How to choose and install different types of roof tiles. Arrangement and installation of a tiled roof Assembly of rafter legs

The manufacturing technology of ceramic clay tiles has been known for hundreds of years. Of course, it has changed and improved, but the principle itself has remained the same: shards molded from clay are fired in a kiln to give greater strength.

Today, clay tiles are available not only in their natural color - red-brown. There are two technologies for its coloring, which give it a different look and properties:

- Glazed ceramic tiles. A tinted vitreous coating is applied to the annealed plate, which is also fired in a furnace. As a result, the surface becomes shiny and very smooth. The shades of this type of tile are very bright and saturated. With every rain, the roof is literally cleaned to a mirror shine: all the dust is washed off the slippery surface.

- Engobing. Tiles painted according to this method have more muted matte shades. After all, engobe is powdered clay mixed with mineral pigment, diluted with a little water. After annealing in an oven, the applied colored layer has a slightly porous structure, the shades are obtained in a muted, restrained tone.

For the conditions of central Russia and the North, engobed tiles are more suitable. After all, its color is the same ceramics. Therefore, its thermal expansions are the same and appearance remains stable for many decades. The vitreous glaze on the tile has a different thermal expansion, which leads to the fact that it cracks, and its appearance becomes far from ideal.

Except different colors clay tiles have different forms and profiles. In form they are:

For flat and wavy ones, grooves are often made, with the help of which they are joined to each other, and also fastened. They are easier and faster to mount, and quick laying does not make the coating less reliable.

By appointment, there are several types of tiles:

- Private. It covers the entire roof.

- Konkovaya. Fits on a skate pitched roof after the installation is completed.

- Wind or edge (right and left). Fits on the edge. It differs from the ordinary one by the presence of a wind bar, which protects the edge of the rafters from the effects of rain and wind.

The variety of ceramic tiles is great. No wonder it is the most favorite roofing material among designers.

Advantages and disadvantages

The first and undoubted advantage of this type of roofing material is its naturalness and environmental friendliness. After all, this is clay with some additives, fired in a kiln at a very high temperature. That's the whole technology and composition. But there are other advantages:

No wonder the ancestors laid tiles on the roof. She has a lot of great qualities. But there are also disadvantages, and you need to know them:

- Big weight. This leads to the fact that the rafter system must be made from a more powerful beam, more often it is necessary to install supports. In addition, a significant mass makes transportation more difficult. The mass of the tile must also be taken into account when designing the foundation.

- Laying is possible only by hand, without the possibility of using mechanisms. Although new models of shingles have made the installation itself much easier.

- The slope should be steeper so that the water flows quickly.

- In painted tiles (by any method), the natural color is visible in the places of chips.

There are not many disadvantages, but they are. How significant they are, everyone decides for himself. How to choose a quality tile, see the video.

Tiled roof device

Shingles work best on fairly steep slopes. Optimum slope from 22° to 50°. If the slope is less steep, additional waterproofing is required; for large slopes, additional fasteners are required. Then each tile is "planted" on a self-tapping screw, roofing nail or kleimer.

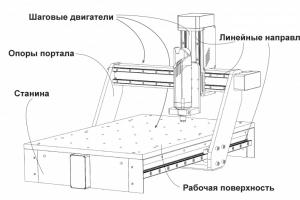

The choice of bars and installation step for the truss system

The basis of the design - rafter system. This roofing material is heavy - the average weight of one square meter of clay tiles is 40-60 kg. A big mass. It is necessary to add to it the thickness of the snow cover that falls in the region. So the truss system needs a powerful one.

But when installing a rafter system, it is unprofitable to use very thick bars. It will be much cheaper if you install medium-sized rafters more often. The bearing capacity will not suffer, and you will pay less for building materials. So in middle lane In Russia, a beam of 75 * 150 mm is considered an acceptable option (may be more or less depending on the amount of snow and slope). Installation step 60-90 cm.

After completing the installation of the rafters, they are treated with antiseptic and flame retardant impregnations. A film of wind insulation is fixed on the rafter system, and then proceed to the installation of the crate.

Lathing device

The distance between the horizontal strips is determined by the size of the selected tile and the angle of the roof. Most often, the installation step is specified by the manufacturer (available in the installation instructions). But you can decide on your own.

Rafter system and crate - two key moments when laying a ceramic roof with your own hands

Rafter system and crate - two key moments when laying a ceramic roof with your own hands The length of the tiles are different, but most often they are 40-42 cm. When calculating the step of the crate, you need to take into account the useful or effective length. After all, the rows overlap with each other. The more one tile overlaps the other, the shorter the useful length. And the amount of overlap depends on the angle of inclination of the roof: the smaller it is, the more the rows overlap (so that water does not flow):

- slope angle 11-25° - overlap 100 mm;

- slope 25-35 ° - entry 75 mm;

- steeper than 35° - lead-in 45 mm.

When calculating the step, take into account that it is possible to make more entry, but less - only to the detriment of the quality of the roof, as water may leak. Too much overlapping of one row with another is unprofitable for financial reasons (more tiles are required), so you should not get carried away with this either.

Under the crate, a beam of 50 * 50 mm or 60 * 40 mm is used. It must also be impregnated before installation. The number of crossbars is one less than the number of rows that will be laid on the roof (one is added along the overhang).

Heat and vapor barrier

The heat insulator is installed from the side of the under-roof space. Usually these are mats mineral wool, they are rigid enough that they can be set aside between the joists.

