor barrier can harm:

- Constant wetting of ceilings and, as a result, their premature destruction.

- Very fast cooling of the bath, it is possible that in the cold season the steam room will not be able to warm up properly.

- Excessive consumption of firewood or electricity.

- The real danger of destruction of ceilings.

Proper ceiling insulation

In this we will tell you how to avoid all these problems and properly insulate the ceiling. The whole process can be divided into three key stages:

- Steam room ceiling insulation.

- Attic waterproofing.

- Vapor barrier.

We, as builders, at this time have a serious advantage over our ancestors - the modern construction market offers the widest range of various thermal insulation materials for every taste and budget. Let's look at the most popular thermal insulation materials.

How to insulate the ceiling in the bath - popular materials.

Mineral wool- the most common insulation material among our compatriots. It is highly valued for its good insulating qualities, ease of installation and, most importantly, cost. Mineral wool consists of many basalt threads intertwined in a chaotic manner, among which there are billions of tiny voids filled with air. Such a mixture of air and basalt keeps heat well and is great for warming the bath ceiling. But min. cotton wool has one big minus - it is afraid of moisture. When wet, mineral wool becomes very caked and loses its thermal insulation characteristics at times. Inexpensive and practical.

Expanded clay- this material is often used for insulation of ceilings. Expanded clay is a set of small granules, each of which weighs less than a gram. The required layer of expanded clay laying is 20-30 centimeters. Although one granule weighs practically nothing, such a mass of expanded clay on small area ceiling will exert a noticeable load on ceilings which must also be taken into account when designing.

The main materials of thermal insulation

Folk insulation- a mixture of clay, earth, sawdust or straw. The most budget option, but unfortunately not the best. A layer of earth (2-3 centimeters) is laid on the ceilings, a layer of sawdust or straw is laid on top of the earth.

Polypropylene- modern heat-insulating material, recently comes to replace mineral wool. It is very light and comfortable material foam structure, which is designed specifically for the insulation of saunas and baths. The material itself holds heat very well, and the foil side of the polypropylene reflects heat radiation in the manner of a mirror. The use of penotherm allows you to reduce the heating of the sauna and bath by 2 or even 3 times.

How to insulate the ceiling in the bath

Let's proceed directly to the laying of thermal insulation. The ceiling device is made after roofing cake laid and the walls erected. The roof is especially important, otherwise your thermal insulation may suffer in the open air.

Consider the main methods of ceiling insulation in the bath:

- Flooring (for small baths).

- Hemming (for large baths).

- Panel (an alternative to the first two).

It also makes sense to consider two types of bath construction - with and without an attic. It is best to make a bath with an attic. Firstly, you will have a place to dry brooms :). Secondly, a large air gap between the ceiling and the roof will significantly reduce the heat loss of the ceiling and save on insulation. Of course, subject to competent roof insulation.

The most popular method of warming the bath

This method is suitable for baths with or without an attic. The main condition for insulation is mounted ceilings. Before starting the installation of thermal insulation, you need to treat the wooden beams with an antiseptic. We present to your attention, in my opinion, the most correct scheme heater installations:

- Stage 1. WITH inside baths we attach a layer of vapor barrier to the ceiling. We talked in detail about the vapor barrier of the ceilings in the bath in this article. In short, a vapor barrier that includes a layer of aluminum is best suited for a bath. Aluminum well protects the vapor barrier and thermal insulation from moisture, and also reflects heat radiation back into the room, which reduces the warm-up time by 2! times. The vapor barrier is attached to the beams using a construction stapler, the attachment points are best treated with a special heat-resistant sealant. The seams of the vapor barrier are glued with adhesive tape, the vapor barrier sheets are overlapped with a 4-5 centimeter approach.

Laying vapor barrier - sectional diagram

From another angle, white material - vapor barrier

Dense laying of thermal insulation

As you can see, even a novice in the construction business can do the insulation of the bath ceiling. In the attic, we also recommend that you lay special guides and lay floorboard. And the waterproofing is intact, and there is free access to the attic. You can start preparing brooms.

Folk method of warming

Watch a video on how to insulate the ceiling with clay, sawdust and straw.

Voting - your choice of insulation

Dear bath attendants, we always welcome feedback from our readers. Please leave your opinions about the warming of the bath, your advice and suggestions, we will be happy to add useful things to the article. And now I ask you to participate in the vote:

A modern bath is the ultimate dream of many cottage owners and country houses. The construction of this building must be carried out taking into account existing rules and technologies. In particular, its functionality and comfort directly depend on how correctly it will be possible to insulate the ceiling in the bath. The operation of this facility implies the creation of a given microclimate inside with air temperature and humidity significantly exceeding the average for the street and residential premises.

The inability to properly insulate the surface, as well as inefficiently performed thermal insulation work, will require increased energy consumption during heating. In addition, condensate will settle on the walls and ceiling, which, dripping and draining, will prevent you from enjoying all the benefits of the bath and will gradually begin to harm the roof structure, increasing the risk of fungus.

Types of roofs in the bath and how to insulate them

Design modern baths, regardless of the material for their manufacture, can be of two types:

- with a warm roof;

- with a cold roof, which provides for the installation of heat and waterproofing directly under the roof on the ceiling.

According to the laws of physics, heated air always rushes up, and, without encountering barriers in the form of insulation, it will freely leave the room, reducing energy efficiency.

Insulation of the ceiling in a bath with a cold roof can be done in two ways:

- from inside the room - simple and easy-to-implement technologies that are suitable for objects with high ceilings, allowing them to be lowered by 15-20 cm, depending on the insulation and finish used.

- outside the premises - it is advisable to use for low buildings, the bearing capacity of the roof of which allows the installation of insulation on the ceiling in the attic space.

The choice of materials for the insulation of the ceiling in the bath

The modern construction market offers a variety of materials with which you can qualitatively and inexpensively insulate the ceiling of any design, structure and area. The main task for do-it-yourself insulation is strict adherence to the laying technology, as well as the installation of additional layers of vapor and waterproofing. Given the harsh operating conditions of ceilings in bath rooms, the insulation used must meet the following characteristics:

- resistance to sudden temperature changes;

- low absorption and stability during prolonged exposure to a humid environment;

- resistance to fungi, rodents and other biological microorganisms;

- simplicity and high speed of do-it-yourself installation;

- enough level fire safety;

- low thermal conductivity to create and maintain the desired microclimate in the room for as long as possible;

- complete environmental safety of the material.

Consider the most common options for thermal insulation materials used for the ceiling in the bath. This will help determine the better one or another insulation in each case.

Expanded clay

It is a natural bulk material obtained by firing shale. The packing density of the material depends on the selected fraction. The smaller it is, the higher the density. Among the main advantages this insulation is complete environmental safety, as well as resistance to any humidity and temperature extremes. It is non-flammable and odorless, and does not form dust during operation.

