Do-it-yourself logosol video drawings. Do-it-yourself sawmill: from diagrams and drawings to a finished structure. How to make a sawmill with your own hands at home Show homemade sawmills

If you calculate what components make up the final cost of lumber - the price of wood + processing + transportation to the destination - it becomes clear what you can save on. Wood blanks (board, timber, slats) are one of the most used samples in the field of construction and repair.

Given the simplicity of working with a tree, it makes sense to deal with its "dissolution" directly on the site. It is enough just to make a sawmill. This article will acquaint you with typical drawings, the procedure for making its tape modification with your own hands, and some design features.

The expediency of such a decision will become even more obvious if you look at the prices for factory sawmills on the websites. They are available for sale, but the cost of the installations is such that most of us are unlikely to want to purchase any model for household use. Depending on the series (in rubles): "Kedr" - from 138,000 to 194,000, "Taiga" - from 116,890 to 172,400. And these are still relatively inexpensive samples. Only mini-machines are cheaper (about 94,000), but they are unlikely to satisfy all the needs of the owner of a private house in woodworking.

There are several modifications of this type of equipment. But if we are talking about assembling a sawmill with our own hands, then the choice is small - an option with a fixed position of the saw and a movable frame (trolley) on which the workpiece is located. It is she who moves in the process of woodworking along special guides (rails). Everything else is improvements, "services" that facilitate the work of staff and ensure product quality. For example, a mobile saw.

Here are some easy-to-make models of homemade band sawmills.

Design features

The dimensions of the sawmill are determined depending on its location. Plots (adjoining, country or other) differ in layout, so the owner will have to choose the optimal size of the installation on his own. All drawings that are available (special literature, the Internet) can only serve as “guidelines” - in terms of the ratio of individual parts, their linear parameters, and so on. With your own hands, the sawmill is made in a way that is more convenient to work in a particular place and with a certain type of raw material. Basically, such equipment is used for dissolving logs and trimming boards.

What to consider when designing a sawmill

The design of this type of installation is good in that it can be constantly refined and improved, more precisely “customizing” its characteristics and capabilities to the growing needs of the owner. For example, if it was originally planned for the dissolution of logs into boards, then it is quite possible that after a while the question of organizing our own production of timber will arise.

It is assembled according to a block-modular scheme, and in the absence of practical experience in the manufacture of complex mechanisms, it is advisable to start with the simplest options. Subsequently, it will be easy to equip a manual band sawmill with automation elements (cutting thickness control, saw feed, programmer, etc.). That is why further - general instructions for drawing up drawings of a band sawmill and assembly. The author strongly recommends that you follow the sequence and install the first installation in your life according to a simplified scheme.

There are many modifications of band sawmills. The first question is in what plane is it supposed to cut? This determines the location of the working tool. Second - will the products of the same type be manufactured or will it be necessary to use the sawmill as a universal device? For example, not only for dissolving timber into boards, but also for cutting logs into separate segments. All this is taken into account in advance. It is desirable that the frame on which the working saw is attached can be reinstalled.

Logs that bloom on a band sawmill are characterized by significant weight. During operation, its frame is also subjected to dynamic loads. The main attention is the stability of the band saw equipment. This is both the quality of the cut and the safety of the attendants.

Craft band sawmill- that's half the battle. Its competent operation requires certain skills in setting up. The main "pitfall" is the wiring and sharpening of the saw. This issue should be studied in detail!

Preparatory activities

Location selection

If there is a suitable room, then it should be noted that its usable area should not be less than 18 "squares". This is enough to dissolve even large logs on a band sawmill.

In the private sector, rarely anyone can allocate an empty building or at least a compartment for installation. As a rule, woodworking has to be done on the street. It is unlikely that the neighbors in adjacent areas will applaud the sawdust and small chips flying in the wind. Yes, and your own territory will quickly become littered. Conclusion - after assembling the band sawmill, you will immediately have to deal with the construction of a solid type fence. For example, from polycarbonate sheets or plywood.

