Why is there air coming out of the plumbing? What are dangerous air congestion in the water supply of a private house and how to get rid of them. How to eliminate cavitation

IN water pipes ah of a private house, air congestion is very often formed. They interfere with the flow of water from the faucet and can accelerate the formation of corrosion in pipes and fittings. Therefore, it is necessary to deal with the causes of air congestion in the water supply.

What is an airlock

In the water going through the pipes of the water supply, there are air bubbles with air. This gas is contained in the water itself, and can enter the water supply from the atmosphere. This happens if the pipe contour is not completely sealed.

If you correctly draw up a project for a private house and correctly calculate the location and introduction of water pipes around the entire perimeter of the house, exclude air from entering the water supply from the atmosphere, then you can avoid traffic jams in the house's drainage system.

Where do air pockets form?

The air bubble contains approximately 32% oxygen, this ratio of oxidizing substances is much higher than in the atmosphere. The shape of the bubbles are heterogeneous.

If the pipes run vertically, then the air-gas formations rise up or are in suspension.

In the water supply system, which is mounted horizontally, air-gas formations are located in the pipe in the highest sections and stick to its walls. This leads to the formation of a condition that contributes to the rapid rusting of the water pipe.

An indispensable mechanism in water and gas supply systems is carpet avk (inspection hatch). Its main purpose is easy access when servicing water seals, condensate collectors and water disposal units.

What you need to know

Bubbles from the air-gas composition can easily be released from the liquid, but also interact with water. It is possible to destroy and remove existing bubbles from the pipe using the speed of the water flow.

Devices from air jams

To get rid of air congestion in the plumbing system, you need to install an automatic air vent on the pipe, it will independently remove air from the pipe or install a mechanical valve, valve or ball valve.

Air regulators have a cylindrical shape with a flat cover. In the middle of the cover there is a threaded plug with a hole in diameter from 3 to 5 mm. In the body there is a ball in the form of a float or a cork that closes the hole in the lid.

Forward

Forward

In water supply networks, air accumulations disrupt the constancy and uniformity of the fluid (water) flow, and can also cause accelerated corrosion of pipelines and fittings. Therefore, it is very important to deal with the formation of air pockets and bubbles. In pressure systems, such gas either leaves the water itself, or is brought in from the atmosphere when the circuit is not completely sealed.

A correctly calculated project and its competent execution completely exclude air intake, and also do not give it a chance to accumulate in specific, permanent places(bends, turns or breaks in pipelines). As for the liquid itself, there are about 30 grams of air mixture for every ton of resource. Accordingly, the air in the water supply system is more actively released, the lower the pressure and the higher the temperature.

Causes of air locks in pipes

Such a by-product contains approximately 32% oxygen, that is, there is a third more oxidizing substance here than in the atmosphere. The freely expressed form of these clusters is not the same. Only bubbles up to 1 mm can be considered spherical. Large quantity may have an ellipsoid or mushroom topology. On vertical sections of water supply risers, air-gas inclusions rise up or remain in suspension. In horizontal pipelines, they always "stick" to the walls at the highest point, which can create conditions for active rusting of pipes.

When the water speed begins to exceed ½ m / s, air accumulations begin to move with it. If the liquid flows in the circuit faster than 1 m / s, then the air in the water supply system breaks into tiny capsules and a kind of emulsion is created from gas and liquid. Practical observations have revealed that the minimum rate of destruction of such accumulations in the water supply system is about ¼ m / s. With a lower flow rate, air pockets are able to hold on long time in the same areas, which is undesirable.

The air-gas mixture can not only be released from the water, but also interact with it, and, at the required flow rate, break down or go outside.

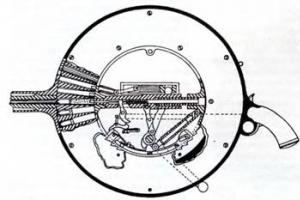

To get rid of air accumulations, various bleed / bleed devices are used. These are automatic air vents, and mechanical valves(for example, the "Maevsky valve"), and conventional shut-off valves (valve, Ball Valves). A standard regulator of this kind is made in the form of a cylindrical shell with a flat cover. In the center of the latter, a threaded plug with a hole of 3-5 mm is mounted. A float ball made of polymer or cork is placed inside the body. When there is no air in the pipes, this element tightly closes the hole in the cover under the action of network pressure. If there is air accumulation in the device, then the ball falls for a moment and allows this mixture to exit through the hole in the lid.

Air vents are also able to perform the opposite action - to introduce a certain amount of oxygen into the pressure network. This happens by accident or is necessary when the resource is quickly drained before the inspection and repair of the water supply system.

In order for the air in the water supply system to be removed in a timely manner, it is necessary to correctly install the mechanisms that discharge it at the right points. They are mounted at the highest points of pipelines, at breaks or bends, since it is there that the air-gas mixture accumulates.