Given the structure of this material, expanded clay insulation is carried out only outside the room. It is covered from the side of the attic floor, if the design of the bath provides for such a space.

The technology for performing work with this material provides for the following procedure:

- surface cleaning from contamination and foreign objects;

- installation of a vapor barrier film, which is attached with a stapler or double-sided tape;

- backfilling of expanded clay is carried out with a layer of 15-30 cm;

- from above, the material is covered with a waterproofing film;

- the final stage of such insulation is the installation of a roof or a wooden attic floor.

Among the main disadvantages of the decision to insulate the ceiling in the bath with expanded clay, experts call the inability to perform installation from the inside of the room, as well as the use only on flat surfaces or with a minimal slope.

Ecowool

Although this material has not yet received very wide distribution, it is quite possible to use it as a modern, highly effective insulation for the ceiling. It consists of the smallest fibers of cellulose, which is harmless to humans and perfectly performs thermal insulation functions in the room.

The technology of working with this material provides for two methods of application. Dry installation involves the external laying of the material, followed by compaction. In turn, wet application of ecowool is more efficient, but requires special equipment, with which the material is applied under pressure to the surface to be insulated. Among the main advantages of using this insulating material, experts distinguish:

- complete environmental safety and the ability to easily endure sudden changes in temperature;

- has a long service life and does not lose its qualities during use;

- minimum weight allows installation on surfaces with low bearing capacity;

- non-susceptibility to the emergence of fungi and lack of attractiveness for rodents;

- flame retardant treatment indicates increased fire safety and a tendency to self-extinguish during fires.

Mineral wool

Deciding which better insulation, many opt for this insulating material. Building supermarkets offer users three types of this fibrous heat insulator:

- glass wool;

- basalt wool, which includes waste from the mining industry;

- slag wool, made from melts of blast furnaces.

This material has low thermal conductivity and is resistant to fungal growths and other biological organisms. Mineral wool is resistant to sudden changes in temperature and is classified as non-combustible. It comes in the form of plates or rolls, which are convenient to mount on any surface.

Effective thermal insulation of the ceiling, which with the help of this material can be made both from the inside and outside of the ceiling. In both versions, a vapor barrier must be installed below the material, and a hydro-barrier must be installed on top. This will help rid the material of its main shortcomings:

- the ability to absorb and accumulate moisture;

- evaporation of phenols, which may be part of the insulation.

Installation of mineral wool from the inside of the building is carried out on a pre-prepared crate, into the openings of which the material is installed. The frame is most often made of wood, but in some cases a galvanized profile can also be used. The surface of the insulation is covered with a vapor barrier and finishing material. In the case of a bath, this can be lining or other structures made of natural wood. You can learn more about the technology of insulating rooms with mineral wool by watching a step-by-step video.

The technology for installing this insulation from the attic side is the same as from the inside of the room. The only difference is the absence of a crate, since the laying is done between the lags. In general, mineral wool can be laid on any surface, as in frame bath and capital, brick construction.

Styrofoam

Despite some drawbacks, this material is one of the most common and is perfect for effectively insulating the bath ceiling from the outside. It is easy to install, does not absorb moisture and has low thermal conductivity. Light weight and the ability to cut to any required size, allow installation on the surface, without regard to the bearing capacity of the building.

The disadvantages of extruded polystyrene is the risk of releasing harmful particles during combustion. Work with this material is carried out as follows:

- leveling, cleaning and surface preparation;

- laying vapor barrier material;

- installation of thermal insulation material;

- fixing plates with special plastic dowels;

- insulation of joints between plates;

- pouring with a screed or laying a finish on top of the heat-insulating layer in the outer part of the ceiling.

polyurethane foam

This material is one of the answers to the question - how can you insulate the ceiling in the bath. The only limiting factor in its use is the need for specialized application equipment, which can be quite expensive to rent. Among the main advantages of such material are:

- high thermal insulation properties;

- resistance to sudden temperature changes;

- high coating strength;

- the ability to work both in a log bath, and frame, brick or cinder block buildings.

A mixture of shavings and clay

It is excellent in its characteristics and at the same time affordable insulation used from the side of the attic. Sawdust and clay are mixed in a ratio of 10 to 1. Vapor barrier films are laid from below. The layer thickness must be at least 20 cm. After drying, the surface is treated with antiseptics and covered with a hydrobarrier.

Earth insulation

This technology belongs to the ancient ones and is suitable for warming the attic space. log sauna. Blocks are stuffed onto the ceiling, the height of which should be at least 6 cm. Next, insulation is made with foil. A layer of clay is laid on top of it to level the surface. After that, it is possible to insulate the ceiling of the bath with earth, the layer of which should exceed 20 cm. To isolate the surface from moisture, a hydrobarrier is laid on top.

Reed insulation

Mats made from these plants can also be excellent, ecological insulation. They are laid between the joists with an overlap, forming a surface with perfectly insulated joints. This natural material is suitable for lovers of eco-buildings. Reed is not subject to deterioration in its properties during operation, its cost is lower than any similar materials. In addition, its low weight will allow it to be used in buildings with low bearing capacity.

Ceiling insulation in the steam room

The main function that the ceiling in the steam room should perform is to isolate it from the penetration of steam, which should accumulate in the room and not leave it during operation. To do this, two layers of vapor barrier and a layer of insulation are installed inside the room.

The standard scheme for warming the steam room is as follows:

- the lower part of the floor beams is sewn up with boards;

- boards are made. These are structures consisting of two layers of perpendicularly knocked down boards, between which a vapor barrier film is fixed. They should not be located close to each other with a gap of 5 cm. From the chimney wooden surfaces must also be at least 25 cm apart;

- the wooden surface of the shields is impregnated with special antiseptic compounds;

- insulation is mounted on the shields. It is necessary to isolate all sections of the ceiling;

- then the steam room ceiling is upholstered with foil. It increases the vapor barrier function and betrays the fire resistance of the surface;

- the next layer is the finishing layer, which is treated with fire-fighting compounds.

After that, the insulation of the ceiling in the steam room from the inside can be considered complete.

Conclusion

Based on the foregoing, we can safely say that the insulation of the ceiling in the bath is a rather complex and time-consuming process, the result of which can have a direct impact on the functionality, efficiency and ease of use of such objects. The complex of the above works is best entrusted to specialists, but if necessary tool, equipment and elementary skills can be handled on your own. The main task in the implementation of insulation is strict adherence to technological processes and willingness to comply with all the rules of work until the desired result is obtained.

How to properly insulate the ceiling in a bath with a cold roof or attic? What is the difference, how to avoid mistakes?

Main page » What is better to build a bath from » Bath insulation » Ceiling insulation in a bath » How to properly insulate the ceiling in a bath with a cold roof or attic? What is the difference, how to avoid mistakes?