The heat insulator should fit very tightly and without gaps: the slightest gap is a bridge along which heat will escape. For baths, this is an unacceptable luxury. Therefore, we insulate especially carefully. Then, a crate is laid on top of the insulation, which will hold the insulation, and a vapor barrier membrane is fixed on top. It is fixed with a counter-lattice, to which it can be attached interior decoration if the space is habitable.

Calculation of the number of tiles

When determining the number of tiles, useful dimensions are used. How to determine the useful length is described above, and the useful width is indicated by the manufacturer. Multiplying them, determine the usable area of one element. The total area of the roof is divided by the found value. Get the number of pieces. But you need a margin for battle and pruning. Approximately 10-15%.

Calculation example. We break the tiles, the useful dimensions of which are 345 * 300 mm. The area of the gable roof of the bath is 24m 2.

- We determine the useful area of the tile: 0.345 x 0.3 \u003d 0.1035 m 2.

- We count the number of pieces for the entire roof. 24 / 0.1035 = 232 pcs.

- With a margin there will be 255 pcs.

Now a little about the cost. The amount required is considerable: the price of one tile is from 1.6 € per piece (beaver tail) to 4.2 € / piece. It turns out that this roof will require only ordinary tiles from 408 € to 1071 €.

The cost of side and ridge elements will also be added to the costs. Fasteners will also be needed. All this will require another 150-250 €. Cheap pleasure. But given that the service life is calculated in decades, it is not so expensive.

Installation of ceramic tiles

Begin installation from the bottom row. First, nail the eaves. It can be metal (purchased with tiles) or wood. In the first row and the last, we fasten each element to self-tapping screws. All side elements are also fixed.

All the rest are fixed with a special form of wire, which is supplied with the tiles. It is passed under the lath of the crate and hooked on both sides for special grooves. Since there are protrusions on the back side, with which the tile rests against the plank, the fastening is flexible and at the same time reliable. Such a roof during shrinkage will easily adapt to all movements, while maintaining tightness. It is only necessary to correctly make the truss system: it must also be movable (floating).

For more information about the installation of clay tiles, see the video. The first half discusses the advantages and disadvantages of natural shingles, while the second shows the installation of elements in the bottom row, as well as elements of subsequent rows.

Cement-sand tiles

Cement-sand tiles - also a natural roofing material

Cement-sand tiles - also a natural roofing material Natural tile is another type of roofing material: cement-sand. It is also called concrete, cement or CPU tiles. As the name implies, it consists of cement and quartz sand to which a coloring pigment is added. That is, these are products made of lightweight concrete. The peculiarity of the technology makes it possible to achieve high density and strength: the service life of a roof with cement-sand tiles is 100 years.

Its technical characteristics and consumer properties are very close to the characteristics of ceramic. Even the mass is almost the same: square meter cement-sand tiles weigh 42-45 kg.

But there are also differences. Since the pigment is added immediately to the solution, there is no difference in the formation of chips: all of it is both outside and in the depth of the same color.

There is one not very good moment: the edges of the concrete tiles are, as it were, chopped off. This slightly worsens the appearance of the roof from above, but when viewed from the side you will not see much difference.

The attraction of this material is its lower price. For example, the products of the German-Russian enterprise Braas from 36 rubles per tile. Compared to ceramic prices, the difference is noticeable.

Roofing with concrete tiles is no different from ceramic. Everything converges to the smallest detail. So there is no news here.

Polymer sand tiles

This roofing material can be attributed to natural with a very big stretch. However, it is on the market. The material has both pluses and minuses. The advantages include:

Disadvantages require attention - you need to make a decision taking them into account:

- Frost resistance of material 200 cycles of defrosting-freezing. This is five times less than that of ceramics and cement-sand tiles.

- Under the influence of ultraviolet radiation, a sluggish process of erosion occurs - the tile gradually becomes thinner. She will serve her term, but one should not hope for a significant excess.

- With temperature changes, the tile is deformed - it changes shape. This can cause the roof to leak.

As you can see, polymer-sand tiles have serious drawbacks. But the price is attractive: a square meter of coverage costs from 340 rubles. When choosing, it is worth remembering that if the production technology is violated, problems begin: after a few years, it begins to crumble, literally with your hands. Therefore, the choice of the manufacturer is very important.

If you decide to cover your bath with polymer tiles, you need to know that there are some installation features: each tile is fixed with two nails or self-tapping screws. At the same time, it is necessary to leave some play: it must be able to move. It is desirable to use stainless fasteners: galvanized nails.

plastic tile

This kind of material is definitely not natural, but it is just as sure that it is much cheaper. The advantages of this type of roofing material are the same as those of polymer-sand material. The appearance is somewhat different from the usual, but not drastically.

It is produced in two formats: in the form of single tiles or sheets of two or three elements. Working with plastic tiles is much easier: it is twice as light and absolutely not brittle. Each has locks, with the help of which a single roofing sheet is assembled. Fastened with nails to the crate.

The installation order is different: they start laying from the ridge, placing the bottom row under the one on top. The material is new, so there is little operating experience. But the price is low and the installation is simple, which makes you think and hesitate when choosing.

conclusions

Tiled roofing can be made from four outwardly very similar materials: ceramic, cement-sand and polymer-sand, as well as plastic tiles. Despite the external similarity, they have differences in price, and some in characteristics.

