How to make a homemade sawmill. How to assemble a homemade sawmill: instructions and tips. Band sawmill with their own hands. Video

The purpose of the sawmill

Wood is the most demanded material, which has a unique structure and high reliability. All this allows the use of wood for the construction of houses and interior decoration. But its quality depends mainly on woodworking devices.

A common processing method is do-it-yourself sawing with circular, band or frame saws. For example, disk machines create quickly various lumber: slats, boards, timber. They are also used for processing logs after cutting with a band saw and producing material from logs. Such an installation has high productivity, because it has many possibilities: end division and sawing, edging.

In carpentry shops and in the construction of wooden buildings, a circular sawmill is simply indispensable. It not only helps speed up, but also simplifies the workflow. Without this machine, the longitudinal cut of a large log will take a lot of time, and with it, on the contrary, a few minutes.

Design parameters of the sawmill

This equipment is a working device on which wood is cut with one's own hands. Such a system works on an electric motor. For the production of an elementary design, sawmills use:

This type of sawmill is made in the form of a machine. A shaft with a disk is attached to it, and the cutting element is based on the rotation of the main part. Mostly used equipment in everyday life, because industrial models have more complex drawings of a sawmill, the sawing angle of the discs in them is easily adjustable.

The circular saw is mounted on the shaft of the engine or the spindle of the machine tool. This design may have one or two saws. And each of them runs on its own motor.

For the manufacture of a machine with their own hands, drawings and metal pipes are used. They are fixed by welding. The rails for the carriage need to be chosen only with high quality, otherwise there will be interruptions in their work all the time. The carriage itself is created from iron elements. Rollers, wheels and frame must be identical.

The saw will run on any gasoline engine, but you need to choose the most powerful one. No chain transmission should occur, otherwise the drive will overheat.

To create a sawmill, wood is often used. The only downside to this design is material decay. especially if the equipment is located in an open area. But such a base is easy to process.

The principle of operation of the machine

On a circular sawmill, raw materials are sawn manually horizontally. An angle sawmill cuts wood in several directions at once: across and along the log. This happens due to the mutually perpendicular arrangement of the saws. On such a device, wood with a size of 70 mm is processed, the thickness of the cut is 1 mm.

On a circular sawmill, raw materials are sawn manually horizontally. An angle sawmill cuts wood in several directions at once: across and along the log. This happens due to the mutually perpendicular arrangement of the saws. On such a device, wood with a size of 70 mm is processed, the thickness of the cut is 1 mm.

When moving the portal. the speed of which is adjusted in steps, the sawing of raw materials is carried out. An electrical wire is used for this.

The equipment should not be installed outdoors, as it must be protected from external precipitation. During operation, sawmills use an electronic ruler. It is with its help that the parameters of the incision are adjusted.

Varieties of sawmills

Of course, the main element of the design is a circular saw. It is fixed so that it can cut in two directions, and is able to rotate 90 degrees. Such features allow classify sawmills into the following types:

- Corner. Has one or two disks. The single disc machine can cut both horizontally and vertically. In it, the disks are mounted orthogonally against each other. Such a device is characterized by high performance;

- Horizontal. Such equipment works with a saw carriage that moves in two directions along the wood, and leaves little waste.

Do-it-yourself circular sawmills

Today, everyone can make such a device. This will require:

Today, everyone can make such a device. This will require:

- Construction goats;

- Tools for working with wood and metal;

- metal plates;

- boards;

- fasteners;

- Electric motor.

First you need to be good study drawings and designs disc sawmill. In addition, you should familiarize yourself with its distinctive parameters. The working part of the machine is a toothed saw. It is mounted on the machine spindle. In some cases, the saw is placed on the motor shaft.

On the device, sawlog processing includes edging and dividing unedged wood, as well as cutting raw materials according to specified dimensions. Before proceeding to work, you should first look at the finished drawings of the sawmill or develop your own scheme.

The simplest element of a sawmill is a table. A shaft with a saw is placed under it, which drives the engine using a belt drive, while the cutting element is placed above the table surface.

The base of the machine is made from goats, suitable both metal and wood products. They are connected to each other by pieces of the board. A table assembled from steel plates, 4 mm thick and about 200 mm wide, is fixed to it. To fasten the plates, jumpers and screws are used.

Disks for equipment, as a rule, are made of duralumin or steel sheet up to 3 mm thick. Their diameter should be equal to 500 mm. If a structure is made for cutting wood, then a saw with 2-3 teeth is used. Such a disc can easily process many breeds.

In general, cutting teeth are the main guarantee of high-quality sawing of logs. It is better to cut them out of a carbide plate or a broken drill. They must have the correct cutting angle and be carefully balanced. The cutting angle of the teeth must be made 30 °, and rear corners are 15° .

But remember, when the cutters are not well balanced, they rub against the walls of the cut.

The cutting part is mounted from below to the table, while the saw blade should be in the center of the gap formed between the plates. It is fixed through the holes created in advance in the base plate and plates. From the front side, they are countersunk and assembled with countersunk screws.

The design of the guide when assembling a sawmill with your own hands is also important. You can make a U-shaped saddle. It is formed from boards in the shape of a log. An engine with a saw is fixed to it power not less than 2 kW .

Then the made table is screwed to the frame with screws, and a slotted insert is placed in the holes between the plates to install the saw blade. It remains only to attach the stop bar to the table using clamps.

Of course, working with such equipment is associated with some difficulties. For example, a worker must be in a special cabin when cutting raw materials. In addition, it is necessary to control the movements of the operating sawmill at all times.

Moreover, the machine must be firmly fixed to the base. Do not forget that its movement in the opposite direction cuts wood without idling.

Do-it-yourself homemade circular sawmill with electric and shinless motor

Today, the sawmill takes pride of place among industrial equipment (unlike mini chainsaws) and is simply an indispensable device in the woodworking industry (read how to cut a tree). Since this kind of device has not only a high level of productivity and an enviable speed of work, but also it has high quality (high-quality chainsaws - here).

But, nevertheless, even taking into account the fact that this tool simply has no analogues at the present time with respect to a significant number of blanks, not everyone can acquire this kind of equipment. In this article we are talking about this device, we will understand its main aspects, and you can learn how to “create” this kind of technique with your own hands. So let's get started.

Design of sawmills

On the table with the working surface there is a disk located on the shaft. How did you figure out that on the working plane itself, the disk cutting part is rotated. In fact, this tool is a fairly simple design, which, of course, will become an indispensable assistant for you at home in a great way.

