Calculate the profiled sheet for the roof. Calculation and installation of corrugated board. How to Calculate the Total Estimated Cost of a Roof

The profile sheet is very much in demand as roofing material, however, its installation is associated with a certain amount of waste, so it is very important to accurately calculate the corrugated board for roof decking, using formulas or online.

1 Calculator for laying roofing from corrugated board - where do the calculations begin?

Before remembering the geometric formulas for calculating the area of \u200b\u200bthe roof that it was decided to cover with corrugated board, you should select the desired type of profile sheet. All your further actions will be based on the dimensions of the material. First of all, it is worth remembering that corrugated board can be not only roofing or load-bearing, but also wall. If the first two are quite suitable for roofing, then the last type is too thin for this, which is why it does not have a sufficient margin of rigidity.

Consider two materials suitable for roofing and compare with. The main difference is the height of the corrugation, which is the main geometric parameter of this material. It serves as stiffeners, protecting rolled metal from deformation. For wall corrugated board, the corrugation height is insignificant, does not exceed 20 millimeters, the sheets themselves are quite thin, but they can be used not only for wall cladding, but also as a material for a fence, however, rather unreliable.

We are more interested in the one used to cover the roof; this can be not only roofing material, but also a rigid carrier. The height of the "wave" for these types of rolled metal is greater than for wall corrugated board, in particular, for roofing it can be from 35 to 75 millimeters. As for others overall dimensions, then the width of the sheets usually varies from 800 to 1050 millimeters for the roofing corrugated sheet, and the length can reach 6 meters, which is very convenient for covering the roof.

The width of profile rolled metal should be considered only useful, that is, minus the overlap area hidden under the next sheet.

Roof Cover Calculator

Specify all surfaces to cover.| Sheet type | Metal profile |

Necessary: |

| Sheet working size, not full size! |

x cm | |

| surfaces |

Add everything rectangular roof sections L= m H= m |

|

| surfaces |

Add everything triangular roof sections L= m X= m |

|

| surfaces |

Add everything trapezoidal roof sections L= X= M= m |

2

Having chosen a material, you can easily find out its area by multiplying the length by the width, while the height of the corrugation is not necessary to take into account, the main thing is not to forget that we are using the useful width, and not the full one. Often, a six-meter strip of profiled metal is enough to cover the entire length of the slope, from the ridge to the roof eaves. But it is better to verify this by using the formula N = (A + D)/ a, Where N- number of sheets, A- slope length, D- the length of the overhang of the eaves, and a- sheet length. Meaning N rounded up to a whole number.

It is very important not to forget about the overlaps, the length of which depends on the angle of the roof slope. If the slope of the slope is less than 14 degrees, the overlap of the sheets will be 200 millimeters or 0.2 meters. When the angle of inclination is from 15 to 30 degrees, the length of the overlap can vary from 200 to 150 millimeters, respectively. If the slope has a steepness of more than 30 degrees, then the sheets will need to be overlapped to a length of 150 to 100 millimeters. The number of such overlaps corresponds to the value N – 1 . Now it remains to calculate the overlap of sheets on corrugated board, to obtain the footage of the lost profile, we use the formula LP = (N – 1) C, Where WITH- the length of the overlap.

To get a general calculation of corrugated roofing, you can use an online calculator or formulas. In the second case, we need the length of the roof, which must be divided by the width of the corrugated sheet. Then we multiply the result with the value we found earlier N, so we get the number of sheets required for one slope. Now we double and get the result for gable roof. Finally, we multiply everything by the length of the corrugated board, and if you need the exact useful footage, then we subtract the total length of the overlaps we found earlier. The new formula takes the form Lcommon = 2 Nla/ b – LP, Where l- roof length b- sheet width a- the length of the corrugated board.

However, roofs are not only gable, among the roof structures there are also hips, not to mention attic and hipped roofs. There are also complex multi-tweezer designs. In order to calculate the area of the corrugated roof for such roofs, you will need a calculator. But first you need to break the surfaces into simple geometric shapes, such as trapezoids and triangles, and use the appropriate formulas. But be prepared for the fact that when sheathing a hip or hipped roof, you will have a lot of waste when laying sheets along beveled hips.