High-quality roofing must meet the conditions of reliability, hydro-, sound insulation and at the same time look beautiful. A tiled roof meets all conditions, since manufacturers offer a sufficient number of types of tiles made from the most various materials. Consider what a roof tile is, what features this or that tiled roof will have, the advantages and disadvantages of each individual product.

One of the most popular types of roofing, supplied in the form of profiled sheets and tiles. The appearance is similar to the natural product, while the manufacture uses galvanized steel, treated and supplemented with protective films to extend the flawless life. It could be acrylic paint, primers, decorative protective additives and other materials. The shape of the metal tile is also diverse: scales, folds, waves - what kind of tile roof will be, the developer himself decides. Material advantages:

- Large assortment of shapes, colors;

- Ease of installation, enough crates of wooden elements;

- Convenience of laying out elements;

- Long service life, but only if the exact installation technology is observed.

Flaws:

- It is strictly forbidden to contact metal sheets with bitumen, this will reduce the quality of the material;

- Low sound insulation, an additional layer of materials will be required to reduce background noise from rain and other factors;

- Snow deposits do not always quickly and simply go off the roof.

The service life is 40-50 years, the cost of the material is quite affordable, so we can assume that metal tile on the roof - this is a spectacular and functional coating.

Ceramic tiles

Roofing classics, the service life of which is limited by centuries. In addition, the material has the following advantages:

- Lack of sensitivity to any temperature changes, climatic factors;

- Non-susceptibility to biological influences, environments;

- Confrontation sunshine, infrared rays;

- Reduced thermal conductivity, high sound insulation, no accumulation of static voltage.

Ceramic natural tiles slowly heat up and cool down just as slowly, so warm air is circulated in the under-roof space and condensation is not collected, which protects the rafter system and other wooden structures from moisture accumulation and damage.

Fact! When arranging residential attic rooms experts strongly recommend choosing ceramic tiles. The strong heating of the sun will be stopped by ceramics in summer, and in winter, on the contrary, ceramic tile roofs “collect” heat, giving it to the attic room.

The expensive price of the material and the need for professional installation are the only drawbacks of the product. The material will be of interest to owners who want to get a reliable and high-quality roof that does not require repairs for almost 80 years! Over the years, the elements do not fade, acquiring a noble shade, and the initial large costs pay off with the low cost of maintaining the roof.

Only low-melting grades of clay, passing through the stages of molding, drying, coating, and firing, enter the production process. The elements of ceramic tiles for the roof can then be glazed, which gives a gloss and strengthens the protection.

Advice! Sound will help to distinguish a natural product from a fake: if you knock on a die, it makes a ringing sound without rattling. The surface is smooth, without notches, the tone is uniform, without raggedness to the edges.

This type of product is suitable for roofs of any shape and complexity with a slope of 12 °. Despite big weight, roofing is considered the best: the mass in this case is an advantage, the layout will withstand both heavy winds and hail, rain and other climatic aggressions without the slightest negative manifestations.

bituminous tiles

Affordable, practical and high-quality material, which has a number of undeniable advantages:

- A continuous layer of waterproofing formed under the influence of heat;

- The lowest noise threshold - bituminous elements ideally conceal noise;

- Ease of installation and minimum effort when applying tiles to the roof;

- Non-susceptibility to corrosion, rotting, cracks, leaks;

- Wide range of colors, resistance to fading;

- Long service life (at least 60 years).

Bituminous products are presented as a flexible tile photo of which you see and soft tiles.

A soft tiled roof is a type of roofing made of small-format flat elements with a figured cutout along one edge. As a rule, one sheet imitates a strip similar to 3-4 tiles. With a wide range of shapes and shades, the builder can choose any aesthetic reproduction of the roof, and the unique flexibility of the material helps to cover both simple and complex roof shapes.

A shingle roof is a kind of multi-layered “pie”. Most often, the application of a modified bituminous coating is carried out on reinforced fiberglass. At the same time, the front side is supplemented with a protective decorative layer that protects the bituminous binder from exposure to sunlight. Sometimes the elements are equipped with an adhesive strip, which facilitates installation.

According to roofers, the material is suitable for cladding roofs of any design with a slope of at least 10 °, the maximum slope is not limited, but with slopes of 10-18 ° it is necessary to equip the lining layer. The disadvantages of roofs with flexible tiles are factors:

- The need to create a continuous crate, which will increase the total weight load;

- The obligatory creation of a waterproofing layer, because the tiled elements do not allow moisture, steam to pass through;

- Some difficulty in mounting flexible elements.

Advice! The specifics of installation requires work to be performed in the warm season. If it is impossible to fulfill the condition, the material should be kept in a heated room for at least a day.

Cement-sand tiles

This type of roof tile is named after the manufacturing components: cement and sand, which go through the process of mixing, shaping and painting finished elements. different affordable price, the material is not inferior to analogues in its positive qualities:

- Environmental friendliness and natural purity;

- Breaking strength;

- Possibility to cover roofs of any shape;

- Non-susceptibility to atmospheric and climatic influences;

- High sound insulation;

- Resistance to biological influences.

The material also has enough minuses:

- Fragility, which requires careful handling during transportation, installation;

- Massiveness, which means that an accurate calculation of the load of all load-bearing elements is needed.

This type of material is best suited for climatic zones with a low level of precipitation. For improvement practical characteristics roofs, before installing the tiles, a layer of waterproofing is needed, and on top of the elements it requires protective coatings of paint, emulsion - the procedure will extend the life of the roofing carpet.