It can be stated with full confidence that for domestic needs it is not necessary and even completely unthinkable to implement the implementation of much more complex schemes. In addition, this kind of saw can be installed both on an electric motor shaft and on a spindle shaft.  The design of the sawmill

The design of the sawmill

Also important is the fact that the cost of such a tool is quite high. That is why, probably, real "aesthetics" can acquire it, or simply without such a tool a person will not be able to carry out his activities. But if you are just an amateur in working with wood, then in this case there is simply no point in acquiring it.

Homemade circular sawmill with an electric motor

As we said earlier, sawmills are very popular because of their versatility and, of course, due to the simplicity of their device. That is why everyone who wants to have such a tool at home, but does not have the financial opportunity to purchase it, can make such a happy device with their own hands.

Also, to save money on repairs, the chainsaw owner can independently adjust the carburetor.  Homemade circular sawmill with an electric motor So, let's actually understand this issue: how to make a circular sawmill with your own hands at home? Let's start. So to start you need a circular saw, the size of which must exceed 500 mm.

Homemade circular sawmill with an electric motor So, let's actually understand this issue: how to make a circular sawmill with your own hands at home? Let's start. So to start you need a circular saw, the size of which must exceed 500 mm.

In general, the larger diameter you find, the better for you in principle. In this sawmill, a kind of mover will represent the electric motor itself, by means of a pulley that increases the speed

So you must produce welding of the required frame. after which it is necessary to put a plate on this frame, metal is mainly used, wooden is used much less often. In the middle, which actually should be a slot designed for the disk itself. But remember that the peculiar gaps between the plate and the disk should have a minimum size.

The next thing you should do is to install the pulley and bearings in the lower part of the plate itself. After that, the electric motor pulley itself and the saw are connected with special belts. This kind of manipulation will serve as a kind of insurance during the jamming of the saw itself.

Do not forget that in order to produce high-quality tension of special belts it is necessary to take into account the weight category of the motor mechanism itself with the addition of weights. The support platform must be made with the ability to move, relative to the shaft itself, with a certain kind of deviation through gravity in the opposite direction.

Homemade sawmill with a gasoline engine

In the process of choosing equipment designed for wood processing, it is also necessary to take into account the high cost of the tool itself. It is for this reason that few consumers can afford to buy a sawmill. But as we said earlier, anyone can make this kind of tool on their own.  Homemade sawmill with a gasoline engine In this paragraph, you can find out how homemade sawmills are made with their own hands with a gasoline engine. We will also get acquainted with a home-made sawmill with a PTO drive. So, let's take a look at this issue.

Homemade sawmill with a gasoline engine In this paragraph, you can find out how homemade sawmills are made with their own hands with a gasoline engine. We will also get acquainted with a home-made sawmill with a PTO drive. So, let's take a look at this issue.

First of all, what you should stock up on is patience and a great desire to acquire such a device.

In order to actually start this process, first prepare the drawings for a home-made circular sawmill (you can take it on the Internet), as well as prepare construction goats, metal plates, boards, screws, screws, nuts, a special tool through which you can work with wood and metal, as well as the actual gasoline engine. And so, let's get started.

Chainsaw won't start when starting? Reasons and what to do in this situation - read here.

Check if you start the chainsaw correctly. Check out our instructions.

You can buy many different chainsaw attachments. which will turn your chainsaw even into a boat motor.

- To get started, you need to get all the necessary information regarding the device itself this tool in order to be able and understand what and what you should produce.

It is worth noting that the toothed circular saw, which is actually installed on the machine spindle, will serve as an analogue of the worker element for you. - In addition, there is another option that has the attachment of the saw itself to the motor shaft. on the very surface of the sawmill, the processing of the so-called sawlog begins, which actually divides the unedged board. And also you need to make sawing of special blanks, each of which must meet the required size.

- It is worth noting that the simplest design of this process is the table. It is under its lower part that you must actually place the shaft itself with the saw installed on it. The cutting part, with which it is equipped, should, so to speak, rise on the very tabletop surface. the movement of the saw shaft is carried out by the action of a gasoline engine on it, which transmits peculiar impulses to the belt itself.

You can watch the video on how to do it:

Summing up…

In this article, you had the opportunity to get acquainted with all the aspects that relate to how you can make this kind of tool with your own hands without having special knowledge in this area. Therefore, it is not necessary to spend a lot of money in order to have a sawmill. but it’s enough to simply arm yourself with the necessary materials and act, taking into account all the tips provided above.

You can also sharpen the chain of your chainsaw yourself - more on that here.

How to make a circular sawmill with your own hands: making a simple design

During the primary processing of wood, you will need a sawmill. This equipment can be of several types - disk or tape. For self-manufacturing, preference is given to the first type, since it has good performance properties and a relatively simple design.

The principle of operation of a sawmill

Horizontal sawmill

Before making a design, you should familiarize yourself with the principle of operation and the purpose of the configuration of a mini sawmill. In most cases, it is necessary for sawing logs of large and medium diameters. As a result of this, the formation of boards or timber occurs.

The main component of the design is the power plant. It should provide the proper number of revolutions of one or two discs. In addition, for maximum automation of work, the following components are required:

- supply line. It can be fixed or with a system for transporting the log to the discs. Most often they prefer to make the first option, since it is the least expensive for self-production;

- cutting unit. Consists of one or more saws. Depending on their location, it can be horizontal or transverse. For simultaneous processing of a log in two planes, an angle sawmill is required;

- Control block. Most often it is located on the outer part of the cut node. With it, the operator can adjust the number of engine revolutions, turn the equipment on or off.

An angle sawmill is necessary for tangential and radial sawing of workpieces. Due to its design, the entire volume of the log is used as rationally as possible.

Mini twin-disc models usually come with two motors. However, their power and number of revolutions may not always coincide. These parameters must be calculated in advance and an appropriate cutting unit made.

The choice of the design of the sawmill

Homemade vertical sawmill

The simplest home-made sawing design consists of a table, above the surface of which there is a cutting disc. You can make a similar model at home. However, its performance will be low.

The main disadvantage of this design is the need to independently feed the log to the sawing site. This will lead to a violation of the geometry of the future board or beam. Therefore, these types of equipment are used only for processing small workpieces or sheet material.

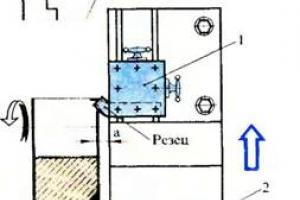

The corner sawmill has much more functionality. It performs two cuts simultaneously in a horizontal and vertical position. However, its manufacture is more complicated than that of the model described above. A do-it-yourself circular sawmill has the following design features:

- movable cutting carriage. It moves along the guides located on the body of the stationary platform. There are two motors on the carriage, on the shafts of which saw blades are mounted. It is imperative to make a device for adjusting the position of the edges of the disks;

- stationary platform for blanks. It has lumber braces. Otherwise, during operation, displacement is possible, which will lead to deformation of the product.

