Sealing of external doors. Rubber door seal for doors: characteristics, photo. Installing a seal on a metal door

If you begin to notice that a draft has appeared in your apartment, or an unpleasant smell has begun to come from the entrance, this is a signal that a door seal is required. Such a problem definitely does not bypass those people in whose apartment a metal door is installed. For this reason, we suggest that you consider how you can fix or prevent the problem by sealing the door yourself.

Sealant selection and classification

Often, metal doors do not cope with their main role, namely the preservation of heat in the house. Although these doors are insulated, the result often leaves much to be desired. You can choose a special sealant that can solve the problem of drafts and unpleasant odors coming from the entrance. There are a large number of sealants that differ in type and method of application. For example, some are glued around the entire perimeter of the door. If the door has a double porch, then the seal is glued to each of them. At the same time, it is recommended to choose a heater in each individual case individually. So, for example, if you buy a very thick sealant, then it can cause obvious problems. Conversely, a very thin material will not give the desired result.

Seals for metal doors are classified according to several technical characteristics.

- Material type. It can be foam rubber, plastic, polyethylene foam, rubber, silicone.

- Design. The seal can be equipped with a clamping metal rail or made from one material.

- Mounting method and system. Seals are either self-adhesive or self-tapping. As for the latter, special strips can only be installed on wooden doors.

If you have a desire, then the seal can be made independently. To do this, you can use foam rubber, after wrapping it in artificial leather or leatherette.

For metal doors, seals are sold in rolls. One roll can be up to six meters. If the door is standard, then one roll will be enough for sealing. Remember that for metal doors it is best to buy a self-adhesive seal.

Sealant for metal doors

The choice of sealant will directly depend on the size of the gap that needs to be eliminated. For example, if the gap at closed door is from one to four millimeters, then you can purchase a rectangular seal, for example, from polyethylene foam, PVC, foam rubber. But in most cases, rubber seals are used for metal doors. They may have different forms, the cross section of which resembles the letters of the Latin alphabet:

- C - the profile is used for those slots that have a thickness of up to three millimeters.

- K - the profile is similar to the first.

- P and V - the profile is able to eliminate gaps with a thickness of three to five millimeters.

- O and D - the profile is mounted in those doors where the gap has a thickness of up to seven millimeters.

Seals are available different colors. This allows you to individually match the color to your door. So, the aesthetics of the doors will not deteriorate in any way. The most common colors are white, black and brown.

Note! According to some studies, the dye can reduce the quality of rubber. For this reason, it is best to sacrifice aesthetics and stick on a standard black seal!

The main requirement for all seals is the sealing of the door. Based on this, the seal must meet high standards. The seal must be waterproof and airtight, must provide excellent shock absorption of the door leaf when it is closed and slammed. When closing a metal door, a light and soft click should be heard, and not rattling and noise. Among other things, the sealant should not freeze and harden in the cold. Regardless of the conditions in which it is operated, the sealant must retain its basic characteristics under any circumstances.

Mounting on a metal door

If you have a branded door, then the manufacturer makes a profile in which there is already a specially designated place for laying the seal. From the point of view of tightness, such metal doors are the most reliable. Therefore, when buying them, pay attention to such a detail.

In the event that you do not have the funds for such a door, the seal should be purchased and installed by yourself. Using self-adhesive tape, this is very easy to do. The most important thing is to choose the appropriate thickness. We talked about this above. Gluing the seal is quite simple. Wrap plasticine in polyethylene and place it between the door and the frame. Then close the door tightly and open it. As a result, you will get a finished cast of the required thickness. As for the sealing sticker, do not rush to immediately remove the protective layer from the entire tape. As the film peels off, glue the seal to the frame. At the same time, press it firmly.

Note! In the event that the seal peels off after a few days or weeks, then glue it with Moment glue.

Wooden door seal

For such doors today it is customary to use a variety of floor rails. They allow you to prevent the appearance of drafts or get rid of them altogether. There are several types of them.

- Wedge plank.

- Plastic tube.

- Plastic or metal strips with a brush, etc.

Consider how to properly install them.

Installation of the wedge strip. The plank must be cut to fit the top of the doorway, as well as the sides of the two sides. At the joints, the strips are cut at an angle of 45 °. In places where there are hinges and a door lock, the bar must be cut. Further, she is nailed. All work will not take you much time.

Installation of the outer bar. The bar, as in the first case, is cut strictly according to the dimensions of the doorway. But only now the bar is screwed on with screws. After its installation, a sheet of paper should fit between the closed door and the plank.

As for sealing the bottom of the door, a slightly different technology and method of using slats is used here. The flashing strips are stuffed to the inside front of the door. It should be noted that there are also several types of slats, each of which has distinctive features.

Flat threshold rails. They are made of plastic or aluminum base. On them, in turn, a rubber plate or brush is attached. They can be used for both external and internal doors.

Planks with plastic shield. They prevent moisture from entering the room. In most cases, they are used to seal the outer door.

Combined rails. They consist of a metal bar as well as a nylon brush. The bar is fixed to the threshold, and the brush to the door. The bar on the threshold prevents the penetration of water into the room, as it has a special groove.

