How to make a block toilet. How to make a country toilet and shower with your own hands under one roof. Video: stages of construction of a country toilet with a shower under one roof

Let's see if it's possible to build. And let's start with how to choose the right place. As far as we know, toilets should be built no closer than 30 meters from an open or closed water source. It is desirable that the building should be located on a hill, so that melt water does not fall into the cesspool.

A reasonable question arises whether there is a well or a well nearby, and how to do it so as not to infect them. To do this, we are negotiating with neighbors in the area, and find out if they have nearby operating wells or wells.

Then, you need to take measurements from the intended location of your toilet, to neighboring wells or wells. Once again, we want to emphasize the distance between your toilet and the nearest wells or wells should be at least 30 meters. It would be nice if you could get receipts from your neighbors on the site that they do not mind the construction of an outdoor toilet in the area where you indicate.

Starting the construction of your structure, you need to decide what type of toilet you want to build at home. Toilets are divided into several types: these are stone, and from boards (frame). As you understand, a brick toilet will be expensive, but a frame one is an economy option. Under brick toilets a foundation is needed, and for wooden toilets, as such, a foundation is not needed, it can be built on wooden poles.

If we consider the construction of a toilet in terms of importance, then the cesspool is the most important part. During its construction, it is necessary to take into account its volume, which should be calculated approximately 70 liters per month per person. It should also be airtight and easily removed from the pit.

The tightness of the pit is achieved by making a castle of clay, the thickness of which should not be 50 centimeters. For this design, ordinary steel or plastic barrel for 200 liters.

What is good foam block? It is light, strong and holds heat well. Under the foundation of such a toilet, an old fireclay brick will go, we lay it out in two rows. We lay waterproofing on top of the brick, for which ordinary roofing material can go.

Foam concrete is an excellent heat and sound insulating material, blocks made of it are light, malleable in processing, and easy to install. Internal partitions in the house can be built from blocks with your own hands without much effort and financial costs.

A bathroom and a toilet made of foam blocks will be no worse than a cast sanitary cabin made of asbestos cement, brick or drywall partitions, but the performance of the premises in terms of sound insulation will far exceed that of other materials.

In the article we will talk about the brands of foam blocks for internal works, about the technology of erecting partitions and ways to protect the walls in the bathroom from moisture.

Advantages of foam concrete blocks

You can build partitions in the house (see), separate the bathroom from the living area, properly organize the space in the apartment using various materials. But foam blocks are in special demand due to their unique technical and operational properties (see).

What attracts builders so much in this material:

- light weight compared to other materials does not exert much pressure on the overlap.

- The dimensions of the blocks can significantly reduce the time of the construction process.

- Due to the ease of processing foam concrete, it becomes possible to perform architectural forms various configurations (niches, arches, etc.).

- Partitions from foam concrete easily give in to redevelopment.

- High soundproof qualities.

- Complete fire safety.

- Affordable price.

The disadvantages include:

- High moisture absorption of the material, in connection with this, a number of measures will have to be taken in the bathroom to protect the walls from moisture.

- Due to the porosity and softness, the foam blocks have some load restrictions, that is, it is rather problematic to hang heavy cabinets on the walls. But this issue is easily solved using a special one.

How to choose the right material

In order for the laying of the foam block in the apartment to be of high quality, even and reliable, you need to choose the appropriate material.

For partitions, blocks of the following sizes are used (length x height x width):

- 600 x 300 x 150 mm.

- 600 x 300 x 100 mm.

- 600 x 200 x 75 mm.

- 600 x 200 x 50 mm.

Since the partition for the bathroom is self-supporting, that is, it is not subjected to any loads from above (ceiling, roofing, etc.) and holds only its own pressure, foam concrete of the D400-D500 grade with strength class B2.5 is usually used for such structures.

Important! The thickness of the blocks is taken equal to or greater than the width door frame, later it will be easier to get door slope than to think about how to ennoble the jamb protruding from the wall.

