Floor parapet gas coppers double-circuit. Gas parapet boiler. Kerber gas boiler with a steel heat exchanger

The parapet boiler takes up very little space.

How to choose the right parapet boiler? Consumer reviews indicate the variety of models of this heating equipment. Today, the choice of device can be carried out according to the following parameters:

- according to the method of installation: wall and floor, left-hand and right-hand;

- by the number of circuits: single and double circuit;

- by the presence of automation: volatile and non-volatile.

In addition, the classification of equipment is carried out according to its performance. So, today you can buy a single-circuit gas parapet boiler with a capacity of 15 kW to 40 kW. When choosing a double-circuit parapet gas boiler and reading its instructions, you will notice that water performance is also added to the usual power. So, a device with a power of 12 kW-13 kW can heat up to 180 liters of water per hour, which is enough for 4 water intake points.

By the number of contours, one and double-circuit boilers. The first option is equipped with a conventional heat exchanger. It has a lamellar structure, which increases the rate of heat exchange between the flame of a gas burner and the heat carrier of the heating system. The heat exchanger is made of steel, 3 mm thick. It is this structural material that ensures the durability of the equipment and a sufficiently high rate of heat transfer. Increasing the thickness of the steel reduces the degree of exchange of thermal energy between the water in the heating circuit and the gas burner.

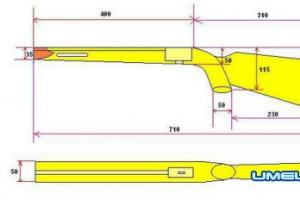

Construction of a parapet boiler.

The double-circuit parapet gas boiler is equipped with an additional copper coil. Due to his work, water is prepared for the DHW circuit of an apartment or house. Water heating is carried out only in a flowing way. The storage capacity inside the boiler will significantly increase the dimensions of the equipment. Thus, it will be impossible to use it for installation in an ordinary apartment.

Dimensions and dimensions directly depend on the performance of the boiler and the number of circuits. So, a single-circuit gas parapet boiler will be smaller and lighter compared to a similar device equipped with two circuits. If we compare two single-circuit boilers, then the one whose performance is higher will be larger. This is due to the size of the gas burner and heat exchanger.

How is a parapet boiler arranged?

There is a coil inside.

The body of the parapet boiler is made of steel with a minimum thickness of 3 mm. Powder coated with outer and inner sides housing makes it resistant to corrosion. Even in conditions of high humidity, which is often observed in the kitchen, the gas heating element will retain a decent appearance and integrity. Thick steel increases the resistance of the instrument case to direct mechanical impact. On its surface, dents and chipped paint are not formed.

Parapet device gas boiler characterized by simplicity and efficiency. The structure of the equipment is as follows:

- steel case;

- closed chamber combustion;

- igniter and gas burner;

- coaxial chimney;

- a steel heat exchanger, if it is a double-circuit equipment - a secondary copper coil.

The security system is presented:

- thermometer;

- thermocouple;

- traction sensor.

Gas boilers floor parapet structure do not differ from wall counterparts. The difference is only in the power of the equipment. With increasing power, the weight and dimensions of the device increase.

The video will help you to understand more about the device of the parapet boiler:

Installation of a parapet gas boiler can be carried out in any convenient location building. The main requirement is that the equipment must be located close to the wall in order to bring the coaxial chimney to the street. The main advantage of parapet heating elements is a closed combustion chamber and a coaxial chimney. These two structural elements allow you to mount the device in any convenient place without fear for human health. After all, a sealed combustion chamber does not allow toxic products of gas oxidation to penetrate into the living quarters.

The coaxial chimney is a steel structure consisting of two pipes. One of them with a smaller diameter is located inside a pipe with a larger diameter. Free space is formed between pipes of different diameters. Through this space, wall and floor parapet gas boilers produce air for combustion of gas. Oxidation products of the energy carrier go out through the inner pipe. As a result of the operation of the boiler, no air is taken from the room. That is why parapet heaters do not need a separate boiler room with good ventilation.

Do-it-yourself installation of a parapet gas boiler is strictly prohibited. Only licensed professionals should install the device. Only employees of the gas service should connect the device to the gas main.

Installation of a parapet boiler is carried out in the same way gas convector . The coaxial chimney is brought out through the wall. Wind protection is a must! Next, the installation of the gas duct pipes, the heating and water supply circuit is carried out.

How does a boiler work?

The movement of flows and the name of structural elements.

If non-volatile equipment was purchased, then its operation begins with the piezo ignition button. As a result, the igniter or the primary burner of the boiler starts to burn. If the equipment is volatile, that is, equipped with automation, it is put into operation using automation. However, non-volatile models are more common in the domestic market due to their versatility.

The principle of operation of a parapet gas boiler is very simple. The igniter ignites the main burner. Its flame is directed to the heat exchanger through which the heat carrier of the heating circuit circulates. The burner operates until the coolant temperature reaches the upper critical level. After that, the automatic heating element is activated. The gas valve is closed. As a result, the gas burner goes out, while the igniter continues to work. As soon as the temperature of the heat carrier in the heating circuit drops to the lower limit, the gas valve will resume the supply of energy to the burner. The latter will ignite from a working igniter. The water in the heat exchanger will start to heat up again.

Several structural elements are responsible for the safety of the boiler:

- firstly, it is a thermocouple, which is located in the flame of a gas burner;

- secondly, boilers are equipped with an element for controlling the presence of traction;

- thirdly, there is a thermostat with a thermometer.

Buying a parapet gas boiler? The instruction is the document on which the choice should be based. The instructions contain information regarding the power of the device, the rules for its installation and operation.

The thermocouple from the heat of the burner produces electricity little tension. It is supplied to the gas valve and keeps it in the open position. If the flame inside the boiler goes out for some reason, the thermocouple stops generating electricity. The valve closes automatically. The gas supply is stopped.

Sectional wall-mounted parapet gas boiler (rear view).

If there is no draft in the boiler, then the main structural element of the safety device (plate) increases its temperature to +65°C. The signal from it goes to the gas supply valve. The latter closes and the gas burner stops working. A similar mechanism is typical for a non-volatile boiler. If the equipment is connected to the mains, then the traction control is under the control of automation.

A thermostat with a thermometer protects the boiler from overheating. As soon as the thermometer fixes critically high temperature coolant in the heating circuit, it sends a signal to the thermostat. The latter also stops the gas supply to the gas burner.

The wall-mounted parapet gas boiler once competed with conventional wall-mounted heating elements despite their versatility. So, the latter were very demanding on the gas pressure in the gas pipeline, scale often formed on their heat exchanger, they needed uninterrupted power supply. Parapet devices are not so demanding on the pressure in the gas pipeline. Non-volatile models do not need power supply. Their coaxial chimney can be mounted both vertically and horizontally, which expands the possibilities of their installation.