So, some features of the installation of such strips.

Installation of a flat threshold bar. Previously, the bar is cut to the width of the doorway. After it is screwed to the bottom of the door. This bar should be as close to the threshold as possible. But it should not interfere with the free opening of doors. Some types of such slats are equipped with special holes for screws, which makes it easy to adjust them.

Installation of a combined plank. In this case, as in the first, the bar and brush are cut off along the width of the threshold. The plank is screwed to the threshold, with the overhanging edge of the plank facing the inside of the door.

As for the installation of the brush, after installation it should exert a slight pressure on the bar. The brush is screwed to the bottom of the door with self-tapping screws.

Mounting the rail on the outer door. Similarly, as in all other cases, the bar is cut to size. The bar should be screwed to the door when closed. It is very important not to use screws that can rust - this can cause the doors to rot.

So, we have considered the main methods of sealing both metal doors and wooden ones. If you know other methods of sealing doors, then write about it in the comments to this article.

Video

Insulation of doors with a seal:

Although metal entrance doors and cast in special molds, but their surfaces are not ideal, especially for the edges of the door leaf. You can observe a poor fit to the box, slight distortions from different sides, and all this can lead to the penetration of cold air, unnecessary noise and even unpleasant odors.

To spare metal door from these shortcomings, it must be pressed tightly against the jamb, and in this the best helper of the home mater will be a special sealant.

Why seal the door

- From the penetration of excessively cold or hot streams of air masses;

- From the occurrence of the effect of a draft - a dangerous phenomenon that causes ailments in households;

- For a better fit of the canvas to the door frame. This is a kind of latch that protects against the play of locks, and if the door is constantly, as they say, in free flight, then in the end the key will not be able to get into the keyhole.

What basic requirements should a high-quality seal for an iron door meet?

- Possess exceptional hermetic qualities;

- Ensure a smooth running gear - it is good to help opening and closing;

- Provide breathability and be a good door shock absorber;

- Withstand sudden changes in temperature;

- Be elastic and pliable - do not harden or soften from any impact.

On the video - a seal for the entrance metal door:

What is used for the front metal door

There are several types of sealants on the market of building accessories, which differ in the following indicators:

- Type of production material. The most common are products made of rubber cloth, silicone base, plastic mass, foam rubber bands or products made of polyethylene foam material;

- According to the fastening method. This group includes self-adhesive webs, magnetic or pressure, special glue is applied to one side, or installed on additional fasteners.

Usually all material is sold in rolls. running meters, must be attached detailed briefing for installation.

Most requested types

Which one is suitable for Chinese metal door?

If you have a Chinese front door installed, then at first it will function well, but over time, you will notice some dents around the entire perimeter, and cold air from outside begins to seep through them. This can happen because the metal itself is of poor quality, it does not have the properties of real steel - strength and strength from any physical influences, and the door frame is wrinkled from frequent slamming.

To fix the situation - do not buy the same new design iron door, first carefully inspect it, measure the perimeter of the door leaf. According to experts, the best insulation there will be a rubber model, you can even with a profile. If not found the right material, you can try to purchase a soft, but thin self-adhesive foam rubber tape, it will perfectly wrap around the entire canvas around the perimeter. But for reliability, apply an additional layer of glue to the contours, you can take the same silicone construction, which is intended for such work.

On the video, replacing the seal on the front metal door:

Application (how to glue)

The insulation material itself should be installed on the metal door frame, but not as tightly as possible. This will provide the best fit, which will affect the thermal and sound insulation properties. Moreover, the position installed door does not play a role, in any case, it is possible to glue the insulation exactly along the perimeter of the door jamb.

If you have a rubber or foam version, adhesives such as Moment are suitable, and other types also adhere well to it.

Before starting work, you need to properly degrease the base for the glue, it can be any solvent or alcohol-based product.

On the video, how to glue a rubber seal to a metal door:

First, apply a thin layer, spread it a little with a spatula and leave to dry for 10 minutes. Then do the same with a strip of insulation, degrease and apply a thin adhesive layer, and leave for the same time. As soon as the layer dries a little, you can install a strip around the entire perimeter, and press it hard. Wait for the result for about 15 minutes, and you can lock the door with a key.

Sealing tape carries not only the function of protecting the home from drafts. In the fight against extraneous sounds coming from the street, the sealant can also play an important role. When choosing, you should pay attention to several aspects: the types of seals, the materials from which they are made, and also use tricks that will help you choose the right door insulation.

Functions

The most important function that a sealant has is draft protection. If the device does not cope with this task, it is a priori of insufficient quality. This is especially true for entrance doors: thermal insulation in this case is extremely important, and only a sufficient level of insulation can provide it. An important heat-insulating function "works" in both directions, at the same time protecting the apartment from cold wind from the street or from the entrance and preventing heat from escaping from the home. It is estimated that doors not equipped with a seal release up to 40% of all heat generated by heating appliances. Heating prices are currently quite high, so no one wants to waste precious heat.