It is believed that for internal partitions the most optimal ratio of price and quality is a block 100 mm thick, this will be enough to keep the noise washing machine in the bathroom or the sound of running water was not coming from the room. A 75 mm thick partition can be laid between the bathroom and the toilet.

The foam block must meet the following characteristics:

- Accurate geometric and linear dimensions.

- Homogeneous surface without dark spots, various inclusions, etc.

- No cracks or chips, dents or bumps.

- Light gray color, partial or complete change of which indicates violations in the technological process.

It must be remembered that the smoother the surface and more accurate dimensions, the easier it will be to finish the walls (see), so high-quality blocks should be selected.

Glue for foam blocks

Since the amount of work is not large, it would be better if the laying of foam blocks in the apartment is carried out not on a cement-sand mortar, but on special adhesive mixtures (see), which include:

- Cement.

- Fine sand.

- A modifier that keeps the mixture from premature cracking.

- A plasticizer that penetrates deep into the pores of foam concrete and ensures reliable adhesion of the blocks to each other.

The composition of the mixtures is similar to the structure of foam concrete, and after the adhesive has completely set, the wall acquires strength and solidity.

The seam between the blocks is made up to 3 mm thick, no more, therefore, per 1 m2 of masonry, depending on the brand of mixture used, the consumption of glue will be approximately from 2 to 6 kg, which is 4–6 times less than when using a cement-sand mortar.

Important! When mixing the adhesive, the instructions for preparation must be strictly observed, otherwise the adhesive properties of the solution will be violated, which can lead to a weakening of the strength of the partition.

The main points of the technology of laying partitions

Before starting work, it is necessary to mark the location of the partition on the floor and wall, then, for laying the first row, install beacons along the marking to prevent the blocks from shifting during work.

As guides, you can use a metal profile for drywall:

- First row of blocks.

If the wall is placed on a cement base, then it is enough to cover it with a primer and lay a layer of mortar under the blocks, when the floor is wooden, then it is recommended to screw in anchors or pins to firmly fix the first row. It must be remembered that how accurately the first row lies, the partition will look so even and aesthetically pleasing.

- subsequent rows.

Since the thickness of the partition is relatively small, the foam block masonry in the bathroom every 2-3 rows should be reinforced with masonry mesh or separate rods (see), the ends of which should be drilled into bearing wall not less than 100 mm. In addition, fixing the rebar will tie the existing wall and the new partition into a single structure and eliminate the risk of wobbling, shearing or, in the worst case, collapse of the partition due to possible mechanical stress.

The doorway is also blocked with two reinforcement rods or a corner, on which blocks are then laid. If possible, you can use a standard jumper.

- The last row.

If a small gap remains when laying the masonry to the ceiling, then it is monolithic with mounting foam.

- The junction of two partitions.

If a separate bathroom is planned, then the partition separating the bathroom and toilet is also reinforced and the ends of the rods are laid between the blocks of the first partition and drilled into the load-bearing wall, thus creating a reliable bond.

It's all about technological process partition walls. But there are a few subtleties that you need to know when working with foam concrete:

- The laying of foam blocks in the bathroom should be carried out with mandatory dressing of the seams, that is, the seams of each subsequent row should not coincide with the underlying ones, the shift is made by about half a block.

- Foam concrete absorbs moisture well, therefore, in order to avoid moisture absorption and premature drying of the adhesive mixture, blocks must be moistened with water before laying it.

- Due to the thinness of the partition, when laying several rows in a row, a shift of the wall in the plane may occur, therefore it is recommended to let the glue stick after each row.

- After finishing the work, it is necessary to putty the seams, various defects that have arisen during the masonry process, clean the surfaces of excess glue and allow the partition to dry well. After that, cover the wall with two layers of waterproof deep penetration primer, wait until it dries completely and proceed with further finishing work.