In addition, you will have to decide in advance where the storage of finished lumber will be organized. Therefore, next to the sawmill there should be at least a small, but free piece of land.

This is what should be taken into account when choosing a workplace for equipment.

Choice of materials and components

Engine. As a rule, one of two types is used - gasoline or electric. The main thing is to match the power. From a practical point of view (if anyone has any doubts) the asynchronous el/motor is much better. Firstly, the problem with connecting to the house electric / network from the category of solvable. Secondly, such a mechanism does not need maintenance or frequent repairs (unlike a benzo / unit). Thirdly, the constancy of turnover will ensure high quality cutting logs at the sawmill. Materials. Given the weight of the processed wood, only metal products are everywhere. Which? For the movable part (trolley) on which the workpiece is placed, a profiled (thick-walled) pipe of square or rectangular section is also suitable. And here is the base frame tape installation, taking into account the total loads, should be mounted from the channel. Accordingly, the rails for the movement of the trolley are from the clearance corner (at least 45). Although you can use the same channel, only with smaller linear parameters.

Tools and equipment

Here it is short - you can not do without a welding machine. With regard to the sawmill, bolted connections should not be practiced. Over time, one way or another, but they will loosen up, and doing daily monitoring of the condition and tightening is not the best prospect.

Sawmill drawings

Below are drawings of a simple band sawmill, which you can easily adapt to your conditions and needs, observing the proportions and principles of operation:

Features of the assembly of the band sawmill

The algorithm of actions is quite simple. Difficulty - in the manufacture (with adjustment in size) of the components.

support platform

A trolley with lumber will move along it. Plus, a frame is attached to the rails, on which the working tool is located. The main requirements are the reliability of such a support and alignment in a horizontal plane. On what to fix it - a specially equipped foundation (for example, columnar) or on racks dug into the ground - is decided on the spot.

Cart

Its purpose has already been mentioned. In order for the log to be in a fixed position during sawing, the mobile frame should be equipped with a “clamp”, which will firmly press the workpiece to the frame and prevent it from moving. Accordingly, the trolley must have wheels to ensure its mobility.

saw frame

The difficulty is in providing the possibility of changing the position of the cutting tool. If there is no regulation mechanism, then all products will turn out to be calibrated (of the same standard size, although the same). There are several engineering solutions, so this issue will have to be dealt with separately. It is pointless to give something specific, without knowing what modification of the sawmill is in question.

The general manufacturing procedure and features of work are noted in the article. The author recommends that you first decide for what purposes it is supposed to assemble a band sawmill. And only then look for the best option. You can simply copy the available drawings and assemble the installation of other sizes with your own hands, observing scaling. Or take a specific scheme as a basis, modifying (modifying) it for your own needs.

Good luck in designing a band sawmill!

When building any object, wood is needed: for rafters, stairs, floorboards, furniture. Purchasing finished products is very expensive. And why? You can do everything with your own hands. All you need is a desire and some materials.

The purpose of the tire sawmill

Wood is essential for human life. different breeds each for its own purpose. It was once processed exclusively with axes and hand saws. They were replaced by and.

The equipment is constantly being upgraded, more and more convenient modern machines appear. Tire sawmills are among them. They cannot replace other machines, such as rounding machine or rim cutter, but they perform their functions of woodworking successfully.

If construction is planned country house or cottages made of wood, then a lot of material will be required. And if there is a forest nearby and there is an opportunity to stock up on it, then it is best to make a tire sawmill with your own hands to process it and make building materials.

Making a sawmill with your own hands will help solve any problem associated with wooden products: make a barn or, a gazebo, a log house.

Tire sawmill of its own manufacture can produce:

- high-quality sawing of logs in the longitudinal direction;

- on it you can give logs the same shape and size;

- saw them into boards, beams, slats, and many other elements.