A similar mini design can be made from improvised materials. It is important that it can withstand the loads and constant vibration that will inevitably appear during operation.

If the sawmill is designed only for the production of boards, you can install another vertical one instead of a horizontal saw. This will increase the performance of the equipment.

An example of a corner sawmill

If a sawmill is needed for commercial purposes for processing large volumes of wood, you should be very careful in self-manufacturing. Home-made models will not always be able to provide a high-quality cut at a constant load. But for small jobs, you can make a design with your own hands.

First of all, you should choose the right power and the number of revolutions of the power unit. When installing electric motors, there will be no such problems, but you will have to connect a 380 V line, since three-phase models will be required to ensure performance. If it is planned to use internal combustion engines, which is extremely rare, a step-up gearbox is installed to increase the number of revolutions of the saw blades.

First you need to make mini drawings of the future design. Since improvised materials will be used for manufacturing, their exact dimensions should be taken before forming the scheme. There are no exact rules for the manufacture of a double-disk sawmill - the design in each case is purely individual.

However, to create reliable equipment, it is recommended to follow the advice of professionals:

- the frame must be made of channels No. 4 or No. 6. For connection, two methods should be used - mechanical with bolts and welded. This will ensure maximum strength and, as a result, durability;

- it is best to use standard P50 rails as carriage guides. They must not be deformed or bent. Wheels for the platform are selected under them;

- during manufacture, it must be taken into account that the width of the carriage and the mobile platform must be the same. Slight adjustment is allowed with the help of wheel hubs;

- engine location. Since most models are air-cooled, the power plant should be located as far as possible from the sawing site. To drive the disk, a shaft or chain drive should be made;

- to protect the operator, a steel shield is installed on the platform. It will prevent the occurrence of dangerous situations. But at the same time, it should not interfere with a normal review.

During operation, it is necessary to periodically check the condition of the equipment. A home-made installation during long-term operation may lose its original qualities. Also, do not forget to sharpen the saws on both sides, and after the end of their service life, change them to new ones.

To make a manual sawmill with our own hands, we will need (depending on the design):

- construction goats;

- boards;

- channels;

- corners;

- electric motors;

- a set of hand tools;

- the presence of two pairs of rails;

- metal plates.

In the video you can see an example of a homemade corner sawmill:

Examples of detailed drawings

Do-it-yourself circular sawmill

In the private sector, a do-it-yourself circular sawmill makes it possible to produce timber, boards from logs of medium and large sections. With the growth of the expected volume of production, the requirements for accuracy, thoroughness of the assembly work, and the quality of the materials used increase.

Homemade corner sawmill

Design choice

A design of a circular sawmill is being developed for specific needs. Productivity, log width, even cut for the entire length of the workpiece require certain technical solutions in the assembled equipment. With manual feeding, the wave of the plane of the resulting board increases. The size of the saw blade, the limits of its displacement relative to the thrust pad will set the maximum size of the wood for sawing.

Master knots

The components of the future machine must first be correctly positioned on the drawing. The device of any home-made sawmill includes:

- frame. Unites all components into a functional whole. At the same time, the distance between the parts should allow safe DIY work, maintenance, cooling, waste disposal. The main qualities are stability, rigidity;

- engine. The electric three-phase option is chosen by power, number of revolutions. Operating voltage 380 V. In the absence of a connection to the network, a gasoline engine with a step-up gearbox is installed;

- cutting unit. It is located horizontally, vertically. Consists of one disc or two (corner). A single saw can be fixed in one predetermined position or rotated 90 ° to prevent reverse idling (corner cutting);

- supply line. Simple homemade is limited to a fixed table with manual feed. Use this type for small do-it-yourself work with workpieces of not large sizes. A massive log is fed under the knife on the carriage;

- Remote Control. Performs on / off operations, available adjustment switches (speed, feed, indication). It is carried out to a place convenient for work and process control on the frame.

Despite the fact that the manufacture takes place at home, safety measures must be observed - rotating parts should be covered with a casing, on the operator's side, a protective sheet of metal should be installed to prevent disc expansion. Woodworking circular sawmills are classified as high-risk equipment.

The design of a circular sawmill with two simultaneously working cutting tools makes it possible to increase the productivity of processing. They are located at right angles to each other. Such homemade devices are more difficult to manufacture.

Each disc is supplied with its own motor and drive. The frequency of revolutions is selected the same.

The horizontal movement of the angular pairs of the disk with the drive mechanism occurs on a movable carriage. Guides are placed under it. To adjust the relative position of the circular saws with your own hands, each pair is equipped with adjusting devices.

Drawing and material

Depending on the design, they draw up drawings of a sawmill of varying complexity. In individual development, certain requirements must be taken into account.

- using the log feed on the carriage, the width of the platform is taken equal to the width of the guide rails. This will provide stability under load. The rail is taken by P50, the rollers are selected accordingly;

- on the platform, provide clamps for the tree trunk, convenient, reliable fixation of various sizes of the workpiece;

- it is advisable not to combine an electric motor and a saw on a hard drive. It should be protected by a belt (chain) transmission. This will improve the air cooling of the windings, remove from the zone of intensive formation of wood dust. Before creating a drawing with your own hands, you need to measure the dimensions of the engine, with the same characteristics, the manufacturer gives his size in terms of size;

- calculate the working area for a saw Ø 500 - 700 mm;

- the frame, depending on the dimensions of the installation, to make welded or collapsible (moving to a new place of work). Channel No. 4, No. 6 are placed in the main harness. Additional stiffeners are made from a steel corner, a pipe (if necessary).

Assembly order

Do-it-yourself installation process is divided into 3 stages. After each, the dimensions, tolerances, travel limit of moving parts are checked against the working drawing.

- Carrier frame. Perform welded (bolted) joints. They check the quality, diagonals, location of seats, stability.

- Delivery part. In the case of a fixed table, the level is set to a horizontal plane. Fix the coincidence of the longitudinal axis with the supporting frame. For a mobile platform, first set the rails at the same level coaxially between themselves and the base. They load it with a trolley with a check for smooth running, the absence of rubbing of the wheel flange. A small home-made sawmill can have a light trolley on bearings, rollers. For them, a guide track is made from a corner for passing forward and backward. On large models, the principle of moving the carriage with the disk over a log fixed on the table is used.