Speaking of thermal insulation, it is impossible not to mention that a number of products can withstand significant temperature fluctuations. The amplitude can vary from -65 to +95 degrees Celsius. Thus, by installing high-quality insulation on the front door, you can not worry that it will crack in summer or winter.

Another plus of the sealant is its soundproofing properties. They are inherent both for metal water doors and for interior doors. It happens that the front door exits just next to the road or the playground, and the insufficient level of sound insulation does not allow residents to feel comfortable enough, because annoying sounds from the street greatly interfere. If the rooms are not well insulated from each other, then another problem arises: the impossibility of each doing his own thing without the risk of interfering with the other. Good sound insulation makes situations comfortable when, for example, they play the piano in one room and read in another.

Cushioning properties - another important factor. Everyone has come across a situation where, in the summer, due to open windows drafts walk around the house, and the doors close with a strong bang, disturbing not only the residents of the house, but also their neighbors. The sealing tape hides an unpleasant sound, preventing the creation of annoying pops, as well as extending the life of the door and door frame (due to sudden slamming, they wear out faster).

The seal well protects the house from unnecessary odors or smoke. For example, something might burn in the kitchen. No one wants the “aroma” of burning to instantly spread throughout all the rooms, so the insulation will help keep the smell only in the kitchen. The same can be said about the door to the bathroom: it is better to leave wet steam directly within the bathroom and not let it out into the hallway or corridor.

Thus, the main property that the door seal carries is the sealing of the door leaf. In the Russian climate, this property of the door is extremely important due to strong temperature fluctuations on the streets. Moreover, you should carefully consider the choice of product if you live in a big noisy city, because many metropolitan areas are very busy both day and night. It is for such "sleepless" cities that doors with seals for enhanced sound insulation are well suited. When choosing a door to the kitchen, you also need to make it as airtight as possible, because it is far from always appropriate and pleasant when food smells are heard, for example, in the bedroom.

Kinds

Seals are classified according to several criteria. The first of these is the type of door:

- For entry doors. The seal of the porches for entrance doors is usually made tubular. The profile with a cavity inside completely ensures a sufficient fit of the door, contributing to complete isolation from external influences.

- For interior doors. There are completely different requirements here: there is no need for such a strong protection of the room from the environment, the aesthetic component comes first. In some cases, isolation is important (for example, in the bedroom), but not necessary.

- For plastic doors. Seals for plastic doors are placed in a separate category, since they differ significantly from seals for ordinary doors. It is necessary that the groove element reacts well with environment. As a rule, such seals are placed on balcony doors. Please note that, as a rule, only such a part is suitable for a plastic door, which is produced by the same manufacturer as the door itself.

- For glass doors. The profile, which is attached directly to the glass, can be aluminum or silicone. Silicone elements must have a special section, they also serve immediately as a heater, while on aluminum profile you need to make a special seal of rubber. The silicone glass seal is suitable for rooms with high humidity, as there is no risk that it will “leave”.

According to the materials, the following types are distinguished:

- Rubber.

- Silicone.

- Foam rubber.

- Magnet.

- Thermoplastic.

- Felt.

By configuration, the following types are distinguished:

- Tape. It is a soft cord with a rectangular cross section, the width of which is approximately 9 mm.

- Tubular. Despite the fact that a tube seal is most often used for entrance doors, it boasts less sealing properties than tape models. It is a hollow tube inside, which is pressed when the doors are closed, due to which there are no gaps between the door leaf and the frame.

- Slotted. It is made specifically for plastic doors, it is a hollow profile made of soft rubber, on one side of which there is a special brush installed in the grooves. Thus, the impact of the external environment on the seal is reduced and is almost completely transferred to the door leaf itself.

- Spring. Attached to door frame and not to the door. When closing, its parts slide along the spring and close the gaps. Only suitable for mounting on perfectly flat surfaces.

- Mortise. Made for wooden doors. Under such a seal, a small niche is specially cut out in the door frame, which allows you to tightly fit the door leaf in the future. A rubber profile is attached to the niche.

- Folding. Suitable for sealing folding doors, bellows and similar structures.

Tape seals are rarely made wider than 10 mm. This is due to the fact that such a width is optimal both for attaching around the perimeter of the door leaf and for the door frame. Tubular options generally have the same characteristics, regardless of what material they were made from. The size of the seal for a plastic door depends entirely on the manufacturer. It often happens that for each specific model doors, only one model of seals is suitable, and there is no way to replace it with an analogue. It is recommended to pay special attention to this issue when choosing a door, whether it is possible to replace parts with those purchased from another manufacturer, otherwise it may be necessary to change the entire door during repairs.

A complex rubber profile remains a universal choice, suitable for both interior doors and entrance doors. It is released in various options, can be made of soft rubber or more dense, the width of the profiles is traditionally 8-10 mm.

- foam rubber it is better not to use the element for front doors and save it in case interior structures. The fact is that foam rubber is not the most durable material and simply will not withstand the kind of exploitation that the front door is subjected to. Foam rubber is quite cheap, while it tolerably copes with the basic functions of a sealant. It is best to use foam inserts for doors that are subject to little use, for example, to the hall.