Going to a hot bath to take a steam bath, we certainly put on a warm hat, though for a beginner it looks more than strange.

Going to a hot bath to take a steam bath, we certainly put on a warm hat, though for a beginner it looks more than strange.

But the hat is like a heat insulator that absorbs moisture and protects your head from overheating. So in the construction of the bath itself - the insulated ceiling is the most important part.

It is unacceptable to forget about this after insulating the floor and walls for which different materials. In order for the bath to keep heat well, it is necessary to correctly select the insulating material and the method of thermal insulation of the ceiling, of course, taking into account the type of roof.

The main types of attic roofs

Types of insulation of the bath ceiling:

- outside- more convenient in execution, most effective for a ceiling located under an uninsulated roof, the insulation is laid out on attic floor and closes with a draft or finishing floor;

- from within- prolongs the durability of the material, there are no temperature differences, but you have to “steal” a few centimeters of the height of the bath, a frame is mounted on the ceiling, after fixing the first layer of vapor barrier, and a heater is placed in it, then the vapor barrier is again attached and attached ceiling covering.

With a cold roof or with an attic - what's the difference

In the presence of attic floor there is a problem with the penetrating temperature threshold from the steam room, from where a large amount of steam, warm and hot air rises and, accordingly, if it is not properly disposed of, it will accumulate in the attic space. Therefore, in order to insulate the ceiling in a bath with a cold roof, you should carefully calculate the thickness of the ceiling insulation, taking into account the loads and take care of the best vapor and waterproofing.

There is an opinion that it is not necessary to insulate the ceiling in a bath with an attic, but an increase in the thermal insulation characteristics in it is more necessary than with an uninsulated attic space, where the heat penetrating outside does not encounter serious obstacles in its path.

Ceiling insulation in a bath with a cold roof

Warm air is lighter than cold air, so it rises. Not meeting the barrier, it will heat the atmosphere, in order not to take part in the progress of global warming, it is necessary to organize the correct thermal insulation. air masses filling the under-roofing space, of course, retain heat leakage, but this is not enough.

Warm air is lighter than cold air, so it rises. Not meeting the barrier, it will heat the atmosphere, in order not to take part in the progress of global warming, it is necessary to organize the correct thermal insulation. air masses filling the under-roofing space, of course, retain heat leakage, but this is not enough.

With well-executed thermal insulation measures, the time for heating the room is significantly reduced, fuel is saved, heat and steam are saved longer, and the life of the ceiling increases. Laying thermal insulation in a multilayer top floor system prevents many types of thermal leakage.

How to insulate

Before laying the heat-insulating layer, a vapor barrier is laid. It prevents the transit of wet vapors and their settling in the insulation layer, because. water accumulated in the thermal insulation will increase the weight of the ceiling system and degrade the insulating qualities.

As a vapor barrier, use: aluminum foil, compacted cardboard impregnated with drying oil, waxed paper, a special film with villi, membrane material.

For more information on using foil, see this page.

How to insulate

Ceiling insulation with sawdust

Traditionally, people warmed wooden houses sawdust and lived, did not grieve in warm houses during severe frosts. The people recommend to this day to insulate the ceiling with dry straw and fragrant sawdust. They are eco-friendly, safe, hypoallergenic, natural. No special skills or special tools are required to use them.

If there is a solid base, a vapor barrier is first laid: roofing material, rubimast, high-strength cardboard or membrane film; the edges are brought out to the sides of the beams and attached with a stapler to prevent spilling down. The slots are pre-blown mounting foam. Then sawdust is poured into pure form or with impurities.

Insulation compositions based on sawdust

Insulation compositions based on sawdust are:

Insulation compositions based on sawdust are:

- clean- sawdust of different fractions is used, the rough layer is coarse chips - 10 cm, the finishing layer is another 10 cm fine, usually this thickness coincides with the height of the beams, so that the sawdust does not scatter from above, spread a diffuse membrane;

- with clay –

- first option: a layer of crumpled clay is laid out - 20-25 mm, on top of sawdust, as a heat-insulating layer - 10-15 cm, dry earth - 10-15 cm;

- second: chips are mixed with clay in equal volumes and laid out on a prepared base 10 cm thick; the ratio of clay and sawdust 2:3;

- with cement - sawdust is mixed with cement, in a ratio of 10: 1, it is closed with water to a state of a very thick solution, it is laid in a layer 20-30 cm thick, an antiseptic and anti-burning agents are added if desired.

Clay-based mortars

Clay concrete- obtained by mixing: sawdust, clay, lime, cement or gypsum with water. To knead 1 cube you will need: 200 kg of sawdust, 300 kg of cement, 70 kg of lime, 300 kg of clay, 350 liters of water. First of all, dry ingredients are combined, then lime and clay are added. It turns out a solution with good thermal insulation qualities, durable, reliable, inexpensive, does not rot.

clay-sand- the ratio of sand and clay is 2: 6, water is added to the consistency of sour cream. The slots of the flooring are covered with liquid clay, after drying, the vapor barrier membrane is laid with an overlap of 15-20 cm, the joints are glued with foil tape, the base is evenly covered with a mixture of sand and clay 5-7 cm thick, after hardening we fill it with dry sand 10-15 cm, logs can be mounted on top and clean floor.

Expanded clay

Thermal insulation material of bulk type. An environmentally friendly product made from clay, perfect for thermal insulation of the bath ceiling. Main properties: non-flammable, does not emit harmful substances when heated, does not big weight, does not create additional load. For insulation of the ceiling, expanded clay is used, having a fraction size of 4-10 mm, a layer thickness of at least 30 cm.

Useful video

Watch a video on how to properly use expanded clay for ceiling insulation, what mistake to avoid:

mineral wool

Fibrous insulation based on minerals, produced in the form of mats, slabs, rolls. It is considered the most effective for thermal insulation of the ceiling, long service life, though its cost is higher. Mineral wool properties: retains heat well, noise insulator. Spread between the lags of the floor. For a bath with an insulated attic, a thickness of 10 cm is sufficient, with a cold ceiling of 15-20 cm.

Other heaters

ecowool from small cellulose fibers;

polystyrene boards- a favorite among heat-shielding building materials, due to ease of installation and low cost;

folgoizol used to keep the heat in the ceilings of baths and saunas, it does not corrode and decay from the environment.

polyurethane foam- material sprayed using special equipment.

Ceiling insulation in a bath with an attic

The attic room is the coldest in the bathhouse, because does not have a “thermal cushion”, therefore, the insulation of the ceiling in a bath with an attic is the main task; with such a constructive construction scheme, thermal insulation of both the floor of the second floor and the roof is used. After all, excess heat from the bath fully heats up the attic room, and the heat-insulating layer prevents it from overheating.