- All work on electrical and plumbing is performed after the adhesive has completely set, the curing time should be viewed on the packaging with the mixture. Since foam concrete lends itself perfectly to drilling, it will not be difficult to bring pipes or throw wiring.

Protection of foam concrete from moisture

The bathroom is considered the dampest room in the house, so the foam block masonry must be reliably protected from moisture penetration into the concrete body.

This is done in several ways:

- Wall plastering with subsequent coating with waterproof compounds (paint, varnish, etc.).

Since foam concrete is a rather soft material, it is recommended to fix a fiberglass reinforcing mesh on the walls before applying the plaster solution. This is necessary for better adhesion of the solution to the surface of the foam blocks and to obtain a better coating.

- Sheathing with moisture-resistant decorative panels or plates (siding, PVC panels And so on).

It is produced by frame or frameless method. In the first case, a frame is mounted under the panels, on which the panels are hung, in the second version, the plates are glued directly to the wall.

With this finish, the foam block masonry in the bathroom will be especially susceptible to dampness, so it is necessary under the frame or facing material fix a vapor barrier membrane on the walls, which will not allow moisture to penetrate inside the masonry, but will bring it out.

In a separate toilet, it is not necessary to take such measures, but nevertheless, experts recommend laying a vapor barrier at least pointwise, in problem areas - around pipes, vents, doorways where condensation may occur.

- Facing with decorative ceramic tiles.

In this case, the tile will perfectly protect the foam concrete from moisture, only it is advisable to make the tile joints as thin as possible and caulk them with a special grout containing moisture-resistant components. When using a simple mixture, mold or mildew may occur. But for perfect laying of wall tiles, it is desirable to level and impregnate with special deep penetration compounds.

In conclusion, it must be said that the use of foam blocks for laying bathroom and toilet partitions is the fastest and most profitable option that even a non-professional can handle. And with proper protection from moisture, a foam concrete bathroom will last more than one year without repair.

If something remains unclear, then we suggest that you look at the photos and videos in this article, which will give a more complete picture of this topic.

Device outdoor sewerage on suburban area often does not require special knowledge, the main thing is to choose the right place and draw up a simple drawing. It will not be difficult to build a toilet in the country with your own hands according to the drawing, if you adhere to the technology and perform each process with high quality. There are several types of country toilets, so before starting construction, you should familiarize yourself with the features of their construction.

Their design is extremely simple: a hole dug in the ground, a solid ceiling with a hole in the center on top, and a frame with doors sheathed with boards or iron. You can put such a toilet in a few hours. More durable structures are made of brick, but the principle remains the same.

The next option is backlash closet. This type of toilet has an absolutely airtight pit, the contents of which are removed using a sump truck. The toilet cabin is not always located above the pit and can be built into the wall of the house. Pros: no need to look for a plot for the building, it is convenient to use in any weather. Minus: for cleaning it is necessary to hire special equipment, which is very expensive.

Another view country toilet- powder closet. This building is being built on a flat area, without cesspool. For feces, a small container is installed under the toilet seat, which is taken out after filling. This option is convenient for those who visit the country house only periodically, because regular emptying of the tank will still require the arrangement of a cesspool.

Choosing a place for a toilet

When choosing a site for construction, it is necessary to take into account the distance to residential buildings and neighboring plots, the height of groundwater, the location of wells with drinking water, landform.

Even with proper care from the toilet, unpleasant odors can come out, and the contents of the cesspool will seep into the ground. According to sanitary rules, the distance between a household well and a country toilet should be at least 25 m. This includes not only wells located on the site, but also those belonging to neighbors.

It is necessary to retreat at least 12 m from a residential building, and 1-1.5 m from the borders of neighboring plots. It is allowed to equip a cesspool only if the height of the groundwater is not more than 2.5 m. plot.

And the last thing: the toilet should have easy access not only to household members, but also to special equipment, which will periodically have to be hired for cleaning. These rules apply only to pit latrines, there are fewer requirements for the construction of other types.