A home-made tire sawmill produces small batches of non-standard wooden blanks and processes wood of different species.

Location and design of tire sawmills

To mount a tire sawmill, you do not need a large area. It can be installed in a small area.

Created with your own hands, it can be stationary, in which an electric motor is installed, or mobile (using a gasoline engine). This will allow sawing equipment to be moved to any place, including the production of lumber in the forest.

The following designs of tire sawmills are made with their own hands:

Appearance of a tire sawmill with an electric motor

- With the movement of the working unit along the processed tree.

- With a longitudinal way of feeding the tree to the unit.

The advantage of the first type of tire sawmill is the control over the working unit throughout the entire section along the log. This ensures uniform cutting and high speed.

In the second case, the control over sawing is more complex. A strong push from the tree can cause the chain to seize or the engine to overheat. The advantage is the absence of a large number of electrical wires moving after the unit.

Components of a sawmill

The working unit consists of:

- Beds:

- tires;

- electric motor;

- clutch mechanism.

The chainsaw chain bar acts as a cutting tool here. When using a chain saw designed for longitudinal sawing for the sawing mechanism, the cutting surface is guaranteed to be even.

As a power unit, a three-phase electric motor with a power of 5.5 kW or a four-stroke gasoline engine with a power of 5.5 horsepower is installed.

The basis of the sawmill is a frame on which a mobile cart moves with a saw fixed in a horizontal position. The base must be of high quality to reduce vibration.

Machine frame design:

- two steel or rails 8 meters long and 14 cm high;

- screeds from segments are installed along the entire length of the channel metal pipe;

- holes are made in the channels and screeds are installed in them after 1–1.5 meters.

Main points of operation

The tire sawmill is installed in any room or in an open area.

Operating rules:

Tire sawmill can be installed in any place convenient for you

- The room must be well ventilated and lit, since the unit is classified as hazardous.

- On outdoors electrical equipment must be protected from precipitation.

- The platform for the equipment must be level. If the surface is uneven, the rail track is placed on anchors.

- The rail track and bus must be horizontal.

- The sawmill is mounted on four support rollers that roll it along the guide rails.

- The thickness of the sawn board is regulated by a vertical screw, which, when rotated, raises or lowers the trolley with the saw unit.

- During the operation of the sawmill, the log is fixed motionless along the frame.

- The clamping stops for supporting the log have a simple and convenient design: the screws press the log against the stop flags.

How a sawmill works

Sawing is carried out by a chain bar mounted on a carriage moving slowly along the log. Please note that the chain is designed for ripping and must be sharp to make sawing easier. If a chain is used for cross cutting, it must be sharpened at a different angle suitable for ripping.

The chain saw attached to the bar has a long service life and is quick and easy to install. If the drive sprocket is worn, it must be replaced before putting on a new chain.

The movement of the carriage with the tire is carried out manually. The height of the tire is also adjusted manually using a special handle on the screw. The bar can be raised or lowered a certain distance to achieve the desired cutting thickness.

The chain tension must be adjusted, this is constantly monitored during operation. In the nose sprocket tires organize a constant flow of oil from the oiler.

The quality of the cut on the tire sawmill does not suffer even with poor sharpening of the chain. The rigidity of the tire allows you to maintain it at an excellent level, without waviness and barrel shape.

Do-it-yourself tire sawmill assembly

Making your own tire sawmill is not difficult, although troublesome. It is necessary to prepare the appropriate materials and tools:

- device diagram;

- channel or rail;

- steel pipes for branch pipes and spacers;

- electric motor or gasoline engine;

- tire, drive sprocket (can be taken from a chainsaw);

- welding equipment with electrodes;

- drill and cutting tool for metal;

- auxiliary materials: chalk, hammer, tape measure.

First, a rectangular frame is constructed:

- a tire is attached in the center of the frame at its base;

- the fastening must withstand the increased load and be reliable.