The attic room is the coldest in the bathhouse, because does not have a “thermal cushion”, therefore, the insulation of the ceiling in a bath with an attic is the main task; with such a constructive construction scheme, thermal insulation of both the floor of the second floor and the roof is used. After all, excess heat from the bath fully heats up the attic room, and the heat-insulating layer prevents it from overheating.

keeping warm under roofing material is also necessary. Both in winter and summer, you will be comfortable. Under the summer sun, the roof heats up, the outside heat is combined with the heat coming from the steam room, as a result, on a bathing day you will get hell on the second floor.

How to insulate

The approximate "pie" of insulation from the inside of the steam room (about heaters for the steam room here) is as follows:

- lining;

- rail;

- foil glued with tape;

- draft board 150 x 20 mm;

- floor beam;

- glassine;

- expanded clay - 120 mm;

- Rockwool insulation - 50 mm;

- glassine;

- batten.

Useful video

See the explanation of the above illustration of the bath roof cake with an attic:

How to insulate

What thermal insulation material to use? Yes, everything that is listed above, from time-tested, natural, natural heaters to ultra-modern ones (wood chips, shavings, sawdust, sand, expanded clay, mineral wool, basalt wool, ecowool). More information on heaters for baths here.

conclusions

The problems of heat leakage must be solved in a complex way, and not only those discussed in this article. There are no trifles in the organization of thermal insulation, window and door openings, walls, roof, ceiling, floor - everything must be done correctly, in compliance with building codes and calculations based on your region. When insulating the ceiling in a bath with an attic, one should also take into account the features of thermal insulation of buildings made of different materials: foam block, brick, frame, timber or logs.

Where to order or buy

When building a bathhouse or having problems with maintaining heat in an already operated building, it is better to turn to professionals or get their qualified advice than to comprehend construction science by trial and error. But for those who prefer to master the technique of building and insulating baths on their own, you should pay attention to companies selling heaters.

Ceiling insulation in a bath with a cold roof: 4 best ways

A cold roof is not designed to retain heat, so bathing in a bath with such a roof will be very uncomfortable. How to insulate the ceiling in the bath to avoid such a problem? We'll figure out.

Why insulate the ceiling in the bath

If the roof of a building is cold, it means that it is not insulated. The under-roof space is separated from the street only by a layer of waterproofing and roofing elements. This gives certain advantages:

- low weight of the structure;

- savings on the purchase of building materials and installation;

- lack of ice in the cold.

But there are also disadvantages. The biggest one is heat leakage. And as a result, the need to heat the room is much more intense. If a bath is covered with a cold roof, the situation is aggravated by the presence of moist heated air. It rises to the uninsulated ceiling, cools down and forms a copious condensate that spoils building structures and drips on people inside.

The presence of condensate on the floors and on the ceiling is highly undesirable. Moisture penetrates the structure and begins its destruction. Depending on the type of coating, it passes at different speeds, but always quickly enough. Fungus and mold dangerous to humans appear. The only way to solve all problems is to make thermal insulation of the ceiling.

Competent warming technique

Under the insulation, it is supposed to lay a layer of insulating material that will keep the heat inside the room. However, only a warming layer in the bath is not enough. He will not be able to complete his task, because he will be saturated with moisture and deteriorate. In order for the insulation to last for a long time, it is required to lay three layers of insulating materials.

Layer 1: vapor barrier

The main task of this layer is to prevent vapor from entering the insulation. All vapors rising from the heated room must be contained. As an insulator for this layer, materials such as glassine or roofing paper, proven over the years, can be used. Or more modern geosynthetic coatings, various membranes and thermofol. Well, if the coating is foil, then it can also shield heat, returning it to the room.

Layer 2: thermal insulation

The second layer of the insulating cake should trap heat without letting it out. A variety of materials can be used here. Which to choose, will tell you the budget and your own skills of conducting construction works. It is important that the insulation be as light as possible (then it will not create an unnecessary load on structures that are resistant to moisture) and non-combustible, as simple and convenient as possible to install.

How to insulate the ceiling in a bath with a cold roof?

If the ceiling is not insulated in a bath with a cold roof, condensate will accumulate on its surface. Chilled drops of water dripping from above on people in the bath will clearly deprive them of the expected pleasure. Droplets of water falling further upwards with warm air currents will contribute to rotting and complete destruction of the ceilings, and in general - the roof truss structure. The only way to prevent the occurrence of such troubles will be the arrangement of ceiling insulation in a bath with a cold roof.

Planning work on the thermal insulation of the roof of the bath

Before purchasing the building materials necessary for work and preparing the right tools, you need to draw up a detailed plan for the insulation work performed. Drawing up a plan will avoid mistakes and alterations of the roof structure.

The process of thermal insulation of the ceiling and roof of the bath is not a very laborious work, therefore it is easy to do it yourself, even in the absence of sufficient experience in repair and construction work. The main thing is that it is necessary to strictly adhere to the sequence (technology) of performing installation operations. Another argument for self-insulating the ceiling is the availability of the necessary heat-insulating materials - they are available in almost all hardware stores.

Insulation of the ceiling in a bath with a cold roof includes 3 stages:

- Thermal insulation.

- Laying a layer of vapor barrier.

- Waterproofing.

At the end of the work, a structure is obtained that looks like a layer cake, in which the lowest layer is the ceiling ceiling, and layers are successively located above it: steam, heat and waterproofing. Then you can start choosing the necessary building materials.

The choice of heat insulator for the roof and ceiling of the bath

In a well-heated bath, it is necessary to maintain sufficiently high values \u200b\u200bof humidity and temperature. The heat-insulating building material must be fully suitable for such requirements and, most importantly, it must not emit substances hazardous to people and the environment during heating. And besides this, a good heat insulator for a bathhouse should not support combustion, be excessively heavy and inconvenient for moving and laying.

mineral wool

One of the most common options for fibrous heat insulators for ceiling insulation in a bath with a cold roof and individual housing construction, produced in 3 types:

- glass wool;

- slag wool, produced from blast furnace waste (slag);

- stone wool is made from melts of basalt and other minerals.

The main advantage of mineral wool, in addition to very low indicators of heat conductivity: mold and fungus spores do not develop on it, and insects and rodents bypass it. For a bathhouse located on a land plot, this advantage of mineral wool is very important. It should also be noted that this building material does not change its volume and shape when the ambient temperature changes, it does not support combustion, it is very convenient for installation, due to its low weight. Mineral wool is produced in rolls or in the form of rectangular sheets/panels.

There are two disadvantages of mineral wool - this is the high ability of mineral wool to absorb any moisture (especially slag wool) and the phenolic compounds contained in it. These 2 shortcomings are easily eliminated: with the help of good hydro and vapor barriers and preventing contact between air flows and mineral wool, especially in the inside of the bathhouse.