Closet construction technology

The most labor intensive is building a toilet cesspool , therefore, it is recommended to study technology from it. The construction process includes the following steps:

- pit preparation;

- strengthening the walls;

- construction of a toilet house;

- ventilation device.

You can complete each step yourself using the simplest tools. After choosing a site for construction, you should decide how to strengthen the walls of the pit, as well as what the house will be assembled from.

For wooden frame any base will do, but if the house is planned to be built of brick or stone, the walls of the pit must be reinforced very securely. For convenience, first draw up a drawing of the future toilet and calculate the amount of material from it. When everything is ready, you can get to work.

To dig and strengthen the hole you will need:

- roulette;

- pegs and cord for marking;

- ladder;

- bayonet and pick-up shovels;

- sand and gravel;

- tamper;

- concrete mortar;

- brick, stone or concrete rings.

On the prepared site, markings are made in the form of a square with a side of 1 m. The soil is selected with shovels to a depth of 2 m, trying to leave the walls even so that the pit does not lose its shape. If the foundation pit is strengthened with concrete rings, the pit is made round; its diameter should be 7-10 cm larger than the diameter of the ring.

It is not worth digging a pit of greater depth: this will require additional material costs, and the time to fill the pit will increase quite a bit. But saving and making the pit too small is also not necessary, because then the toilet will have to be cleaned very often.

All the soil taken out of the pit does not need to be removed immediately - it will still be needed to backfill the floor. If ground water lie close, and the soil on the site is not dense enough, the pit should be made airtight to avoid soil contamination. To do this, the bottom is covered with a layer of sand and fine gravel, carefully compacted, poured with concrete.

The concrete solution is prepared in the following ratio:

- 1 part of cement M 400;

- 4 parts of sand;

- 6 parts of small gravel.

Crushed stone can be replaced with medium fraction slag, reducing the amount to 4 parts. Water is added after mixing the dry ingredients in small portions. The finished solution should easily slide off the shovel, but not spread. After pouring concrete, work is suspended for at least 7 days: during this time, the bottom will harden enough, and subsequently it will not be washed away by the contents of the pit. To avoid cracking, during drying, the bottom should be periodically moistened with water and covered with a film from sunlight.

Most practical option strengthening the walls of the pit is brickwork. You can lay out the walls with bricks yourself, even without the appropriate experience. It is not recommended to use silicate brick, it is better to take burnt red. Masonry is done in half a brick in a checkerboard pattern, on a sand-cement mortar. The wall thickness should be about 20-25 cm, then the reinforcement will be quite reliable and durable. Top row brick wall usually rise above the soil level by 10-15 cm.

In order for the masonry to remain vertical and not deform during work, it is recommended to lay out no more than 6 rows of bricks at a time and continue work no earlier than after 7-8 hours. During this time, the solution will have time to grab and dry a little, so the walls will remain smooth. Every 3 rows, you need to check the verticality of the masonry with a building level. Finished walls are plastered with the same mortar and covered bituminous mastic.

If concrete rings are chosen for strengthening, you will not be able to do the work yourself. To facilitate the installation process, the hole is first dug to a depth corresponding to the height of the ring. With the help of technology, the concrete product is lifted above the pit and carefully lowered down, and then they dig in with a shovel and select the ground from under the base.

The soil must be chosen evenly so that the ring settling under its own weight is located horizontally. Any, even minor, distortions will complicate the sealing of the pit.

After installing the first, proceed to the installation of the second ring. The concrete is again lifted on cables and leveled above the pit, after which it is gently lowered. Now, in the same way, they dig the ground below until the concrete sinks to the desired depth. The last ring should rise about 10 cm above the soil. All joints are sealed with mortar and covered with bituminous mastic. When the walls are strengthened, the bottom is covered with rubble and sand, rammed and poured. concrete mix.