Advice! Cement-sand tile is a material that, at its inexpensive cost, serves for a long time and flawlessly. The main thing is to comply with all installation requirements and find a good protective coating for the surface of the tiles, while the service life of the roof without repair increases to 20-25 years.

Polymer sand tiles

Enough new type roofing has already managed to establish itself as a practical and durable material. Made from a mixture of sand, dyes and polymer fillers, the product has a lot of positive qualities:

- High mechanical strength;

- Resistance to aggressive, climatic environments;

- Tiles do not fade sunbeams on the contrary - under the rays, the elements are sintered into one stable mass, which, when cooled, is practically indestructible;

- High bio-, chemical, frost resistance (more than 500 cycles);

- Wide range of color shades.

Such a roof is not covered with plaque even after 5-7 years, and strength and practicality allow long time do without renovation and repair roofing work. Reducing the cost of the roof is a clear plus of the product, as is the ease of installation. Sufficiently light weight, small geometric dimensions and high impact resistance of the tiles facilitate installation and allow even a novice master to perform work on the roof.

There are practically no drawbacks to polymer-sand tiles for the house, except for some fragility (70% sand), the need to equip a waterproofing layer.

Types of flat strip tiles

When choosing a flat strip tile, you should be aware that there are several types of this material. The most common is the "beaver tail" - the layout is carried out in one row on the solution. Laying out in two rows significantly increases material consumption.

There are elements such as "baking" or Dutch, laid out with scales, fastening is carried out with nails or clamps to the bars of the crate.

Grooved types of tiles are distinguished by the presence of a longitudinal type of closure-groove, which facilitates the fastening of elements. Tiles are used for arranging a roofing carpet on simple roofs, one-, gable type. Fastening is carried out in a single layer, starting from the gable structures along the cornice to ridge element, the rows are parallel.

Stamped slotted tiles have two more cross-cuts, that is, the elements are fastened with closed folds along the entire perimeter, which prevents moisture from entering under the coating and ensures a long service life of the roof structure. The device of tiled roofs made of stamped material is single-layer, the direction from the cornice to the ridge with an overlap on the length or width of the fold.

The tiled roof is a classic that came from ancient times. It would seem that its century has already passed, because cheaper, but no less durable roofing materials have replaced it. But life has shown that, like bricks, tiles made of clay in the form of ceramic products are very popular. Especially recently, when the boom in private construction began. In the article we will talk about the types of tiles, about the technologies for their production, we will indicate the positive and negative qualities of the material, we will talk about the technology of its installation on the roof of houses.

Source memphite.comTypes of tiles

Today, this term covers several roofing materials. We will be interested in only three, one of which is a tile, the other two are its analogue, very similar in shape and size. So:

ancestor of tiled structures - tiles ceramic;

its counterparts are cement-sand And polymer-sand modification.

Ceramic tiles

From the name it becomes clear that this product is made of clay. It is molded and fired high temperatures. Final result - Brown tiles. It should be noted that there is no standard in terms of shape and size. Manufacturers today offer a rich assortment in this regard. I would like to note glazed tiles, the workpiece of which is smeared with glaze before firing. On the surface of the finished product, a shiny glossy surface is obtained.

As for the range, we can list the most popular models:

tape flat;

tape groove;

one- or two-wave;

grooved and others.

More recently, strip-type shingles were mainly used, which were laid in two layers to ensure that leaks were avoided. Today, this is not necessary, because a groove-type material has appeared.

In the design of this variety there is a groove on one side and a spike on the other. When connecting two adjacent roofing elements, the spike of one is inserted into the groove of the other, which ensures 100% tightness of the joint. At the same time, there is a so-called eyelet in the design of the tile. It is located in the lower plane. Its purpose is to fasten piece material to the crate with wire. Each element does not need to be fixed, the tiles are tied with wire through a row vertically.

It is believed that the main disadvantage of ceramic tiles is their large mass. That is, under this roofing, you will have to build a powerful truss system and crate. But on the other hand, a lot of weight is a good wind resistance. Even a heavy gust will not blow the roof off. Most likely, the main disadvantage is the high price.

Cement-sand tiles

An analogue of the classics was specially invented. The reason is to reduce the cost of roofing material and make it massively available. There was only one way out - to remove from technological process the firing stage, in which the main costs are reduced to the consumption of an expensive energy carrier. But clay does not become strong unless it is fired. Therefore, it was replaced by inexpensive but affordable ingredients: sand and cement, which together created a durable, long-lasting material.

It should be noted that there is no firing during the production process, but there is a drying stage at +600C. Even that was cheaper. In all respects, the cement-sand variety is not inferior to the ceramic one. Even there is superiority - a variety of colors, which is achieved by applying polymer-based paints. Paint and varnish products of this type provide both protective and decorative functions.

On our website you can find contacts construction companies who offer services roof design and repair. You can directly communicate with representatives by visiting the exhibition of houses "Low-Rise Country".

Polymer sand tiles

This product consists of three components:

sand (70%) giving strength to the product;

polymer, usually polyethylene waste, acting as a binder (25%) ;

rest dye, which gives the material the necessary decorative effect.

The production process of polymer-sand tiles is based on pressing a heated mixture under high pressure. It turns out a very durable product, which in all respects will not yield to either the ceramic variety or the cement one. It even surpasses its competitors in color design, where all colors and shades are present.

Tile installation technology

Note that a tile roof (any) is assembled using almost the same technology. There are, of course, certain differences that relate to the form and design features material. But the basic sequence of operations is the same.

