How to make a bath - a barrel of boards. Barrel baths: features, advantages and disadvantages of designs Do-it-yourself frame bath barrel

Own steam room in the country is the dream of many owners of suburban areas, but it interferes with its realization high price log or panel structures of traditional form. The optimal solution in this case, it is a compact and mobile barrel bath, which is quite realistic to build with your own hands. To do this, you will either need to have the skills of self-processing wood, or purchase a set of blanks and assemble them using metal components. More details on how to make a barrel bath and which layout option to choose will be described below.

Advantages and disadvantages of barrel baths

Compared to square and rectangular shape, a bath in the form of a horizontally inverted cylinder has some specific features. The advantages of this design include compactness, efficiency, mobility, fast heating and long-term heat retention. The bath-barrel looks very original and attractive, while taking up a minimum of free space. Due to its low weight, the barrel bath does not need a foundation. Models on wheels can be moved around the site or even transported using a trailer or truck.

The biggest disadvantage of a spherical building is the limited interior space. Usually the length of the barrel ranges from 2 to 6 m, the height is 2.2–2.5 m. The resulting area is enough to accommodate 2–4 people at the same time, but this option is not suitable for numerous companies.

Material selection

Given the difficult operating conditions, such as regular heating and cooling, humidity, the influence of the external environment, only the highest quality and durable building materials should be used to build a barrel bath.

Maximum attention should be paid to wood. The cylindrical body of the steam room is entirely made up of boards - edged, located one above the other with a slight overlap, or tongue-and-groove, which are fastened according to the "thorn in the groove" system. The most suitable species for this purpose are oak, aspen, Siberian larch, linden, cedar and spruce.

It is extremely important that the wood is well dried, smooth and clean, without cracks, knots, wormholes and darkening. Coniferous boards, when heated, can exude resinous glue and form unaesthetic smudges in places where dark brown spots are found. Even before the start of construction, the wood should be treated with an antiseptic, oily moisture impregnation and fire retardant.

The semicircular roof in the bath-barrel is laid from flexible bituminous tiles. Its color can be any - according to the preferences of the owners.

As for the metal components of the steam room, they must all be stainless. Experienced craftsmen recommend using only light-colored self-tapping screws during installation, and making hoops from steel tape with increased corrosion protection.