In areas with dense soil and low level groundwater sealing the pit is not needed. After excavation of the earth, the bottom of the pit is covered with sand and tamped, and then the red brick walls are laid out. The laying of the lower rows is made with gaps in a checkerboard pattern, which provide additional drainage. As the walls rise, the gaps between the bricks are reduced, and, starting from the middle and to the top of the pit, the masonry should be solid.

Such reinforcement will protect the walls from destruction by the roots of trees that may grow nearby. Finally, the bottom is covered with a layer of large pebbles or gravel for filtering.

Floor construction

Overlappings for a country toilet must be strong enough to withstand the weight of the house and the person. For wooden structure a simple one will do columnar foundation and overlappings from a thick bar. At each corner of the cesspool, stepping back from the walls by 15-20 cm, they make a square recess, fill it with crushed stone and sand and concrete.

Brick pillars up to 20 cm high are laid out on top of the concrete and covered with a piece of roofing material for waterproofing. While the foundation is standing, the floor beams are being prepared. Choose strong, even beams of dense wood, cut them to desired length, impregnated with an antiseptic primer and dried.

Dry beams must be covered with two coats of paint to prolong the life of the wood. After that, a rectangular frame 1x1.2 m is assembled, fixing the beams with bolts. In the middle, the frame is fastened with a bar, and then one of the halves formed is once again blocked by a piece of the bar.

Now the frame is mounted on poles so that a whole half of the frame is located above the pit. The part with the partition will be under your feet. The frame fixed with bolts is sheathed with boards 3 cm thick.

If the toilet will be made of brick, it is necessary to make strip foundation. A shallow trench 25-30 cm wide is dug from three sides of the pit. The fourth side of the pit should protrude 20 cm beyond the perimeter of the foundation. Crushed stone is poured into the bottom of the trench, a reinforcing cage is laid, and the foundation is poured with concrete.

The resulting box is covered with metal channels or concrete columns every 30 cm, the rest of the space is covered with reinforcement or chain-link mesh. A spacious hole is left above the pit itself, and fastened on the side plastic pipe with a diameter of 15 cm. One end of the pipe is lowered into the pit by 10 cm, the second end is brought out.

After that, the ceiling is poured with concrete.

Construction of a wooden house

To build a wooden house you will need:

- dry timber with a section of 100x100 mm;

- 4 wooden beams;

- boards for sheathing;

- level and tape measure;

- hammer, nails;

- hacksaw or jigsaw;

- primer for wood;

- slate;

- loops and hook.

First, the front and back of the frame are assembled from the timber. The height of the front part is approximately 2.1 m, the height of the back is 2 m. Both frames are about 1 m wide. From the inside, the frames are reinforced with spacers made of timber, while in the front part the spacers should not block the passage. 4 beams are installed on the floor base at the corners and fixed with metal plates and anchor bolts. All elements of the frame are treated with a primer and proceed with the installation of the frame.

A front frame is inserted between the front beams and aligned vertically with a level. Having fixed it with nails, insert the rear frame and align it too. The frames are fastened together with transverse bars on the sides of the building.

The upper bars, on which the roof will be attached, are located at an angle, since one frame is lower; the bars should protrude 30 cm in front, 15 cm in the back.

The next step is to install the frame for the pedestal. To do this, another beam is nailed inside the box at a height of 45 cm, which will divide the toilet into 2 parts. Parallel to it, the same beam is attached to the rear frame and 2 more on the sides. When the frame is ready, you can sheathe it. Boards, thick plywood, timber imitation, corrugated board are suitable for sheathing. Inside, the pedestal is sheathed with boards in which a hole is cut.

Above the doors, you can insert glass or just cut a small rhombus.