Follow a certain sequence of manufacturing a tire machine:

- The cutting element is mounted on a high-strength steel axis. To do this, use the hole that is on the driven sprocket.

- Due to the axis, the saw cannot move in a horizontal direction.

- To prevent vertical displacement, bearings are mounted on the axle on both sides directly next to the tire.

- The bearings are clamped with a sleeve, the axle is welded to the frame.

- On the other hand, the engine and the chain tension control unit are placed. All spare parts can be taken ready-made, from a chainsaw.

- The driving drum is fixed on the motor shaft and fixed with a longitudinal key.

- They center the structure and securely fix it in the body.

The engine needs special attention. To eliminate strong vibration, the trolley under it must have sufficient rigidity. It is mounted from a steel sheet with a thickness of 4–6 mm. To eliminate the transverse play, a thrust corner is attached to the trolley.

Installation of the structure on the base

After the assembly of the working unit is completed, it is fixed on metal frame, which can also be made by hand.

Frame mounting sequence:

- Weld two workpieces with the letter P from durable steel pipes.

- Weld or bolt the tops of the blanks.

- Weld vertically 4 pipes in the center of the frame.

- On each branch pipe, on the outside, make recesses at a distance of 20 mm from each other.

- Weld four branch pipes to the working unit. They are put on the branch pipes of the frame.

The design provides the sawing unit with freedom of movement in the vertical direction. To fix the assembly in a certain vertical position, it is required to install bolts.

Stationary unit

For a stationary sawing unit, a concrete base is sometimes made.

You can install the clutch yourself. This is an intermediate transmission mechanism from the engine to the drive gear. The transmission is carried out by belts stretched over the engine pulleys and gears. Belts are pressed by special rollers. Such a device makes the work of the sawmill more efficient.

The assembly process is multi-stage, but it is quite possible to make such a unit with your own hands. Tire sawmill installation suburban area or in the country will bring a lot of benefits. After all, with its help you can make a wide range of necessary wooden products rather than running around in search of expensive material shopping. A handmade product does not require large expenditures.

Dear site visitors « from the presented material you will learn how you can independently make your own band sawmill. Every craftsman dreams of having his own sawmill on his farm, because its presence will reduce the cost of lumber tenfold. With the help of this machine, you can dissolve the logs into boards and bars yourself, it is also an excellent option and, that is, boards can be produced directly at the construction site of the future house. It is also possible to open your own private sawmill and dissolve the boards already for money and replenish the family treasury with additional income. In general, the machine is very good from all sides, and its self-assembly will again cost much cheaper than the factory counterpart, because many spare parts can be used used and available to the motorist, for example: wheels from passenger car, hubs, bearings, bolts and other things that you can get in the garage)

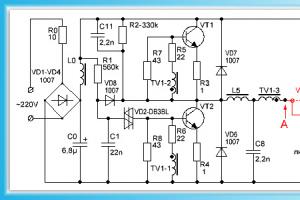

The design of the band sawmill consists of 1. rail track 2. frame with a power unit 3. blade 4 adjustment and tension mechanisms 5. carriage 6. flat surface (preferably a foundation plate)

And so, let's get acquainted with the list of necessary components for assembling the machine. We will also analyze the whole process step by step.

materials

- corner 100x100, channel, rails from a narrow-gauge railway (for the manufacture of rails)

- car wheels

- hubs

- bearings

- square pipe

- threaded stud

- jack

- dropper

- power unit (gasoline or electric motor)

- fittings

- bolts, nuts, washers, engravers

- sheet metal 1 mm

- belt

Tools

- welding machine

- drill

- emery

- Bulgarian

- hammer

- roulette

- set of wrenches

- Laser level)

- ruler

- corner

The process of assembling a band sawmill.

And so, the first thing to do is to get acquainted with the drawings, because any business begins with markup, as they say, “Measure seven times, cut once.