Important: when performing any work with mineral wool, you must be in tight outerwear, and use protective devices(goggles and respirator) to protect the eyes and respiratory organs, as its small elements affect the skin, eyes and lungs of a person.

Expanded clay

This building material is a small porous clay pebbles. For all its properties, expanded clay is considered the most suitable heat insulator to insulate the ceiling in a bath with a cold roof.

Warming the roof of the bath with expanded clay

Warming the roof of the bath with expanded clay

This material is safe - it does not support combustion, does not harm people and environment, does not emit polluting and harmful substances to humans. Expanded clay - durable, does not collapse under the influence of the sun's rays. In this building material, spores of fungi and bacteria do not develop, it is inexpensive and its installation is simple.

Expanded clay also absorbs much less water than mineral wool, however, it is also necessary to use hydro- and vapor barriers for its laying.

Styrofoam

More recently, this heat insulator was one of the most popular among all heat-insulating building materials. But, despite its excellent heat-insulating properties, foam plastic cannot be used to insulate the roof or ceiling of the bath - this building material is combustible, and when burned, it emits toxic substances that are dangerous to human life. It can also decompose and lose shape under the influence of high temperatures in the bath.

Ecowool

This is a fibrous natural heat insulator made from cellulose fibers with various additives that give additional properties - resistance to burning and protecting against the appearance of rodents, microorganisms and insects. Ecowool has a small specific gravity and can fill absolutely all the gaps and cracks.

Like expanded clay, ecowool is an environmentally friendly heat insulator that does not emit hazardous substances into the air.

Roof insulation with ecowool

Roof insulation with ecowool

However, this heat insulator has a significant drawback - it absorbs a lot of liquid, which leads to a deterioration in heat-insulating properties. Therefore, when using ecowool, excellent ventilation of the under-roof space and a high-quality waterproofing layer are necessary. Another disadvantage of its use is the complexity of laying; with a “wet” installation method, special equipment is required.

A mixture of cement and sawdust

This is a "classic" building material-insulation, which was used before the advent of polystyrene foam and mineral wool. Sometimes clay is used instead of Portland cement, and sawdust is replaced with straw.

Important: the sawdust used in this mixture must be dried for several months, and even better - for a year.

This is a very cheap and environmentally friendly heat insulator, but with low heat-insulating characteristics. In addition, the preparation of the mixture is very laborious.

Materials for hydro and vapor barrier

The vapor barrier of the ceiling in the bath is very important, otherwise the moisture circulating in the room will worsen the properties of the heat insulator and lead to the development of mold and fungi both on the ceiling itself and on the details of the truss structure. For vapor barrier, special films and coatings are most often used - in particular, with anti-condensation membranes (preferably with a layer of foil). The leading places, at the moment, in the market are occupied by TechnoNIKOL vapor barriers.

As a waterproofing agent, you can also use both special films and cheaper building materials - roofing felt or thick polyethylene.

Insulation of the ceiling in the baths

There are 3 main types of ceilings in baths:

The floor type ceiling is common in small baths, which are used seasonally and quite rarely. On the upper parts of the walls are placed boards adjusted to each other, fixed without support beams. The resulting design is very simple, but it cannot withstand a lot of weight, so the heat insulator layer must be thin and light.

Important: a floor-type ceiling must be erected just below the upper boundary of the walls in order to get space for filling expanded clay or placing mineral wool.

From the side of the attic space, a film vapor barrier is placed on the flooring so that the foil on it is directed downwards. The vapor barrier itself is laid with an overlap of 10-15 cm, and the joints and seams are sealed with special adhesive tape for vapor barrier with a layer of foil.

Mineral wool is laid on top of the vapor barrier, expanded clay or a cement-sawdust mixture is placed. The layer of insulation should not be thick.

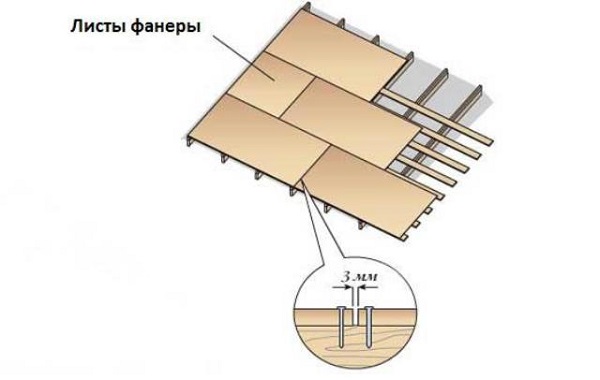

Then the heat-insulating layer is closed from above with a waterproofing agent (film or roofing material), on top of which boards or plywood sheets are nailed.

Hemming type ceiling insulation

For this type of ceiling, on the upper parts of the walls, not flooring is placed, but supporting wooden beams made from beams or finger-jointed boards. Then, the floor of the attic and the ceiling are placed on these support beams from below and above. And in the space between the attic floor and the ceiling, layers of heat, steam and waterproofing are mounted.

Stages of the installation of a false ceiling in the bath

Stages of the installation of a false ceiling in the bath

The process of placing a heat insulator is performed as follows. From the side of the roof on the beams, a film waterproofing agent is placed and attached with a stapler. Next, boards or plywood sheets are laid on top of it. The hemmed-type ceiling is durable, so the resulting under-roof space can even be used as an attic.

Mineral wool is placed between the beams. The thickness of the heat insulator depends on the location of the bath structure: for mid-latitudes 15.0-18.0 cm, in areas with severe winter frosts - 20.0-25.0 cm. Layers of heat-insulating building material are laid so that the joints of the previous layer overlap with the next layer .

A vapor barrier film is attached to the floor beams from below. On top of the vapor barrier, the slats are fixed perpendicular to the beams.

After that, the lining is laid, which is nailed or fixed with screws directly to the rails.

Insulation of a panel-type ceiling is the most difficult and is practically not used for self-production. First, the panels are made directly, and then they are lifted up and fixed - either on the cross-beams or on the upper parts of the walls.

Important: the choice of the type of ceiling and heat-insulating building material must be carried out based on the planned budget, building experience, the area of \u200b\u200bthe bathhouse and the frequency of its use.

Greetings, dear readers, the topic of today's article is how to insulate the ceiling of the bath and how it is better to do it. In the last article, we chose the optimal height of the ceiling, now let's go directly to the installation and insulation of the bath ceiling.

A bit of theory. We all know that warm air is lighter than cold air and rises to the ceiling. And imagine the situation - hot steam has risen up, and the ceiling is cold. What will happen? That's right, condensation will fall. You soar with brooms in the bath, and the rain drips on you :). Let's see how improper insulation of the ceiling and the lack of vapor barrier can harm:

- Constant wetting of ceilings and, as a result, their premature destruction.