Bath layout options

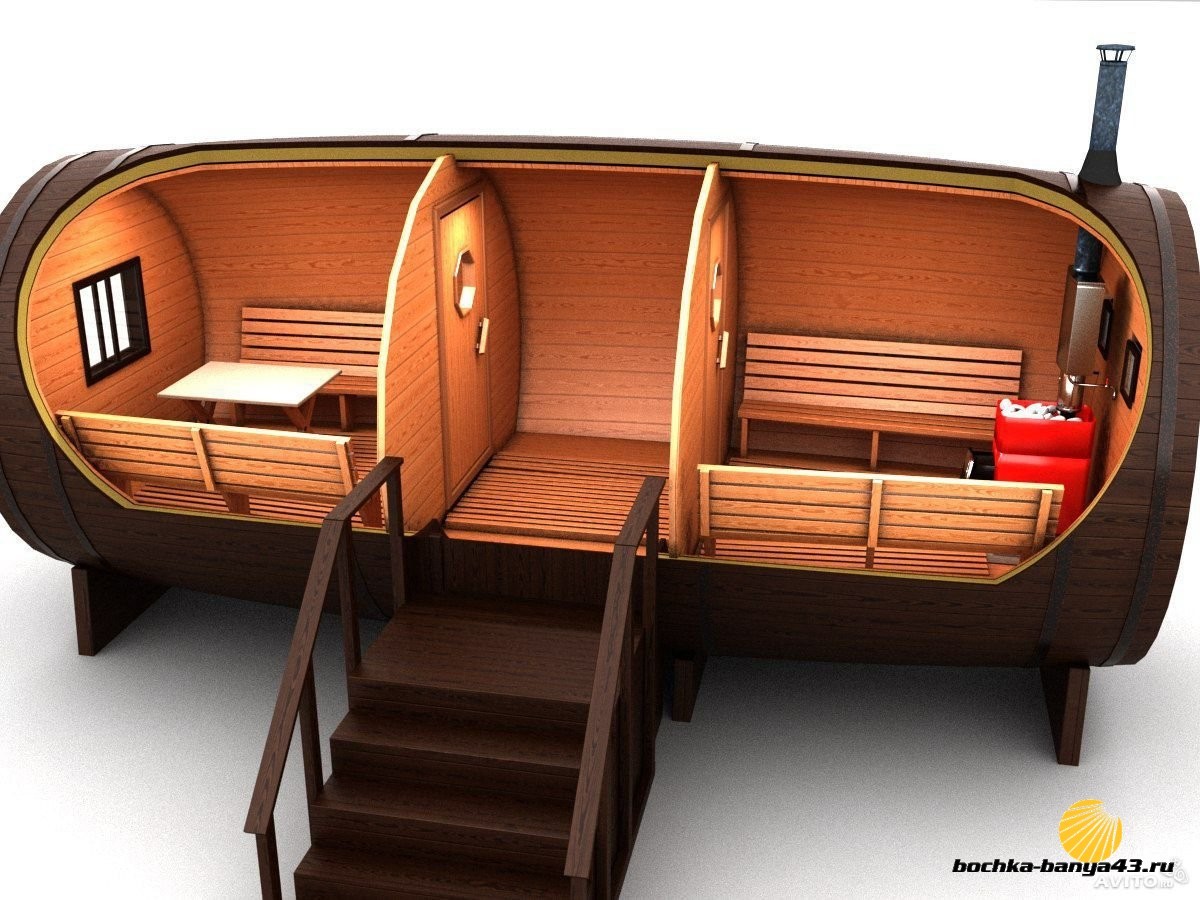

Depending on the dimensions of the bath-barrel, from one to three internal compartments can be equipped in it. The actual steam room, where the stove and stove benches are located, is about 2–2.5 m long. A six-meter structure usually also provides a place for a dressing room (with a dressing room and a table) and a washing room. Sometimes an impromptu porch is made in front of the entrance, slightly increasing the size of the roof - so that a canopy is obtained.

The door to the oval bath can be located both on the end side and on the side. Internal passages are usually closed with a sheet of tempered glass. Thanks to transparent inserts, a small room seems brighter and more spacious. Windows in the steam room significantly improve air exchange, which is very important for creating a comfortable microclimate. For this reason, two small gaps are left on the end side near the furnace - on both sides of chimney. An additional window can also be in the dressing room, if there is a seating area with benches and a table.

Stages of assembling a bath-barrel

Having decided on the drawing and location of the future steam room, as well as preparing necessary materials, you can proceed directly to the assembly. The whole process should take place step by step, from the preparation of the foundation to roofing works. With the construction of a bath-barrel with your own hands, if you have blanks, tools and certain skills, you can cope in a few weeks.

Base

The area under the oval bath must be flat and, if possible, as dry as possible. In swampy areas and where there is a close occurrence ground water, wooden building should be protected from moisture by installing it on galvanized screw piles. Under favorable conditions, a base made of concrete, crushed stone, paving slabs or stone. On top of the chosen base, wide wooden stands are fixed in the amount of 2–4 pieces (depending on the length of the structure), on the outer part of which recesses are made around the circumference of the barrel. For stability, the slats must be 30 cm smaller than the diameter of the cylinder. For example, with a trailer width of 2.5 m, the length of each stand will be 2.2 m, width - 30-40 cm, and thickness - 4-5 cm.

Frame

The body of the bath-barrel begins to be mounted from the bottom up. First, the floor is attached to the bases, then the end elements (including internal partitions), side lintels and the sheathing itself. Profile boards are fitted to one another at the seams, while the curly protrusion (thorn, comb) is tightly laid into the recess (groove). Edged ones are mounted overlapping - so that each subsequent one closes the previous one by 3 cm. After the work is completed, the cylindrical frame is additionally reinforced with metal hoops.

Roof

Installation of the roof begins with the attachment of narrow rails on both sides of the barrel - they somewhat change the angle of inclination of the flexible tiles and divert the drains further from the wooden walls. Bituminous elements are nailed to the top of the barrel with nails, one on top of the other with an overlap. In the center of the roof, using a building hair dryer, a “horse” made of the same flexible material is glued.

Furnace, chimney, ventilation

Installation of the furnace and chimney requires special attention to fire safety. To protect the wood from high temperatures and fire, the stove is placed on a mineralite substrate. It is necessary to sheathe the back wall with the same plates, along which the chimney runs, and the side parts of the benches adjacent close to the heating device. For the safe removal of combustion products, you cannot do without a strong and high-quality pipe, complemented by refractory sandwich panels and a chimney with a wind shield.

Water supply and drain

It is worth taking care of the water supply and arranging the sewerage even before the start of construction. It is best to arrange a standard pipeline, and not drain the used water under the base, because high humidity is very harmful to the tree and reduces the life of the steam room.