A ventilation pipe is attached to the back wall with the help of special clamps and its upper end is led out through the roof. Then boards are stuffed onto the frame bars at regular intervals, and slate is laid on them. It remains to assemble the door, fasten the hinges and hook, hang the door leaf. Many people spend a light in the toilet so that it is more convenient to use it in the dark. For greater decorativeness, the house can be painted or painted.

brick house

To build a brick house for a toilet, you need to have at least minimal skills. Such a structure is more reliable and durable, besides it has an attractive appearance.

It is very important to lay out the corners correctly, otherwise the structure will be skewed.

After laying the first two rows of bricks, install wooden frame for doors; it must be strengthened with spacers from beams or timber installed outside. At the level of 40 cm from the floor between the bricks of the back wall are inserted metal corners for fixing the podium. Having reached the top, 1-2 more rows of bricks are made in front to raise the roof. If wiring is planned in the toilet, a piece of hollow tube is concreted between the bricks, through which it will be easy to stretch the wire.

For the podium, boards 30 mm thick are attached to the corners, and the vertical part is laid with bricks. You can sheathe the entire podium with boards by cutting a hole from the top.

The next step is fixing the ventilation pipe. Not yet roofing, a plastic pipe mounted in the base of the toilet from the side of the pit is lifted and fixed on the back wall with clamps. The upper end is passed through the floor beams and raised above the building by 20 cm. After that, the roof is mounted, the door is hung, the light bulb and switch are hung.

Such a toilet is equipped directly in country house or next to it. A wide pipe departs from the toilet bowl, the second end of which is built into the septic tank. The construction of a septic tank begins with digging a pit, the depth of which is about 1 m. The bottom is covered with rubble, formwork is installed along the walls, and then everything is poured with concrete mixture. When the concrete gets stronger, the formwork is removed, and after complete drying, the surface is treated with mastic.

Outside, around the perimeter of the pit, clay is poured with a layer of about 50 cm. From above, the septic tank is covered with shields, covered with clay, and only a small hole is left for the hatch. The hatch is tightly closed first with cast iron, and then wooden lids by laying a heater between them.

Do not deny yourself comfort even in the country. There are a huge number of projects for country toilets that every person can bring to life. But first you need to decide on the drawing and, according to it, build the future structure.

A huge amount of materials and all kinds of projects for country toilets leads to the fact that people are simply lost in the background of all this diversity. That is why the theoretical part is so important. Based on the information in this article, you will be able to choose optimal design for your cottage.

Typical projects of country toilets

Basically, to create a country toilet project, the following types of structures are used:

- toilet house with a cesspool,

- dry closet,

- closet powder.

Each of these designs has its own advantages. That is why it is so important to determine the type before starting construction.

Country toilet with a cesspool

In the project, it is imperative to provide for a pit. You also need to take care of its arrangement. For this, a plastic barrel or brickwork reinforced with reinforcement can be used.

In the project, you must provide the right amount of brick and cement, and do not forget about the fittings. The walls you created are subsequently covered with plaster. It is the pit that sets the character of the ground building. This is usually small wooden house, created from improvised materials. It can be in the form of a hut, a miniature house and even a tower.

According to this country toilet project, all waste will accumulate in the pit. For its further cleaning you will need a sewer. The main disadvantage of the project is an unpleasant smell. That is why it is very important to provide ventilation at the planning stage.

Ventilation can be either natural or forced. In the first case, two holes are made in the design from below and from above. Their purpose is extremely simple - to create air disturbances. Thus, the unpleasant smell will not linger inside for a long time.

Forced ventilation is a simple fan that blows all the bad smells out of the toilet. When installing it, you need to think about a compensation hole through which air will penetrate inside. Its diameter should not be less than the diameter of the fan. All this is written in the project.

Important ! Don't forget the cesspool. It also needs air circulation. For this, a ventilation pipe is installed.

Powder closet

When creating this project country house cesspool is not provided. All waste is collected in a tank under the toilet seat. It is best to include two containers of different sizes in the design. In the smaller one, you need to make several different-sized holes and insert it into a large container, on the side of which there will be a round exit. A drain hose is connected to it.