Household sawmill Astrogan 2

- Cutting organ. The first is the shaft of the sawmill with a saw. The support bearing assembly is attached to the subframe, the axis of rotation is checked, the presence of beats. Then the engine is hung on the landing grooves. The fastening bolt should not be located at the edge of the groove. If a V-belt / chain drive is used, then with repeated revolutions it loosens, subsequent tension is necessary. When replacing with a new product, the engine is again fed closer to the shaft. Infinite adjustment can be made with spacer bolts on each side. A heavily tensioned belt or chain will overheat when the equipment is used for a long time.

When assembling a corner sawmill with your own hands with a block of discs on a movable carriage, the design distances are controlled along the entire length of the stroke. An unexpected change in the angle of inclination of the saws during sawing will lead to damage to the raw materials, an accident.

Individual approach

Where a high-capacity sawmill is not required, a mini-machine is designed with a sliding feed on a fixed plate.

With an increase in weight, the length of the workpiece, the table is equipped with freely rotating rollers to facilitate manual pressure.

A swivel (90°) gearbox for a circular saw will be a universal solution. In some cases, the owner prefers to install end clamps to rotate the workpiece around the longitudinal axis.

Moving a tree or a saw is a crucial issue in the design of a sawmill.

You may also be interested in articles:

Do-it-yourself band sawmill Circular sawmills Homemade chainsaw sawmill How to make a do-it-yourself wood planer

Do-it-yourself corner sawmill

Today, more and more manufacturers of quality sawn timber give preference to the angle sawing method, appreciating the economic benefits and new opportunities from the use of angle sawmills and machines.

The purpose of the corner sawmill

Modern angular circular sawmills, being convenient and multifunctional equipment, allow you to quickly, and most importantly, produce high-quality radial sawing of boards. Thanks to the innovative technology underlying the operation of the corner sawmill, the capabilities of this type of equipment are significantly expanded compared to the traditional way of manufacturing lumber, which favorably affects the range of finished wood products.

Radial sawn boards, obtained as a result of the work of the angle saw sawmill, are distinguished by an even, beautiful texture, increased strength and high cost, which in no way reduces the demand for them. The excellent quality characteristics of radial sawn boards make it possible to successfully use them for the formation of glued beams and the manufacture of cabinet furniture, elite wooden windows and doors.

Returning to the question of the cost of radial sawn boards, it should be noted that the manufacture or purchase of an angle sawmill is the beginning of a stable and profitable business: high-quality wood, being a fundamental building material, is always in demand, and this will provide you with a constant flow of orders and considerable profit.

In addition, organizing the production of lumber based on the use of coal saws will be much cheaper than if you stop at the traditional approach.

It should be noted that a hand-made sawmill is in many ways inferior to a reliable and high-quality factory-assembled sawmill. Having extensive experience in the manufacture of angle grinders and the ability to use the latest components and assemblies, manufacturers regularly improve technical characteristics, increase functional load and safety level. And this means that the risk of doing business based on the use of artisanal products may not be justified.

Angular sawmill: equipment and specifics of work

The angle sawmill is used to manufacture:

- edged lumber, including radial;

- all kinds of blanks for molded products;

- multilayer timber;

- parquet;

- individual cutting of logs with culling of waste.

The standard equipment of the angle sawmill includes an electric winch with adjustable speed, which, using special buttons on the control panel, ensures vertical positioning.

Thanks to the use of a circular sawmill, the scheme of which can be easily downloaded on the Internet, you can achieve higher accuracy compared to a flywheel or band sawmill. The design of the angular disk machine provides the optimal solution for the log cutting scheme, the rational exit of the edged board and eliminates the idling of the sawmill.

Compared to band sawmills, angle saws have the following advantages:

- Higher reliability: the saw blade, acting as a cutting tool, has a long service life, does not break, "waves" and microcracks are excluded, the working tool does not need "rest";

- As a result of sawing, a high-quality edged board is formed with a minimum percentage of waste;

- The sawing of a log is carried out from one installation, the need for tilting and coups is eliminated;

- Qualitative sharpening of disks provides high purity of processing.

To control the sawing process, the condition of the equipment, and most importantly, the convenience of working on an angular disk machine, the operator is placed in a special movable cabin. Fixation of logs when working on a circular angle sawmill is carried out by using reliable clamps that firmly hold the logs, preventing them from changing their position during cutting.

Specialists distinguish single disc And two-disk angle sawmills.

The main feature of double-disk machines - this is the presence of two circular saws located vertically and horizontally relative to each other, which provides the sawmill with greater productivity and efficiency. So, in the process of sawing, saw blades turn a single log into finished products with a radial arrangement of fibers.

A distinctive feature of single-disk angle grinders is the possibility of sawing logs in any direction: in the forward and reverse, changing its horizontal position to vertical.

Feature of the angle sawing method

Angle sawing, being a new direction in the field of primary woodworking, is carried out on disc log saw equipment with orthogonal saw blade feed or using automatic turning mechanisms of the working unit. The technological process is quite simple: orthogonal saw blades sequentially cut logs into planks with annual rings located radially, that is, at an angle of 45 ° to the largest plane of the lamella profile.

Using two saw blades located in the horizontal and vertical planes, sawing of logs is carried out, which are fixed on a fixed frame of the equipment, along the guides of which the portal with the saw tool moves.

Using a multi-disc machine and equipment with a rotary saw spindle, it is possible to obtain high-quality lumber of a given section directly from a log, eliminating the stage of processing unedged wood material. The design of rotary coal saw equipment is based on a special rotary cutting mechanism.

A feature of this machine is sawing with a movable carriage along a fixed log with a set of saw blades. The operator independently determines the log sawing scheme, taking into account the optimal log cutting model and the shift task. It should be noted that modern models of charcoal saw equipment are equipped with automatic cutting optimization programs that set the main parameters of the angle sawmill operation - the speed, width and depth of the cut, the possibility of shifting the working tool along the orthogonal axes of the cut.

Often, the drives of such installations have motors with controlled speed using a frequency converter to determine the angular speed of the working motor and automatically control the feed rate of the saw spindle. In this way, the most suitable ratio of cutting speed can be obtained, taking into account the hardness of the wood and the choice of saw blade.

Radial and tangential cutting methods

A cut is considered radial if the cut plane runs parallel to or through the core of the trunk. The resulting boards of radial cut are characterized by the presence of a uniform texture and color, the minimum inter-ring dimensions. Finished lumber has high wear resistance, as it is resistant to external influences and is not subject to deformation. The shrinkage ratio of a radial sawn board is 0.19% and the swelling ratio is 0.2%. It should be noted that these indicators for radial sawn boards are twice as good as those for tangential sawn timber.

As for the cost indicator, it is quite high, since the yield of radial sawn timber reaches only 10-15% of the total volume.