A water well is a convenient alternative to autonomous water supply in the private sector. With a number of advantages, the design requires not only correct installation, equipping with a filtration system, but also timely cleaning, as well as prevention and washing. Due to non-fulfillment of at least one point, violations in the operation of the entire station are possible. For example, often water from a well comes with air. The life of the pump, water quality and much more depend on the timely identification of the causes and their elimination.

Before you start clarifying the issue, it is important to know: pumps are installed depending on the diameter of the well! Suitable for dimensions 100 mm submersible pump, smaller diameter requires a circular or plunger pump.

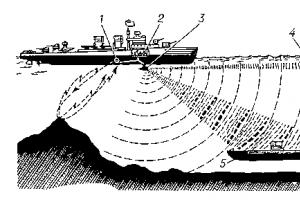

What is cavitation? This is a violation of the continuity of the liquid flow, otherwise - filling the water with bubbles. Cavitation occurs in those areas where the pressure drop reaches a critical rate. The process is accompanied by the formation of voids in the flow, the release of bubble formations of air that appear due to vapors and gases released from the liquid. Being in the area of reduced pressure, the bubbles can grow and collect into large hollow caverns, which are carried away by the fluid flow and, in the presence of high pressure, collapse without a trace, and in the conditions of an ordinary household well, they often remain and it turns out that the pump during operation pumps air bubbles from wells without producing the required amount of water.

Identification of the cavitation zone is sometimes impossible due to the lack of special devices, but it is important to know that such a zone can be unstable. If the disadvantage is not eliminated, then the consequences can be devastating: vibration, dynamic effects on the flow - all this leads to a breakdown of the pumps, because each device is characterized by a specified value of cavitation reserve. Otherwise, the pump has a minimum pressure, within which the water that has entered the device retains its density properties. With changes in pressure, caverns and air voids are inevitable. Therefore, the selection of the pump should be carried out depending on the volume of water needed to meet economic and domestic needs.

The destruction of air bubbles occurs only when they are transferred by the flow to the area high blood pressure, which is accompanied by small hydraulic shocks. The frequency of impacts leads to the appearance of a hissing sound, by which it is possible to determine the presence of air in the well.

Elimination of cavitation

What can be done to avoid the appearance of air in the well and the entry of water with bubbles:

- Replacing the suction pipe of small diameter with a larger one;

- Moving the pump closer to the storage tank.

Attention! When moving the pump, observe the established regulations: the distance from the pump to the tank must not be less than 5 diameters of the suction pipe!

- Reduce the pressure of the suction element by replacing it with a smooth pipe, and the valve can be replaced with a gate valve, and the check valve can be removed altogether;

- The presence of a large number of turns in the suction pipe is unacceptable, they must be reduced or the bends of a small radius of turns should be replaced with large ones. The easiest way is to align all the bends in the same plane, and sometimes it is easier to replace rigid pipes with flexible ones.

If all else fails, you will have to increase the pressure on the suction side of the pump by raising the level of the tank, lowering the axis of the pump installation or connecting a booster pump.

Note that all manipulations are shown based on a large amount of water consumption and the installation of powerful pumping devices. And, it is important that cavitation can only occur at a depth below 8 meters. It is with such a length of all elements and the presence of high pressure in the pipes that the liquid passes into a gaseous state and water goes with air.

Other causes of air bubbles in the well and ways to eliminate them

When using a well to pump out small volumes of water or seasonal operation of a structure, there are several possible causes and ways to eliminate them. So, why does the pump pump not only water, but also air:

- suction air mass in the suction section. At the same time, water with air goes for a long time, but the problem is “treated” only by the complete replacement of the pipeline and all related elements. You can check by removing the pipeline from the well and pumping water, for example, in the bathroom.

- Small filling of the aquifer with large pumping. Reducing volumes or drilling a new well will the best option solutions. It is only important not to break through to the former lean aquifer, so as not to get water with air from the well again.

- Pump failure, when the stuffing box seal is fragile, as a result of which air bubbles are in the discharge chamber and water goes with air. You will have to disassemble the device yourself or it is easier to give it to a repair shop.

Hydraulic systems are akin to electric ones - the laws are the same here. Understanding the problem of why the pumping station pumps air is sometimes possible only with a series of technical measures. And if the proposed options for identifying the problem and eliminating the deficiencies did not help and the water also comes with air, it is better to turn to professionals servicing the pumps. The cost of the service is from $50, but you will be spared the problem and will be able to find out exactly why your pump does not pump water the way you would like.

Water is needed in the country, in the garden or in the garden throughout the warm period, but not everywhere there is a main water supply. Therefore, to obtain water, a well is sometimes drilled, in the operation of which there are certain problems. For example, when a certain amount of air appears in the water from the well, as a result of which the pump fails, and therefore the water supply is interrupted, the pressure drops and other difficulties arise. All this reduces the quality of the water supplied, reduces the life of the pump and all hoses.

What is cavitation

The appearance of a different number of air bubbles in the water flow (interruption of the water flow) is called cavitation. This happens with a strong decrease in pressure, which can occur for various reasons. In this case, the number and volume of bubbles can increase and combine, resulting in rather large volumes of air that are located in the water flow.