- Very fast cooling of the bath, it is possible that in the cold season the steam room will not be able to warm up properly.

- Excessive consumption of firewood or electricity.

- The real danger of destruction of ceilings.

Proper ceiling insulation

In this we will tell you how to avoid all these problems and properly insulate the ceiling. The whole process can be divided into three key stages:

- Steam room ceiling insulation.

- Attic waterproofing.

- Vapor barrier.

We, as builders, at this time have a serious advantage over our ancestors - the modern construction market offers the widest range of various thermal insulation materials for every taste and budget. Let's look at the most popular thermal insulation materials.

How to insulate the ceiling in the bath - popular materials.

Mineral wool- the most common insulation material among our compatriots. It is highly valued for its good insulating qualities, ease of installation and, most importantly, cost. Mineral wool consists of many basalt threads intertwined in a chaotic manner, among which there are billions of tiny voids filled with air. Such a mixture of air and basalt keeps heat well and is great for warming the bath ceiling. But min. cotton wool has one big minus - it is afraid of moisture. When wet, mineral wool becomes very caked and loses its thermal insulation characteristics at times. Inexpensive and practical.

Expanded clay- this material is often used for insulation of ceilings. Expanded clay is a set of small granules, each of which weighs less than a gram. The required layer of expanded clay laying is 20-30 centimeters. Although one granule weighs practically nothing, such a mass of expanded clay in a small area of \u200b\u200bthe ceiling will exert a noticeable load on the ceiling, which must also be taken into account when designing.

The main materials of thermal insulation

Folk insulation- a mixture of clay, earth, sawdust or straw. The most budget option, but unfortunately not the best. A layer of earth (2-3 centimeters) is laid on the ceilings, a layer of sawdust or straw is laid on top of the earth.

Polypropylene- modern heat-insulating material, recently comes to replace mineral wool. This is a very light and comfortable foam structure material, which is designed specifically for warming saunas and baths. The material itself holds heat very well, and the foil side of the polypropylene reflects heat radiation in the manner of a mirror. The use of penotherm allows you to reduce the heating of the sauna and bath by 2 or even 3 times.

How to insulate the ceiling in the bath

Let's proceed directly to the laying of thermal insulation. The ceiling device is made after roofing cake laid and the walls erected. The roof is especially important, otherwise your thermal insulation may suffer in the open air.

Consider the main methods of ceiling insulation in the bath:

- Flooring (for small baths).

- Hemming (for large baths).

- Panel (an alternative to the first two).

It also makes sense to consider two types of bath construction - with and without an attic. It is best to make a bath with an attic. Firstly, you will have a place to dry brooms :). Secondly, a large air gap between the ceiling and the roof will significantly reduce the heat loss of the ceiling and save on insulation. Of course, subject to competent roof insulation.

The most popular method of warming the bath

This method is suitable for baths with or without an attic. The main condition for insulation is mounted ceilings. Before starting the installation of thermal insulation, you need to treat the wooden beams with an antiseptic. We present to your attention, in my opinion, the most correct installation scheme for insulation:

- Stage 1. From the inside of the bath, we attach a layer of vapor barrier to the ceiling. We talked in detail about the vapor barrier of the ceilings in the bath in this article. In short, a vapor barrier that includes a layer of aluminum is best suited for a bath. Aluminum well protects the vapor barrier and thermal insulation from moisture, and also reflects heat radiation back into the room, which reduces the warm-up time by 2! times. The vapor barrier is attached to the beams using a construction stapler, the attachment points are best treated with a special heat-resistant sealant. The seams of the vapor barrier are glued with adhesive tape, the vapor barrier sheets are overlapped with a 4-5 centimeter approach.

Laying vapor barrier - sectional diagram

From another angle, white material - vapor barrier

Dense laying of thermal insulation

As you can see, even a novice in the construction business can do the insulation of the bath ceiling. In the attic, we also recommend that you lay special guides and lay the floorboard. And the waterproofing is intact, and there is free access to the attic. You can start preparing brooms.

Folk method of warming

Watch a video on how to insulate the ceiling with clay, sawdust and straw.

Voting - your choice of insulation

Dear bath attendants, we always welcome feedback from our readers. Please leave your opinions about the warming of the bath, your advice and suggestions, we will be happy to add useful things to the article. And now I ask you to participate in the vote:

Ceiling insulation in a bath with a cold roof: 4 best ways

A cold roof is not designed to retain heat, so bathing in a bath with such a roof will be very uncomfortable. How to insulate the ceiling in the bath to avoid such a problem? We'll figure out.

Why insulate the ceiling in the bath

If the roof of a building is cold, it means that it is not insulated. The under-roof space is separated from the street only by a layer of waterproofing and roofing elements. This gives certain advantages:

- low weight of the structure;

- savings on the purchase of building materials and installation;

- lack of ice in the cold.

But there are also disadvantages. The biggest one is heat leakage. And as a result, the need to heat the room is much more intense. If a bath is covered with a cold roof, the situation is aggravated by the presence of moist heated air. It rises to the uninsulated ceiling, cools down and forms a copious condensate that spoils building structures and drips on people inside.

The presence of condensate on the floors and on the ceiling is highly undesirable. Moisture penetrates the structure and begins its destruction. Depending on the type of coating, it passes at different speeds, but always quickly enough. Fungus and mold dangerous to humans appear. The only way to solve all problems is to make thermal insulation of the ceiling.

Competent warming technique

Under the insulation, it is supposed to lay a layer of insulating material that will keep the heat inside the room. However, only a warming layer in the bath is not enough. He will not be able to complete his task, because he will be saturated with moisture and deteriorate. In order for the insulation to last for a long time, it is required to lay three layers of insulating materials.

Layer 1: vapor barrier

The main task of this layer is to prevent vapor from entering the insulation. All vapors rising from the heated room must be contained. As an insulator for this layer, materials such as glassine or roofing paper, proven over the years, can be used. Or more modern geosynthetic coatings, various membranes and thermofol. Well, if the coating is foil, then it can also shield heat, returning it to the room.

Layer 2: thermal insulation

The second layer of the insulating cake should trap heat without letting it out. A variety of materials can be used here. Which to choose, will tell you the budget and your own skills in carrying out construction work. It is important that the insulation be as light as possible (then it will not create an unnecessary load on structures that are resistant to moisture) and non-combustible, as simple and convenient as possible to install.

How to insulate the ceiling in a bath with a cold roof?

If the ceiling is not insulated in a bath with a cold roof, condensate will accumulate on its surface. Chilled drops of water dripping from above on people in the bath will clearly deprive them of the expected pleasure. Droplets of water falling further upwards with warm air currents will contribute to rotting and complete destruction of the ceilings, and in general - the roof truss structure. The only way to prevent the occurrence of such troubles will be the arrangement of ceiling insulation in a bath with a cold roof.