In order to obtain a high-strength glued laminated timber, it is necessary to glue the lamellas along the face, obtained by splicing blanks "on the mustache" from semi-radial and radial cut dies. The so-called “fiber resistance” effect, which has arisen from gluing a layer with annual rings at an angle of inclination up to 45 °, largely determines the strength characteristics of glued laminated timber, its rigidity and stability of geometric parameters.

Thus, for the manufacture of knotless and glued wood, slabs and lumber obtained by the method of radial or semi-radial sawing are used.

The cut is considered tangential if the cut plane lies at a distance from the core of the trunk, tangential to the annual ring. The resulting lumber has a pronounced texture and has a rich wavy pattern of annual rings. The coefficient of shrinkage and swelling of tangential sawn boards is much higher, the possibility of warping is not ruled out, as a result of which the cost of finished lumber is an order of magnitude lower.

The use of angular sawmills, the cost of which is quite high, nevertheless, greatly simplifies the technology for the production of finished lumber. The unique design of the machines allows you to get a good output of high-grade boards and the ideal geometry of sawn timber, and in combination with the lowest initial investment and maintenance costs of the units, it is quite effective for implementation in small and medium-sized enterprises.

It is customary to read that the purpose of circular sawmills for radial cutting is solely in the production of radial lumber. This judgment is incorrect due to the technological features of the angle sawing method. It would be more logical to argue that the method of angle sawing, together with the manufacture of traditional edged lumber, also allows radial boards from a single log.

Using individual cutting of a log by means of angle sawing, it is possible to simultaneously obtain radial boards from defect-free areas of the log, as well as traditional edged boards from the area where defects are located. At the same time, the width and thickness of sawn timber cut in sequential order is limited solely by the diameter of the working disk.

Having received 15-20% of radial boards from ordinary raw materials from the total volume of lumber produced, you can increase your profit several times at the same level of costs. If this rule is not observed, the woodworker as a whole will receive low efficiency.

cutting cycle

The saw blade at the beginning of the cutting process is in a horizontal position. Moving forward, the disc makes a horizontal cut along the entire length of the log. Having reached the end of the log, it changes its location and becomes vertical. When performing a reverse stroke, the notched area is separated by vertical cutting. Then the saw blade changes its location to horizontal and the cycle repeats. This technology allows you to get edged lumber of a given section. Multirip saws with orthogonal placement of circular saws The cutting cycle is similar, although somewhat more complicated, since instead of turning, the method of approaching circular saws in one plane and retracting in another, then vice versa is used.

So, the key to the successful work of a woodworker is the ability to rationally produce a high-quality cut of a log into lumber. At the same time, one should not forget that any equipment, no matter how modern and “smart” it may be, is just a tool with a specific set of technological operations. And only many years of experience, professionalism and imagination of the operator determine the number of sawing cycles in the sequence of sawing boards on saw machines equipped, for example, with a mechanism for automatically turning the working saw unit.

youtube video

The video clearly shows the production of edged boards with dimensions of 50x100 on a basic sawing machine.

Corner sawmills: sawn timber cutting scheme

Angular sawmills, in particular those using automatic saw blade turning mechanisms, are considered the most acceptable and suitable equipment for small and medium-sized sawmills.

Not every manufacturer can provide himself with high-quality raw materials for the manufacture of radial lumber. For example, for the simple reason that basically you have to deal with low-quality sawlogs and a diameter of 24-26 cm. However, in practice, good quality radial boards can be made from a diameter of at least 32 cm, without taking into account the core, knots and other defects in them. Ideally, high-quality radial lumber of high quality is obtained only when using high-quality raw materials with a diameter of 38-40 cm. In this case, it is only advisable to spend all the logs on radial boards of a certain section.

Otherwise, you run the risk of becoming the owner of a lot of short-length blanks and waste, as a result, the cost of production will become high, and production will become too laborious and unprofitable. Since the majority of manufacturers do not deal with their own raw materials, but with purchased ones, they are familiar with all sorts of difficulties associated with the supply of raw materials for the manufacture of high-quality lumber. Only by optimizing the performance of angle sawing machines, the woodworker will be able to process such a volume of material that he can supply and not worry that the sawmill will stop its work due to the lack of quality raw materials in the required volume.

Do-it-yourself corner sawmill assembly

There is no doubt that the corner sawmill is an indispensable equipment for those who have connected their lives with woodworking and for those who plan to build a wooden house with their own hands in the near future.

Manufacturing equipment for angle sawing in the factory is not a cheap pleasure, which means that buying an angle sawmill at a factory price is advisable for those for whom professional timber production is the main source of income.

However, if you are not a businessman, but you still need a sawmill, then the best choice would be to make a corner sawmill with your own hands. At the same time, the manufacturing process will not require large investments from you, but you will have to be smart and patient to develop a drawing of an angle sawmill, design and prepare an angle sawmill device, individual parts and assemblies, and assemble the finished structure.

Highlights of assembling a homemade sawmill

- So, for the manufacture of a circular sawmill with your own hands, first of all, you will need a strong metal frame, which can be made from any metal pipes or guides.

- For a reliable connection of pipes, use the welding method.

- For the development and creation of guides for the carriage, experts recommend choosing high-quality rails without external defects, otherwise the carriage wheels will constantly jump off or get stuck, however, the rollers or wheels must ideally fit the finished rails.

- Directly the carriage can be assembled from metal parts and parts.

- When manufacturing a sawmill, it is necessary to pay attention to the fact that the geometric parameters of the frame with rollers or wheels fixed to it must correspond to the distance between the finished rails, which will ensure smooth and free movement of the carriage during the operation of the angle sawmill.

- Any gasoline engine can serve as a drive for a circular saw. When creating a circular sawmill, it is necessary to install a higher power engine, since the work will be carried out by two saw blades.

- And finally, it should be recalled that in order to exclude the possibility of overheating of the drive, it is necessary to replace the chain drive with a more reliable and durable analogue. This way you will secure the machine and significantly extend its operational period.

Wood is one of the oldest materials that mankind still uses today. They cannot do without it either in construction, or in the production of furniture, or in many other areas where a sufficiently strong, easily processed, inexpensive material is required.

And making wooden products with your own hands can be not only professional, but also a favorite thing, which, in addition to benefits, also brings pleasure.

1 General data

Working with wood begins with sawing the tree trunk into boards, timber or slats. And in this case, the most suitable device for obtaining the appropriate lumber from a log is a sawmill:

- disk;

- chain;

- tape;

- disc angular (charcoal).

All these types of sawing machines you can do it yourself for home or small business use. A home-made sawmill, for all its clumsiness, will work no worse than a factory one.