So we got acquainted with the drawings, and now I also want to note that there are several types of home-made sawmills

So we got acquainted with the drawings, and now I also want to note that there are several types of home-made sawmills

1 Band sawmill with electric motor.  2. Band sawmill with gasoline engine.

2. Band sawmill with gasoline engine.  3 Tire sawmill.

3 Tire sawmill.  Principle of operation tape machine for cutting wood. The blade is stretched on 2 horizontally located pulleys, in this case these are ordinary automobile wheels with a tire and a chamber, an indisputable plus of this design is that it is possible to tension the saw by inflating tires.

Principle of operation tape machine for cutting wood. The blade is stretched on 2 horizontally located pulleys, in this case these are ordinary automobile wheels with a tire and a chamber, an indisputable plus of this design is that it is possible to tension the saw by inflating tires.  The limiter and supporting rollers are located directly at the bottom.

The limiter and supporting rollers are located directly at the bottom.  Well, I hope the principle of operation is clear, then it’s worth taking care of placing the railroad along which the carriage with the saw blade will go and dissolve the logs on the boards. The site must be at least 3 x 6 m in size, and most importantly, flat! Therefore, it is necessary to pour a foundation slab under the sawmill and level it to a perfectly flat surface. A recess is dug, a sand cushion is laid and a reinforced concrete slab is poured.

Well, I hope the principle of operation is clear, then it’s worth taking care of placing the railroad along which the carriage with the saw blade will go and dissolve the logs on the boards. The site must be at least 3 x 6 m in size, and most importantly, flat! Therefore, it is necessary to pour a foundation slab under the sawmill and level it to a perfectly flat surface. A recess is dug, a sand cushion is laid and a reinforced concrete slab is poured.  Next comes the installation of the railroad itself, at best it can be made from rails from a narrow gauge railway, but it is difficult to get one, so you have to make it from a channel or a corner. Note!!! In the photo, the corner is located with an edge up.

Next comes the installation of the railroad itself, at best it can be made from rails from a narrow gauge railway, but it is difficult to get one, so you have to make it from a channel or a corner. Note!!! In the photo, the corner is located with an edge up.  You can connect the corner to each other by welding, but when the metal is heated, it can lead, and we need a perfectly flat road, you can also attach the rail directly to concrete base with anchor bolts.

You can connect the corner to each other by welding, but when the metal is heated, it can lead, and we need a perfectly flat road, you can also attach the rail directly to concrete base with anchor bolts.  Support rollers can be made from ordinary bearings, or ordered from a familiar turner.

Support rollers can be made from ordinary bearings, or ordered from a familiar turner.  After that, the saw frame itself is made directly, where pipes are used different diameter which can be inserted one into the other. whereby the slider can move up and down.

After that, the saw frame itself is made directly, where pipes are used different diameter which can be inserted one into the other. whereby the slider can move up and down.  The frame is welded from a square-section professional pipe.

The frame is welded from a square-section professional pipe.  Support rollers are installed at the bottom. they must match the width of the railroad.

Support rollers are installed at the bottom. they must match the width of the railroad.  Next, the lifting mechanism is made.

Next, the lifting mechanism is made.

After that, pulleys and hubs are installed.

After that, pulleys and hubs are installed.

Connection to the power unit.

Connection to the power unit.  Alignment and support of the saw blade is carried out by bearings.

Alignment and support of the saw blade is carried out by bearings.

From above it is mandatory to install a protective casing made of metal. Safety is paramount here, because the canvas can fly out.

From above it is mandatory to install a protective casing made of metal. Safety is paramount here, because the canvas can fly out.  The tension mechanism can be made from a small jack.

The tension mechanism can be made from a small jack.  After complete assembly the sawmill is a test run, if everything is in order, then the engine is turned off and the log is laid and fastened.

After complete assembly the sawmill is a test run, if everything is in order, then the engine is turned off and the log is laid and fastened.