Possible problems with this type of gas equipment

Formation of ice on the chimney.

Parapet gas boilers for heating can create several problems for their owners. First, their sealed chamber consists of two structural elements that are interconnected by a porous, thermally resistant polymer-based material. If Maintenance the boiler is carried out at the wrong time, you may not notice how the thermoplastic will lose its tightness. Carbon monoxide and other poisonous constituents of the exhaust gas can enter the living area and cause poisoning. That is why timely maintenance of parapet boilers is a must.

Secondly, the coaxial chimney in inexpensive models is made of steel of ordinary grades. At the same time, operating rules gas equipment require only stainless steel to be used when creating chimneys. Otherwise, soot and condensate accumulating on the walls of the chimney can form a chemically active environment.

It eats through steel walls. carbon monoxide from inner pipe enters the air flow to the gas burner. As a result, there is not enough oxygen in the gas chamber for the full combustion of the energy carrier. Equipment performance drops. Soot forms on the walls of the boiler, which accelerates the corrosion process.

Thirdly, with a coaxial chimney, there is always a danger of blowing out the burner flame with strong gusts of wind. That is why, when installing the device, it is mandatory to install protection against the wind.

How justified is the use of parapet boilers?

The parapet boiler can be placed on the floor, right in front of the battery.

Parapet boilers today can compete with similar full-fledged gas-fired heating devices. After all, parapet equipment is distinguished by its compact size and dimensions, it is not inferior to conventional boilers in terms of performance. The main advantage of parapet devices is the presence of a closed combustion chamber and a coaxial chimney. This allows you to place the device in living rooms. The chimney can be placed both vertically and horizontally, which gives even more freedom in terms of placement of heating equipment.

The equipment can work both as a heating boiler and in parallel as a conventional convector. In addition, the equipment is able to serve the DHW circuit. The advantages of the equipment include their durability, efficiency, long service life, safety in use. The thermocouple, draft control and coolant temperature are responsible for the quality of the last parameter. TO possible problems include the poor quality of the coaxial pipe, untimely service, blowing out the burner flame with strong gusts of wind.

Most citizens prefer to live not in apartments, but in separate private houses. But in order for the home to be comfortable and warm, an independent heating system is needed. Previously, coal was used as fuel, the reserves of which had to be constantly replenished. Natural gas has become an alternative to this type of fuel, and the heating system using a parapet gas boiler is successfully operated not only in cottages, but also in apartments.

This boiler uses natural gas

Parapet type boilers

This type of gas equipment was created as a replacement for wall-mounted columns, which, having many advantages, were still demanding on the conditions of use. . For trouble-free operation, they needed:

- good quality gas;

- soft water;

- sustained pressure;

- uninterrupted power supply.

In this video you will learn how a parapet boiler works:

Over time, they were successfully replaced by parapet gas boilers, which have less stringent requirements and ensure the most stable operation of the heating system. A parapet boiler is a unit designed for space heating(houses and apartments) and their supply hot water. Thanks to the combustion chamber closed type combustion products do not enter the room.

Design and principle of operation

In terms of design features and technical characteristics, parapet boilers are similar to mounted boilers. gas heaters. The boilers are equipped with:

- housing made of steel sheet with a minimum thickness of 3 mm;

- closed type combustion chamber;

- gas burner and igniter;

- a heat exchanger made of steel (if the device has two circuits, then the secondary coil is copper);

- coaxial chimney;

- safe use system (thermometer, thermocouple, draft sensor).

Similar boilers consist of 6 elements

Similar boilers consist of 6 elements Inside and outside the case is treated with a special powder coating that protects it from corrosion. Thick steel prevents mechanical damage. All this provides a decent appearance and reliability of the unit.

The principle of operation of a parapet boiler is simple: the burner ignites from the ignition device, the flame is directed to the heat exchange device, inside which the coolant circulates. As soon as its temperature reaches the required limit, the automatic heating element is activated. The gas valve closes automatically, the burner goes out, the igniter continues to operate. When the water cools to the lower critical level, the gas supply to the burner will resume, the latter will light up from the igniter, and the water will begin to heat up.

Devices with one and two circuits

Parapet boilers are produced in a standard rectangular shape, single- and double-circuit, left- and right-handed, which makes their installation easy and convenient.

Single-circuit are intended only for heating. They are equipped plate heat exchanger, which ensures the rate of heat exchange between the flame of the gas burner and the coolant.

An additional copper coil is provided in the double-circuit parapet boiler, which provides the house with hot water. Water heating occurs only in a flowing way. If you use a storage tank, the size of the equipment will increase significantly, which will make it impossible to install it in an ordinary apartment.

Rules and installation locations

Equipment of this type is used in rooms where a traditional chimney is not provided. A parapet gas boiler can be installed anywhere in the house thanks to a closed combustion chamber and a coaxial chimney, but the main condition is the location near the wall. This ensures the output of the coaxial pipe to the street.

The coaxial chimney is a stainless steel construction consisting of two pipes different diameter located one inside the other. Thanks to this design, a space is provided through which the flow occurs air mass to ensure gas combustion. Combustion products are discharged through a pipe of smaller diameter. The coaxial chimney is directed through the wall to the street, and wind protection is required. After that, the installation of flue pipes, heating circuits and hot water is carried out.

Installing the equipment is quite simple, but it is strictly forbidden to do it yourself. You should contact licensed professionals. Connection to the gas pipeline is carried out exclusively by employees of the gas service.

Advantages and disadvantages

Despite the widespread use, this type of heating equipment has its pros and cons. Compared to similar functional models, The main advantages of using parapet boilers include:

- Efficient space heating.

- No need to stock up on fuel.

- Ability to adjust the amount of fuel consumed.

- Ease of installation and maintenance.

- No dirt and litter.

- Temperature control.

Along with the advantages, there is also a significant drawback: the installation of equipment requires obtaining permission from the cadastral organizations. This is not an easy procedure. In total, it will take approximately 12 months to coordinate the documentation, issue a permit, install equipment, check and seal the meter.

There are currently a wide range of the lineup parapet gas boilers, so you should choose carefully. Which parapet gas boiler is better - single-circuit or double-circuit - depends on the operating methods and equipment parameters.

For many owners of private houses, choosing a heating boiler is not an easy task.

Need to pick up best option, which has the most successful set of functions and characteristics.

This is possible only if there is sufficient knowledge about the design and principle of operation of gas boilers, an understanding of their features and advantages.

Exist different types gas units with their own features and capabilities.

Consider one of the groups of such equipment - parapet boilers.

Parapet gas boilers are heating units that combine the features of atmospheric and turbocharged models. They are completely non-volatile, but equipped with a closed-type combustion chamber.