Any installation process begins with design and calculations. Both stages are not easy, the quality of the final result depends on them, so professionals should deal with them. The only thing to note is that in the process of carrying out the calculations, the amount of the required roofing material is determined, as well as the number of additional elements: ridge, valley, cornice overhangs, ventilation grilles and other things.

Be sure to carry out the calculation of the truss system. The tile is a heavy material, which means that powerful rafters and batten elements will have to be installed under it. Therefore, at the design stage, the sections of the required lumber are calculated, the step of their installation.

Assembly of rafter legs

In principle, here is a standard construction operation. The main thing to consider:

the correct geometry of the truss structure on each roof slope;

the upper ends of the rafters should be located in the same plane;

the same applies to the crate, here the deviations should not exceed 5 mm per 2 m of the length of the element.

An important point is the ratio of the installation step rafter legs with a cross section of the lathing bars. The ratio is:

if the installation step of the rafters is up to 75 cm, then the crate can be assembled from bars with a section of 30x50 mm;

step - 90 cm, section - 40-50 mm;

step - 110 cm, section - 40x60 or 50x50 mm.

Now a dropper is mounted on the installed crate. This is a metal bar in the form of a corner. It covers part of the roof overhang, the purpose is to prevent condensate and precipitation from penetrating into the under-roof space.

Previously, roofing tiles were assembled quite simply. Basically, the craftsmen sought to correctly lay the roofing elements in order to create an airtight plane. Today, more and more often the attic space is made warm. That is, between the rafter legs are laid thermal insulation material, which is closed on the upper side with special films that withstand leaks.

Even if the project does not have a warm under-roofing space, these films are laid all the same, just in case the tiled roof suddenly leaks. How it is done:

the waterproofing film is laid along the rafters in strips, starting from the overhang, moving to the roof ridge;

waterproofing strips are overlapped with an offset of 10-20 cm, the upper strips are laid on top of the lower ones;

the joints of the films are closed with adhesive tape;

fasten the insulation to the rafters with small carnations with a wide head or metal staples using a stapler.

After that, a counter-lattice is laid on top of the laid film along the rafters. Its purpose is to create a ventilated gap. And already on top they mount the crate. And on this we can assume that the assembly of the truss system is completed.

Video description

In the video, the expert talks about the vapor barrier film that is used for laying under roofing material:

Installation of the drainage system and additional elements

The next step is the installation of a drain. It lies in the fact that you need to install brackets, on which the gutters of the horizontal part will subsequently be mounted. drainage system. The mounting technology of the brackets depends on the type chosen. More often these are elements with a long leg, which are attached to the side ends of the rafter legs.

Brackets are installed with a slope within 2-5 °. Fastening is carried out with wood screws.

As for the extensions, it is precisely before the tiles are assembled on the roof that they first form the valley, if there is one in the roof structure. The joint of two slopes is covered with polymer-bitumen roll material, and a metal element is laid on top, which is attached to the rafter system. The length of the corner elements is 1 m, so they are overlapped 10 cm along the length of the valley, starting from the bottom point to the ridge. Fastener - roofing nails.

An important point is that the visible gutter of the valley (between the tiles) should not be less than 15 cm wide. If this parameter is reduced, then it is likely that a large amount of water will collect on the valley. And this will surely lead to leaks.

And the last additional element at this stage is a ventilation grill that closes the space between the rafter system and the walls of the house. For this, various types of lattice materials made of plastic or metal are used. Each model has its own installation method. The main thing is to install them so as to tightly close the opening. That is, the air will pass through it unhindered, and for debris, birds and insects it is a formidable barrier.

Installation of tiles

So, let's move on to the main stage - the connection of the roof and tiles. Let's face it, this process is not easy. The master is required to have knowledge of technology and experience in carrying out this type of work. The only thing to note is that there are certain requirements for the installation process itself. Here are some of them:

laying starts from the overhang to the ridge, from any corner of the building;

if the roof tent or hip, then the installation starts from the middle of the slope;

one tile should lie on two elements of the crate;

fastening spend different ways, but more often self-tapping screws through mounting holes in the roofing material.

Please note that the holes are not through. That is, if there is a need, then they are drilled through. If the tile is not attached to the crate, then there is no need to make holes through. This ensures the tightness of the roofing.

In fact, it is quite difficult to convey the editing process in words, so we suggest watching the video.

Video description

The video shows the installation process of ceramic tiles:

Installation of tiles on the roof ridge

For this, an additional element is used, made using the same technology as the tile itself. It has a peculiar shape that helps close the ridge hermetically. But since the latter is used in the roof structure system and as an element of the ventilation system, first a bar is mounted on it on special brackets, and an aeration element in the form of a mesh element is installed on top. It closes the ridge of the roof, leaving holes for air to escape from under the roof space.

And after that, ridge additional elements are mounted. They are attached to the ridge beam with clamps, because this is what fastener can ensure the tightness of the ridge assembly. The extensions themselves are assembled according to the type of socket connection. That is, on the one hand they have a seat of a larger diameter, on the other, a smaller one.

Installation of back tiles

This stage is used if a hip or hip roof is being erected over the houses. Only in these structures there are ridges - the joints of two slopes that form an external ledge. It, like other protrusions or concavities, is a place of intense exposure to natural precipitation. Plus, a joint of two slopes is produced in this area. Therefore, it is very important to properly seal. We will not paint how to do it right. Just watch the video footage.

