Do-it-yourself vacuum cleaner from a barrel. Homemade vacuum cleaner for a carpentry workshop. Device, principle of operation and methods of filtering building vacuum cleaners

Choosing the right Festool mobile dust extractor is as easy as operating it. Ideal Solution for individual tasks, thanks to the perfect coordination of all components of the dust extraction system.

Promotions Arsenal Master:

Production FESTOOL (Germany).

The Festool professional tool (Festul) knowingly won the hearts of millions of Masters around the world. Since 1925, the Festool brand has been synonymous with highest quality, precision and durability. Festool products are developed on the basis of interaction with customers in order to fully match the application. "It's better with the system!" - tools, accessories, consumables perfectly fit and can be combined with each other. "Master's Arsenal" invites you to the world of owners and lovers of Festool tools, and you, like so many, will also say: "Perfectly thought out, a pleasure to work with!"

What dust classes do you have to work with?

All types of dust are divided into three main classes L, M, H.

They indicate the suitability of the mobile dust extractor for certain types of dust and compliance with the concentration limit values. harmful substances in the air working area(MPC). In addition, the classes determine what degree of air purification the filtration system should provide. When choosing a dust extractor, you should be guided by the type of dust you are dealing with.

First of all, let us recall a few advantages of dust removal - tool operation with a vacuum cleaner:

Cleanliness in the workplace.

good review working area due to the suction of sawdust and dust from it.

MULTIPLE service life increases: the tool itself, consumables: saws, cutters, abrasive wheels.

A significant reduction in the cost of secondary work - cleaning and tool cleaning.

Improving your professional status in the eyes of the client due to "clean", and therefore more qualified and expensive work.

4.

Consumables: filters and bags.

An important point in the selection of a vacuum cleaner (in terms of operating costs) is the material of the dust bag.

Bags can be disposable and reusable:

Included with the vacuum cleaner are standard disposable bags. They are paper or non-woven fabric. Paper bags do not allow dust to pass through, but can be torn. And the paper bag does not allow you to use the maximum useful capacity of the vacuum cleaner. In this regard, disposable bags made of synthetic canvas make much better use of volume. In addition, they are breathable: when you turn off the vacuum cleaner, they crumple, thereby compressing the dust a little, which ensures better filling of the bag.

Reusable - made of durable multi-layer material and due to the use of convenient large fastening valves, they have the ability to quickly clean.

When choosing bags, remember that cheap bags are usually made of poor quality fabric that allows fine dust to pass through. Yes, and the gluing of the bag attachment sleeve with the fabric bag itself can be weak. And this means that the bag at the time of high load can simply come off, which threatens to quickly replace the filter - the most expensive consumable part of the vacuum cleaner.

Industrial and construction vacuum cleaners can also work without a bag. Such vacuum cleaners include vacuum cleaners having an automatic shake or "self-cleaning" mode. At the manufacturer Festool, for example, such vacuum cleaners are marked “AC” in the model name. The essence of self-cleaning is periodic vacuum discharge inside the vacuum cleaner, which is accompanied by a light pop. Due to this rarefaction, the filter is shaken and dust is removed from it. With such constructive solution the vacuum cleaner works without a bag. This is convenient in terms of saving on bags, but reduces the life of the filter. By the way, there are vacuum cleaners, both with a manual filter shaking mode, and with an automatic one. Automatic mode can also be permanent and switchable. This is necessary to be able to work with and without a bag. This option is more versatile and ensures greater safety of the filter.

Filters can be both for dry dust and shavings, and for wet or liquid consistency. By the way, almost all construction and industrial vacuum cleaners are adapted to collect water or liquid dirt. In this case, only the presence of a special filter is required. And ideally, the presence of a vacuum cleaner reservoir filling sensor.

Filters are structurally made in the form of flat or cylindrical cassettes. It is believed that the higher the useful plane of the filter, the cleaner the cleaning. In fact, the useful filtration area through which air is driven is directly related to suction power and hose diameter. The correct ratio between these parameters is what manufacturers themselves try to maintain. And you and I, as users, should not even think about this in the same way as why it is 220 volts in the electrical network now.

The most important thing that you and I should know and remember when choosing a vacuum cleaner for consumables is the following:

a vacuum cleaner with a large supply of capacity - less often you need to clean and change bags less. A vacuum cleaner of smaller capacity - on the contrary, is more expensive to operate with the same performance.

if you are supposed to have both dry and liquid dust, then you need two different filters.

if the filter (usually cylindrical) eats up the useful capacity of the vacuum cleaner tank, then this means you have to choose between compactness and performance.

5.