A feature of this design is the use of a coaxial chimney, which is attached to the rear of the unit and brought out into the street. Smoke extraction and fence fresh air occurs as a result of convection processes.

When the boiler is put into operation, no odors are felt in the room, there are not even traces of soot and other combustion products.

In addition, oxygen does not burn out in the room, which allows you to maintain the microclimate in a normal state.

Another feature of parapet boilers is the possibility of using them as independent heating elements. At the bottom of the case there are special holes through which hot air escapes.

It circulates in the room and provides the desired temperature in it.

What is the difference from the usual?

The main difference between parapet models and conventional boilers is the ability to obtain increased safety from a non-volatile design and the absence of impacts on the internal atmosphere of residential premises.

If a conventional atmospheric boiler consumes ambient air, actively burning oxygen and requiring constant ventilation, then parapet models are completely isolated and do not violate the air exchange regime.

Another difference is the ability self heating air, making the parapet boiler look like a stove.

Advantages and disadvantages

The advantages of parapet boilers include:

- lack of electricity consumption;

- internal air is not used, there is no additional load on the ventilation system;

- no need to connect to a common chimney;

- low fuel consumption;

- efficiency, practicality, resistance to external loads.

- installation requires making a hole in the wall from 25 to 31 cm in diameter;

- installation is possible only near the outer wall;

- it is not possible to provide full-functional control and protection of units and parts of the unit (for non-volatile models).

Despite the shortcomings, parapet boilers are highly rated by users. The demand for them is constantly growing.

Device

The design of the parapet unit almost completely repeats the design of any non-volatile boiler.

The heat carrier enters the primary (main) heat exchanger, where it receives a high temperature and enters the three-way valve (mixing unit). In it, a colder “return” is mixed into the hot liquid, as a result of which the temperature of the OB takes on the parameters set by the mode.

In double-circuit models, before entering the three-way valve, the coolant passes through a secondary heat exchanger, where hot water is prepared.

The difference lies in the structure of the combustion chamber and chimney, which are not typical for such devices. To remove smoke, a coaxial double pipe is used, through the outer cavity of which fresh air enters, and the inner cavity is a chimney.

Air is sucked into the closed combustion chamber and ensures the combustion process. When heated, it expands and displaces smoke and other gases that occur when fuel is burned. Some models are equipped with two separate pipes, one of which supplies air and the other exhausts smoke.

This option allows you to enhance convection and stabilize the movement of gases.

Kinds

Exist different variants designs of parapet boilers, which can be conditionally divided according to specific features.

According to the installation method:

- wall. Installed in a hinged way on the outer (bearing) wall. According to the installation conditions, they are limited by weight and power;

- floor. Installed on the floor. If it is wooden, a non-combustible stand is required. There are no restrictions on weight, dimensions and power.

By way of power supply:

- volatile. The design contains components that require the use of electricity - circulation pump. electronic control board, etc.;

- non-volatile. Work only on mechanical control. A good choice for remote villages and areas with power outages.

By feature set:

- single-circuit. They are only able to provide heating of the coolant;

- double-circuit. In parallel with heating, the OV is able to cook hot water for household needs.

NOTE!

Most users prefer single-circuit floor models, which show the greatest efficiency.

Principle of operation

The operation of a parapet boiler differs little from the normal operation of gas convection units.

The burner heats the coolant, which gives off part of the energy for the preparation of domestic hot water or is discharged into the heating circuit after preparation in a three-way valve.

There are no changes in this. A specific feature is the ability of the boiler to perform the function of a convector, which makes it possible not to install radiators in the room where the unit is located.

In addition, a special method of air supply and smoke extraction was used. When the burner is ignited, excess air pressure is created in the upper part of the combustion chamber, forcing it to be discharged along with the smoke to the outside.

At the same time, a rarefaction is formed in the lower part, creating a suction of fresh flow through outer part coaxial pipe. There is a pressure difference similar to that used in conventional furnaces.

This allows the use of a closed combustion chamber without a turbo fan..

In some designs, the chimney and air intake pipe are made separately, but this does not change the principle of operation.

Rating TOP-5 parapet gas boilers

Parapet boilers are devoid of many of the shortcomings of wall models, so their range is constantly increasing.

Consider the most popular models:

Lemax Patriot-12.5

Floor non-volatile parapet boiler of domestic production. The power of the unit is 12.5 kW. It is suitable for rooms up to 125 sq. m.

The main characteristics of the unit:

- Efficiency - 87%;

- gas consumption - 0.75 m3/hour;

- dimensions - 595x740x360 mm;

- weight - 50 kg.

The boiler is single-circuit, but it is possible to connect an external boiler. This will allow you to get a full-fledged DHW line.

Lemax Patriot-20

Floor parapet boiler manufactured by the Taganrog plant. The power of the unit is 20 kW, so the size of the room should not exceed 200 square meters. m.

Only the basic task is performed - heating the coolant. If you need to expand the functionality, you should purchase and connect an external storage boiler.

Boiler parameters:

- Efficiency - 87%;

- coolant temperature - 80 °;

- pressure in the system - up to 2 bar;

- gas consumption - 1.2 m3/hour;

- dimensions - 670x790x400 mm;

- weight - 67 kg.

Users and experts note low fuel consumption, which increases the efficiency of the unit and allows you to get noticeable savings.

Lemax Patriot-16

Another sample of domestic heat engineering. Parapet floor boiler 16 kW designed for use in rooms up to 160 sq. m.

Like other models of the Patriot series, this is a single-circuit unit with a steel heat exchanger.

Its characteristics:

- Efficiency - 87%;

- coolant temperature - 80 °;

- pressure in the system - up to 2 bar;

- gas consumption - 0.95 m3/hour;

- dimensions - 670x790x400 mm;

- weight - 67 kg.

Units of the Patriot series with a capacity of 16 and 20 kW are the same design, only one of the models has an artificially reduced performance.

Lemax Patriot-10

Product of engineers from Taganrog. A 10 kW parapet boiler is suitable for a country or private house up to 100 sq. m.

- Efficiency - 87%;

- coolant temperature - 80 °;

- pressure in the system - up to Bar;

- gas consumption - 0.6 m3/hour;

- dimensions - 595x740x360 mm;

- weight - 50 kg.

NOTE!

Reliability and low fuel consumption make Lemax Patriot parapet boilers the most successful choice for all users.

ATON Compact 12.5E

Gas parapet boiler of Ukrainian production. The power of the model is 12.5 kW, and the service area is up to 160 square meters. m. Non-volatile unit designed for floor mounting.

The main parameters of the boiler:

- Efficiency - 90%;

- coolant temperature - 90 °;

- pressure in the system - up to 1.5 bar;

- gas consumption - 1.39 m3/hour;

- dimensions - 630x700x275 mm;

- weight - 50 kg.