Installation of electricity

Bringing light into the bath requires special care and compliance with all fire regulations. Also, do not forget that steam has the same high conductive properties as water, so any mistake in the installation of electricity can be fatal. All switches and sockets should be in the dressing room, cables should be insulated in a corrugated plastic pipe, and holes in the tree should be protected with steel sleeves.

One of the most safe options For self installation – LED Strip Light 12 volt battery operated. If, nevertheless, a 220-volt network is carried out, this business should be entrusted to a professional electrician who understands the specifics of its operation in conditions of high humidity, critical temperatures and an environment of such a flammable material as wood.

Interior furnishing

For a comfortable stay inside the barrel bath after completion construction works you need to take care of the interior. Beds, headrests, a folding table, upper shelves for accessories, hooks for brooms and towels - this is the main list of items that you cannot do without during bath procedures. You can choose them according to your taste, but it is recommended to pay special attention to the quality of workmanship, that is, the thoroughness of wood processing, its species, evenness of surfaces, etc.

Barrel bath - photo

Although building a barrel bath with your own hands is quite difficult, some amateur craftsmen cope with this task very successfully. Examples of such designs are presented in the photos collected in our gallery. Each of the already implemented options can always be supplemented or changed according to own project. Perhaps the experience of other people will inspire you to install a cylindrical steam room on your site and enjoy pleasant treatments at any convenient time.

To date, barrel baths are a very popular product. Beautiful view baths in the form of a barrel captivates the eye. The idea to create a barrel-shaped sauna came to our country from neighboring Finland. Barrel baths have been popular there for many years. To date, the Russian market has a large number of proposals for this product, for every taste and budget. The cost of such a bath depends, of course, on its size and materials from which it is made. Barrels are produced in length from two to seven meters, and on average they are two meters in diameter. In a short bath, only the steam room itself is placed, and in a large one you can place all the amenities of an ordinary stationary bath: a shower room, a rest room, a toilet. For the mobility of the bath, it is installed on a trailer of a light car and is very often used for commercial purposes. All these additional options lead to an increase in the price of the bath at times.

We will analyze and calculate the cost of a barrel bath, if you do it yourself. Take for example a barrel four meters long and two meters in diameter, in several versions. Drawings of such a bath can be easily found on the Internet.