- Unlike foam, magnetic constructs are used only for entrance doors. The magnetic inserts on the soft rubber profiles guarantee the best fit of the seal, so that protection against drafts or heat leakage from the house is guaranteed. Problems can only arise with the installation of elements, they must be matched exactly to the size of the door, otherwise the magnetic protrusion simply will not allow the door to close.

Another relevant option is colorless heaters. Many people think that they are a good solution only for glass doors, however, this is far from the case. A transparent seal looks great on wooden, plastic, and metal doors, since it is practically invisible. Thus, it can be used in cases where the owner is afraid to spoil the aesthetic appearance of the door or if, from a stylistic point of view, the use of a seal is inappropriate.

According to the invoice, the following types are distinguished:

- Flexible. Smooth or flexible profiles can be made from a variety of various materials, including rubber, silicone, magnet.

- Liquid. Usually used for insulating front doors. It is a kind of liquid foam rubber, which, under the influence of pressure, is applied to the desired areas.

- Pile. The fleecy version is very familiar to many, since it was felt that was originally the only alternative for making door insulation. At this stage in the development of the repair business, a tourniquet and tape are produced not only from pure felt, but also from synthetic fleecy fabric.

Location options are as follows:

- Threshold. They are a good solution in cases where the design of the door does not provide for a threshold. It is mainly done on automatic control, which allows the profile to "adjust" to the width of the gap between the door and the floor in the open or closed position.

- Contour. Contour options are the easiest to understand. They are attached around the entire perimeter of the door leaf or frame, while simultaneously eliminating gaps everywhere. Most often used for entrance doors, a triple profile is taken.

- Firefighter. A similar thermally expanding option is a substance that, when heated strongly, turns into foam. The foam completely seals the door, preventing the passage of smoke and preventing oxygen from reaching the source of ignition.

Dimensions

Depending on the type of sealant, its dimensions also vary. Also optimal size depends on the gap, on how thick it is. The overall footage also plays a significant role. door structure, as well as features of the purpose of the door. For example, entrance doors require thicker and wider insulation. Flexible rectangular profiles are sold in large rolls, the footage of which depends only on the manufacturer. They are great for eliminating narrow gaps that do not cause much discomfort to the owners of the door.

In some cases, rubber profiles of complex configuration are used. They are suitable for ordinary doors, and even for heavy armored doors. Each of the profiles has its own special shape: C, P, O and so on. Each of the shapes is designed for slots of certain dimensions, however, remember that these profiles serve to insulate gaps 1-4 mm wide, but some shapes are good for insulation and larger slots.

- Profiles of forms C, K, E are suitable for masking small gaps, the size of which does not exceed 3 mm.

- Forms P and V will do an excellent job of masking lye up to 5 mm.

- Less commonly used profiles O and D, which allow you to work with gaps up to 7 mm.

When calculating the required amount flexible profile to insulate the door, keep in mind that you will definitely need at least 5-6 m of material. It is always better to take a soft seal with a small margin, since if a part of the installed profile suddenly deteriorates, it can always be quickly changed. Rigid seals are made directly to the size of the door. As a rule, independent measurement and acquisition causes certain difficulties, so it is better to turn to professionals with this issue. There is only one seal on the market that requires such a delicate selection - this is a magnetic option.

Seals differ in thickness. Soft thin profiles are selected for interior doors, while entrance doors need more impressive insulation. Thick rubber profiles, often multi-layered, have impressive dimensions compared to miniature interior samples. Thus, when choosing a seal of the required size, it is imperative to focus not only on the type of seal, but also on the functional purpose of the insulated door, on the size of the existing gaps. Pay attention to where the element will be attached: around the perimeter of the door frame or directly on the door leaf. Traditionally, thicker options are mounted on the door frame than on the door itself, since when installed on the door frame, there is little risk that the door simply will not close.

Which seal material is best?

At the moment, a huge range of materials from which door seals are made is presented. After reviewing the characteristics of each of them, you will be able to determine exactly which option is right for you.

- Rubber sealant, perhaps the most popular today. This is due to the versatility of the material, since it tolerates temperature extremes, high humidity and other negative effects. So that bacteria do not multiply at the joints or a fungus does not appear, the rubber is pre-treated with a special compound that prevents the activity of bacteria and disinfects the surface.

- Silicone option is a good alternative to a rubber seal. Mostly silicone is used for insulating glass doors, since it is tightly glued to the glass, one has only to moisten it with water and let it dry. Silicone does not crack under the influence of strong temperature changes and does not come off glass. Silicone elements are much better than rubber ones, they are suitable for rooms with high humidity, such as a bathhouse, sauna, bathroom.

- A special place is occupied by modern TEP seals. They are distinguished by the ability to adapt to extremely high or extreme low temperatures. Sometimes the spread can be more than 100 degrees - from -70 to +95 degrees Celsius. The European formulation of thermoplastic elastomer guarantees high reliability, long service life, good resistance to impact loads, and low profile deformation during operation.