3

Even the most accurate online corrugated roofing calculator will help you determine just the amount of material you need. But sometimes this is not enough, especially in those years when the country is in an economic crisis. And no program will tell you exactly how you can minimize costs when buying material and laying it. Here it should be immediately clarified that profile sheets with different corrugation heights are produced from the same metal strip in width, and therefore the higher the "wave", the smaller the width of the material. When reducing the transverse size of a sheet of corrugated board, more will be required, in addition, the higher the corrugation, the more expensive the material.

Usually the roofing corrugated sheet H60 is the most popular, but recently H57 has been added to the standard grades according to GOST 24045-94. And many sellers offer the latter, claiming that it is quite identical, because the difference is insignificant, only 3 millimeters of corrugation height. However, the useful width of the H60 sheet is 845 millimeters, while the dimensions of H57 are far from the usual standards, and the useful width of this material is 750 millimeters. That is, such an acquisition will certainly not be profitable.

However, you can still save on dimensions. As mentioned earlier, the lower the corrugation, the closer the characteristics of the sheet to the wall profile, the rigidity of which is not high enough to withstand a large load. However, a sheet with a slight wave is wider, so nothing prevents you from using it for roofing, making the crate more frequent.. In this case, the cost of additional timber crossbeams will be less than the cost of expensive roofing material with a high "wave", which, moreover, will be required.

There is also an opportunity to save on profile sheet waste, which is the greater, the more the shape of the slope deviates from the rectangular geometry. Even if you come across a program for accurate calculation of corrugated board, which will help you cut corrugated sheets with minimal losses, there will still be trimmings. But do not forget about the canopies over the windows and the canopy over front door perhaps the waste can be accommodated there. Yes, and on some outbuildings, you can make roofing from scraps, for example, on a chicken coop, or even on a doghouse.

Choosing a corrugated board for the roof of the house, it is very important to buy the right amount.

Not everyone can do this so that there is not a lot of waste left, and you also do not have to buy material again.

That is why there are certain methods that allow you to calculate the required number of sheets.

You need to familiarize yourself with them before making a purchase, as this allows you to save construction costs in some cases to a significant extent. Also calculate roofing from corrugated board our corrugated roof calculator, which is located just below, will help you.

Roof decking is a metal profiled sheet made of high-strength steel by stamping and protected with special substances. It happens that differ significantly from each other. This also applies to their sizes, which are completely different in order to fully satisfy the needs of customers.

Thanks to the technical capabilities of modern machines, roofing corrugated boards up to 14 meters long can be manufactured at the plants. This allows the client to purchase such materials that, in terms of their dimensions, will be as close as possible to the size of the building itself.

It is a slightly smaller material parameter, since it takes into account that there must be an overlap between the vertical sheets.

Long products can significantly reduce the number of joints, with regard primarily to their horizontal position. This is important because this, in turn, has a direct impact on the tightness of the roof itself. If the length of one slope is less than 14 meters, horizontal joints can be completely avoided.

Profile dimensions

The use of long profile products also makes it possible to reduce material consumption, since short corrugated boards need to overlap each other.

- Most commonly used for roofing corrugated board 6 meters long. This is due to the fact that it is quite simple to deliver it to the construction site, while 14-meter products need to be loaded into special vehicles. smallest length, which reaches a sheet of profiled metal, only 0.5 meters.

- No less important is corrugated board width, the standard size of which is only 1250 millimeters. Often, wider sheets fall on the machine, but taking into account the bends, they lose their width. The higher the corrugation height, the narrower the material itself will be. That is why the profile of the C8 brand has a width of 1200 millimeters, and the H75 brand has a width of 800 millimeters.

Calculation of corrugated roofing: online calculator

With this online calculator, you can calculate not only the amount of corrugated roofing, but also.

Designation of calculator fields

Calculation of corrugated roofing: online roofing calculator.