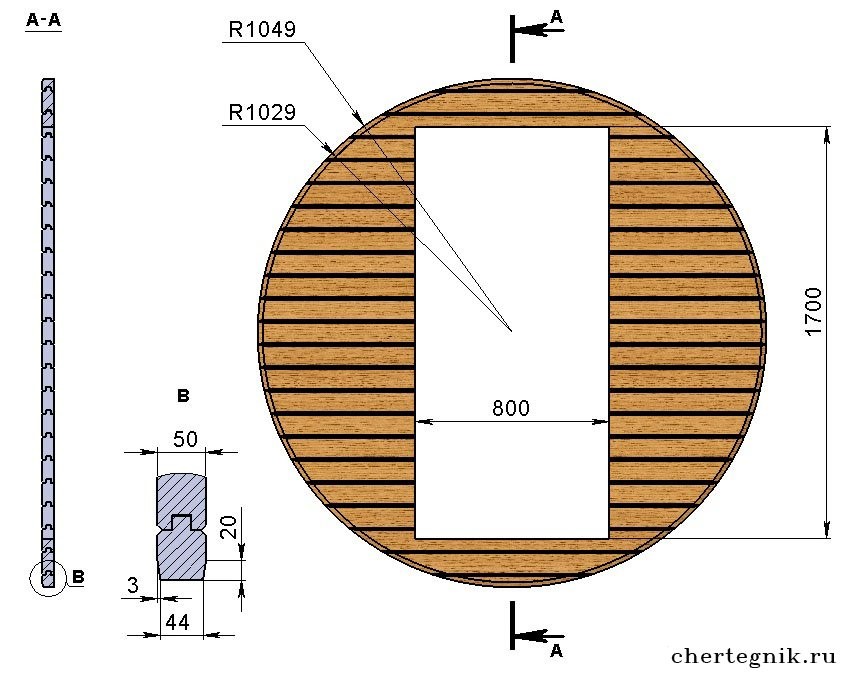

Bath from a barrel board 44 mm thick without the use of insulation

The simplest and most inexpensive option for making a barrel bath with your own hands will be a bath from the so-called barrel board without additional insulation. The barrel board is so called because it has a semicircular groove and a spike of the same shape and is used to produce large barrels. Calculate the required number of boards. To do this, we calculate the circumference of the barrel, which is equal to 2πR. A barrel diameter of two meters means 2*3.14=6.28 meters. Boards can be used of any width, but most often their size is 15 cm, and taking into account the fact that part of it will go into the groove, we will take 12.5 cm as a working width. And so, we calculate the number of boards needed 6280/125 = 50 .24 pcs. The required number of boards is 50 pcs. There will be a small gap equal to 0.24 * 125 = 30 mm. It will close when the outer boards are tightened, as the diameter of the bath will decrease slightly. The decrease in diameter is due to the fact that a small groove is cut in the outer boards for a closer fit to vertical walls and partitions. Boards are usually sold with a length of 6 meters, which means that this volume of boards (50 pieces) is enough for two walls and one partition. It must be remembered that the board must be well dried. Searching for ads on the Internet, we find a pine board with a moisture content of 15% worth 11,500 rubles per cubic meter. There are 22 boards in a cube, so we need 50/22=2.27 m3. We multiply cubes by money and get 26105 rubles for the whole bath. A bath barrel made of cedar will cost more, because 1 m3 of cedar board costs about 35,000 rubles, and larch about 40,000 rubles. Metal hoops for screed boards must be used from stainless steel. For this bath, it will be enough to use three hoops. Their cost will be about 6000 rubles. Cover the bath can be flexible shingles or polycarbonate. Let's calculate the roof area: 6.28/2=3.14*4=12.56 m2. The cost of shingles varies greatly depending on the manufacturer. Let's take the average price of 400 rubles per m2 and get 5024 ruble. Two doors, the entrance and the steam room, will cost 7000 rubles. For a rest room, it is necessary to make benches from any tree, and for a pair of shelves from hardwood (linden). Lounge benches 500 rubles, for a steam room 3000 rubles. wooden lattice on the floor 1000 rubles. In the barrel bath, it will be enough to install two sockets and two lamps, which must be connected through a separate machine. electrical equipment 1000 rubles. And finally, the most important thing without which a bath is not a bath is a stove. In barrel baths, wood-burning stoves of low power are usually used, since due to the lack of nodes in the steam bath, the bath warms up quickly. A Russian stove with a chimney and a tank for heating water will cost about 20000 rubles. The place where the stove will stand must be finished with non-combustible material, such as asbestos sheets. Their purchase will cost 1000 rubles. The wood outside must be protected from moisture and treated with a special impregnation. Adding more 3000 rubles. For the stability of the design of the bath, the barrels are placed on special stands with a semicircular cutout. For these purposes, you can use a board 50 * 150 mm. 1000 rubles. We will set aside more for fasteners and unaccounted expenses 5000 rubles.

Today, a barrel bath, four meters long in the basic configuration, is offered to be purchased for 170-205 thousand rubles. Let's calculate the cost of a barrel bath made by yourself with your own hands. We get 79629

rubles for a non-insulated pine bath and 132974

rubles for an uninsulated cedar bath.

Bath from a barrel board insulated with foil insulation

When insulating a barrel bath, in addition to a heater, it is also necessary to purchase a lining, which will have to finish the walls. Calculate the required amount of insulation. Standard Width foil insulation 600 mm or 1200 mm. The circumference is 6.28 m, the length of the bath is 6 meters, therefore, we need 6000/1200 = 5 segments 6.28 m long. 6.28 * 5 = 31.4 m of insulation. Insulation of partitions is also necessary and will amount to 3.14 * 3 = 9.42 m2, that is, about 8 more m of insulation with a width of 1200 mm. As a result, we get about 40 meters of insulation costing 2500

rubles. For gluing the joints of the insulation, use foil tape ( 350

R).

Calculation of the required amount of lining

The working width of a standard lining is 110 mm, the circumference of the bath is 6.28 m, which means you need 6280/110 = 57 pieces 2 meters long for a steam room and 57 pieces for a rest room. For finishing the steam room is most often used wooden lining from linden. She will cost 15000 rubles. The lining for the rest room will cost 5200 rubles.

Bottom line: do-it-yourself barrel bath from a barrel board with foil insulation will cost 102679 R. from pine and 156024 from cedar.