Video description

The video shows the technology of covering the roof ridge with ceramic tiles:

Conclusion on the topic

The roof, covered with tiles, looks presentable. It is impossible to argue with this. She emphasizes the status of the owner of the house. Because the roofing material itself is not a cheap pleasure. Plus, a powerful truss system will have to be laid under it. And this is also a lot of money. Yes, and the service of installing tiles on the roof will cost a lot.

tiled roof is intended not only to protect the roof from the effects of undesirable external factors, but is also used as decorative ornament, which sometimes changes beyond recognition nondescript country house or a gazebo. Among other things, it has advantages, the main of which is a long service life, ease of installation and fire safety.

Installation and device of a tiled roof.

Since the tile has an impressive weight, the design of the crate must have a large mass. The roof should be sloped at least 40-45 degrees.

Roofing lathing is made of wooden bars or wide boards having a cross section of 0.5 by 0.5 or 0.6 by 0.4 centimeters. Prepared boards or bars are laid out along the eaves, while taking into account that the tiles of the initial row attached after that should enter freely into the crown of the lower tiles.

The number of vertical and horizontal rows of tiled roofing must be an integer value.

Boards or bars need to be fixed, directing them from the roof ridge to the eaves. After installing the crate, boards should be laid along the edge of the eaves, the width of which is 15 centimeters.

To avoid difficulties when working with laying tiled roof, a leveling rail should be installed along the cornice edge.

Then the tiles are lifted onto the roof and laid on the navigation bridges in such a way that it is enough to make 2-3 rows. The roofer performs further work while sitting on a triangular bench, which is attached to the crate.

Tape tile.

Tape tile roofing can be laid in two ways: in two layers and scales. Regardless of the type of masonry, first of all, the tiles are laid from the main slopes of the roof, then on the hip ribs, and lastly on the ridge.

Flat strip tiles are laid in parallel rows on the main slopes, which in this way go from the eaves to the ridge, so that the lower row of tiles is completely covered by the upper one. In this case, the odd row ends with whole plates, and the even row with halves. As a result, the bricks should move slightly relative to each other.

Tiled roof of the first row it is fixed with spikes that are attached to the inner edge of the lower crate bars. The second row of tiles is attached to the top of the first row. The next rows are fastened in the same way as the first ones, and for the ridge, like the second row.

Tiles, located along the eaves and gable overhangs, are attached to the sheathing beams, regardless of the angle of the roof. In subsequent rows, only the second and third tile bricks should be attached.

Tape tiles are fastened to the sheathing beams by means of clamps and nails, which can be driven in in pairs. First, it is necessary to fasten the tile with spikes to the crate, then clamps are installed along the entire length of the row so that their horizontal lapel is on top of the tile, and under the left one it is possible to bring the next brick of the tile.

To date, there are several varieties of tape shingles.

The most common is the "beaver tail". It is laid on a specially prepared solution in one row. Material consumption is usually 32 pieces per square meter of roof. If the tiles are laid in two rows, then the consumption will be 45 pieces per square meter.

Preparation of a special solution for a tiled roof.

Sift cement, sand and lime in advance, observing the proportions 1:1:5. Pour all this with clean water. Mix the resulting mass thoroughly until a homogeneous mass is obtained. The resulting solution should not be too greasy, because when hardened, it may begin to crumble. In the manufacture of a bonding solution, all proportions should be carefully observed, otherwise it may turn out to be too thick, which will provoke significant loss of material.

Another common type of tile is the "pan" type. It is laid in scales and fastened with nails or clamps to the crate bars.

Grooved tiles.

Another type of tiled roof - grooved. It differs from the flat one by the presence of a longitudinal closure-groove, which is intended for better bonding of the material.

Slotted tiles are used to cover simple roofs with one or two slopes. It is laid in one layer and is directed at the same time from the pediment, along the eaves and to the ridge, where the rows run parallel to each other.

Grooved stamped tiles.

It differs from all previous ones by the presence of transverse cuts, in addition to longitudinal ones. In this case, the bricks are interconnected by folds that prevent water from entering under the roof.

Stamped tiles it is laid in one layer, while it is directed from the overhang of the cornice to the ridge, while an overlap is made along the entire length and width of the tile for the width and length of the fold.

This type of tiled roof is attached to the crate with a wire that is pulled through the eye of the brick. With this wire, the tiles are tied to the crate bar, which is driven in beforehand.

At the end of all work, all the resulting horizontal seams should be thoroughly lubricated with a special solution that will protect the roof from blowing.

The ribs and ridge of the roof must be trimmed with grooved tiles, which are made specifically for this purpose. In this case, it should be borne in mind that the ridge is lined from the bottom up, and the ribs are laid out in the direction from the bottom up.

So, roof tiles can even turn a nondescript cottage, country house or gazebo into a fabulous work, completely changing the appearance. In addition to its design advantages, this material is also very strong and durable. In order for the tile to please you for more than one year of operation, it should be laid, observing all the rules and regulations.

Thanks to a large assortment of tiles, everyone can turn their home into a real fairy-tale palace, which will not only please the eye, but also become reliable protection from external factors.

A reliable tiled roof can be the pride of any home owner. But years go by, and it periodically begins to leak. Perhaps there was a defect in the roofing, the thermal insulation layer got wet, or the drainage system failed. There are many reasons, but is it possible to return a tiled roof to its former reliability?

To determine the strategy by which it is supposed to repair a tiled roof, it is necessary to determine exactly what the leak is connected with, its type.