Specify roofing material:

Select a material from the list -- Slate (corrugated asbestos-cement sheets): Medium profile (11 kg/m2) Slate (corrugated asbestos-cement sheets): Reinforced profile (13 kg/m2) Corrugated cellulose-bitumen sheets (6 kg/m2) Bituminous (soft , flexible) tiles (15 kg/m2) Galvanized sheet (6.5 kg/m2) Sheet steel(8 kg/m2) Ceramic tiles (50 kg/m2) Cement-sand tiles (70 kg/m2) Metal tiles, corrugated board (5 kg/m2) Keramoplast (5.5 kg/m2) Seam roofing (6 kg/m2) Polymer-sand tiles (25 kg/m2) Ondulin (Euro slate) (4 kg/m2) Composite tiles (7 kg/m2) Natural slate (40 kg/m2) Specify the weight of 1 square meter of coating (? kg/m2)

kg/m2

Enter the roof parameters (photo above):

Base Width A (cm)

Base length D (cm)

Lift height B (cm)

Length of side overhangs C (cm)

Front and rear overhang length E (cm)

Rafter:

Rafter step (cm)

Type of wood for rafters (cm)

Working section of the side rafter (optional) (cm)

Lathing calculation:

Purlin board width (cm)

Lathing board thickness (cm)

Distance between decking boards

F(cm)

Snow load calculation (pictured below):

Choose your region

1 (80/56 kg/m2) 2 (120/84 kg/m2) 3 (180/126 kg/m2) 4 (240/168 kg/m2) 5 (320/224 kg/m2) 6 (400/280 kg/m2) 7 (480/336 kg/m2) 8 (560/392 kg/m2)

Wind load calculation:

Ia I II III IV V VI VII

Height to building ridge

5 m from 5 m to 10 m from 10 m

Terrain type

Open area Closed area Urban areas

Calculation results

Roof pitch: 0 degrees.

The angle of inclination is suitable for this material.

The angle of inclination for this material is desirable to increase!

It is desirable to reduce the angle of inclination for this material!

Roof surface area: 0 m2.

Approximate weight of roofing material: 0 kg.

Number of rolls insulating material with 10% overlap (1x15 m): 0 rolls.

Rafter:

Load on the truss system: 0 kg/m2.

Rafter length: 0 cm

Number of rafters: 0 pcs

Lathing:

Number of rows of lathing (for the entire roof): 0 rows.

Uniform distance between the boards of the crate: 0 cm

The number of boards of the crate with a standard length of 6 meters: 0 pcs

Volume of boards of an obreshetka: 0 m 3 .

Approximate weight of the boards of the crate: 0 kg.

Regions of snow and wind load

The amount of vertical and horizontal overlaps

The most important function of a roof is to protect a building from the elements. That is why the roof should be as more hermetic. In the case of roofing materials, this is achieved by laying sheets overlapping each other A. To prevent water from flowing under the roof, you need to adhere to certain material installations.

If for some reason it was not possible to purchase sheets of corrugated board corresponding to the length of the roof slopes, during installation it is necessary horizontal joints will be formed. In this case, it is important to overlap the sheets so that water flowing from above cannot penetrate between two adjacent profiled products in the same row. This value directly depends on the height of the profile itself, as well as on the roof slope.

In the case of using corrugated board of the HC8 brand with a roof slope angle of more than 15 degrees and a continuous crate, the overlap is two waves of the profile. This also applies to material grade HC10 with a roof slope of up to 15 degrees and a solid type of crate. In all other cases, sheets in one row can be overlapped in the amount of one profile wave.

Overlap size

As for the vertical overlap, only the angle of inclination of the roof slope affects it. The smaller it is, the more one profile product should overlap the other.. Experts distinguish the following indicators:

- Up to 12 degrees– 200 mm overlap using a sealant for better protection;

- Up to 14 degrees- an overlap of 200 or more millimeters;

- 15 to 30 degrees- an overlap of 150-200 millimeters in size;

- More than 30 degrees- an overlap of 100-150 millimeters in size.

By correctly positioning the sheets of corrugated board, you can not worry about the fact that water will flow under the roof.