- Felt is the most traditional and familiar material from childhood. Due to the fact that felt is still made from natural wool, it protects the room well from the cold and is on the list of leaders largely because of this. During the entire service life, felt insulation does not lose its original properties, well enduring Russian harsh weather realities, and saves heat. Contrary to popular belief, felt is completely fireproof because it has a very dense structure that makes it difficult to burn.

What are the colors?

To date, seals are produced in mass color solutions, which include not only classic black or white. It is possible to choose the necessary model for the door of any shade, be it a balcony plastic sample white color or a bright door to the nursery. However, it is the white and black variants that are used greatest success at consumers. White models are selected mainly for plastic doors when the owners need to decorate some cosmetic flaws. Also white seals look good on interior options, while on the front door it is unlikely that a white element will look appropriate.

For the front door, on the contrary, black insulation - best solution. Black models go well with almost all types of metal doors, and this fact should be taken into account. In addition, painted rubber insulation for entrance doors do a worse job of their functions, since the paint significantly changes chemical composition material. The same can be said about balcony doors from plastic. It is best to choose a black sealant, it will protect the living rooms as much as possible from drafts from the outside.

There are a lot of color models. There are no texture swatches or patterned options, but color choices are virtually unlimited. The most popular is the whole range of brown shades, since seals are often selected for wooden doors, and people try to choose them so that they are as invisible as possible on the door leaf, and do not spoil the overall impression. Please note that often, for a relatively small fee, they offer to immediately supply the door with a suitable seal of the desired color. As a rule, this option is more preferable, especially if you know in advance that you need to install such a semblance of a slot cover. The decision to buy a door with a ready-made sealing element will greatly save you the time and effort that you would have spent searching for, and it will not hit your budget too much.

Whatever color seal you choose, remember that the overall appearance of the room and the door separately must remain harmonious, however, it is much more important that the selected sample does its job well.

What are they fastening?

There are several options for attaching seals. Each of them is determined by the type of fastening that a particular option is equipped with.

- Groove installation. Profiles for fastening in a groove are equipped with a special fastening-brush. You don't need to install Additional materials, however, this does not make the installation of such elements the easiest. The main difficulty that most people have when working with groove seals is fitting them to required size. It should be understood that rubber is a material that stretches easily and takes its original shape just as easily, therefore, when cutting or pressing directly into the groove, you cannot pull the product directly into the groove, on the contrary, you should “pick it up” a little. The cutting of the groove seals should be carried out after they have been installed in place, otherwise there is a high risk of cutting off the excess, and this will inevitably negate the entire effect that was planned to be obtained due to the installation of the elements.

- Self adhesive option. Usually installation with self-adhesive tape causes the least difficulty. As in the previous case, the only equipment you need is a paint knife, which, after gluing, needs to cut the insulation to desired length. Most important place V preparatory process surface preparation takes: it must not only be well cleaned of dirt and dust, but also thoroughly degreased. Traditionally, the tape is glued from left to right and from top to bottom, that is, on the sides, pasting must begin from the top corner. Gradually, little by little, the protective layer is removed from the sticky side of the seal, the tape, without stretching, is fixed on the surface, and only after it is completely fixed, you can again release a little adhesive tape and fix it further. The step is approximately 10 cm.

- For nails or screws. This option has not been very popular lately, since duct tape or glue is a good alternative to nails. In some cases, it is impossible to install a self-adhesive sample (for example, if the surface is uneven or the sealant is too heavy), and then traditional nails are remembered again. The distance between the nails is 5-7 cm, it is not recommended to install fasteners less often, as sagging may occur through which cold air will enter the room. When installing the insulation on self-tapping screws or nails, you need to act very carefully, because if the hats are not deepened enough, the door will close with difficulty or not at all. The option is mainly suitable for entrance doors, and in the case of interior doors, it is better to do without a sealant at all than to choose a nail mount.

How to choose the right door heaters?

- For wooden door log house a good solution would be to use silicone insulation. Pay attention to how easy it is to replace one model with another. Wooden houses over time, they "sit down", and after a few years, the door will be hard to close, then it will be necessary to replace the existing sample.

- For wooden doors in ordinary houses, installation is very popular. mortise seals, which are almost invisible against the background of the door. If possible, it is recommended to choose this particular contour option, as it will provide you with good sound insulation, and if the door dries out, the seal can be simply removed without harm to aesthetics.

- It is imperative to select a sealant to match the door structure so that it looks as organic as possible against the general background and does not spoil the whole look.

How to fix the door seal, see the video below.

The level of protection of the house from street noise and cold is affected not only by the quality of the entrance doors, but also by the material that contributes to their tight fit to the box. The absence of gaps creates good tightness, preventing drafts from roaming: in this case, sounds and smells from the outside will not be able to penetrate inside the house.

The classification of materials for sealing doors is carried out according to some basic characteristics. First of all, we are talking about the dimensions, material of manufacture and types of doors for which this seal was developed.

For example, wood and iron doors are issued different types tapes, although outwardly they are very similar. To choose the right equipment for your door, it is important to navigate this classification.