Frame bath

A barrel bath can be built not only from a barrel board, but also using frame technology. going to wooden frame it is sheathed from the inside with clapboard, outside with a board, and insulation is laid inside the wall. The frame will require only a few boards 100 * 50 mm. Exterior wall board will cost order 8000 R. and it will need about 50 pcs. When sheathing a bath with an ordinary board, they are laid with a small whip on top of each other, so we take the working width as 130 mm. For interior decoration the lining will take the same amount as for the previously calculated options for making barrel baths. Insulation is used to insulate walls. mineral wool with foil and it will take about 40 m2 ( 6000 rubles). The cost of the frame can be attributed to unaccounted for and additional costs.

Bottom line: do-it-yourself barrel bath using frame technology will cost 61524

A barrel bath is a truly unique invention that organically combines the healing properties of an ordinary bath, useful qualities natural wood, mobility and maximum convenience of a collapsible design.

Subject to competent assembly, a bath in the form of a barrel turns out to be very reliable and as durable as possible. Such a design can be attached to a car without any problems and taken to any desired place.

The bath has a small volume and warms up in the shortest possible time. Despite its modest size, such a steam room can be equipped with all the necessary devices for a full and most comfortable rest. At the same time, you can handle the assembly of the barrel on your own.

Mobility

The bath can be transported or even rolled (transferred) manually with the help of several friends. The weight of the bath-barrel is on average 1.5 tons, so it will be possible to handle the transportation of the structure over short distances manually, and almost any machine is capable of pulling such a weight.

For comparison, only a brick oven for an ordinary bath can weigh much more than 1500 kg.

High warm-up rate

In warm weather in such a bath in half an hour it will be very hot.

compactness

The average area occupied by a bath in the form of a barrel does not exceed 10 m 2, so this design is ideal for placement in small areas.

original design

The bath has an attractive and very pleasant appearance. Psychologists around the world say that the contemplation of rounded shapes helps a person to relax, and this is very useful when visiting a bath.

frugality

You will spend much less money on assembling a bath in the form of a barrel compared to building a capital steam room of a similar area.

Also among the advantages of the considered design should be attributed the absence of the need to equip the foundation. For a stationary installation, it will be enough to prepare a pair of strong beams, rigidly and securely connected to each other, and install the barrel on them.

Extreme ease of maintenance and operation

Fewer corners - less dirt in hard-to-reach places, less area- Less cleaning hassle.

Ergonomics

Even with a modest area inside such a bath, you can equip a shower, a dressing room and all the necessary equipment. On average, a barrel bath can accommodate 4-8 people.

Thanks to high-quality thermal insulation and multi-layered barrels, the effect of a thermos is created inside such a bath, which can significantly reduce fuel and electricity costs.

The averaged data of numerous calculations show that, thanks to the round shape alone, 20-30% less money will be spent on the operation of the barrel bath than on the maintenance of an ordinary steam room.

What materials are used to make a bath-barrel?

With the assembly and further operation of the barrel, there will be no problems and difficulties if you initially pay due attention to the choice of suitable materials.

To assemble the bath, use only well-dried and correctly sawn wood into pieces of a suitable size. Choose the type of wood according to your preferences and material capabilities. It is recommended to give preference to oak, linden, pine, spruce, and cedar.

The optimal width of the boards is 9 cm, the thickness is 4-5 cm. It is desirable that the wooden boards initially have a tongue-and-groove connection - this will allow you to assemble the structure with the least amount of time and effort.

But even if such spikes and grooves are absent initially, make the said connection yourself. It allows you to get durable, reliable, stable and durable prefabricated systems, which, if necessary, can be repeatedly disassembled and assembled without compromising the performance properties of the structure.

Additionally, you need to purchase or make your own a few strong steel hoops. These products will provide additional fixation of the barrel around the entire perimeter.

All the required devices are purchased without any problems in specialized stores that sell various products for baths and saunas.

The required number of metal hoops and wooden planks calculate individually according to the size of your future steam room. Typically, the length of such a barrel varies from 250 to 500 cm. Additionally, this design can be equipped with various extensions.

A bath in the form of a barrel, if it is planned to be used throughout the year, needs to be equipped with high-quality thermal insulation. Traditionally, mineral wool materials are used for insulation.

The top of such a steam room can be decorated at your discretion. Here, focus on personal preference. The main thing is that the roof reliably protects the bath from adverse atmospheric phenomena and ensures effective and timely removal of moisture.

Barrel bath assembly guide

Ready-made kits for assembling the barrel are available for sale. Prefabricated elements have a variety of sizes, so you can easily choose and buy the right material. This will save time and energy.

Also, all the necessary structural elements can be made by hand. The assembly of the barrel is carried out in the following sequence.

First step. Make the base of the steam room. Saw a board measuring 5x20 cm into pieces according to the diameter of the barrel. Place the supports in increments of up to 150 cm. Determine the specific number of supports individually in accordance with the length of the structure.