How to calculate corrugated roofing

It is very important to correctly calculate before purchasing corrugated board  the number of sheets it will take to cover the roof well without the additional cost and another visit to the hardware store. The main indicator that must be taken into account when determining the number of sheets is the area of \u200b\u200bthe roof itself.

the number of sheets it will take to cover the roof well without the additional cost and another visit to the hardware store. The main indicator that must be taken into account when determining the number of sheets is the area of \u200b\u200bthe roof itself.

If the slope figure is triangular, you need to multiply its height by the length of the base.

For simpler calculations, it is worth breaking the roof into simple shapes. After determining the area of \u200b\u200beach of the slopes, it must be summed up.

The resulting number will represent the area of \u200b\u200bthe sheets of corrugated board that would be needed if they were installed next to each other. But since the material overlaps, this margin must also be taken into account, both vertical and horizontal elements.

CAREFULLY!

It is also important not to forget to take into account the cornice overhang, which is usually 100 millimeters.

After obtaining the value of the required area of the material, it must be divided by the area of \u200b\u200bone selected sheet. The number that will be the result of this calculation must be rounded up. The resulting number of sheets and should be ordered.

An example of the calculation of roofing corrugated board for a roof

As an example, the calculation of roofing corrugated board can be considered a conventional gable roof with a dormer window on one side. First you need to measure all the initial data:

- Skate length - 6.6 m;

- The length of each of the slopes is 3.2 m;

- Cornice overhang - 0.1 m;

- Size A (length from the side edge of the slope to the dormer window) - 2.5 m;

- Size B (length from the lower edge of the slope to the dormer window) - 1 m;

- Size C (length of the lower edge of the dormer window) - 1.1 m;

- Dimension D (length from the point of intersection of the slopes of the dormer window to the roof eaves) - 1 m;

- Size E (dormer window eaves length) - 2 m;

- Size F (length of the lower dormer windows) - 1.5 m.

This roof consists of 4 elements, the area of the material for each of which must be calculated. The first element is the roof slope where the dormer is located, the second element is the opposite roof slope, the third element is one dormer slope, the fourth element is the second dormer slope. The overlap was chosen to be 0.5 m. The consumption rate of corrugated board per 1 m2 of roofing has the following indicators:

- Element No. 1: total area 21.12 m2 (useful area 21.78 m2, total area 23.36 m2, waste 3.03%);

- Element No. 2: total area 20.46 m2 (useful area 21.78 m2, total area 23.36 m2, waste 6.06%);

- Element No. 3: total area 1.5 m2 (useful area 2.75 m2, total area 2.95 m2, waste 45.45%);

- Element No. 4: total area 1.5 m2 (useful area 2.75 m2, total area 2.95 m2, waste 45.45%).

The data obtained is as follows:

- Sheets 0.9 m long - 2 pcs;

- Sheets 1.6 m long - 2 pcs;

- Sheets 3.3 m long - 12 pcs.

total area running meters for the considered roof was 44.60 m2. In order not to count manually, you can use our corrugated roofing calculator, which is presented above.

Conclusion

A preliminary calculation of the required amount of roofing material before purchasing it allows you not to worry that the work will not go as planned. Therefore, builders recommend that anyone who is going to block the house apply well-known techniques in practice, as this saves money, money and time.

It is worth remembering that the more complex the roof, the more difficult it will be to calculate, but this activity is worth its result, fully justifying itself.

In contact with

The professional flooring is very popular in low-rise construction. It is widely used not only for roofing, but also for installation, for example, fences. The material is affordable, lightweight and comfortable to wear. self-assembly, has an attractive appearance.

One of the important points when working with corrugated board is the exact calculation of the required volume of material. Today we will consider how, with the help of specialized calculators, you can independently calculate the corrugated roofing.

In this article

Understanding roof construction

Before performing the calculation of corrugated roofing, it is important to clarify all the parameters of the roof. The design of the rafters, the height of the ridge, the slope of the slopes and many other parameters will affect the number of sheets required for the arrangement of the roof.