Helpful information:

Sealing tapes by types of doors

For each individual variety, its own sealant was developed.

Input

Most often, the finishing of entrance doors is carried out with a dense material in the form of a tube, inside of which there is a void. Significant thickness and bubbling of the material create a secure fit of the door to the frame. How to choose reliable and warm doors to the house.

Of particular interest is the internal structure of these rubber bands for door insulation. Due to the presence of internal pores, a multiple increase in the warming effect is achieved. Most often, the seal for the front door has a self-adhesive base, which makes its installation very fast.

On the other hand, over time, the adhesive loses its characteristics, and the strips begin to lag behind along the perimeter. You can.

Interroom

The seal for interior doors is not assigned the function of protecting the room from the cold outside, as in the previous case.

This allows you to make it more aesthetic by using more elastic and soft silicone instead of dense rubber. The method of installation of these products may differ, as will be discussed below.

If during the repair process you decide to change the doors, then be sure to read.

Plastic

This group of materials is characterized by a high rate of laying and dismantling. On plastic doors grooves are usually applied along the line of contact with the box, so the seals are given a special shape that repeats the configuration of these grooves. Due to the presence of walls on the sides of the fixing point, the sealing strip receives additional protection from external aggressive influences. The sealant for plastic doors is not afraid of moisture and temperature changes, so it can be used both outdoors and indoors without much difference. interior doors. It is important to keep in mind that this rubber seal has been designed specifically for grooved plastic doors, so it is not recommended to seal other types of doors with it. In addition, different manufacturers complete their plastic doors with individual seals: this should also be clarified when selecting a suitable material.

glass

In the manufacture of a sealant for glass doors, silicone is used, equipped with a special profiled notch. During the installation of the strip, it is necessary to first moisten the area where it will be placed: this will make the connection as strong as possible. Since the design of glass doors can be very different, therefore, a special seal is developed for each of them.

What are door insulation made of?

In order to choose the most suitable door seals for your home, you should also be guided by the materials of their manufacture.

Rubber

Most often, entrance doors are equipped with a rubber seal. Moreover, the material of manufacture is not simple rubber, but its modified varieties that can withstand the most extreme conditions operation, including severe frost and heat. Besides the draft.

Silicone

The performance characteristics of silicone products are slightly lower than those of rubber. This is due to the fact that silicone cannot be given additional resistance to aggressive external influences even by introducing appropriate additives into its composition. For this reason, silicone liners are mainly produced for wooden doors. interior type which are operated in comfortable conditions.

Foam rubber

It is the material for the manufacture of the cheapest door insulation, which fails within one year. The reason for this can be temperature fluctuations, dirt and moisture, which provoke crumbling and disintegration of foam rubber. The material gradually loses its original volume, which affects the functionality of products made from it.

Magnet

An innovative development, with the help of which expensive metal doors are mainly completed. The average layman is familiar with the magnetic sealant from household refrigerators and freezers, in which permanent magnets along the perimeter of the doors are attracted by attraction poles. Most often, metal doors are equipped with three-circuit magnetic seals. The location of the two circuits is the door leaf itself, while the third is mounted on the door frame. The main disadvantage of such products is a rather high pressing density, which a child or child will not always be able to cope with. old man. If the action of the magnets is weakened, then proper tightness and sound insulation will not be provided.

Advantages of a magnetic door seal

Soft filler is made of thermoplastic, which is characterized by the following advantages:

- Considerable service life.

- Persistent transfer of sharp temperature fluctuations (from -65 to +95 degrees).

- Opportunity recycling after loss of performance.

Felt

Usually they are made out with a felt seal. Such tapes cannot provide special protection against noise and cold. They are used solely to prevent dust from entering the cabinet or room.

Basic ways to install door seals

When starting to install a door seal, the first thing to do is to find out what type of product you have to deal with. This will allow you to choose the most optimal way to glue the seal. The most common sealing gum grooved and self-adhesive types.

Groove seals

The installation of this material is very simple, so it is most often used for self-repair of doors. The most difficult moment of laying the seal for doors in the groove is finishing the corner sections. Beginners are advised to use accurate trimming of the material. More experienced users achieve continuous laying, without docking sections. The latter option is more preferable, since the level of door sealing in this case is an order of magnitude higher. However, to implement it, you will need to show some skill. Door seals on the bottom are equipped with a special edge on which there is a brush: such a structure of the material contributes to a fairly quick installation into the groove cavity.

In the course of laying both rubber and silicone seals, it is important to avoid even minimal stretching of the tape. Otherwise, an unacceptable voltage is formed inside the sealing layer, which will affect its performance. No matter how high-quality silicone or rubber is, they will gradually stretch, losing their original volume and elasticity. Experienced craftsmen, when laying the seal in the groove, try to compress it slightly, which significantly extends the life of the door insulation. Trimming of excess parts is carried out upon completion of laying. It is more convenient if only one edge of the rubber or silicone tape is left for trimming: in this case, the remaining segment is longer and can be used to insulate another door.