Additional equipment.

As additional equipmentfor industrial and professional vacuum cleaners for tools can be:

Compartment or coil for hose and cord

Additional tool and accessory holders

6. Additional features of the vacuum cleaner.

An important factor when choosing a vacuum cleaner for a tool is the presence of additional features:

attachment of tools and accessories

use of a vacuum cleaner as a storage system, when it is possible to fix cases with tools and materials on the vacuum cleaner

using the vacuum cleaner as a mobile cart

using a vacuum cleaner as a complete mobile workplace.

Any additional function Of course, it increases the initial cost of a vacuum cleaner, but at the same time it saves you time, nerves and other resources in the future. It is worth remembering that, according to the experience of the Masters, the purchase of any additional option(opportunities in the form of equipment) after purchasing the product costs at least twice as much as if you purchased all this at once.

What else should you pay attention to is completeness of the vacuum cleaner.

The kit of an industrial or construction vacuum cleaner for a tool, as a rule, includes as standard: a hose and a bag for dust (dirt, debris). But the nozzles for cleaning the premises may not be included initially in the package. Of course, it is better to purchase a vacuum cleaner complete with nozzles and nozzles right away - kits are always cheaper. But perhaps you need some special nozzles or metal rather than plastic nozzles. This is true, for example, for an industrial workshop. Then it makes sense to choose a kit individually for your tasks.

IMPORTANT!

The dust extraction nozzle of a grinder and a jigsaw, for the most part, has an outer diameter of 25 or 27 mm. Saws and milling cutters - 35, 36 mm. Therefore, the inner diameter of the hose coupling must be correct. Construction vacuum cleaners initially have a larger hose diameter and a coupling with an inner diameter of 35, 36 mm.

1 example :

Pick up a vacuum cleaner for a carpentry workshop.

For a carpentry workshop, that is, for working with wood dust, ideally (in terms of following labor safety standards), you need a class "M" vacuum cleaner. However, according to Russian experience, most workshops are content with "L" class vacuum cleaners.

For full-fledged carpentry work during 1 shift, a vacuum cleaner with a useful tank volume of at least 15 liters, and optimally - more than 25 liters, is required.

or (for a small difference in price, MIDI has almost twice the capacity compared to MINI).

If you have a dealership with a good flow of cars, then it will be more profitable for you to use a vacuum cleaner with a larger capacity, for example, or - in case of normal work.

If it is supposed to work on grinding aluminum (body panels of some modern cars are made from it), then only an explosion-proof vacuum cleaner can be used here - for example:

3 example :

Choose a vacuum cleaner for the wall and ceiling grinder Festool Planex Lh225.

For work focused on this machine, it is better to use an M-class vacuum cleaner with an automatic filter shaking mode. In addition, if a full shift is to be used, the tank must be larger than 30 liters (based on the capacity of the Festool Planex grinder). Thus, the most suitable vacuum cleaner would be:

-

FESTOOL CLEANTEX CTL 36 E AC-PLANEX dust extractor with Autoclean system

Work in the workshop requires special conditions. Any task, whether it is surface treatment, working on a machine or with power tools, with wood or metals, inevitably leads to the formation of a large amount solid waste. Industrial dust and debris reduce the quality of working conditions and safety, and can cause ignition and fire.

Usually, small rooms are allocated for workshops. This means that workshop cleaning equipment must not only have enough power and endurance to deal with industrial waste, but also be compact, lightweight and manoeuvrable. These are the qualities that the universal industrial vacuum cleaners NTS eSwift from Starmix have.

Universal vacuum cleaners for the workshop

The models of household vacuum cleaners familiar to us are not suitable for cleaning up construction debris and large wastes such as metal, wood or plastic chips, since during work in a carpentry or any other home workshop, a large amount of garbage is often generated, which ordinary vacuum cleaners simply cannot handle. Household models do not have sufficient endurance, reliability and power, while industrial machines are initially designed for heavy loads.

In addition, NTS eSwift vacuum cleaners are versatile, which allows them to be used not only for cleaning woodworks and garages, but also in Everyday life. They are designed for any task, from simple dust collection in rooms to serious cleaning during repair work. In addition to dry debris, Starmix vacuum cleaners are ideal for collecting liquids - specially designed nozzles are available.

Workshop vacuum cleaners from our catalog:

Distinctive features of professional vacuum cleaners for the workshop:

- High level of safety and comfort. The absence of debris and dirt and a decrease in the concentration of dust in the air facilitate work, improve visibility within the working area, and reduce the negative impact of construction waste particles on the human body. Safety says: the use of power tools in a dusty room is unacceptable, because. may cause a fire. The NTS eSwift models allow you to use the vacuum cleaner directly during the work process, since the kit includes a tool socket and 6 additional slots on the body, in which it is convenient to store the necessary accessories.