Decking - roofing material used to cover pitched roofs various designs, both simple (single, gable) and complex (four-slope, hip, etc.) An important point is the choice of the slope of the slopes. Depending on it is the ability of the roof to withstand the load of wind and snow. A number of parameters will depend on the selected angle of inclination:

- The thickness of the material and the height of its relief;

- Quantity of corrugated board.

With a larger angle of inclination of the roof, its area increases. This increases the wind load, because the windage of the structure increases. However, snow load in this case, it decreases: snow melts faster from a steep roof. Based on this, we conclude that roofs with an angle of 45 ° or more are covered under corrugated board of a smaller sheet thickness.

More gentle roofs must be cleared of accumulating snow masses. That is, it is desirable to equip such roofs with thicker sheets that will withstand the weight of the snow mass and do not deform under the weight of a person.

The amount of horizontal overlap of corrugated sheets depends on the angle of inclination of the roof:

- With a slope of up to 14 °, the sheets must be joined with an overlap of 20 cm or more. At a lower value, the likelihood of leaks is high;

- An angle of 15-30° is assumed to be a joint of 15-20 cm;

- Roofs with a slope of more than 30° require an overlap of 10-15 cm.

The brand also affects the values of horizontal and vertical overlaps when laying a profiled sheet. Information about this can be found in the information tab of the material itself.

Thus, the parameters of the roof directly affect the number of sheets of corrugated board that you need to purchase for its improvement.

Working with online calculators

The Internet now offers many roofing calculators freely available that can calculate the amount of roofing material for any type of roof structure.

To work in this program, you must enter data about the roof: shape, main dimensions, angle of inclination of the slopes.

Working with such programs is convenient for a number of factors:

- Calculator in short time and with maximum accuracy calculates the amount of material for the roof of any, even complex shape;

Recall that complex types of roofs are not entirely suitable for covering with corrugated board, since in this case the material will give a lot of unsuitable for further use scraps.

- The program will automatically present a 3D drawing of the future roof and itself will choose the best option for laying out the sheets;

- You can change the design parameters and compare the results obtained by choosing a more cost-effective option;

- The calculator calculates not only the required number of profile sheets, but also the dimensions of the required additional elements: valleys, various planks, plugs, etc.

Note that the computer calculation of the roof is always very accurate. With a complex roof structure, we recommend using this particular method, since manual calculation gives a much larger error.

Manual roof calculation

- Area of slopes. With simple pitched structures, when the slopes are in the shape of a rectangle, this is not at all difficult. It is enough to multiply the length of the slope by its width;

- Profiled area. For this parameter, it is important to take not the actual, but the useful area of \u200b\u200bthe sheet. The dimensions of the overlaps are subtracted from the total area of the coating, the magnitude of which depends on the grade of the coating and the slope of the roof. Consumption of corrugated board increases with a smaller angle of inclination of the slope and a smaller size of the waves of the sheet itself.

Let's give an example of how to calculate the area of \u200b\u200bcorrugated roofing. We take into account that the standard sheet width is 118 cm, while usually about 8 cm go under the overlap. The useful width of the corrugated board is 110 cm. To calculate the number of sheets, it is necessary to divide the length of the roof slope by the calculated useful width of the sheet.

Calculate the number of sheets in one row. At the same time, it should be taken into account that the length of the roof includes a cornice overhang of at least 5 cm. It is also important to take into account the dimensions of the vertical overlap, which, depending on the slope, ranges from 15 to 30 cm. Manufacturers supply profiled sheets of various lengths to the market - from 50 cm to 6 m. When buying material, it is important to choose in advance the most convenient and economical size of sheets for laying.

Additional calculations

Sheets of corrugated board are laid on the crate, the calculation of which is also important for obtaining a solid roof. The crate for corrugated board is made of wood treated with antiseptics, with a thickness of at least 20 mm. The calculation of the amount of material for the crate depends on its step, which, in turn, is associated with the slope of the slopes:

- A more gentle design requires a smaller crate step - in the region of 20-30 cm;

- With a steeper roof, which experiences less snow load, the distance between the ribs of the purlin system can be increased to 50 cm.