Classification "drops"

Repairing the roof should be started immediately after the first leaks, since prolonged leakage can cause rotting of the supporting structure, which means that the cost repair work will increase greatly.

Repair of a roof made of natural tiles

Leakage of roof tiles is most often caused by the following reasons.

- Cracks in tiles laid at junctions with chimneys, antennas or on roof overhangs. The reason for the formation of the cracks themselves is in the unequal linear deformation of various parts of the roof, in other words, in their uneven compression and expansion with changing climatic conditions - a typical phenomenon for a tiled roof.

- A leak may occur due to the appearance of cutting out (crumbling) over time cement mortar hardened in the joints of tiles of natural tiles. According to experts, this phenomenon is associated with deformation wooden frame roofs caused by wind and snow loads.

- Another reason for the leak is damage to the waterproofing layer under the roofing material between the rafters and the battens to which it is attached.

Natural tile roof repair technology

Replacing damaged roof tiles

Wedges of wood are hammered under the overlying tiles and, prying the damaged one, they try to remove it. If it is nailed to the rail, then by changing the position of the trowel - turning or lifting it, the mount can be loosened and the damaged plate removed. If, nevertheless, nothing works, you can use a special tool for removing nails.

If the tiles are damaged in different layers, then they are removed, moving from the bottom up.

Sealing of crumbled joints

To strengthen the roof structure, the rafters are lined with boards of the following sizes: thickness - 38 mm, width - 150-180 mm, which connect 3-4 rafter legs. The crumbled pieces of mortar from the joints of the tile plates are replaced with a new mortar, prepared in the ratio: one part of lime accounts for two fine-grained sand, to which flax fibers from tow are added. Between the tiles, the mortar is laid from the side of the attic. To cut tiles, if necessary, soak it in water for a day.

Replacement of damaged waterproofing

Having removed the nails with which the slats are fixed to the rafters, a piece of cardboard (hard) is inserted under the slats and placed on one side of the damaged area. It is needed in order to safely cut the slats. Sawing them with a saw on one side, the cardboard is moved to the other side and the slats are cut in the same way. Now access to the damaged area of waterproofing is free. It is cut out with a sharp knife and replaced with a patch, it should be slightly larger in size. Its edges are smeared with adhesive and the hole is closed. It remains to restore the missing pieces of rails and treat them with a layer of antiseptic.

Repair of metal tiles: dependence on damage

Repair of a metal tile roof is usually necessary if:

Fasteners, self-tapping screws, are either tightened or replaced with new, better ones.

Mechanical damage found

- Cracks and holes in roofing eliminated with special putty.

- Scratches are covered with a special anti-corrosion paint, leaks and gaps are sealed with a roofing silicone sealant, and through holes are patched with steel, which is welded with a soldering iron.

Roofing errors were made

The most common mistake is the use of cheap films with low water permeability to cover the insulation. It needs to be replaced with a superdiffusion membrane.

When Do Shingles Need Repair?

replacement soft tiles produced only in the presence of significant damage. As for small cracks or lagging areas, they can be easily restored. The tile is lifted and smeared with roofing adhesive with inside, then firmly pressed to the base.

To replace a shingle element

- using a small crowbar, lift the overlying tile and remove the damaged one from under it;

- the nails with which the damaged element was fixed are removed using a nail puller;

- glue is applied to the upper edge of the new tile from the inside;

- leading under the top, it is put into place, additionally fixing with nails (cap diameter - 1 mm);

- the edges of the lower and upper tiles, where necessary, are lubricated with roofing glue and pressed.

Repair of a roof from a natural tile

The most popular in Europe are cement-sand and ceramic tiles. There is a reasonable explanation for this: houses with such a roof look not only beautiful and attractive, but also very respectable.

The most popular in Europe are cement-sand and ceramic tiles. There is a reasonable explanation for this: houses with such a roof look not only beautiful and attractive, but also very respectable.

Natural tiles fit perfectly into any design and blend seamlessly with the natural environment. The following must be added to its advantages:

- durability;

- reliability;

- frost resistance;

- low thermal conductivity;

- aesthetics;

- fire safety;

- versatility.

Amazing variety colors of this roofing material: from the usual classic shades to unusually bright colors. Its surface can be not only matte, but also glazed, glossy.

Why does a tiled roof start to leak?

The most likely cause may be a rupture of the waterproofing membrane located between the counter-lattice and the rafters. In this case, repair and restoration work must be carried out according to the following plan:

For a more accurate determination of the causes of leakage, it is recommended to call a specialist. He will inspect the problem area of the roof and provide recommendations for repairs. At your request, the company's managers will make a preliminary calculation of the cost of repair work or installation of a new tiled roof.

Repair of a roof made of natural tiles from the company "RSK 24"

RSK 24 LLC provides services for the restoration and complete replacement of roofs made of natural tiles. Experts will quickly determine the cause of the damage and promptly carry out repairs.

Capital repairs of a tiled roof

Tiled roofing is one of the most common, not only because of the reasonable price, but also because good quality and variety of materials. Sand-cement tiles, flexible and ceramic - all these materials can serve for decades, and their price does not hit the pocket.

Overhaul of a roof made of different types of tiles is a long and rather complicated process, which must be approached with the utmost care. How exactly - we will talk about this below.