Self-adhesive seal

Laying such material also does not have any particular difficulties, although several useful tips should be taken into account. In order for the self-adhesive rubber seal to stick to the seat with high quality and for a long time, it should be pre-prepared. This procedure includes several steps. Firstly, all dirt must be removed from the surface of the door: this is done not only along a narrow installation area, but by some expansion to the sides. For these purposes, soapy water or detergent is usually used.

Special scrupulousness will require preparation wooden surface. It should not be too moistened - it is enough to wipe it thoroughly with a damp cloth. If the seat has roughness, protrusions and irregularities, they must be eliminated. In this case, the operation technology also depends on the surface material. For example, wood can be lightly sanded and puttied; for a metal or plastic surface, a gentle grinding will suffice. Individual protrusions can be carefully removed with a chisel or sandpaper. After the area for laying the sealant is cleaned and washed, it must dry completely. Sometimes, if the work is carried out in a closed room, or when it is necessary to speed up the process, a regular hair dryer is used to dry.

Before gluing the seal on the door, it must be degreased. When choosing a degreaser, it is important to consider the surface material. Most often, this procedure is carried out with white spirit, acetone or ordinary alcohol. However, it should be understood that all these agents are toxic and explosive, and they should be handled very carefully. It is better if it is possible to ventilate the premises well after application.

Useful advice: in cases where the seal is laid where people are at that time, it is better to use a special low-toxic emulsion or an aqueous alkaline solution for degreasing.

As for the direct laying of a self-adhesive sealant, this procedure is not particularly difficult. All that needs to be done is to release the lower part of the material from the protective film, and carefully lay it along the edge of the door. It is more convenient to remove the entire film not at once, but in segments of 10-15 cm, immediately mounting the freed area on the seat. At the same time, it must be pressed tightly against the surface of the door, achieving high-quality gluing. A similar algorithm of actions is maintained throughout the entire procedure. It is more convenient to start work from above, and when you reach the bottom edge of the door leaf, cut the rubber band with a sharp knife or scissors.

The second article from the series "Entertaining plumbing". As I promised, I'll tell you about the installation threaded connections. Further more interesting!

Dmitry BelkinSeals for threaded connections of water pipes - choose the best

And since the question of glue remains open, the tape has more disadvantages than advantages, the thread is terribly expensive and this is also not its only drawback, you have to use linen, in which the balance between advantages and disadvantages is quite decent and outweighs more towards advantages. Furthermore! I suggest novice plumbers not to suffer and choose flax for work. Do not worry! It is modern, reliable and very honorable. Let me remind you that I myself was worried about this, but a professional plumber very successfully reassured me on this subject.

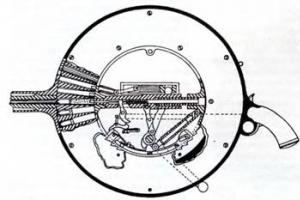

Thread sealing principle when using different sealing materials

I would like to "load" readers with a fair portion of information about the principle of sealing threads in water connections. I am sure that many do not even suspect that each material has its own sealing principle, that is, it is completely different from others.

Notice! I am not writing a textbook here, but I am reporting my observations to you. If you think otherwise, please comment. Registration is not required for this.

Tape sealing principle

We wind the tape on the thread. We make it tight. The denser the better. But if the tape is pulled hard, it stretches (another drawback). Since the tape itself is soft and, it seems to me, that it also melts when the thread is tightened, the tapes must be wound not a little, but not too much. Unfortunately, when we start to twist our parts, the sharp ends of the thread cut the tape into a rather thin noodle. Care must be taken to ensure that all the noodles remain in the thread grooves and seal them properly. No lubrication is needed for the belt. It is slippery in itself and when twisting, I usually cannot determine how well (tight or not) the thread is connected, that is, the connection is twisted as if there is no seal, or there is too little of it. This circumstance also does not at all contribute to my sympathy for the tape.

Attention!

The principle described above may not be the only one and not the most correct one possible. Look at the comments. There is a tape lover's opinion. The reader tells us how to use it correctly and economically.

Thread compaction principle

When compacting with a thread, the principle of use is fundamentally different from other materials. We do not wind it into grooves. It is wound across the thread. The instructions for the thread say so - "Make sure that the thread does not fall into the grooves." The thread is thin, very strong, and coated with a material that makes it look a bit like ribbon. I think it's polystyrene or something like that. When twisting parts, the thread does not break with a thread (it should not break), because it is very thin and, as it were, lubricated. Moreover, the fact that the thread lies across the grooves does not allow it to unwind, and, very importantly, to spin in the thread. What do I understand by this? The fact that if the thread lies in the grooves, then when we wind anything on our pipe, say a coupling, the thread will spin along the pipe thread together with the coupling and will not seal the thread, but will come out from under it. As a result, we will get a not very reliable connection, since it is quite possible that only one or two threads will be sealed. And the rest of the thread will simply unscrew from the thread in the course of winding the coupling.