At the same time, it will save a lot of money and help you become a real specialist in the field of woodworking.

1.1 Circular sawmill

Making a disc sawmill with your own hands is the easiest, since this does not require any special knowledge. It is enough to study several ready-made projects, or borrow the principle of operation and layout features from factory samples.

Do-it-yourself circular sawmill

- "Ural" is a circular sawmill that allows you to work with workpieces with a diameter of up to 800 mm and get from 65 to 75% of the output of processed wood. Productivity is up to 10m³ per shift;

- Corvette is a charcoal sawmill that can work with raw materials up to 1000 mm in diameter.

A homemade sawmill consists of only a few nodes:

- beds;

- electric motor;

- circular saw.

Everything else (the drive, the power supply circuit, the system for feeding and fixing the wood blank) is added to these parts in accordance with one's own desires and capabilities.

Simplest version of the mini sawmill is a table, with a shaft attached from below, on which a toothed disk is located, rotating in a narrow slot of the table top. The drive is carried out by transmitting torque through a belt from an electric motor.

For the manufacture of the frame (table), you will need metal corners or wooden bars, from which you can make a frame, on which the desktop is then fixed.

Cutting discs can also be made with your own hands from a steel or duralumin sheet 3 mm thick. The size (diameter) of the disk should be within 50 cm and it is enough to equip it with just two or three teeth. This is quite enough to work with almost any type of wood.

You can make cutting teeth from a broken drill or carbide steel. Their cutting angle must be kept within 30 degrees, and the back angles must be at least 15 degrees. After fixing the teeth on the disc, it must be balanced in order to avoid unnecessary vibration during rotation.

1.2 Band sawmill

A more accurate definition of such a mini do-it-yourself device is the expression - a home-made tire sawmill. Because often, the saw blade of such a device is located on two ordinary car wheels from a passenger car.

Tape mini A sawmill can have the following main characteristics:

- frame 1.2 m high with a width and depth of 0.9 m each;

- guide rails (rails) along which the frame moves 0.9-1.2 m wide and up to 8-10 meters long.

- the saw band is located on wheels with tires R13 of any standard height and width;

- the band saw, connected in a ring, has a length of 2.66 m.

The total weight of the structure moving on rollers along the guides usually does not exceed 50 kg, and the guides themselves can be made collapsible.

Therefore, the word mini is quite suitable for such a device, since, if necessary, it can be easily transported unassembled, even in a car.

2 Construction

In order to make such a mini sawmill it is enough to adhere to the following principles:

- create a frame moving on rollers (along guides), on which a band saw on wheels and a drive equipped with a gasoline or electric motor will be fixed;

- lay guides (rails) for manual movement of the working structure during sawing;

- provide elements for fastening the workpiece (log) between the rails;

- equip the working part of the structure with an accurate lifting (lowering) mechanism for setting the dimensions (thickness) of the future board;

- provide water cooling of the saw (a jet of water from a tube derived from a highly located tank).

2.1 How it works

Rotating on two wheels, the band saw, closed in a ring, with its lower part passes through the wood, sawing it. To move forward, you need to make a small effort, pushing the movable structure in front of you.

The tires on the wheels need to be balanced to eliminate vibration that can affect the quality of the cut. With each new pass, a layer of a certain thickness is removed from the workpiece, which is set by lowering the movable part with the cutting unit vertically.

2.2 Angle sawmill

A mini charcoal sawmill, which is quite possible to do with your own hands, will allow you to get very high quality lumber. This is due to the fact that it can be used to obtain radial sawn boards, which are distinguished by their excellent quality and rather high price.

The basic principles that must be followed in order to make such a device with your own hands are very similar to the creation of a band sawmill.

Requires a frame moving along the guides with an electric motor and a circular saw. The only difference is that the cutting angle can vary from 0 to 90 degrees, and not be strictly horizontal.

It is possible to make a slightly different device - with two cutting elements that will work alternately, but do not require rotation, since they were initially installed in planes perpendicular to each other.

2.3 The sawing process at the angle sawmill (video)

2.4 Cutting technology

At the beginning of the dissolution of the log, the saw blade is set horizontally. Having made a horizontal cut along the entire length of the workpiece to a predetermined depth, during the return pass it is set vertically, and thus, it cuts a board or beam from the log with the required parameters.

This sawing technology allows you to immediately obtain lumber of a specific configuration (a certain section).

In the variant with two discs, there is no need to change the sawing plane. First, a horizontally located saw passes, and then it is retracted, and another, vertically located, starts to work.

2.5 Chainsaw sawmill

A homemade sawmill from a chainsaw that you can make yourself is the easiest option for mini sawmills of all those presented above. The chain saw is already securely positioned, driven and does not require any additional devices.

Initially, the chainsaw was designed as a hand tool. But in order to carry out an accurate and even cut, stability in movement is required, which the human hand is simply not able to provide.

Therefore, the idea arose to create a device (device) that provides reliable movement of the cutting element along the sawn workpiece.

To make a sawmill from a chainsaw with your own hands, you will need the following materials:

- two channels (140-180 mm) 8-10 meters long;

- corner 50 × 100 mm, length 80-100 cm 4-5 pieces;

- corner 40 × 40 mm;

- pipes with a cross section of 35-40 mm with movable rods on them.

From channels and corners a path is made for the movement of the trolley along it, made of corners, and mounted on rollers (bearings). Fixing elements are installed on the track to hold the workpiece (log) with the help of movable rods.

The chainsaw is mounted on a trolley tripod, as well as a grinder on a home-made cutting machine, with the possibility of changing its height.

2.6 Working principle

The workpiece is securely fixed in the middle of the guides. The chainsaw is mounted on the trolley frame in a strictly horizontal position of the sawing unit. During operation, the trolley moves along the workpiece manually sawing the log as it moves.

A circular sawmill is a high-performance woodworking equipment that is present in almost every facility related to mining, wood processing and the production of wood products.

- Do-it-yourself purchased or assembled sawmill allows you to perform unedged, edged lumber;

- The processes of sawing with circular saws take place immediately after the wood has been processed with a band saw;

- Single-disk and double-disk plant provide the production of various log-based materials;

- After the band saw has completed its sawing steps, the vertical sawmill or its analogues come into operation. The device is designed for sawing in various ways - end, edging, dividing;

- Such disc units as PDPU 600, DPA 600, Grizzly, Lesnik 450, Shinka or DPA 550 can become an indispensable unit in matters of fast and high-quality longitudinal sawing.

Design features

A circular sawmill (DP) is a hardware machine that is designed for longitudinal sawing of materials and is powered by a specific engine. By studying the drawings of the device, certain conclusions can be drawn regarding the design.