Overhaul of the roof of sand-cement tiles

Sand-cement tiles became widespread in the 19th century, but if then only wealthy people could afford it, now it is more than an affordable material. It is made from a cement-based solution with the addition of quartz sand. After casting into special molds, additional layers are applied to it, providing high strength. The main disadvantage is the complexity of installation due to the large weight of the products. , but after the completion of all the work, this disadvantage turns into a virtue.

Features of the overhaul of a sand-tiled roof

As mentioned above, this material is quite heavy - one square meter can weigh 40-50kg . Creating difficulties during the installation of the crate, a lot of weight after completion of the work becomes an advantage: it allows the tiles to withstand even very strong gusts of wind, and the sound of rain is simply muffled and not a sound is heard in the house.

After removing the old tiles, it is necessary to carefully examine the crate: in 99% of cases it will have to be replaced. The large weight of the tiles implies a strong and reliable construction of the crate, and if there is a need for major repairs, then the old crate has probably become unusable. If the angle of inclination of the roof is less than 22 degrees, then it is also necessary to carefully examine the rafters and, if possible, strengthen them or replace the weakest points.

Stages of installation of a new tile with overhaul:

- The first step is the laying of a waterproofing film, which is attached directly to the truss system using small nails or a construction stapler. The film is laid with an overlap of 15 cm and with a slight sag to ensure unimpeded drainage of condensate.

- Next, you can proceed to laying the thermal insulation, and the main thing here is to leave a gap between the waterproofing film and the insulation itself. The gap should be at least 5 cm, and it is needed to ensure air circulation.

- Installation of a new crate should be started only after a full calculation of the materials, since the step of the crate changes depending on the size of the blanks. On average, when using 50x50 mm bars, the pitch is 32-39 cm.

Laying a new sand-cement tile has its own characteristics:

- 1. Installation must begin from the lower right corner, gradually moving along the edge, that is, from right to left and from bottom to top;

- 2. To attach the tiles to the crate, it is necessary to pre-drill two holes for nails, since if you try to simply hammer in a nail, the product will break;

- 3. The bottom row is mounted with a descent over the edge of the crate.

The most important is the bottom row: the service life of the entire roof largely depends on how well and correctly it is fixed (especially in the case of a sloping roof with a large angle).

Capital repairs of a roof from a flexible tile

A soft tile is called a roofing material made on the basis of bitumen. It also includes fiberglass and granulate (stone dressing). This tile has one indisputable advantage: one is really soft and flexible, which allows it to be mounted on roofs of complex shapes.

Features of the overhaul of the roof of shingles

The entire installation process can be divided into stages:

- dismantling of the old bituminous tiles (the tiles are glued together and come off in large layers);

- dismantling or repair of the crate and truss system;

- laying of insulating layers;

- installation of new tiles.

As in the case of cement-sand tiles, the service life of the flexible one also depends on the quality of the crate. For flexible tiles, a continuous crate of OSB sheets. The surface of the crate must be smooth, clean and dry - this is important. It is also necessary to process wooden structure antiseptic agents.

The thermal insulation layer is laid between the rafters and the crate, and to ensure effective waterproofing, it is recommended to make a layer of glass isol or roofing material.

Laying of flexible tiles starts from the center of the eaves (from the bottom of the slope) towards the gables. To fasten the tiles to the crate, galvanized nails are used: 4-5 pieces are used per tile.

Nails are not the only thing that fastens the coating. If the shingles are overhauled in the summer, they will heat up from the sun and the tiles will stick together (and stick to the batten), providing additional strength. If the work is carried out at other times of the year, then the tiles must be heated with a building hair dryer.

Other nuances during the overhaul:

- 1. All outlets must be additionally sealed with a special apron for flexible tiles (meaning the outlets for pipes, antennas, vents).

- 2. If there is a brick pipe with a cross section of more than 50x50 cm on the roof, then in order to avoid accumulations of snow, it is necessary to arrange a groove.

- 3. The junction of shingles and vertical wall are mounted using a triangular rail nailed to the wall. A tile tile is already being installed on it, on top of which it is attached roll material. The final layer is bituminous mastic.

Overhaul of a roof from a ceramic tile

When overhauling a roof made of ceramic tiles, the most important thing is again the crate and the truss system. Ceramic tiles, like sand-cement tiles, have a lot of weight, so the load will be serious.

Features of the overhaul

If the roof has an angle of no more than 22 degrees, then waterproofing is a must. , for which rolled membrane material is best suited.

The waterproofing layer is laid as follows:

- overlap of cloths not less than 10 cm;

- along the lines of pitched and front overhangs there should be overlaps of 15 cm;

- an overlap of 15 cm is made through the protruding corners.

Although ceramic tiles are a durable roofing material, it is still dangerous to walk on it, so before laying it is necessary to calculate the required amount and raise it to the roof in advance. No need to stack all the tiles in one place: distribute them in even "stacks".

Stages of installation of a new ceramic tile during the overhaul of the roof:

- along the ridge and the eaves, one row is laid out without fixing;

- lines of future vertical laying are outlined (using dyeing laces);

- start fixing the tiles from the lower right corner, moving to the left and up.

If the tiles are mounted on top of layers of hydro- and thermal insulation, then there must be ventilation gaps to ensure air circulation. The first gap must be placed between the waterproofing membrane and the insulation layer, and the second between the waterproofing and the tile itself. If the diffusion film acts as a waterproofing, then the first ventilation gap is not needed.

Overhaul of a tiled roof is a complex process that is not much different from installation. Following the recommendations and using quality materials you can carry out repairs once and for many decades, enjoying a reliable and beautiful tile roof.