The unit is equipped with a stainless steel heat exchanger and has a protective gas valve.

Reviews of parapet gas boilers

Consider user opinions about parapet gas boilers:

(( reviewsOverall )) / 5 Owner rating (3 votes)

Your opinion

0"> Sort by: Most Recent Highest Score Most Helpful Worst Rated

Be the first one to leave a review.

Parapet boilers are non-volatile non-volatile devices, the use of which is carried out mostly in private houses, as well as apartments, where the design does not provide for a traditional chimney. Basic distinctive feature The design of these parapet gas boilers is that they have a closed combustion chamber, which is isolated from the room where the gas boiler is located. In particular, the favorableness of this advantage can be manifested precisely in small rooms from which air will not be taken for better combustion.

The chimney consists of just a pair of pipes, they are placed one inside the other. With outer tube air goes into the chamber, and due to the internal one, the products of combustion are removed. As you can see, everything is quite easy and convenient.

Another advantage that parapet gas boilers have is that they have a convection hole lining. This addition helps to ensure the heating of the room in which the gas boiler is located, without installing a special heating radiator in it.

Important Features

Boilers are manufactured as standard in a rectangular shape. This makes it possible to make their installation easier and more convenient. Also, such boilers are left or right. Boilers that are made on the left have an automatic system located on the left side of the device, and the pipes that are required in order to connect to the heating system and the hot water supply system are located on the right. The Helios gas boiler in the right version has all the same nuances, but only on the other hand. (See also: )

Gas boilers for heating related to parapet view, are produced in single-function and dual-function types. Dual-function boilers have a tubular instantaneous water heater, which is mounted in the boiler body, and is required in order to heat water for a variety of household needs. The metal used for the production of such heaters is mainly copper, since it has a fairly high thermal conductivity.

The Italian parapet gas boiler has one significant plus: due to the fact that it does not need to be connected to a chimney, it can be installed anywhere. Parapet boilers do not depend on energy. In a residential building, parapet boilers are often installed in a window sill niche. They are also used for heating buildings that have a water heating system with a forced natural circulation system.

Kerber gas boiler with a steel heat exchanger

Such boilers, which have a steel heat exchanger, do not require chimneys and can be installed in a private house, as well as in an apartment. The dimensions of the parapet boiler allow it to be mounted where it is convenient, including under the windowsill. You can connect the heating system both on the left and on the right, or simultaneously on both sides. Also, this type of boilers can operate not only on natural, but also on liquefied gas. (See also: )

Let's define the technical design of the parapet boiler:

- Coaxial deflector with silicone seal, which ensures the tightness of the connection with the heat exchanger;

– Turbulators, which have a special design, increase the efficiency of heat transfer from combustion products to heat transfer fluids and help ensure high level efficiency, they are installed in pipes through which combustion products are discharged;

- A window with visual control over the combustion of the main and pilot burners;

Boilers Siberia and Renay

Some companies may offer a series of improved parapet boilers with hermetic combustion chambers and universal connection to the heating system. Gas heating boilers Siberia have heat exchangers rectangular shape, which is a one-piece welded body made of steel three millimeters thick. Welds are made on semi-automatic welding installations, which makes it possible to obtain high-quality uniform locks. Each seam is external and easily accessible if repairs are required. Inside the body, seamless pipes are welded through which the combustion products pass. The housing is designed to work in a heating system that operates under a pressure of 0.3 MPa.

The gas boiler Renay is characterized by the fact that it works safely and stably both with fluctuations in gas pressure in the pipeline and during low pressure. Cylindrical microflare gas burners provide a uniform distribution of the flame over the entire area of the combustion chamber, which helps to ensure rapid and uniform heating of water in the heat exchanger.

Suggested range

Parapet gas boilers are equipped with modern automatic gas systems with piezoelectric ignition and microtorch burners. Heat exchangers of parapet boilers are made of steel having a thickness of three millimeters.

A distinctive feature of parapet models of boilers is completely new design heat exchangers, which makes it possible to get rid of the left-hand and right-hand versions, which makes it possible to significantly facilitate their installation. The uniqueness of the connection lies in the fact that the branch pipes for connecting the boiler to the heating system and hot water supply are removed on both sides of the device, which makes it possible to refuse side doors, which helps to save working space in the room, and parapet boilers will ideally fit into the interior of any kitchen.

During the development of new models of parapet boilers, special attention is paid to the fact that the appearance of the device is being improved. The main requirements are aesthetic modern design and convenient use. Ultimately, the new parapet boilers will receive a working panel, which has devices for regulation and visual control, which is very convenient during use, as well as an original elegant appearance, which helps to distinguish this series of boilers from other Russian analogues.

A little about the design

Air is taken in by parapet gas boilers with the help of a special horizontal pipe - coaxial, which passes through the outer wall of the house. Combustion products are discharged through it. The coaxial chimney includes two pipes located in each other. The inner one is designed to remove gas, and the outer one is for air to enter.

By type, parapet gas boilers are divided into those that have two circuits and with one circuit. In double-circuit, the housing is included instantaneous water heater for hot water system. Copper is often used as a material for heat exchangers due to its high thermal conductivity. Efficiency fluctuates around 92 percent.

Domestic parapet boilers have few worse performance than the imported ones. But they may also have an electronic control system in order to automatically change the power and regulate the domestic hot water system. Also, electronic control boards can protect the boiler from overheating or freezing, pump jamming or pressure drop in the pipes.

What are the features?

A distinctive feature of these devices are closed and isolated from the premises of the combustion chamber. Due to this, the air in them, which is used for breathing, does not go into consumption for burning gas. This is especially true for small spaces. Another of the features that are suitable for the living room, kitchen and hallway is that the boilers operate almost silently.

Among the advantages of this type of equipment, one can also highlight the fact that there is a hole for convection, due to which the room is heated without heating radiators. Among the shortcomings, small capacities of such units can be distinguished, which can affect the maximum amount of space that is heated.

In conclusion, I would like to say that there are quite a few models of boilers and therefore it is worth choosing very carefully. Agree, the difference will be obvious among boilers of foreign and domestic production. It also depends on the number of contours and much more. We wish you good luck with your choice!

Parapet boilers are non-volatile non-volatile devices, the use of which is carried out mostly in private houses, as well as apartments, where the design does not provide for a traditional chimney. The main distinguishing feature of the design of these parapet gas boilers is that they have a closed combustion chamber, which is isolated from the room where the gas boiler is located. In particular, the favorableness of this advantage can be manifested precisely in small rooms from which air will not be taken for better combustion.

The need for air intake for combustion, as well as the removal of combustion products in a parapet gas boiler, cannot be bypassed, so everything is done using the outer wall of the house, this requires the installation of a special horizontal coaxial chimney. (See also: What is the most economical gas boiler?)