The destruction of such air voids and bubbles occurs only under the influence of very high pressure. During such a process, which occurs very quickly, a kind of hiss appears. It always accompanies cavitation.

Typically, the process of bubble formation (cavitation) occurs in wells with a depth of more than 8 meters under the influence of high pressure and long pipes.

At this depth, the water begins to turn into a gaseous state, and the water flow is filled with air.

Most often, this process appears in water sources that have a telescopic structure. This means that the well consists of several pipe sections (from 2 to 4-5), each subsequent one is smaller than the previous one. Remember the children's folding telescope (they have the same structure).

Telescopic tube

As soon as air bubbles and voids begin to appear in the water stream, you need to start acting, because as a result of cavitation, vibration, hydraulic shocks can occur, which in turn leads to a decrease in water pressure, a decrease in pump performance, destruction of parts, their corrosion, and breakage pumping stations (or simply pumps).

It is quite difficult to determine where the formation of air bubbles occurs without special equipment. But let's try to name the main reasons why this process occurs, as well as the requirements that must be met so that cavitation does not appear.

Your own well in a private house is wonderful. No need to depend on plumbing, and the water itself seems especially clean ...

How to eliminate cavitation

To begin with, remember that the choice of a pump for a well directly depends on its diameter. For a well with a diameter of 10 cm, a submersible pump is bought, and for a smaller diameter, a plunger or circular type of pump is needed. You also need to know that the water storage tank is located at a distance from the pump of at least five diameters of the pipe leading from the well to the tank.

When air appears in the water pumped from the well, such actions must be carried out. First of all, it is worth trying to increase the diameter of the suction pipe.

You can get rid of cavitation if you move the pump closer to the tank where water from the well is collected.

The formation of air bubbles and voids in the water flow depends on the number of turns in the pipe that leaves the well and goes to the water tank. It is best if it has a minimum number of turns that should be located in the same plane. 90 degree pipe bends should be especially avoided.

Drilling a well on the site seems to be the solution to all water problems. Such volumes are able to cover drinking and ...

Since it is quite difficult or almost impossible to completely get rid of pipe turns, it is best if they have an angle of inclination from 30 to 45 degrees. This solution allows to reduce vortex processes, and also increases the diameter of the suction pipe and helps to reduce cavitation. In addition, if there are taps of small diameter, then it is better to replace them with a slightly larger size. It is also desirable to replace the rigid type pipes with flexible ones.

Gate valve

To eliminate strong cavitation, which causes irreversible consequences and, accordingly, destruction, it is worth removing the check valve, installing a gate valve, and replacing the suction part of the pipe with a pipe with a smooth surface, which helps to reduce pressure. The main part of the gate valve is a piece of steel plate, which, using a stem with a drive, completely cuts off the flow of water. To facilitate the work with this type of valves, the drive is made electric, mechanical or pneumatic. Of course, it is produced manual drive, but some physical strength is required to use it.

Since the formation of bubbles and air voids can be overcome by high pressure, which is much higher than atmospheric pressure, it is possible to increase the pressure of the suction force of the pumping station by additionally connecting a booster pump, increasing the water level in the tank and lowering the level of the pump. To lower the level of the pump, they dig a small pit, the width and length of which allow the pumping station or pump to be placed, and so that there is room for convenient maintenance.

The bottom of the pit must be leveled, compacted, and in addition, it can be covered with a small layer of gravel or sand. This is necessary so that the earth does not stick to the sole of the shoe and to the metal bases of the pump.

Other Causes of Air Bubbles in Water

All of the above causes of cavitation (the formation of air bubbles and voids in the water flow) occur during the operation of devices with increased power and when large volumes of water are consumed. And this is by no means full list, because of which cavitation appears, and therefore we will continue to talk about this topic.

If a well in a country house or garden is used only in the warm season, or it is required only to obtain not too large volumes of water, then there are several moments at which air may appear in the water from the well.

- When preparing a pump or pumping station for operation, be sure to pay attention to the seals. These are the so-called gaskets, which are used to seal the connection of the pumps, and do not allow water to enter the pump motor. They are a cord woven from several cotton, asbestos or bast fibers and having a square section. In the middle of such an gland there is a lead core, but 4 lead wires can also be woven into it. Old and worn seals interfere with pump operation. As a result of leaks in such connections, air seeps into the discharge section of the pump, and it goes with the flow of water.

- The appearance of air bubbles can occur due to suction on a pipe segment located in the well. In this case, carry out complete replacement pipes in this area, as well as all related parts.

- Also, cavitation can appear if there is not enough water in the layer to which the well is dug. Under such conditions, there are usually two options to get rid of air bubbles in the water stream. For starters, you can try to reduce the amount of pumped water. But if the lack of fluid becomes a problem, then you should think about a new well. The main thing in this matter is to find a full-fledged aquifer with a sufficient supply of water on your site. good quality. And for this, it is better to turn to specialists, since the search for a source and drilling work are quite costly and take a lot of effort. You can find out more about how to choose a good place for.