The calculation of the roof for corrugated board requires the calculation of the number of a number of additional elements. Here are the basic rules that will help you quickly calculate these parameters:

- The elements for the valley are calculated with a coefficient of 1.7, since the valley is laid with joints of 30 cm. It is important to remember that the standard length of all additional elements is 2 m. So, in order to calculate the required amount of material, for two elements of the valley, the total length is .5 m, you need 3.5 / 1.7 \u003d 2.05 elements;

- The remaining additional elements are installed with an overlap of 10 cm. For their calculation, a coefficient of 1.9 is applied;

- When calculating the required number of self-tapping screws for attaching sheets to the crate, it is taken into account that 1 m2 of the profile requires 7-8 elements.

It would be useful to mention the rule according to which all calculations made must be rounded up.

Summing up

So, the calculation of the number of profiled sheets is associated with a number of parameters:

- The slope of the slopes;

- The brand and characteristics of the roofing material itself.

It is possible to make calculations using online calculators, which is recommended for roofs of complex shapes, or on your own. When calculating independently, we recommend that you carefully consider all the little things, without losing sight of the features of the crate system, the dimensions of the material overlaps, various roof extensions, for example, the size of the pitched overhang.

When buying a profiled sheet, based on the results of the calculations, it will not be superfluous to add 10% to the figures obtained, since even the most accurate and powerful calculator is not immune from errors in the calculation due to incorrect data or from unforeseen situations during the installation itself.

Decking is a widely used roofing material for both industrial and civil construction. Relatively low cost, light weight, manufacturability, ease of installation and good performance attract many developers. The most expensive types of profiled sheets are not inferior in terms of service life to high-quality metal tiles, but they significantly benefit in terms of cost.

It is explained simply. Metal tiles have large protrusions; to give such a profile, steel must have high ductility. For the manufacture of metal tiles, only high-alloy steel grades are used.

The metal profile does not have such a complex pressing geometry; accordingly, lower quality and cheaper steel is suitable for production. Due to the difference in materials, the cost of production decreases. All indicators of galvanizing, coatings with polymer paints and other additional surface protection against corrosion processes for both roofing materials are completely identical, and it is these coatings that affect their durability.

Roof made of corrugated board

Prices for corrugated board

The calculation methods are influenced by the following indicators of profiled sheets.

How to use the calculator

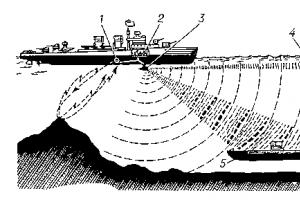

The fastest and easiest way to calculate roof decking is to use a special calculator. Before starting work, you need to decide on the type and technical parameters sheets and roofs. The calculator will require the following input data:

- sheet size, meaning not general, but only effective (working);

- linear dimensions rectangular slopes and their number;

- linear dimensions of triangular slopes (hips) and their number;

- dimensions of trapezoidal slopes and their number.

The calculator has a simple program that allows it to determine the area of each geometric figure and sum them up. Professional roofers rarely use such calculations. No computer program can take into account all individual roof options, too many unforeseen factors affect the final calculations.

Such a calculator can be used with great care, and then only to obtain indicative values. It does not take into account the length of the sheets, and the number of joining points depends on this. The calculator does not take into account the angle of inclination of the slopes, and this parameter affects the width of the overlap, etc.

A practical example of calculating roofing material

You can calculate the number of profiled sheets using trigonometric formulas. But not every elderly builder can remember what arctg or cos are, where to look for them and what to do next with them. We offer the simplest method of calculation, in order to use it, you need to know only first-class arithmetic lessons.

For example, let's take the simplest and most popular roof - a gable roof.

Note that there is no difference between calculating the amount of corrugated board and metal tiles, roofing materials have the same laying technology, the same additional elements and fixing methods, identical performance characteristics. The appearance and price are slightly different, but these parameters do not affect the calculation method. For a better understanding, the instructions give the dimensions of the roof, and in your calculations you need to use the parameters of a particular type of metal tile and truss system.