The log is unraveled on the boards. You can also see the work of the sawmill clearly in the video.

The log is unraveled on the boards. You can also see the work of the sawmill clearly in the video.

Here is such a wonderful sawmill, in general, it turned out, now dissolve the boards and bars for construction and repair as much as you like, just have time to throw logs)

Thank you very much for your attention!

The mechanism is used for the primary processing of wooden building materials. It's no secret that the simplest models of a sawmill can be made by hand. To figure out how to do this, the instructions of specialists, the tricks of craftsmen, photos and examples of drawings will help.

This type of sawmill is most convenient for domestic use. It is easier to design it than mechanisms of a different principle of operation (tape or tire). On a circular sawmill, as a rule, large and medium-sized logs are cut into timber, boards, slats, veneer. The main functional elements of the tool:

- Power point. Most often - the electric motor. He must set the rotating mechanism to the required speed in order to process the tree.

- Cut node. Consists of one or two circular saws put on a shaft. On factory machines, they can be tilted towards each other to ensure a cut at a given angle.

- Sawmill control unit. Responsible for starting and stopping, changing the speed of rotation of the motor shaft.

- Feeder. Helps move the workpiece to the point of cut. In factory models, sawmills can be driving. In those designed with their own hands - static, needed for convenient fixing of the log on the surface.

To make a sawmill at home, you do not need to refer to complex drawings and diagrams. To ensure one-time construction and installation needs of your house and land, it is better to simplify the design as much as possible. The light version is safer. Experts advise to stay on the following scheme:

- a solid working plane (it is also a convenient fixed supply line);

- circular saw on a spindle or electric motor shaft;

- reliable fixation of both elements in the same plane.

Preparing to assemble the disk mechanism. Mounting the work surface

In the work on the manufacture of a sawmill, you will need to draw up a drawing. Since the device itself is not complicated, you can take one of the typical ones. Assembly begins with the installation of the desktop. It must be stable, durable, withstand the weight of the log, so the wooden parts should be reinforced with metal.

To work on the base of the sawmill, you will need:

- metal plates;

- wooden boards;

- nuts;

- screws;

- screws;

- tool for fixing fasteners;

- devices for processing metal and wood.

Pay special attention to the saw. It may have an electric or gasoline engine. The motor will perform the function of a rotating device with the help of a pulley that increases the speed of the shaft.

Attention! The diameter of the cutting disc of the sawmill must be at least 500 mm. The bigger, the better. Optimal Thickness- 3 mm. Material - steel or duralumin. The disc should have 2 or 3 teeth.

Having decided on the size of the table, proceed to assemble it:

- Weld the frame, placing the supports crosswise for greater stability and reliability of the sawmill.

- Firmly fix a metal plate on it (less often they take a wooden one). Often the supports are attached to wooden lid, and heavy metal is placed on top of it with a solid sheet or plates (fixed with bolts).

- Make a slot in the center, into which the circular saw will subsequently be deepened. The dimensions of the hole should provide a minimum gap between the plate itself and the cutting surface. The slot should be countersinked and then fastened with screws.

Advice. Calculate in advance and make holes in the plate to secure the engine.

Mounting the engine and the final stage of assembling the sawmill

Installing the engine is the most difficult part of making a home sawmill. It requires meticulous precision and reliability of connections. Loose elements will not be able to perform their tasks efficiently. In addition, they are quite dangerous to the health and life of the worker behind the machine.

The final stage of the design of the sawmill:

- Bearings and a pulley are attached to the underside of the plate, which is connected with a safety belt to the saw. This trick will protect the engine if the saw jams.

- The belts are well tensioned, not forgetting the mass and power of the engine itself.

- The saw is fixed strictly in the middle of the working surface.

- The main part of the work is completed by the installation of a thrust platform for a gasoline or electric motor. It must be movable relative to the shaft.