Planning work on the thermal insulation of the roof of the bath

Before acquiring the building materials necessary for work and preparing the necessary tools, you need to draw up a detailed plan for the insulation work to be performed. Drawing up a plan will avoid mistakes and alterations of the roof structure.

The process of thermal insulation of the ceiling and roof of the bath is not a very laborious work, therefore it is easy to do it yourself, even in the absence of sufficient experience in repair and construction work. The main thing is that it is necessary to strictly adhere to the sequence (technology) of performing installation operations. Another argument for self-insulating the ceiling is the availability of the necessary heat-insulating materials - they are available in almost all hardware stores.

Insulation of the ceiling in a bath with a cold roof includes 3 stages:

- Thermal insulation.

- Laying a layer of vapor barrier.

- Waterproofing.

At the end of the work, a structure is obtained that looks like a layer cake, in which the lowest layer is the ceiling ceiling, and layers are successively located above it: steam, heat and waterproofing. Then you can start choosing the necessary building materials.

The choice of heat insulator for the roof and ceiling of the bath

In a well-heated bath, it is necessary to maintain sufficiently high values \u200b\u200bof humidity and temperature. The heat-insulating building material must be fully suitable for such requirements and, most importantly, it must not emit substances hazardous to people and the environment during heating. And besides this, a good heat insulator for a bathhouse should not support combustion, be excessively heavy and inconvenient for moving and laying.

mineral wool

One of the most common options for fibrous heat insulators for ceiling insulation in a bath with a cold roof and individual housing construction, produced in 3 types:

- glass wool;

- slag wool, produced from blast furnace waste (slag);

- stone wool is made from melts of basalt and other minerals.

The main advantage of mineral wool, in addition to very low indicators of heat conductivity: mold and fungus spores do not develop on it, and insects and rodents bypass it. For a bathhouse located on a land plot, this advantage of mineral wool is very important. It should also be noted that this building material does not change its volume and shape when the ambient temperature changes, it does not support combustion, it is very convenient for installation, due to its low weight. Mineral wool is produced in rolls or in the form of rectangular sheets/panels.

There are two disadvantages of mineral wool - this is the high ability of mineral wool to absorb any moisture (especially slag wool) and the phenolic compounds contained in it. These 2 shortcomings are easily eliminated: with the help of good hydro and vapor barriers and preventing contact between air flows and mineral wool, especially in the inside of the bathhouse.

Important: when performing any work with mineral wool, it is necessary to wear thick outer clothing and use protective devices (goggles and a respirator) to protect the eyes and respiratory organs, since its small elements affect the skin, eyes and lungs of a person.

Expanded clay

This building material is a small porous clay pebbles. For all its properties, expanded clay is considered the most suitable heat insulator to insulate the ceiling in a bath with a cold roof.

Warming the roof of the bath with expanded clay

Warming the roof of the bath with expanded clay

This material is safe - it does not support combustion, does not harm people and the environment, does not emit polluting and harmful substances to humans. Expanded clay - durable, does not collapse under the influence of the sun's rays. In this building material, spores of fungi and bacteria do not develop, it is inexpensive and its installation is simple.

Expanded clay also absorbs much less water than mineral wool, however, it is also necessary to use hydro- and vapor barriers for its laying.

Styrofoam

More recently, this heat insulator was one of the most popular among all heat-insulating building materials. But, despite its excellent heat-insulating properties, foam plastic cannot be used to insulate the roof or ceiling of the bath - this building material is combustible, and when burned, it emits toxic substances that are dangerous to human life. It can also decompose and lose shape under the influence of high temperatures in the bath.

Ecowool

This is a fibrous natural heat insulator made from cellulose fibers with various additives that give additional properties - resistance to burning and protecting against the appearance of rodents, microorganisms and insects. Ecowool has a small specific gravity and can fill absolutely all gaps and crevices.

Like expanded clay, ecowool is an environmentally friendly heat insulator that does not emit hazardous substances into the air.

Roof insulation with ecowool

Roof insulation with ecowool

However, this heat insulator has a significant drawback - it absorbs a lot of liquid, which leads to a deterioration in heat-insulating properties. Therefore, when using ecowool, excellent ventilation of the under-roof space and a high-quality waterproofing layer are necessary. Another disadvantage of its use is the complexity of laying; with a “wet” installation method, special equipment is required.

A mixture of cement and sawdust

This is a "classic" building material-insulation, which was used before the advent of polystyrene foam and mineral wool. Sometimes clay is used instead of Portland cement, and sawdust is replaced with straw.

Important: the sawdust used in this mixture must be dried for several months, and even better - for a year.

This is a very cheap and environmentally friendly heat insulator, but with low heat-insulating characteristics. In addition, the preparation of the mixture is very laborious.

Materials for hydro and vapor barrier

The vapor barrier of the ceiling in the bath is very important, otherwise the moisture circulating in the room will worsen the properties of the heat insulator and lead to the development of mold and fungi both on the ceiling itself and on the details of the truss structure. For vapor barrier, special films and coatings are most often used - in particular, with anti-condensation membranes (preferably with a layer of foil). The leading places, at the moment, in the market are occupied by TechnoNIKOL vapor barriers.

As a waterproofing agent, you can also use both special films and cheaper building materials - roofing felt or thick polyethylene.

Insulation of the ceiling in the baths

There are 3 main types of ceilings in baths:

The floor-type ceiling is common in small baths, which are used seasonally and quite rarely. On the upper parts of the walls are placed boards adjusted to each other, fixed without support beams. The resulting design is very simple, but it cannot withstand a lot of weight, so the heat insulator layer must be thin and light.

Important: a floor-type ceiling must be erected just below the upper boundary of the walls in order to get space for filling expanded clay or placing mineral wool.

From the side of the attic space, a film vapor barrier is placed on the flooring so that the foil on it is directed downwards. The vapor barrier itself is laid with an overlap of 10-15 cm, and the joints and seams are sealed with special adhesive tape for vapor barrier with a layer of foil.

Mineral wool is laid on top of the vapor barrier, expanded clay or a cement-sawdust mixture is placed. The layer of insulation should not be thick.

Then the heat-insulating layer is closed from above with a waterproofing agent (film or roofing material), on top of which boards or plywood sheets are nailed.

Hemming type ceiling insulation

For this type of ceiling, on the upper parts of the walls, not flooring is placed, but supporting wooden beams made from beams or finger-jointed boards. Then, the floor of the attic and the ceiling are placed on these support beams from below and above. And in the space between the attic floor and the ceiling, layers of heat, steam and waterproofing are mounted.

Stages of the installation of a false ceiling in the bath

Stages of the installation of a false ceiling in the bath

The process of placing a heat insulator is performed as follows. From the side of the roof on the beams, a film waterproofing agent is placed and attached with a stapler. Next, boards or plywood sheets are laid on top of it. The hemmed-type ceiling is durable, so the resulting under-roof space can even be used as an attic.