Of course, winding the thread across the threads of the thread is a kind of breakthrough. But in the same way, this imposes on the plumber a certain duty to ensure that the winding is very uniform. If the thread will often lie on the thread (on past turns), it will give too thick a seal, which will either be cut when winding, or wrinkled, and then the result is generally undefined. It can be said for sure that the ability to wind the thread across the grooves is the MAIN difference between the thread and other sealing options.

Adhesive sealing of threads

I believe that it has practically no flaws. There is only one question. Do such adhesives actually exist, and if so, what is the technology for their use. It seems very likely to me that these could be hot melt adhesives, that is, they soften at a certain temperature. Again, adhesive threads are the realm of fantasy, since I have never seen such adhesives. Well, in general, there are questions about the environmental friendliness of such glue.

No fantasy!

For first-hand information, namely from professionals who have dealt with sealants and adhesives, see the comments.

Linen seal.

When compacting with flax, we twist a thread of the required thickness and wind it into the grooves of the thread. Of course, flax can unscrew along the thread according to the process that I described when I talked about the thread. In order to prevent this from happening, we need to lubricate the surface of the flax so that the coupling (for example) is screwed onto our threads stronger (tighter). Then the friction between the flax and the pipe will be greater than the friction between the flax and the coupling. This will allow the sleeve to firmly seal the flax into the thread grooves. It is this approach that ensures the primacy of flax when used by professional plumbers. But you need to choose the material for lubrication well and correctly.

My personal take

You know, when I learned to combine water pipes, could not find a normal printed manual. He acted exclusively by "poke". It was hard but not too hard. I very quickly found a way to wind flax on a pipe, which I use now. It is likely that it is in general use, because it lies on the surface. Here's how I do it.

- First, I weave a thread from linen, which corresponds in thickness to the thread. There is no guide here. Purely by eye. Obviously, the thread should not fill the entire thread. Then there will be no room for the counterpart of the thread on the part that we will wind.

- Then I wind the linen around the pipe, but not from the end, but vice versa, from the beginning of the thread to the end of the pipe. With the first turn, I try to firmly fix the tip of the linen thread on the very first thread of the thread. But having fixed and properly tightened the first loop, I begin to wind the remaining thread. I wind in the same direction in which the coupling will be wound onto the pipe. It is quite obvious that with this method of winding in one place there will be a transition of the flax thread through the thread of the thread. But it will be only one for each revolution and does not interfere. It is only necessary to carefully monitor that the winding is more or less accurate and there are not very many jumps over the thread. Otherwise, the clutch may cut the flax when winding it up, crush it and push all the flax out. In practice, this is not easy to do. It takes some practice and no rush.

That's all. Then you need to cut off the excess flax, lubricate it and start winding the clutch.

Note!

I bypassed the breakthrough that was introduced by the thread. I also have flax jumps over the thread. And in the amount of exactly one per turn. Thus, the thread does not have a single advantage that it (the thread) can be proud of.

Flax lubricant for sealing threaded connections

Oil paint

But I saw references to lubrication in books. In the books of the Soviet era, flax was proposed to be compacted (lubricated) oil paint. And old plumbers successfully use this method. Oil paint, of course, is something. She first lubricates, and then glues the connection almost tightly. I encountered one of these. I dismantled one heating and cursed everything in the world. Almost every connection I had to heat almost to red. Only then could I unlock it. I note that not everywhere you can just use a hair dryer or a burner like that. There are all sorts of factors, such as wallpaper on the walls, that you don’t want to burn. But it has to.

Silicone sealant

Personally, after I encountered oil paint, I realized that I would not use it. I decided to use silicone sealant. I have personally used it myself in my house for both heating and plumbing. And I liked it. Sealant perfectly lubricates flax. After winding the coupling (for example), some amount of sealant is squeezed out and it can be neatly and even beautifully wrapped around the connection (more precisely, along the side, which is formed by the connected parts). And finally, the sealant has the ability to dry out, which is also very, very nice.

Already after I used this sealant, I read a warning that silicone sealant should not be used in threaded connections. That the sealant is an acid that corrodes the thread completely.

I gladly report. It's a bullshit! As mentioned in the announcement of the cycle, I changed the plumbing, assembled on silicone 10 years ago. When examining the threads with a magnifying glass, I did not find any (!!!) traces of the sealant on the thread. What's more, the threads under the sealant retained their virgin luster! Another thing is that it was not easy to tear off the flax with the sealant from the thread! But even here I very quickly found a way. I cleaned the threads with a dense metal brush. As I said, the threads under the sealant unwinded well and remained virgin, which allowed me to reuse many non-ferrous metal parts.

The next two pictures illustrate the above, namely that the silicone sealant not only ruined the thread, but, on the contrary, made it better. Even the section of the pipe that was exposed to air was worse preserved than the thread under the sealant (in the case of a galvanized pipe).

Modern materials for sealing (lubricating) flax

Remember I told you about my conversation with a professional? So it was he who told and showed me a tube of a special ointment for sealing threaded joints. I bought one and tried it out. I'll be honest. This is something amazing. The effect is simply amazing. I have now forgotten about silicone sealant forever and I have no idea how I used to live and work.