A good powered saw is a balanced mechanism with a correct blade angle that produces a clean cut and edges. The whole process of assembling even the elementary sawmill mechanism requires a serious approach. You can evaluate the subtleties and an example of installation in the video.

Before work stock up not only necessary materials but also patience. In this case, you will assemble an affordable analogue to expensive machines and make an alternative to low-quality factory lumber yourself.

Homemade sawmill: video

When it is necessary to process a large number of boards and wood, it is best to use a do-it-yourself sawmill. Many people think that it is best to purchase a ready-made unit, but it will not be difficult to make it yourself. The main thing is to decide on what the volume of the forthcoming work will be, as well as on the wood, after which it is necessary to choose the type of sawmill for the successful completion of the task.

Assembling the unit with your own hands, special attention should be paid to security issues, because such a device is considered an object of increased risk. Manufacturing various kinds sawmills are presented further in the video.

How the sawmill works

Explain, how does a sawmill work, you can use the example of spools of thread. Such a device resembles the rotation of two coils with a thread stretched between them. It is she who acts as a saw, and the distance between the coils will be the optimal size of the log.

Do-it-yourself sawmill allows you to:

- adjust logs to one shape and size;

- sawing logs according to a specific pattern after the equipment is set up;

- after sawing, small defects often form, which cannot be eliminated, so the tree has to be processed manually.

The work of the sawmill is carried out as follows: a log is fixed on the platform, which remains motionless, and at this time the mobile cart starts to move and cuts the tree. The saw must be in a horizontal position.

To get boards as a result required size, initially the operator sets the desired parameters. The saw blade acts as a saw blade and must be well taut.

How to make sawmills with your own hands

by the most common types of sawmills are angle, band and chain, as well as devices assembled using a chainsaw.

band sawmill

Collect band sawmill do-it-yourself at home is quite difficult. This is explained by the fact that it is difficult to achieve the maximum coherence of all its constituent elements in the process of work. In addition, the necessary components and special tools will be required, but, most importantly, the necessary drawings should be at hand. The finished structure should work with a material whose weight is about three hundred kilograms. In addition, it is necessary to debug the adjustment of the threaded thickness and observe safety precautions.

Do-it-yourself sawmill assembly carried out on a site of the required size which should be prepared in advance. The device will need special wheels and band saws. Then, in accordance with the drawings, the frame of the future unit is assembled. Work on the frame begins with the manufacture of special rails. To do this, you can pick up a corner and set up one of the sides. Then install the wheels, observing the ultimate strength.

Between two corners set in parallel, sleepers are made from a profile pipe, which are designed to ensure their reliable fastening to each other. To this profile pipe weld fasteners for logs, freely moving in all directions. Then, according to the drawing, the trolley is assembled and the wheels are attached to it.

Finally, the installation of an electric motor connected through a special pulley to the working mechanism of the device is carried out.

chain sawmill

The principle of operation of such homemade looks like a band sawmill, with the only difference being that it uses a chain saw. The design of such a device is much simpler and smaller, which means that it is much easier to make it yourself. The chain sawmill is installed on a flat area in such a way that it is convenient to approach it from any side.

The principle of operation of such homemade looks like a band sawmill, with the only difference being that it uses a chain saw. The design of such a device is much simpler and smaller, which means that it is much easier to make it yourself. The chain sawmill is installed on a flat area in such a way that it is convenient to approach it from any side.

Chain assembly begins with the fact that the frame is made of a metal profile. Having assembled the main part, several technological holes are made, while maintaining the utmost accuracy. The number of holes depends on the stride length. Then they begin to assemble the racks and install a frame on them, after which additional stiffeners are made. Thus, the basis of the chain structure is obtained.

In addition, it is necessary for the sawmill to assemble a movable cart with your own hands. To do this, prepare the base and attach the stop, gaskets, clamping plates and mounts for the electric motor to it.