The chimney consists of just a pair of pipes, they are placed one inside the other. With the help of an external tube, air enters the chamber, and due to the internal one, the products of combustion are removed. As you can see, everything is quite easy and convenient.

Another advantage that parapet gas boilers have is that they have a convection hole lining. This addition helps to ensure the heating of the room in which the gas boiler is located, without installing a special heating radiator in it.

Important Features

Boilers are manufactured as standard in a rectangular shape. This makes it possible to make their installation easier and more convenient. Also, such boilers are left or right. Boilers that are made on the left have an automatic system located on the left side of the device, and the pipes that are required in order to connect to the heating system and the hot water supply system are located on the right. The Helios gas boiler in the right version has all the same nuances, but only on the other hand. (See also: Gas boilers)

Gas boilers for heating, related to the parapet type, are produced in single-function and dual-function types. Dual-function boilers have a tubular instantaneous water heater, which is mounted in the boiler body, and is required in order to heat water for a variety of household needs. The metal used for the production of such heaters is mainly copper, since it has a fairly high thermal conductivity.

The Italian parapet gas boiler has one significant plus: due to the fact that it does not need to be connected to a chimney, it can be installed anywhere. Parapet boilers do not depend on energy. In a residential building, parapet boilers are often installed in a window sill niche. They are also used for heating buildings that have a water heating system with a forced natural circulation system.

Kerber gas boiler with a steel heat exchanger

Such boilers, which have a steel heat exchanger, do not require chimneys and can be installed in a private house, as well as in an apartment. The dimensions of the parapet boiler allow it to be mounted where it is convenient, including under the windowsill. You can connect the heating system both on the left and on the right, or simultaneously on both sides. Also, this type of boilers can operate not only on natural, but also on liquefied gas. (See also: Sitemap)

Let's define the technical design of the parapet boiler:

– Coaxial deflector with silicone seal, which ensures the tightness of the connection with the heat exchanger;

– Turbulators, which have a special design, increase the efficiency of heat transfer from combustion products to heat carriers and help to ensure a high level of efficiency, they are installed in pipes through which combustion products are discharged;

- A window with visual control over the combustion of the main and pilot burners;

- The hot water circuit is made in the form of coil-water heaters made of copper tubes with a diameter of 12 millimeters. It is intended to heat industrial water. Copper is an excellent conductor of heat, so water heats up much faster, saving time and resources. (See also: Room thermostat for gas boiler)

Boilers Siberia and Renay

Some companies may offer a series of improved parapet boilers with hermetic combustion chambers and universal connection to the heating system. Siberian gas heating boilers have rectangular heat exchangers, which are a one-piece welded body made of steel three millimeters thick. Welds are made on semi-automatic welding installations, which makes it possible to obtain high-quality uniform locks. Each seam is external and easily accessible if repairs are required. Inside the body, seamless pipes are welded through which the combustion products pass. The housing is designed to work in a heating system that operates under a pressure of 0.3 MPa.

The Renay gas boiler is characterized by the fact that it works safely and stably both with fluctuations in gas pressure in the pipeline and during low pressure. Cylindrical microflare gas burners provide a uniform distribution of the flame over the entire area of the combustion chamber, which helps to ensure rapid and uniform heating of water in the heat exchanger.

Suggested range

As for the model range, it includes gas boilers with a capacity of 7, 10, 12.5 and 15.5 kilowatts with one circuit and with a water heating function. Parapet boilers can be used in houses and apartments in which the total heating area is up to 140 square kilometers, where there is no possibility of connecting to a chimney. (See also: Advantages and disadvantages of mounted gas boilers)

Parapet gas boilers are equipped with modern automatic gas systems with piezoelectric ignition and microtorch burners. Heat exchangers of parapet boilers are made of steel having a thickness of three millimeters.

A distinctive feature of parapet models of boilers is a completely new design of heat exchangers, which makes it possible to get rid of the left-hand and right-hand versions, which makes it possible to significantly facilitate their installation. The uniqueness of the connection lies in the fact that the branch pipes for connecting the boiler to the heating system and hot water supply are removed on both sides of the device, which makes it possible to refuse side doors, which helps to save working space in the room, and parapet boilers will ideally fit into the interior of any kitchen.

During the development of new models of parapet boilers, special attention is paid to the fact that the appearance of the device is being improved. The main requirements are aesthetic modern design and convenient use. Ultimately, the new parapet boilers will receive a working panel, which has devices for regulation and visual control, which is very convenient during use, as well as an original elegant appearance, which helps to distinguish this series of boilers from other Russian analogues.

A little about the design

Parapet gas boilers take in air with the help of a special horizontal pipe - coaxial, which passes through the outer wall of the house. Combustion products are discharged through it. The coaxial chimney includes two pipes located in each other. The inner one is designed to divert gas, and the outer one is for air to enter.

By type, parapet gas boilers are divided into those that have two circuits and with one circuit. In double-circuit, a flow-through water heater for a hot water supply system is included in the housing. Copper is often used as a material for heat exchangers due to its high thermal conductivity. Efficiency fluctuates around 92 percent.

Domestic parapet boilers have slightly worse characteristics than imported ones. But they may also have an electronic control system in order to automatically change the power and regulate the domestic hot water system. Also, electronic control boards can protect the boiler from overheating or freezing, pump jamming or pressure drop in the pipes.

What are the features?

A distinctive feature of these devices are closed and isolated from the premises of the combustion chamber. Due to this, the air in them, which is used for breathing, does not go into consumption for burning gas. This is especially true for small spaces. Another of the features that are suitable for the living room, kitchen and hallway is that the boilers operate almost silently.

Among the advantages of this type of equipment, one can also highlight the fact that there is a hole for convection, due to which the room is heated without heating radiators. Among the shortcomings, small capacities of such units can be distinguished, which can affect the maximum amount of space that is heated.

In conclusion, I would like to say that there are quite a few models of boilers and therefore it is worth choosing very carefully. Agree, the difference will be obvious among boilers of foreign and domestic production. It also depends on the number of contours and much more. We wish you good luck with your choice!

What is a parapet gas boiler?

Parapet gas boilers are becoming more and more popular. In this article, you will learn what a parapet gas boiler is.

Parapet gas boilers

The heating system with the participation of a gas boiler is one of the most affordable and profitable. But not everyone has the opportunity to refuse centralized heating, even if its quality is unsatisfactory. This is due to the fact that a conventional stationary gas boiler needs a flue.

Such a structure is not present in all buildings, especially multi-storey ones. Residents of private houses and cottages have long enjoyed all the advantages of heating gas boilers, now residents of apartments have such an opportunity. Which gas boiler is better to choose?

What is a parapet boiler?