Step 1. Check sheet sizes. The manufacturer indicates the total and working width of the sheets. The working width takes into account the size of the wave overlaps during installation. In our case, the total width is 119 cm, and the working one is 110 cm. A wider wave will always lie on top, which ensures a tight fit. The upper wave completely covers the lower one - the probability of snow or rain entering the under-roofing space is excluded. The corrugated board does not have waves, it has only ridges located parallel at the same height, which somewhat simplifies the calculation process, there is no need to take this parameter into account during the selection ridge element and windshields. For a profiled sheet, you can buy strips with lower sidewall sizes, they cover a small gap between the roof and the crate.

Step 2 Measure the dimensions of the truss system. In our case, the distance between the two extreme rafter legs 11 m 67 cm, and the distance between the walls of the building is 10 m 60 cm. The house is quite large, rafter system must be made in accordance with all the rules, provide the necessary load capacity and rigidity.

Important. In order to reduce the amount of non-productive waste of corrugated board and facilitate roofing works it is recommended to adjust the dimensions of the crate to the dimensions of the profiled sheet. This will not only eliminate the need to adjust the sheets, but also improve the appearance of the roof. It will be symmetrical, the screws will be located at an equal distance. Another problem of cut sheets is that the cut metal at the cut points quickly oxidizes. The size of the rust is not critical, the metal does not deteriorate very quickly. The problem is that rust is washed off with water onto the roof covering and forms ugly red streaks. It is impossible to remove them, iron oxides firmly eat into the surface of the coating.

Step 3 Count the number of metal profile sheets. In our case, 11 pieces are needed for the roof. × 110 cm + 90 cm = 12 m 19 cm. During the calculations, it was understood that 11 sheets with a working width of 90 cm are not enough, in connection with this it is necessary to increase the coverage by 9 cm and due to this, to achieve roof dimensions along the ridge of 12 m 19 cm. In this case, the overhang along the ridge will be 12 m 19 cm - 10 m 60 cm = 159 cm/ 2 = 79 cm. Finally, after choosing the best option the length of the roof ridge turned out to be 12 m 1 cm. Taking into account the dimensions of the sheets, the crate under the roof should have dimensions of 12 m 1 cm along the ridge and 7 m 97.5 cm along the slope of the slope.

Step 4 Mark the length of the ridge and transfer it to the opposite underside of the roof (cornice) at a distance of 7 m 97.5 cm. Carefully check the corners, they should be perfectly rectangular. If the first row lies unevenly, then all the rest will be steps. It is very difficult to straighten sheets by slight displacement in the floor profiles and is strongly discouraged by manufacturers. If they do not lie on the same line, then several problems will arise.

- The gaps in the places of overlapping sheets increase, there will be risks of blowing snow or rain. To eliminate the problem, it is necessary to increase the length of the overlap of profiled sheets, and this changes all calculations, increases the consumption of expensive roofing materials.

- In places of bending, the sheets touch each other not along the surface plane, but along the line. This situation causes significant loads along the lines, the thickness of the profiled sheets is not designed for them. As a result, the coating can sag in these areas, the protective layers are damaged, and oxidative processes are accelerated. In the future, leaks appear at such points, requiring repair of the roof.

The correctness of the angle of the crate must be checked by measuring the diagonals of the rectangle. If there is a difference, then only the cornice section of the crate can be shifted in one direction or another, the ridge section should always be stable.

Practical advice. Before placing an order, you need to talk with a representative of the manufacturer. It is required to agree on the length of the sheets, in some cases it will have to be changed depending on the possibilities of production and the difficulties of delivery. If you buy a finished metal profile standard sizes, then it is necessary to take into account the amount of overlap depending on the angle of inclination of the slopes.