- The main structural elements of the saw are a pair of engines, a circular saw, an operator's cabin, carriages and rails.

- The simplest factory or home-made sawmill has the form of a table where a shaft with a cutting disc is installed, and the cutting edge rotates above the plane. Such a single-disk saw, although mobile, easy to assemble, is only suitable for home use.

- When choosing a device for more serious sawing, it is better to focus on high-performance machines, which are distinguished by the ability to perform a wide range of functions. Some of them are charcoal saws, with which sawing at an angle is carried out;

- The working tool of all band saws is a circular saw. It is mounted on the spindle shaft or directly on the motor shaft.

- If this is not a single-disk, but a double-disk sawmill, then each individual saw is driven by a separate motor. There can be a certain difference in power between engines. This is due to the fact that one engine is responsible for the larger cutting disc, and the second is designed to work with small lumber.

- The frame is made on the basis of high-strength metal pipes, which are connected mainly by welding.

- The carriage or trolley moves on rails. In this case, it is better to immediately pay attention to what material they are made of. Good rails ensure smooth movement of the carriage, therefore they should not have defects, irregularities, etc.

- The carriage is made of high-strength metal. It may have wheels or rollers. Which is better depends on the consumer and the characteristics of the operation of the DP. Most importantly, the rollers matched the rails perfectly, there was no jamming, slipping from the surface.

- If you are going to make your own sawmill for sawing at home, it will have to be equipped with an engine. Experts note that any engine can be installed. Gasoline models are better suited, and electric ones show themselves well for production shops. The performance of the selected motor must be high to ensure the operation of two saws. Factory models are equipped with a separate motor for each saw of a circular sawmill.

Kinds

Like a band saw, a disc saw performs well in wood processing and performs corner sawing, which is what the corner sawmill is designed for. Tape and disk installations are two inveterate competitors, each of which can seem better in certain areas.

To make multi-saw, rotary sawing devices equipped with an electric or gasoline engine, you first need to understand the types of installations.

But if you need mobile, stationary, powerful, equipped with certain functionality, capabilities, it is better to make a short digression.

- Corner. Such sawmills allow you to cut in two directions - along and across the workpiece. The process of sawing on an angle sawmill is possible when processing logs with a diameter of 7 cm or more. The angle model is more mobile, since it is not mounted on special platforms. But so that productivity does not fall, and the device does not fail, the corner sawmill must be protected from precipitation. It is impossible to work in the rain, as the instructions say;

- Horizontal. No less common models, the performance of which provides an excellent result in wood processing. This is a mobile unit, as it is easily disassembled and transported to facilities. The main advantage is not only performance, but also the absence of idling. It does not require special instructions, lengthy training, to master the work with a horizontal DP for a beginner. Management is implemented through the appropriate remote control for DP;

- Vertical. It is not uncommon to find multi-saw installations of vertical execution. Such sawmills are relevant in the manufacture of timber, boards. Using vertical type DP, you can get finished lumber in one go;

- With cutting blocks. This is a DP with a special mechanism that is installed on the main DP carriage in order to be able to produce edged lumber in one machine approach;

- Double disk DP. These are devices whose performance is at a very high level. This performance is due to what the sawmill uses to drive at the same time.

Homemade vs Factory

Numerous reviews and video instructions make it clear that it is quite possible to assemble a mini sawmill yourself. The only thing that can stop the master from buying sawmills such as Kedr, PD 2000 mini, PDPU 600 or Grizzly is the high price, which ranges from 150 thousand rubles. With all due respect to home craftsmen, it is almost impossible to assemble a full-fledged analogue of a high-performance factory sawmill.

During the primary processing of wood, you will need a sawmill. This equipment can be of several types - disk or tape. For self-manufacturing, preference is given to the first type, since it has good performance properties and a relatively simple design.

The principle of operation of a sawmill

Before making a design, you should familiarize yourself with the principle of operation and the purpose of the configuration of a mini sawmill. In most cases, it is necessary for sawing logs of large and medium diameters. As a result of this, the formation of boards or timber occurs.

The main component of the design is the power plant. It should provide the proper number of revolutions of one or two discs. In addition, for maximum automation of work, the following components are required:

- supply line. It can be fixed or with a system for transporting the log to the discs. Most often they prefer to make the first option, since it is the least expensive for self-production;

- cutting unit. Consists of one or more saws. Depending on their location, it can be horizontal or transverse. For simultaneous processing of a log in two planes, an angle sawmill is required;

- Control block. Most often it is located on the outer part of the cut node. With it, the operator can adjust the number of engine revolutions, turn the equipment on or off.

An angle sawmill is necessary for tangential and radial sawing of workpieces. Due to its design, the entire volume of the log is used as rationally as possible.

Mini twin-disc models usually come with two motors. However, their power and number of revolutions may not always coincide. These parameters must be calculated in advance and an appropriate cutting unit made.

The choice of the design of the sawmill

The simplest home-made sawing design consists of a table, above the surface of which there is a cutting disc. You can make a similar model at home. However, its performance will be low.

The main disadvantage of this design is the need to independently feed the log to the sawing site. This will lead to a violation of the geometry of the future board or beam. Therefore, these types of equipment are used only for processing small workpieces or sheet material.

The corner sawmill has much more functionality. It performs two cuts simultaneously in a horizontal and vertical position. However, its manufacture is more complicated than that of the model described above. A do-it-yourself circular sawmill has the following design features:

- movable cutting carriage. It moves along the guides located on the body of the stationary platform. There are two motors on the carriage, on the shafts of which saw blades are mounted. It is imperative to make a device for adjusting the position of the edges of the disks;

- stationary platform for blanks. It has lumber braces. Otherwise, during operation, displacement is possible, which will lead to deformation of the product.

A similar mini design can be made from improvised materials. It is important that it can withstand the loads and constant vibration that will inevitably appear during operation.

If the sawmill is designed only for the production of boards, you can install another vertical one instead of a horizontal saw. This will increase the performance of the equipment.

If a sawmill is needed for commercial purposes for processing large volumes of wood, you should be very careful in self-manufacturing. Home-made models will not always be able to provide a high-quality cut at a constant load. But for small jobs, you can make a design with your own hands.

First of all, you should choose the right power and the number of revolutions of the power unit. When installing electric motors, there will be no such problems, but you will have to connect a 380 V line, since three-phase models will be required to ensure performance. If it is planned to use internal combustion engines, which is extremely rare, a step-up gearbox is installed to increase the number of revolutions of the saw blades.

First you need to make mini drawings of the future design. Since improvised materials will be used for manufacturing, their exact dimensions should be taken before forming the scheme. There are no exact rules for the manufacture of a double-disk sawmill - the design in each case is purely individual.