Through the hose, the liquid goes into the ground or drainage system. The main role in this country toilet project is played by the container for the filler. Peat is most often used as a mixture. The filler helps to contain unpleasant smells. As soon as the tank is full, it should be taken out to the compost heap.

When you make a drawing, it is important to take into account the convenience of removing the container. There are two possible options solutions to this problem. In the first of these, the tank is removed when the seat is raised. In the second, a small door is cut out at the back of the building. It allows you to easily remove the filled container.

dry closet

You don't even need to build anything here. In fact, you are buying finished project country toilet. All you need to do is install the product in convenient location. In this case, you can purchase both a finished design and a whole booth.

Advice ! Finished construction easy to install even at home. All you need to do is take care of the drainage.

Shower and toilet under one roof

Now projects of a country toilet combined with a shower are very popular. This is especially beneficial from a financial point of view. In addition, such a project allows you to significantly save free space on the site.

In the project, a toilet with a shower will have one common wall. The result is savings building materials. At the same time, the bathroom can work both on the basis of a tank with a mixture, and on the basis of a cesspool.

How a drawing is created

The main task of the drawing when creating a project for a country toilet is to detail the design. The size, shape and type of building are clearly indicated on the paper. At the same time, there are a number of standards that must be observed.

Firstly, the distance of the country toilet for the place of water supply cannot be less than 30 meters. This must be specified in the project. Secondly, a residential or commercial building should not be closer than 15 meters. Of course, there are exceptions in the form of the same septic tank with a biological treatment system.

Dimensions are of particular importance in the drawing. You are free to ask them yourself. But there are certain standards that allow you to create a beautiful and comfortable building with a high guarantee.

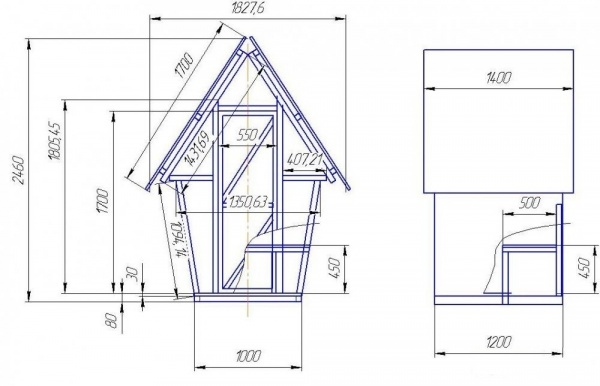

The height of the future dacha building should not exceed two and a half meters. In this case, the minimum indicator is at the level of 2 meters. The length of the building is from 1.2 to 1.8 m. The width is in the range from 1 to 1.2 m.

Many novice builders do not attach sufficient importance to the parameters of the cesspool. It is unacceptable. After all, it must also be included in the drawings. The estimated depth is 1.5-2 m, the diameter is from 2 to 2.5 m. If the groundwater is close to the surface, then the pit will have to be abandoned.

Projects of superstructures for a country toilet

When choosing a suitable project for a country toilet, the selection of material is of particular importance. It is he who sets the parameters of the future building to the greatest extent. There are several typical options, which will be discussed further.

Brick toilet

The advantages of this material can be listed indefinitely. It is resistant to atmospheric influences, retains heat and cool equally well, and is environmentally friendly. Moreover, it allows you to give the structure any shape.

The basis of this project is the foundation. Without it, the creation of a country toilet made of bricks is simply impossible. Separately, it is necessary to mention the quality of the masonry. This is the real art of laying bricks for centuries. From above, the structure is covered with a roof, a material for which, in most cases, slate serves.

In the picture you see an example of a related project. In one design, a toilet and a shower are combined. This is not only practical, but also allows you to save a lot on the cost of building materials.

wooden toilet

The project of a wooden country toilet is a classic. Its construction takes a minimum of time, but in order for the structure to serve you faithfully, it is necessary to strictly follow the plan in the process of work.