To connect, cut grooves in the upper ends of the boards. The shape of such grooves should follow the circumference of the barrel. Determine the dimensions of the grooves so that the remaining uncut part of the board has a width of 100 mm or more.

Second step. Collect the required number of internal partitions, as well as the end walls of the future bath. For assembly, use a grooved board. The connection of wooden boards is carried out using transverse bars. Fix the transverse bars themselves in such a way that in the future they do not interfere with the installation of windows and doors.

In ready-made kits, the necessary end elements are sold assembled, which is very convenient.

Third step. Cut the grooved board according to the length of the barrel. Sand the ends of the elements, and then treat the boards with antiseptic impregnation.

Fourth step. Install the supports with the same pitch. Lay out the bottom of the bath-barrel on them from several wooden boards connected using the tongue-and-groove method. Once a sector of the circle has been formed that is large enough to mount the end walls, place these walls in the appropriate places and continue laying out the boards until the circle is completed.

Fifth step. Fasten the assembled barrel with metal hoops.

Sixth step. Install windows and doors.

seventh step. Set up the roof. Reliable Option- roof on rafters. To create rafters, use a beam with a section of 5 cm. You can cover such a roof with corrugated board, metal tiles or other similar material. Attach the finish coat to the pre-assembled plank batten.

If the bath will be visited only in warm weather, insulation can be abandoned. The design of the steam room is such that it can warm up enough in about half an hour and retain heat for 2-3 hours, and this time is enough for most visitors to the steam room.

In conclusion, it remains to treat the outer surfaces of the walls with a fire retardant, and the inner ones with an antiseptic, then you can proceed to the internal arrangement of the steam room.

Internal arrangement of a mobile bath

Inside, such a bath can be equipped like any other steam room. It even has enough space for a small dressing room and compact shower.

When choosing a stove, focus on modern electrical models. Such units do not take up much space and do not need a chimney. For a barrel bath, a 6 kW electric heater will be more than enough. However, such furnaces are capable of producing exceptionally dry steam.

If you don't like it, give preference small metal wood stove . specific model and choose the dimensions of the structure with a focus on the volume of the steam room. Do not forget about fire safety measures: wooden structures they are necessarily protected from all heating elements with the help of sheet non-combustible materials, and the places where the chimney pipe passes are insulated with fire-resistant insulation.

When arranging the floor, be sure to make a slope in the direction of the drain. There should be a slope of approximately 1 degree per 1 m of surface length.

For interior decoration of floors, walls and benches it is best to use larch. Such wood will not burn the skin. Place the benches along the wall opposite the stove. You can also install benches at the side walls.

Lay electrical wires in fire-resistant insulation. Sockets, switches, lamps - all this must have an appropriate protection class.

It is very easy to care for such a bath.- it is enough to regularly ventilate the steam room and at least annually treat the walls with high-quality protective equipment.

Thus, in just a couple of days you can independently assemble a barrel bath, which will delight you and your guests with its light steam for many years. Follow the instructions and everything will definitely work out.

Successful work!

Taking a steam bath after a hard day's work is the dream of almost any person. But going somewhere to the steam room, renting a room and paying for it, by the way, really a lot of money, will not please everyone. If you have built your own house and are thinking about how to equip the site, then be sure to consider creating your own bathhouse, which you can visit at any time convenient for you with minimal fuel costs. In addition, it will be possible to take a steam bath in the company of friends who also like this format of recreation. But if you appreciate this idea, but don’t know where to start, then first of all, check out the existing building projects and choose among them the one that you like best. Recently, barrel baths have begun to be especially popular, which have a lot of advantages, in addition to obvious accessibility and practicality. In this article, we will consider all the features of creating such steam rooms, as well as materials that you cannot do without.

The advantages of such facilities

Undoubtedly, it is not advisable to build a capital bath complex next to a small cottage or cottage, especially if you live in a house all year round but only during the summer. In addition, it is worth noting that the bath is a somewhat expensive pleasure. Yes, such a construction will pay for itself quite quickly, but no one has canceled the initial expenses, which, alas, cannot be dispensed with. But what about those people who do not want to abandon the idea of creating a bath, but do not have the necessary funds? In this case, it is recommended to pay attention to the budget options of the complexes, which in terms of their functionality and durability are in no way inferior to massive outbuildings.