Mineral wool is placed between the beams. The thickness of the heat insulator depends on the location of the bath structure: for mid-latitudes 15.0-18.0 cm, in areas with severe winter frosts - 20.0-25.0 cm. Layers of heat-insulating building material are laid so that the joints of the previous layer overlap with the next layer .

A vapor barrier film is attached to the floor beams from below. On top of the vapor barrier, the slats are fixed perpendicular to the beams.

After that, the lining is laid, which is nailed or fixed with screws directly to the rails.

Insulation of a panel-type ceiling is the most difficult and is practically not used for self-production. First, the panels are made directly, and then they are lifted up and fixed - either on the cross-beams or on the upper parts of the walls.

Important: the choice of the type of ceiling and heat-insulating building material must be carried out based on the planned budget, building experience, the area of \u200b\u200bthe bathhouse and the frequency of its use.

Ceiling insulation in a bath with a cold roof in St. Petersburg on a turnkey basis

The bath needs high-quality warming of the flow. If this is not done, then it will take longer to heat the bath, and it will cool down faster. The heat-insulating layer on the ceiling is also important so that drops of cold condensate do not fall on the head and steamed body during bath procedures.

Ceiling insulation materials

The process of insulating the ceiling is quite simple. And if you approach its implementation correctly, then this can be done without involving a team of craftsmen. That means you save a lot of money.

Today, in any hardware store you can buy everything you need to insulate a bath.

The question is only what to choose?

Insulation of any ceiling takes place in three stages:

- installation of vapor barrier;

- insulation installation;

- waterproofing installation.

Properly made layer cake, sheathed decorative material, perfectly cope with all duties.

Benefits of working with our company

We do it on time or for free. Construction is divided into stages with an agreed deadline.

"Full construction". All work is done by one company.

Ability to accept payments by installments or on credit.

There are no hidden fees. The price is final at the stage of the contract.

Quality control is carried out at every stage of building a house by our competent services.

Quality construction work thanks to. We have over 300 successfully completed projects.

Delivery of materials within 200 km from the Ring Road free of charge

The choice of insulation for the ceiling

Since the environment of a heated bath is different from the environment of residential premises, it is very important to take this into account when choosing a heater.

Since the environment of a heated bath is different from the environment of residential premises, it is very important to take this into account when choosing a heater.

The most popular solutions for warming the ceiling of the bath today are:

- mineral wool;

- expanded clay;

- ecowool;

- sawdust cement.

Mineral wool is the most common insulation. There are several varieties of such material. All of them have approximately the same characteristics. An important advantage of this material is that mold does not develop in it.

But mineral wool also has disadvantages:

Both disadvantages are minimized with the help of quality material insulation in the ceiling puff pastry. When working with this material, it is necessary to protect the eyes, skin of the hands and respiratory organs with personal protective equipment.

Another great solution for warming the bath is expanded clay. It has the following benefits:

- environmental Safety;

- lack of combustibility;

- is not an environment for the development of mold;

- costs less than analogues.

Catalog of standard bath projects (more than 450 pieces)

It is also worth noting that expanded clay is easy to use. This material practically does not absorb moisture and has great durability.

To insulate the ceiling, you can use ecowool. It is made up of cellulose fibers. Special additives make them resistant to elevated temperatures and protect against mice. Unlike mineral wool, ecowool does not poison the body. But also how it absorbs moisture. Therefore, it needs high-quality waterproofing.

To insulate the ceiling, you can use ecowool. It is made up of cellulose fibers. Special additives make them resistant to elevated temperatures and protect against mice. Unlike mineral wool, ecowool does not poison the body. But also how it absorbs moisture. Therefore, it needs high-quality waterproofing.

A mixture of cement and sawdust, as well as foam, is rarely used today. This outdated solution may have a low cost and high security, but in terms of thermal insulation properties it loses to the above materials.

Add a comment

Any bath needs high-quality insulation of the ceiling - warm air, according to the laws of physics, tends to rise up. And if there is no heat-insulating layer on its way, then significantly more fuel will be needed to heat the bath and maintain a consistently high temperature in it.

But that's not the only problem - in the absence of insulation on the ceiling of the bath, condensation will accumulate, and drops dripping from above on the head and back are unlikely to bring great pleasure to anyone. And the moisture going up along with the heat will contribute to the destruction of the ceilings and the roof support system. The only way to avoid these troubles is to make high-quality ceiling insulation in a bath with a cold roof. And our material will tell you what and how to do it.

We plan work

Before you buy materials and take on tools, you should carefully plan your actions. A clearer understanding of the matter will save you from annoying mistakes and the need to redo everything in the future.

The first question is whether it is possible to insulate the ceiling in the bath on your own.? Or is it worth entrusting this business to a team of builders? By itself, the process of insulating the ceiling is not something complicated, because it is not difficult to perform it on your own, even without great experience in renovation and construction. The main thing is to carefully observe the technology and approach the matter responsibly. In favor self-insulation the ceiling also says the availability of the necessary materials - they can be found in any large hardware store or in the market.

The second question is what, in fact, needs to be done? Insulation of the ceiling in a cold bath consists of three stages:

- vapor barrier;

- thermal insulation;

- waterproofing.

The result should be a kind of "layer cake", bottom layer which the ceiling covering protrudes, and above it, vapor barrier, thermal insulation and waterproofing are located sequentially from bottom to top. More details about why this is necessary and how to do it will be described below. Now it's time to think about the choice of materials.

We select a heater

In a melted bath, a very heat and humidity. The heat-insulating material must meet these conditions and, most importantly, not release when heated. harmful substances. In addition, a good heater for a bath should be fire resistant. It is undesirable that the thermal insulation material be too heavy or inconvenient to carry and install. Now consider the materials in more detail.

It is the most common type of insulation for baths and private houses; This is a fibrous heat-insulating material that exists in three types:

- glass wool;

- stone wool, which is made from basalt or other molten rocks;

- cinder wool, made, like cinder blocks, from blast-furnace slags.

The main advantage of mineral wool, in addition to its very low thermal conductivity, is that it is not a breeding ground for fungi, mold, insects or rodents. For a bath located on a private plot, this is especially important. It is also worth noting that this material does not burn, does not change its volume and shape when heated or cooled, and is very easy to install due to its low weight. Mineral wool is produced in the form of rectangular panels or in the form of rolls.

As for the disadvantages, there are two of them - the ability of mineral wool to absorb moisture (especially slag wool) and the potential harm of the phenols contained in them. Both of these shortcomings can be eliminated if you correctly approach the issue of vapor and waterproofing and prevent contact of mineral wool with the air flow, especially inside the bath.