The picture shows one of the most popular options among summer residents - a teremok. As you can see, it has a small internal space and small dimensions. This allows you to install it anywhere. Also worth noting is the aesthetic appearance.

metal toilet

This version of the project will appeal to those who want to save time and money. When building, you can use sheets of metal left over from building a house. The only thing you need to take care of is the inner lining. Of course, you can do without it, but in winter it will be very problematic to be in such a structure.

The main advantage of the project is the absence of the need for any knowledge. Almost anyone can build such a country toilet. This is the most cost effective option imaginable. The only thing you need to pay attention to is the toilet seat. It is best made of wood so that it is comfortable to sit on.

Types of wooden cabins

It is wooden cabins that are most popular among summer residents. This is explained quite simply. The timber is inexpensive, but provides good thermal insulation and has a pleasant appearance. During construction, the following projects are most often used:

Results

As you can see, there are many different projects for country toilets. During construction, you yourself choose the material, type of construction and internal organization. Any of the above options has its own advantages and disadvantages. Therefore, it is very important to weigh all the pros and cons of each project and make a choice in favor of the optimal one.

After acquiring a private house, first of all, you should think about a bathroom on the street, even if there is one in the house itself. outdoor toilet- This is a very profitable building in the warm season. At the same time, when working in the garden, you do not need to go into the house in dirty clothes. It is built quite quickly and the construction will cost quite inexpensively. Walls can be built from various materials: boards, slate, brick, cinder block, etc., but do not forget about the external beauty of the bathroom.

We bring to your attention the option of building an outdoor bathroom from cinder block.

Necessary materials

1. Red brick (depending on the size of the cesspool).

2. Old boards.

3. Fittings.

4. Sand, crushed stone, cement.

5. Hatch for a cesspool.

6. concrete blocks(12 cm thick).

7. Frame for doorway.

8. Window frame.

9. Door.

10. Window.

11. Plastic (for interior decoration).

12. Tiles (for interior decoration).

13. Toilet bowl with a cistern.

14. Decorative mesh (for vent).

15. Decorative rock.

16. Slate or other roofing material.

17. Decorative stone for exterior wall decoration.

To begin with, it is worth deciding on the place of the future bathroom. It must be removed from the recreation area, but the path to it should not be difficult.

It is necessary to dig a hole 2x2.5 with a depth of 1.5 m.

The bottom is not concreted, and the walls are laid out of red brick. Why from red? Because it is more resistant to moisture. At the same time, do not forget about the gaps between the bricks, which should be quite a lot. They are needed so that moisture goes into the ground.

Along the upper perimeter of the walls of the pit, formwork should be laid and a hole of 150 mm should be left for mounting the drain. At the back of the pit, provide a hole with a diameter of 50 cm for the hatch.

Reinforcement, old boards should be laid on the formwork and poured with pre-prepared cement mortar(cement, sand, gravel and water). This is the future floor of the summer bathroom. For reliability, it should be 10 cm high.

The floor freezes for several days. If the weather is hot, then to prevent cracks, it should be watered periodically.

Then the walls of concrete blocks are laid out, but first you need to install and secure the frame for the doorway. If desired, you can also consider a window.

On top of the walls, it is necessary to install logs and formwork for the future ceiling with a slope to drain water.

Fill the ceiling with cement mortar and, after complete solidification, cover with any roofing material of your choice.

A door is hung and a window is installed.

Begins interior decoration. The walls and floor can be tiled, and the ceiling can be sewn up with plastic.

A toilet with a cistern is installed. An outlet should be made in the wall and covered with a decorative mesh.

Then water and light are supplied. Plastic or metal-plastic pipes for water must be laid through the air in order to winter period let down the water.

An exhaust pipe is installed from the cesspool so that unpleasant odors do not get into the bathroom.

It is necessary to install a sewer hatch.