- Significant savings in time and energy costs. Starmix NTS eSwift vacuum cleaners achieve perfect cleanliness in as soon as possible. Due to their light weight, dimensions and maneuverability (vacuum cleaners have a low center of gravity and are equipped with special rollers that are not afraid of obstacles), they are convenient to use even in small spaces. Also, each model has a large platform where you can comfortably arrange tools and small parts required in the course of work.

- Reliability in operation. NTS eSwift vacuum cleaners are shockproof and stable, have an optimized tank and are suitable for jobs of any level of complexity.

Benefits of using NTS eSwift vacuum cleaners

Comfortable working conditions in the workshop largely depend on the right equipment. Too noisy, heavy and clumsy vacuum cleaner will only get in the way in a small workshop. Collecting garbage in the usual way - with a brush and dustpan - will take a lot of time and will not allow you to achieve perfect cleanliness. The basic household model, not designed for use in the workshop, will quickly fail. And industrial universal vacuum cleaner from Starmix, on the contrary, will facilitate cleaning.

Wood has always been considered an environmentally friendly and safe material. Fine wood dust generated during the processing of a wooden blank is not as harmless as it might seem. Its inhalation does not contribute to the saturation of the body with useful microelements. Accumulating in the lungs and upper respiratory tract (and wood dust is not processed by the body), it slowly but effectively destroys respiratory system. Large chips constantly accumulate near machines and working tools. It is better to remove it immediately, without waiting for the appearance of insurmountable blockages in the carpentry space.

In order to maintain the necessary level of cleanliness in your home carpentry, you can buy an expensive exhaust system, consisting of a powerful fan, a cyclone, chip traps, a chip container and auxiliary elements. But the users of our portal are not one of those who are used to buying what they can do with their own hands. Using their experience, anyone can assemble an exhaust system that will meet the needs of a small home workshop.

Sawdust vacuum cleaner

Chip blower using a conventional household vacuum cleaner is the most budget option of all existing solutions. And if you manage to use your old cleaning assistant, who, out of pity, has not yet been thrown into the trash, then your inherent frugality has once again served you in good stead.

ADKXXI FORUMHOUSE User

My vacuum cleaner is more than fifty years old (brand - "Uralets"). Completely copes with the role of a chip cutter. He is heavy only, like my sins, but he can not only suck, but also blow. Sometimes I take advantage of this opportunity.

By itself, a household vacuum cleaner installed in a place of honor in the workshop as a chip blower will be useless. And the main reason for this is that the volume of the bag (container) for collecting dust is too small. That is why between the vacuum cleaner and the machine there must be an additional unit of the exhaust system, consisting of a cyclone and a volumetric tank for collecting sawdust.

axis FORUMHOUSE User

The easiest installation–vacuum cleaner and cyclone. Moreover, the vacuum cleaner can be used at home. Instead of a cyclone (cylindrical cone), a separating cover can be used.

DIY sawdust vacuum cleaner

The scheme of the chip blower we are considering is extremely simple.

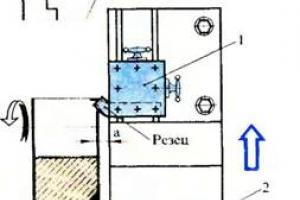

The device consists of two main modules: a cyclone (pos. 1) and a chip container (pos. 2). The principle of its operation is as follows: with the help of a vacuum cleaner, a vacuum is created in the cyclone chamber. Due to the pressure difference inside and outside the device, sawdust, together with air and dust, enters the internal cavity of the cyclone. Here, under the action of inertial and gravity forces, mechanical suspensions are separated from the air flow and fall into the lower container.

Consider the design of the device in more detail.

Cyclone

The cyclone can be made in the form of a cover that is installed on top of the storage tank, or you can simply combine these two modules. To begin with, consider the second option - a cyclone made in the body of the chip container.

First of all, we should purchase a tank with a suitable volume.

ForceUser FORUMHOUSE user,

Moscow.

Capacity - 65 l. I took it according to the principle - we need volume and convenience while carrying a filled container. This barrel has handles, which is very convenient for cleaning it.

Here is the list additional elements and materials that we need to assemble the device:

- Screws, washers and nuts - for fastening the inlet pipe;

- Line segment sewer pipe with cuffs;

- Transitional coupling (from the sewer pipe to the suction pipe of the vacuum cleaner);

- Glue gun.