A barrel bath is a structure that you can create on your own without much difficulty, spending a minimum of finances and your precious time on it. You can build a steam room in a matter of days, and at the same time its appearance will be very attractive and complete thanks to the finishing works. The most important thing is to adhere to the chosen scheme and the advice of specialists in the field of construction and design.

The length of such a structure can be at your discretion - from two to six meters. If your budget is severely cut, you can create a compact "barrel" in which there will be only a place for a steam room and the stove itself. If we talk about well-equipped and large baths, then they can have a relaxation room, a shower room, an imitated loggia, as well as almost any other room that your soul desires.

In addition, it is worth noting the following advantages, namely:

- original appearance;

- a small amount of space is required for the creation of a structure;

- high-speed work performance;

- a barrel bath has exactly the same functionality as capital structures, in no way inferior to them;

- no need for a massive base;

- you can create a steam room from materials that remain, for example, after building a house;

- availability and low price;

- you can build a barrel bath according to drawings and diagrams yourself.

- if you wish, you can create an individual building project and implement it based on your own wishes and preferences.

- Sauna barrel do-it-yourself drawings of which you can easily find on the net and choose among them exactly those that are suitable for your site, and, of course, the budget.

Choosing a building material

most accessible and practical option are tongue and groove boards

To create a bath barrel on your own, without involving a team of craftsmen, of course, you should use wood. You can choose the breed at your discretion, but the safest for human health and environment there will be pine, spruce and fir. But if we are talking about the creation of such a structure in the conditions suburban area, then you should definitely take into account the climatic conditions, the amount of precipitation and the planned service life. That is why, for such objects, it is best to give preference to cedar, as well as larch, which, although they are not cheap, will last long enough and will please with their aesthetic characteristics.

It is especially important to carefully consider the form in which wooden blanks for the future bath will be made. A planed edged board with a tenon-groove fastening type is perfect for these purposes.

To simplify the assembly process, construction experts strongly recommend processing the material so that it takes on slightly rounded shapes. To do this, you can use pre-created templates. The material should have a small thickness and width, so that it is most convenient and easy to work with it, both at the preparatory and at the final stage.

Barrel bath: do I need a foundation?

People who have thought about building their own barrel bath according to simplified drawings, first of all, think about whether it is necessary to create a foundation for this kind of construction? Often, no foundation is required. All you need to do is prepare the area. To do this, remove all debris, vegetation, and other objects that may interfere with installation from it. It is also important to level the surface. Support elements should be placed on it, which will serve as the base.

The support for the barrel bath can be:

- The territory that was previously concreted or asphalted; ;

- The area on which the tile was laid;

- Cover with a well-fixed shield (usually made of wood).

If you do not have the opportunity to carry out such work, then it is safe to say that the old one can be perfectly used as an impromptu foundation. reinforced concrete slab dimensions you need.

At the time of creating the foundation of the supports, try to follow a few tips:

- When creating bases, it is recommended to use a reliable edged board, which has a thickness of at least 5 centimeters, after having been treated with high-quality impregnation in order to prevent the formation of fungi and mold.

- Make sure that there is not too much distance between each support. The most optimal is one and a half meters, and the number of boards varies depending on the size of the tank bath.

- When assembling the structure, make a small rounded notch on the transverse boards so that the support exactly repeats the contour of the bath (it should not be created from the edge, but closer to the center, leaving at least 10 centimeters at the free edge).

- To make the foundation rigid, when creating the structure, all kinds of metal elements are used, which are fixed at the corners of each constituent base.

Assembly order

The process of assembling the body of the structure itself should begin with the installation of partition walls, which are fixed transversely to the base. Equipping them, do not forget that any bath should have several door and window openings, and that this material should be additionally treated with a protective solution.

After that, boards of the most optimal length are laid alternately on the finished foundation (based on the parameters of the future bath). They are connected according to the principle of "thorn in the groove" in order to give the structure a rounded shape. Upon completion of these works, the end partitions are fixed, which are mounted at the site specified in the drawing.

Decoration of the interior of the bath

The necessary rigidity of such a structure is provided through the use of special metal hoops. To ensure their reliable fastening, it is recommended to purchase special clamps, which, after the timber has completely dried, will tighten the structure and prevent the appearance of gaps and cracks.

The exterior finish of the barrel bath is optional. If you still decide that you need it, then for the work it is quite the usual one will do soft roof, which is installed directly on the top of the structure. First, the surface should be treated with a special waterproofing material (the budget option is simple polyethylene), and bituminous tiles. After everything is ready, you need to wait a few weeks for the wood to dry completely. It will be possible to equip the steam room with everything necessary and start full operation in a month. Of course, this rule is not necessary to follow, but if you want the bath to please you with its practicality and durability, experts in the construction industry still advise taking these recommendations into account.