Parapet gas boilers are units designed for space heating, as well as providing them with hot water. Design features such equipment is very well suited for safe operation at home. The power of parapet units varies from 15 to 45 kW, this is enough for heating and hot water supply of an apartment or house, but it all depends on the size of the heated area, heat loss and minimum temperature air outside the window. To choose the right gas heating unit, it is necessary to take into account all these factors.

Parapet boilers can be mounted independently, you just need to follow the installation instructions.

The main differences and characteristics of a gas parapet boiler

- Parapet boilers are non-volatile units.

- One of the differences between a parapet boiler and a stationary gas unit is the design of the fuel combustion chamber. The parapet gas boiler has a closed-type combustion chamber, which ensures the complete removal of combustion products outside the room in which it is installed.

It also excludes the combustion of oxygen in the room, which is an important factor for small areas with poor ventilation. This design of the combustion chamber provides better fuel combustion, which increases the efficiency of the entire heating system.

- In connection with the use of a closed type combustion chamber, there is no need to install bulky gas ducts. This is suitable for those who do not have the opportunity to build such structures.

- According to its characteristics and structural features parapet boilers are very similar to mounted gas boilers. But the latter are very "capricious" in their operation, despite their popularity. For stable and durable operation of the wall-mounted unit, constant pressure maintenance in the circulation system is required, high quality gas, soft water and other nuances.

To simplify the operational requirements, parapet boilers were developed, which, despite their versatility, are picky in operation, but some of the requirements specified in the unit's passport must still be met.

- There are special convection holes in the body of the parapet boiler, which provide heating of the room even without installing additional radiators. Thus, this multifunctional unit combines the functions of a "heater" and a "radiator" at the same time.

- Varieties of parapet boilers in terms of functionality can be: single-circuit - capable of providing only space heating, double-circuit - provide heating and hot water at the same time.

- The parapet gas boiler can be operated from a gas cylinder with a propane-butane mixture, as well as from a gas pipeline with natural gas.

The design of a gas parapet boiler

- The body of the parapet boiler can have different sizes, designs and shapes.

- Installation of this unit can be made in any convenient place. Can be hung on the wall or placed on the floor.

- Equipped with a closed type combustion chamber.

- can be installed Various types burners, which are mainly divided into single-level, two-level and modulating.

- The heat exchanger of a parapet gas boiler can also be various kinds: cast iron, steel or copper. Each of the heat exchangers has a number of advantages and disadvantages.

- The flue gas extraction system is a coaxial chimney.

- For ignition, a piezo or an electronic ignition system can be used.

- To ensure complete autonomous and safe operation of the heating system, a variety of electronic sensors and programs are used.

- To control the normal operation of the unit, as well as the settings of the operating modes, the device is equipped with the necessary controllers.

The chimney goes outside the room through a hole in the wall, this pipe performs the function of removing combustion products, as well as supplying air, which is involved in the combustion process.

coaxial chimney- These are two pipes of different diameters. The smaller diameter pipe runs inside the larger diameter pipe. Flue gases exit through the inner channel, and fresh air is taken in through the outer channel.

Advantages of a parapet gas boiler

Drawing a conclusion on the characteristics of this unit, we can note its positive points:

- Possibility of use in premises of any purpose and even in apartments, without the construction of additional structures.

- Low cost compared to other types of gas boilers.

- Compact size and easy installation.

- A design feature that allows you to heat the room where the parapet boiler is located without the use of additional radiators, that is, the boiler itself is a heater due to the presence of convection holes.

- Multifunctionality and a wide range of capacities.

Despite the simplicity of design and operation, parapet boilers are gas equipment, which has clear requirements that must be met.

To do right choice gas heating boiler for the house, you need to take into account the heated area and heat loss. To do this, you need to take 2 kW of boiler power per 10 m2 of the area of \u200b\u200bthe house.

A parapet boiler is a versatile and convenient unit for heating, which can be installed even in an apartment.

Parapet gas boilers: advantages and disadvantages

What are parapet gas boilers. Features of installation and operation of parapet gas boilers.

Parapet gas boiler

What is good parapet gas boiler? Consumer reviews point to its compact size, ease of use and versatility. This type heating devices are recommended for installation in rooms with a small area. For example, in a standard city apartment, it will not take up much space in the kitchen under the window. You can place a parapet boiler in living quarters without looking back, since it does not use oxygen to burn gas from the room. The perfect smoke removal system makes this technique absolutely safe to use. Read also: Which is better - a single-circuit or double-circuit outdoor gas boiler».

Typical variety of equipment

The parapet boiler takes up very little space.

How to choose the right parapet boiler? Consumer reviews indicate the variety of models of this heating equipment. Today, the choice of device can be carried out according to the following parameters:

- according to the method of installation: wall and floor, left-hand and right-hand;

- by the number of circuits: single and double circuit;

- by the presence of automation: volatile and non-volatile.

In addition, the classification of equipment is carried out according to its performance. So, today you can buy a single-circuit gas parapet boiler with a capacity of 15 kW to 40 kW. When choosing a double-circuit parapet gas boiler and reading its instructions, you will notice that water performance is also added to the usual power. So, a device with a power of 12 kW-13 kW can heat up to 180 liters of water per hour, which is enough for 4 water intake points.

By the number of circuits, single- and double-circuit boilers are distinguished. The first option is equipped with a conventional heat exchanger. It has a lamellar structure, which increases the rate of heat exchange between the flame of a gas burner and the heat carrier of the heating system. The heat exchanger is made of steel, 3 mm thick. It is this structural material that ensures the durability of the equipment and a sufficiently high rate of heat transfer. Increasing the thickness of the steel reduces the degree of exchange of thermal energy between the water in the heating circuit and the gas burner.

Construction of a parapet boiler.

The double-circuit parapet gas boiler is equipped with an additional copper coil. Due to his work, water is prepared for the DHW circuit of an apartment or house. Water heating is carried out only in a flowing way. The storage capacity inside the boiler will significantly increase the dimensions of the equipment. Thus, it will be impossible to use it for installation in an ordinary apartment.

According to the method of installation, there are wall and floor models. However, the classification of parapet devices does not end there. There are boilers with a left-hand arrangement of branch pipes for connecting a gas main, a heat and hot water circuit. There are also right hand ones. When buying equipment, given fact don't lose sight of. Read also: How to choose a wall-mounted gas boiler for home».

Dimensions and dimensions directly depend on the performance of the boiler and the number of circuits. So, a single-circuit gas parapet boiler will be smaller and lighter compared to a similar device equipped with two circuits. If we compare two single-circuit boilers, then the one whose performance is higher will be larger. This is due to the size of the gas burner and heat exchanger.

How to install a chimney for a gas boiler without errors?

How to install a chimney for a gas boiler without errors?