However, to create reliable equipment, it is recommended to follow the advice of professionals:

- the frame must be made of channels No. 4 or No. 6. For connection, two methods should be used - mechanical with bolts and welded. This will ensure maximum strength and, as a result, durability;

- it is best to use standard P50 rails as carriage guides. They must not be deformed or bent. Wheels for the platform are selected under them;

- during manufacture, it must be taken into account that the width of the carriage and the mobile platform must be the same. Slight adjustment is allowed with the help of wheel hubs;

- engine location. Since most models are air-cooled, the power plant should be located as far as possible from the sawing site. To drive the disk, a shaft or chain drive should be made;

- to protect the operator, a steel shield is installed on the platform. It will prevent the occurrence of dangerous situations. But at the same time, it should not interfere with a normal review.

During operation, it is necessary to periodically check the condition of the equipment. A home-made installation during long-term operation may lose its original qualities. Also, do not forget to sharpen the saws on both sides, and after the end of their service life, change them to new ones.

To make a manual sawmill with our own hands, we will need (depending on the design):

- construction goats;

- boards;

- channels;

- corners;

- electric motors;

- a set of hand tools;

- the presence of two pairs of rails;

- metal plates.

In the video you can see an example of a homemade corner sawmill:

Having your own sawmill is a huge plus in the household. Such a unit is needed for sawing and dissolving logs into tes, chopping blocks and various bars that are needed during construction. Therefore, the owners tend to make a homemade sawmill with their own hands. The main financial costs are borne by the electric motor and the saw blade itself. Everything else can be found in your yard and garage.

Making a machine from a grinder

It is necessary to approach the creation of a large sawmill gradually. This is due to special safety precautions when working with saws.

The most elementary type of machine is a sawmill from a grinder. It is assembled with its own hands in just a few hours, if there is a ready-made saw blade. Of course, it is difficult to call it a sawmill in the broad sense of the word, however, in the first case, it will fit perfectly to gain experience. A good grinder has a power of about 2 kW and a speed of up to 3 - 5 thousand rpm. With this device, boards with a thickness of not more than 50 mm are dissolved and used as an additional circular saw in carpentry shops.

For the manufacture of this sawmill, you need: the grinder itself, a 250 mm circular saw, a small table with a table top and a sheet of iron 1 - 1.5 mm thick. The protective cover is removed from the grinder.

For the manufacture of this sawmill, you need: the grinder itself, a 250 mm circular saw, a small table with a table top and a sheet of iron 1 - 1.5 mm thick. The protective cover is removed from the grinder.

The tabletop is covered with thin tin for better sliding of the lumber. Then a slot is made in the center of the table for the saw blade. This gap should be larger than the disk by 3-4 cm in length and 1.5-2 cm in width. This is necessary for saw adjustments and self-removal of sawdust. The saw blade is fixed to the grinder with standard nuts. Then this tool is securely fixed from the bottom of the countertop with clamps and bolts. In this case, the saw part of the disk itself should protrude from the top of the table by about 10 cm.

The sawmill is almost ready for work. You just need to install and strengthen the ruler along the sawing with clamps or bolts as in the photo. It is needed to stop the board during the dissolution. And also it regulates the width of the production of lumber.

The height of the projecting part of the saw can be set by raising or lowering the tabletop. To do this, one edge is fixed to the hinges, and the other to high adjusting bolts. Then such a machine can cut grooves and quarters on the boards, which is often necessary in the production of joinery.

Sawmill from a manual circular saw

The fastest way to make a sawmill is to use a standard hand saw, which you can buy at any hardware or hardware store. It, just like a grinder, is fixed from the bottom of the tabletop, a slot is made for the disk and a ruler for emphasis. The machine is ready to work.

The fastest way to make a sawmill is to use a standard hand saw, which you can buy at any hardware or hardware store. It, just like a grinder, is fixed from the bottom of the tabletop, a slot is made for the disk and a ruler for emphasis. The machine is ready to work.

Such a device has one advantage over a grinder machine. The standard model of the hand-held circular saw has a cutting tool tilt from 0 to 70 degrees, which allows you to make cuts at different angles. This is necessary in the manufacture of, for example, triangular skirting boards or figured rails. In the production of window wooden frames, a special coal saw (charcoal saw) is often needed, for the role of which hand-held circular saws are just right.

Large makeshift device

For such a powerful unit, a reliable frame is made of channels and corners. On it will be mounted: an electric motor with a power of 3 - 5 kW, a movable subframe and an adjustment system for the operation of the machine. The sawmill device also includes a carriage, guide rails and devices for keeping logs from moving.

If in circular machines the operator needs to feed lumber to the saw, then the opposite is true here. The log is fixed on the base in front of the bed, and the sawing unit itself is pushed to the workpiece along the rails. With proper installation and adjustment of moving parts, operation is smooth and effortless on the part of the operator. Such a machine is capable of cutting workpieces horizontally and vertically. The rotation of the engine with the saw is carried out by the worker.

When moving forward, the disc cuts horizontally. After the pass, the operator turns the motor 90 degrees, the saw becomes vertical. A backward movement is made with simultaneous sawing of the log. After that, the subframe with the engine is lowered by the adjusting screw to a predetermined size. And then a new cycle of work is repeated. It takes only about 2-3 minutes to move forward and backward.

Of course, you can make a sawmill that will cut both horizontally and vertically at once. But for this you need two electric motors of the same power and speed. At the same time, the device of the unit will become significantly and unreasonably complicated, which is unprofitable at home.

A self-made angle sawmill can cut from 5 to 8 cubic meters of wood in one working day. It is used to make:

- preparations of running lumber;

- timber multilayer for construction of houses;

- radial and edged lumber for carpentry;

- parquet board;

- make individual cutting of logs for special purposes.

An angle sawmill has a number of advantages over a band saw of the same type. Namely:

- the smallest amount of sawing waste;

- high reliability;

- eliminates the waviness of the surface of the board. This happens with a poorly tensioned saw band;

- high quality cutting;

- sawing takes place on one installation.

At large woodworking enterprises, the Finnish circular sawmill Kara is used. It is a two-saw system with a moving belt for feeding wood. Able to dissolve logs up to 80 - 90 cm thick. Productivity up to 20 cubic meters per hour. It has a complex control system. Service staff 2 people. The disadvantage is the high price not only for the sawmill itself, but also for the saw blade, the cost of which is about 20 thousand rubles. For sawing hardwoods, such as oak or larch, they are used with stellite tips. These saws are several times more expensive than ordinary ones.

Self-made production of such machines is not carried out due to their complexity and the high cost of individual components.