In this article, we have reviewed all the main features, as well as the advantages of barrel baths. Such facilities are a really worthy alternative to capital buildings, so if you have a desire to build a sauna in your home, be sure to consider them.

Reading time ≈ 5 minutes

For most owners of suburban real estate (mansions, cottages), it is preferable to have a bathhouse in the perimeter of the house adjoining area. Due to various reasons, the construction of a full-fledged capital bath building is not always considered possible, economically justified. In many cases, it is the bath-barrel that is the most successful solution to the problem, despite the fact that it is quite possible to build such a structure without the help of professionals, with your own hands.

The advantages of a bath-barrel include its compact size, the absence of the need to build expensive supporting structures: foundations, walls, roofs. Also, the future owners of the bath-barrel are impressed by the mobility of such a structure, since, if necessary, it is quite possible to rearrange it to another, more suitable place on the site, or even transport it to another address.

Drawing up a drawing of a future bath-barrel

In order to build a bath-barrel with your own hands, you must first draw up drawings of the future structure, focusing on the desired usable volume, based on the size of the site for installation, the number of users. In addition, when considering: how to build a barrel bath, it is worth considering the conditions for its operation (year-round or seasonal use).

Necessary tools and materials

Before starting work on the construction of a bath-barrel, you will need to purchase the required carpentry and power tools. For assembly you need: a hammer, an ax, hand saws, tape measure, electric or chainsaw, grinder, brushes.

When deciding how to make a bath-barrel, you should know that the optimal material for such a structure will be a board with a thickness of at least 40 mm. It is best to take hardwood that does not emit resin when heated.

Description of work stages

1. Guided by the photos that show the barrel bath outside and inside, you should make round elements that are internal partitions and external end walls of the structure. At the same time, if the option of a mini-bath is chosen, the manufacture of an internal partition is not required - it is enough to equip only two end walls.

2. In order to carry out the initial installation of the transverse structures of the bath, as a base, it is necessary to provide for the presence of a trapezoidal beam with a rounded notch. Such a bar is assigned the role of a support. Also, it is designed to serve as an obstacle to overturning the structure. Several boards mounted on a beam will become the basis for transverse structures.

3. Installing round elements in vertical position and connecting them in the upper part with each other with the help of bars, you can start making the outer shell of the bath from the boards. For a tighter connection, it is advisable to use a board with a selected quarter.

4. In internal partitions and end walls, it will be necessary to provide for the presence of openings for the subsequent installation of windows and doors.

5. Additional rigidity of the structure will be provided by its screed along the circumference using a galvanized metal strip.

6. In order to protect the bath-barrel in winter from snow, in the off-season, in summer from rain, hail, it is best to cover the upper part of the structure using soft bituminous tiles.

7. To give mobility to the bath, it is advisable to arrange mounting loops in its upper part or provide for the possibility of placing slings under the bottom of the structure.

8. The surface of the walls of the bath-barrel from the inside and outside is subjected to thorough polishing. After that, the walls and partitions are processed with special compounds that protect the tree from high temperature, humidity, preventing the appearance of mold, fungus.

9. It is highly desirable to create an opportunity to drain water from the floor. To do this, it is worth installing a small ladder at the lowest point of the floor with plastic pipe draining dirty water.

10. If the bath will be used throughout the year, thermal insulation of the walls should be performed, including: expanded polystyrene or a dense mini-plate, reflective foil layer, vapor barrier. On top of the heat-insulating layer from the inside of the bath, a wooden lining or board is stuffed.

11. After the completion of installation, finishing work, it is allowed to proceed with the installation of doors and windows. In parallel, you can start creating power supply systems, ventilation to remove excess moisture.

12. The final stage implies the arrangement of the internal space of the bath-barrel - the installation of furniture: wooden shelves, benches, benches, a table, a wardrobe, a tub for water, fixtures for lighting fixtures.

Helpful information

Bath barrel can only perform the function of a steam room (sauna). However, many users wish to be able to exercise water procedures after visiting the steam room. As a result, it is desirable to organize a water supply or equip a small polypropylene pool outside.

The furnace for a bath-barrel can be either electric or powered by various kinds fuel (wood, gas, etc.). The installation of a furnace structure requires the construction of an efficient chimney. Particular attention must be paid to the fire protection device at the junction with wooden walls.

In the steam room, it is worth attaching thermometers to control the most comfortable temperature.