All about aluminum chimneys for gas boilers can be found here.

How is a parapet boiler arranged?

There is a coil inside.

The body of the parapet boiler is made of steel with a minimum thickness of 3 mm. Powder coating on the outer and inner sides of the body makes it resistant to corrosion. Even in conditions of high humidity, which is often observed in the kitchen, the gas heating element will retain a decent appearance and integrity. Thick steel increases the resistance of the instrument case to direct mechanical impact. On its surface, dents and chipped paint are not formed.

The device of a parapet gas boiler is simple and efficient. The structure of the equipment is as follows:

- steel case;

- closed combustion chamber;

- igniter and gas burner;

- coaxial chimney;

- a steel heat exchanger, if it is a double-circuit equipment - a secondary copper coil.

The security system is presented:

Gas boilers floor parapet structure do not differ from wall counterparts. The difference is only in the power of the equipment. With increasing power, the weight and dimensions of the device increase.

Installation of a parapet gas boiler can be carried out in any convenient place in the building. The main requirement is that the equipment must be located close to the wall in order to bring the coaxial chimney to the street. The main advantage of parapet heating elements is a closed combustion chamber and a coaxial chimney. These two structural elements allow you to mount the device in any convenient place without fear for human health. After all, a sealed combustion chamber does not allow toxic products of gas oxidation to penetrate into the living quarters.

The coaxial chimney is a steel structure consisting of two pipes. One of them with a smaller diameter is located inside a pipe with a larger diameter. Free space is formed between pipes of different diameters. Through this space, wall and floor parapet gas boilers take in air for burning gas. Oxidation products of the energy carrier go out through the inner pipe. As a result of the operation of the boiler, no air is taken from the room. That is why parapet heaters do not need a separate boiler room with good ventilation.

Do-it-yourself installation of a parapet gas boiler is strictly prohibited. Only licensed professionals should install the device. Only employees of the gas service should connect the device to the gas main.

Installation of a parapet boiler is carried out in the same way gas convector. The coaxial chimney is brought out through the wall. Wind protection is a must! Next, the installation of the gas duct pipes, the heating and water supply circuit is carried out.

How does a boiler work?

The movement of flows and the name of structural elements.

If non-volatile equipment was purchased, then its operation begins with the piezo ignition button. As a result, the igniter or the primary burner of the boiler starts to burn. If the equipment is volatile, that is, equipped with automation, it is put into operation using automation. However, non-volatile models are more common in the domestic market due to their versatility.

The principle of operation of a parapet gas boiler is very simple. The igniter ignites the main burner. Its flame is directed to the heat exchanger through which the heat carrier of the heating circuit circulates. The burner operates until the coolant temperature reaches the upper critical level. After that, the automatic heating element is activated. The gas valve is closed. As a result, the gas burner goes out, while the igniter continues to work. As soon as the temperature of the heat carrier in the heating circuit drops to the lower limit, the gas valve will resume the supply of energy to the burner. The latter will ignite from a working igniter. The water in the heat exchanger will start to heat up again.

Several structural elements are responsible for the safety of the boiler:

- firstly, it is a thermocouple, which is located in the flame of a gas burner;

- secondly, boilers are equipped with an element for controlling the presence of traction;

- thirdly, there is a thermostat with a thermometer.

Buying a parapet gas boiler? The instruction is the document on which the choice should be based. The instructions contain information regarding the power of the device, the rules for its installation and operation.

The thermocouple from the heat of the burner generates an electric current of low voltage. It is supplied to the gas valve and keeps it in the open position. If the flame inside the boiler goes out for some reason, the thermocouple stops generating electricity. The valve closes automatically. The gas supply is stopped.

Sectional wall-mounted parapet gas boiler (rear view).

If there is no draft in the boiler, then the main structural element of the safety device (plate) increases its temperature to +65°C. The signal from it goes to the gas supply valve. The latter closes and the gas burner stops working. A similar mechanism is typical for a non-volatile boiler. If the equipment is connected to the mains, then the traction control is under the control of automation.

A thermostat with a thermometer protects the boiler from overheating. As soon as the thermometer detects a critically high temperature of the coolant in the heating circuit, it transmits a signal to the thermostat. The latter also stops the gas supply to the gas burner.

The wall-mounted parapet gas boiler once competed with conventional wall-mounted heating elements, despite their versatility. So, the latter were very demanding on the gas pressure in the gas pipeline, scale often formed on their heat exchanger, they needed uninterrupted power supply. Parapet devices are not so demanding on the pressure in the gas pipeline. Non-volatile models do not need power supply. Their coaxial chimney can be mounted both vertically and horizontally, which expands the possibilities of their installation.

Why the arrangement of chimneys for boilers is of the utmost importance when assembling a heating circuit.

Why the arrangement of chimneys for boilers is of the utmost importance when assembling a heating circuit.

What are the options for chimneys for gas boilers? The answer is here.

Possible problems with this type of gas equipment

Formation of ice on the chimney.

Parapet gas boilers for heating can create several problems for their owners. First, their sealed chamber consists of two structural elements that are interconnected by a porous, thermally resistant polymer-based material. If the maintenance of the boiler is not carried out on time, then you may not notice how the thermoplastic will lose its tightness. Carbon monoxide and other poisonous constituents of the exhaust gas can enter the living area and cause poisoning. That is why timely maintenance of parapet boilers is a must.

Secondly, the coaxial chimney in inexpensive models is made of steel of ordinary grades. At the same time, the rules for the operation of gas equipment require that only stainless steel be used when creating chimneys. Otherwise, soot and condensate accumulating on the walls of the chimney can form a chemically active environment.

It eats through steel walls. Carbon monoxide from the inner pipe enters the air flow going to the gas burner. As a result, there is not enough oxygen in the gas chamber for the full combustion of the energy carrier. Equipment performance drops. Soot forms on the walls of the boiler, which accelerates the corrosion process.

Thirdly, with a coaxial chimney, there is always a danger of blowing out the burner flame with strong gusts of wind. That is why, when installing the device, it is mandatory to install protection against the wind.

How justified is the use of parapet boilers?

The parapet boiler can be placed on the floor, right in front of the battery.

Parapet boilers today can compete with similar full-fledged gas-fired heating devices. After all, parapet equipment is distinguished by its compact size and dimensions, it is not inferior to conventional boilers in terms of performance. The main advantage of parapet devices is the presence of a closed combustion chamber and a coaxial chimney. This allows you to place the device in living rooms. The chimney can be placed both vertically and horizontally, which gives even more freedom in terms of placement of heating equipment.

The equipment can work both as a heating boiler and in parallel as a conventional convector. In addition, the equipment is able to serve the DHW circuit. The advantages of the equipment include their durability, efficiency, long service life, safety in use. The thermocouple, draft control and coolant temperature are responsible for the quality of the last parameter. Possible problems include the poor quality of the coaxial pipe, untimely service, blowing out the burner flame with strong gusts of wind.