Then the trolley is mounted to the frame, fix the engine with a saw, pull the chain and that's it, the do-it-yourself chain sawmill is ready.

Angle or circular sawmill

If there is a need for a radical sawing of boards, then it is best to use an angular or disk design for this.

If there is a need for a radical sawing of boards, then it is best to use an angular or disk design for this.

corner sawmill has a lot of functions and is used for large volumes of work. It is best to make such a design with your own hands, because the finished equipment is very expensive. To assemble it, you should use the appropriate drawings, and before starting work, you need to purchase all the necessary components and components.

First, a frame is assembled from metal pipes and high-strength guides. All joints are fastened by welding. It is best to use rails as guides. Then the carriage is assembled. During assembly, special attention should be paid to the accuracy of all dimensions indicated in the drawing.

in a corner or circular sawmill install high power gasoline engine, which effectively affects the process of sawing wood. The engine is mounted on the frame of the structure and connected to the working elements through special holes. Most often, such sawmills are installed chain drive, but in some cases this leads to overheating of the drive itself. When assembling the drive, it is necessary to pay due attention to safety precautions and to eliminate possible risks during its operation.

Chainsaw sawmill

IN living conditions most often such a large sawmill is not required, That's why optimal solution in this case, it will be considered a mini-machine, which can also be made by hand. There are several types of mini-sawmills, they have small size and, if necessary, they can be easily moved to another place. Such a device is made using a chainsaw, which acts as the main element.

IN living conditions most often such a large sawmill is not required, That's why optimal solution in this case, it will be considered a mini-machine, which can also be made by hand. There are several types of mini-sawmills, they have small size and, if necessary, they can be easily moved to another place. Such a device is made using a chainsaw, which acts as the main element.

To make a mini sawmill from a chainsaw with your own hands, you will need:

- two channels;

- corners;

- rails.

Work begins with the assembly of the frame, on which it is necessary to drill several technological holes. Then install screeds from a metal pipe. Their fastening is carried out by fixing bolts in advance drilled holes. During installation, be sure to control the angles between the elements: they must be straight.

Work begins with the assembly of the frame, on which it is necessary to drill several technological holes. Then install screeds from a metal pipe. Their fastening is carried out by fixing bolts in advance drilled holes. During installation, be sure to control the angles between the elements: they must be straight.

To strengthen the frame, several stiffeners are mounted. Then, the movable trolley is assembled from a steel plate. At the bottom of this plate, two corners are welded, after which it is placed on bearings or rollers. Two corners are welded to the upper part of the movable cart, designed for fastening the chainsaw.

In the end, a special design is installed for fastening the processed logs.

Do-it-yourself sawmill video.

Because sawmill is considered a rather dangerous unit of impressive size, then before assembling it with your own hands, you need to carefully consider where it will be used. Good for this:

Because sawmill is considered a rather dangerous unit of impressive size, then before assembling it with your own hands, you need to carefully consider where it will be used. Good for this:

- barn;

- garage;

- an ordinary utility room with a concrete base.

Such a place should be well ventilated, be spacious and have sufficient lighting. A place for this device can also be found on the street, but a canopy must be equipped for it.

If the sawmill has an electric motor, then you need to carefully consider the installation of wiring and installation of the necessary switches and circuit breakers. If there is a warehouse for finished boards near the place of work, then this greatly facilitates the whole process.

When assembling the unit with your own hands, special attention must be paid to its cutting and moving parts, which are considered the most dangerous elements. In general, safety precautions should be observed when operating the device.

After assembling the sawmill and before starting work, it is imperative to check all fasteners and components, as well as the stability of the structure. The first start-up of the device is performed after following all the necessary recommendations.

Thus, making a sawmill with your own hands is a simple matter. These devices are different types and the process of their assembly is presented in the video. Also, be sure to use the drawings so as not to be mistaken in anything. When operating a sawmill, it is necessary to observe safety precautions, because this is a rather dangerous device.