Do-it-yourself barrel vacuum cleaner: assembly sequence

First of all, a hole is made in the sidewall of the tank for the inlet pipe, which will be located tangentially to the body. The figure shows a view from the outside of the tank.

It is advisable to install the branch pipe in the upper part of the plastic barrel. This will achieve the maximum degree of cleaning.

From the inside, the inlet pipe looks like this.

The gaps between the pipe and the walls of the tank should be filled with mounting sealant.

At the next stage, we make a hole in the lid, insert the adapter there and carefully seal all the cracks around the pipe. Ultimately, the design of the chip blower will look like this.

The vacuum cleaner is connected to the upper outlet of the device, and the pipe that removes the chips from the machine is threaded into the side pipe.

As you can see, the presented design is not equipped with additional filters, which does not greatly affect the quality of air purification.

day_61 FORUMHOUSE User

I made a chip blower based on the theme. The vacuum cleaner "Rocket" with a power of 400 W and a barrel with a volume of 100 liters are taken as a basis. After assembly of the unit, tests were successfully carried out. Everything works as it should: the sawdust is in the barrel, the vacuum cleaner bag is empty. So far, the dust collector has been connected only to the router.

Whatever it was, but the cyclone still cannot detain a certain percentage of wood dust. And in order to bring the degree of cleaning to the maximum, some users of our portal are thinking about the need to install additional filter fine cleaning. Yes, a filter is needed, but not every filter element will be appropriate.

axis FORUMHOUSE User

I think that it is not entirely correct to install a fine filter after a cyclone. Or rather, you need to install it, but you are tormented by cleaning it (you will have to very often). There, just a filter cloth will roll (like a bag in a vacuum cleaner). In my Corvette, the top bag holds the bulk of the fine dust. I see this when I remove the bottom bag to remove sawdust.

A fabric filter can be created by attaching a frame to the top cover of the cyclone and covering it with a dense material (can be a tarpaulin).

The main task of the cyclone is to remove sawdust and dust from the working area (from the machine, etc.). Therefore, the quality of air flow cleaning from fine suspensions plays a secondary role in our case. And, given that the standard dust collector installed in the vacuum cleaner will certainly retain the remaining debris (not filtered by the cyclone), we will achieve the required degree of cleaning.

Cyclone cover

As we have already said, the cyclone can be made in the form of a cover that will be put on the storage tank. A working example of such a device is shown in the photo.

The point of the log FORUMHOUSE User

The design should be clear from the photographs. The plastic was soldered with an ordinary soldering iron using a fine steel mesh. The cyclone is quite effective: when filling a barrel of 40 liters, no more than a glass of garbage accumulated in the vacuum cleaner bag.

Despite the fact that this cyclone is part of a home-made construction vacuum cleaner, it can be successfully introduced into the design of a carpentry chip blower.

sawdust pipeline

Hoses connected to a chip extractor are best purchased from a vacuum cleaner. A plastic pipeline with smooth inner walls can be laid along the wall. It will connect the machine to the suction pipe of the cyclone.

A certain danger is static electricity, which is generated during the movement of sawdust through a plastic pipe: sticking of sawdust to the walls of the pipeline, ignition of wood dust, etc. If you want to neutralize this phenomenon, it is better to do this during the construction of the sawdust pipeline.

Far from all owners of home workshops pay attention to the phenomenon of static electricity inside the sawdust pipeline. But if the design of the chip blower is made in accordance with the rules of fire safety, then a corrugation with a built-in metal conductor should be used as a sawdust line. Connecting such a system to a ground loop will help avoid problems during operation.

alex_k11 FORUMHOUSE User

Plastic pipes must be grounded. Hoses should be taken with a wire, otherwise static accumulates very strongly.

And here is a solution for combating static electricity in plastic pipes offered by one of the FORUMHOUSE users: plastic pipe foil and connect it to a ground loop.

Exhaust devices

The design of devices that remove chips directly from the working bodies of carpentry equipment depends on the characteristics of the machines themselves. Therefore, products made of plastic, plywood and other suitable materials can be used as exhaust elements.

In order to solve this problem, the tank body can be equipped with metal frame, or insert several metal hoops of a suitable diameter inside (as suggested by the user alex_k11). The design will turn out to be more cumbersome, but absolutely reliable.

Chip blower for multiple machines

The system based on a household vacuum cleaner has a small capacity. Therefore, it can only serve one machine at a time. In other words, if there are several machines, the suction pipe will have to be connected to them one by one. It is also possible to install a chip blower centrally. But in order for the suction power not to fall, idle machines should be disconnected from the general system using gates (flaps).