Parapet gas boiler, reviews, specifications

What is a parapet gas boiler for heating? Equipment reviews. Device and principle of operation, classification of equipment. Wall and floor models.

How to choose a parapet type gas boiler?

Natural gas can be safely called the most popular and convenient type of fuel for use in autonomous heating systems of private houses, since, unlike coal, you do not need to worry about regular replenishment of supplies, you just need to connect to the local gas pipeline. That is why the largest number of individual heating systems are designed to use gas. One of the best options is a parapet gas boiler, which can also be used to heat a city apartment.

Such a boiler can be used to heat a city apartment

Initially, such boilers were developed as an alternative to wall-mounted ones, which, despite the fact that they had a lot of advantages, were very demanding on operating conditions. For stable operation, they needed stable pressure, high quality gas, soft water and uninterrupted power supply. For this reason, they often failed and needed regular service. Therefore, over time, they were replaced by parapet boilers, which have not such stringent operational requirements and ensure more stable operation of the entire heating system.

A parapet boiler is a non-volatile heating installation designed for installation in private houses and apartments, combining positive traits gas boilers and convectors.

Boiler device

Parapet boilers have a closed combustion chamber, which does not communicate with the room in which the unit is installed, and does not emit combustion products into its atmosphere, which is of great importance for small rooms with weak ventilation systems. For the same reason, such boilers do not require the creation of a traditional chimney, only a lateral coaxial (coaxial) chimney is sufficient, which is mounted from two pipes located in each other to supply fresh air to the combustion chamber and output combustion products to the outside. Due to the presence of holes in the body of the parapet boiler, it is not necessary to install additional radiators in the room. With the correct calculation and choice of the boiler model, it alone will be enough for full heating.

Parapet boiler device

Parapet gas boilers are mounted according to the same principle as convectors - by means of nozzles, the unit is connected to the gas and water supply systems, if the boiler is double-circuit, and is attached to the wall with brackets. The coaxial chimney has a small diameter and can be laid directly into outer wall, on which the unit itself is located. The branch pipe is best displayed next to the window, so that it is easier to control its condition during the operation of the heating system.

Main advantages

- The main advantage of a parapet boiler is the already mentioned closed combustion chamber. Thanks to this design device, there is no need to install a full-fledged chimney, so the boiler can be installed in any room in which at least one of the walls is external.

- The presence of convection holes in the boiler body provides full heating of the entire room without the need to install additional convectors, since the parapet boiler is both a “furnace” and a “battery”, combining everything positive sides these devices.

- Possibility of installation in a city apartment. All that is required for a parapet boiler is the presence of a gas pipeline and electricity in the house. In apartments, the installation of parapet boilers is usually carried out in the window sill space in the kitchen, but if there is none, the unit can also be installed near the wall, but in this case it will be necessary to create an external hole in it for a coaxial chimney.

The heater can be installed simply against the wall

- A wide range of parapet boilers allows you to choose the best option for premises of any area. Power can vary from 15 to 40 kW, depending on the model chosen.

- Versatility. Among the model range there are options with both one and two contours. A parapet boiler with two circuits not only heats the room, but can also be used to heat water if there is no hot water supply in the house.

- For an individual heating system, parapet boilers have a relatively low cost, which makes them affordable for most segments of the population. Modern design housing does not spoil the overall appearance of the interior if the unit is installed in a conspicuous place.

Choosing a gas boiler

Between themselves, parapet boilers, in addition to specifications and power, can differ in efficiency and reliability.

Reliability primarily depends on how thick the steel is used in the design of the heat exchanger. Unfortunately, not all manufacturers indicate this parameter, therefore, when choosing a boiler, you need to clarify this point with the seller in a separate order, since this can play a key role in the operation of a parapet boiler.

Steel with a thickness of around three millimeters is considered optimal. If the steel is thicker, then the heat transfer process will slow down, which will negatively affect the overall efficiency of space heating. In addition to the thickness of the steel, its quality also matters. The quality of the metal and the entire boiler as a whole can be determined by the maximum level of pressure that is allowed by the manufacturer. The higher it is, the more reliable and better the selected parapet boiler is made.

The quality of the metal during manufacture can be determined by the maximum level of pressure

The efficiency of a parapet boiler is affected by the design of the heat exchanger and its efficiency. In order to determine how economical the selected boiler will be in operation, you need to find out its efficiency (coefficient useful action), this parameter will most accurately show the efficiency of the heat exchanger and the boiler device as a whole.

To date, almost all manufacturers have achieved an acceptable level of efficiency, which is 90-92%. But just in case, it is worth clarifying the level of efficiency when buying, since in some cases even two or three percent can matter. This indicator is the only one that objectively reflects the efficiency of the boiler, because different rooms differ from each other in the level of their own thermal insulation, so the reviews of people who have already bought a boiler will always be subjective.

to meaningful technical parameters include the size, dimensions of the boiler, the location of the connectors for connection and power. The size and dimensions are selected in each case individually and depend on the place and conditions of installation. Also important for the boiler is the location of the connectors. The modern model range includes options with both right and left connection of the boiler to gas and water supply. There are also universal models that can be connected from any side.

Boilers come in various sizes, it all depends on the power

The power of a parapet boiler is no less important characteristic than its efficiency. It is from the choice of a model with optimal power that the quality of space heating, as well as the efficiency of using the boiler, will depend, because if it is too powerful, then gas and electricity will be wasted. The formula 1 kW per 10 m 2 is often used, but in fact this is not correct, since this indicator is so averaged that it almost never corresponds to reality. When calculating the power of 1 kW per 10 m 2, the difference between an apartment and a house, the number of windows in the room, wall material, ceiling height and other parameters that make up the overall level of thermal insulation are not taken into account.

It is best to double this formula, that is, take 2 kW of power for 10 m 2, and not one. In this case, a margin is obtained that takes into account windows, possible drafts, thin walls or high ceilings. But, of course, it is best to consult with specialists when buying and determine the optimal power of the boiler in individually in order to achieve the most optimal ratio of price and quality of heating.

The parapet boiler is economical, easy to operate, has a low cost, can serve as a water heater and does not require the creation of an additional heating network, since it is both a stove and a convector. The ease of installation allows you to connect the parapet boiler yourself, without resorting to the help of specialists.

Summing up, we can say that a parapet boiler is a convenient modern heating device that can be installed in any type of premises, in a private house, apartment, garage or any outbuilding.

Parapet gas boiler: design and principle of operation

A parapet gas boiler is a heating device using gas energy, most adapted for use in residential premises. What are the advantages of parapet boilers, and what is needed