Step 5 Calculation of additional elements. They must be ordered at the same time as the purchase of the roof. Most manufacturers produce elements of standard sizes with a length of one and two meters. For complete installation gable roof such additional elements are needed.

| Name of the additional element | Calculation algorithm |

|---|---|

| In our example, the length of the roof ridge is 12 m 1 cm, you should buy an equal number of pieces plus one element in stock for overlapping. If the skates are two meters, then 6 + 1 pieces are required. For skates, immediately buy plugs of the appropriate profile and seals or special gratings that prevent birds and large insects from entering the under-roof space. |

| Installed at the bottom of the roof, designed to protect the crate from moisture. In addition, cornices perform a very important decorative function. The number is calculated in the same way as the ridge, but it must be borne in mind that these strips are attached to both sides of the roof, the total number is doubled. In stock for overlaps, you can take not two strips, but one. Of course, if the total amount of overlap allows such savings. |

| One side is fixed to the board, and the other to the wave of the sheet. The main task is to protect the roof from undermining by strong gusts of wind. Additional - to improve the design of the roof. The calculation is not difficult, keep in mind that the wind bars are screwed on four sides of the slopes. |

| The roof of the house is large, the snow load can reach significant values. It is recommended to buy tubular elements, they have a special rigid design for fixing and can withstand significant forces. Thin corner snow holders deform profiled sheets with considerable effort, and in some cases they can completely tear out self-tapping screws. Appear in the roof through holes needs urgent repairs. It must be remembered that repairing the coating will always cost tens of times more expensive than acquiring a reliable snow retainer. The number of elements is selected taking into account their length, they should be placed across the entire width of the roof, it is advisable not to take breaks between them. |

This completes the preliminary calculations of the roof. You can multiply the number of elements by their price and get the cost of the roof. But not everything is so simple. Why? Because the price of a roof includes not only the cost of coverage, you need to take into account the full estimate of the construction and make the most complete calculation.

How to Calculate the Total Estimated Cost of a Roof

Some inexperienced developers quickly calculate the cost of acquiring metal tiles, add the cost of additional elements to them, and hope that for this amount they will be able to put up the roof of their house. And then, in the process of construction work, it turns out that the actual amount is many times greater than the planned one, there are great difficulties with financing the facility, sometimes it is necessary to freeze the construction site. Any temporary suspension of construction work due to lack of materials incurs direct, and considerable, losses. After the resumption of construction work, many elements have to be repaired or completely redone, and this is an extra waste of money.

In order not to get into unpleasant situations, you must be able to correctly calculate the cost of the roof. How to do it? For clarity of the example, we will take the real prices for metal coatings as of the summer of 2017.

Where does the calculation of corrugated roofing begin?

Usually the total roof area is calculated, then the number of sheets and additional elements is determined, the data is multiplied by the cost. For example, with an area of roof slopes of 200 m2 and an approximate cost of profiled sheets of 300 rubles / m2, it is determined that 60 thousand rubles will be needed for the roof.

To cover various unforeseen expenses, the amount increases by another ten percent, and the developer is sure that this is quite enough to equip the roof of the house. The amount is small family budget holds it without a problem. The more experienced will estimate the cost of lumber, and this is where the calculations end.

Is it possible to act in this way, will the received amounts match the real ones? Let's figure it out. Let's talk about which items make up the cost of the roof, what you can save on, and where you don't need it. There is a house with pitched roof with an area of 200 m2, a metal profile of a budget option costs about 300 rubles / m2.

The roof is the cheapest bet of insulation, the attic is non-residential. We specifically chose this simplified version to find out the minimum cost of the work.

Step 1. Let's calculate the cost of lumber for the truss system. We will not count exactly to each board and lath of the crate.

Based on practice, about 9 m3 of lumber will be needed for such a roof, the cost of a cubic meter of boards of the first grade is within 7.5 thousand rubles. In total, after elementary calculations, we find out that 67.5 thousand / rubles are needed for the rafter system. for lumber.

Prices for different types of building boards

Building boards

For the construction of the structure, various fasteners are required, the amount of 5 thousand rubles. we also take from practical experience. This is the minimum cost of fasteners, but in fact, rarely does a master fit into it.

To this amount should be added the cost of delivering materials to the construction site, specific amounts depend on the length of the transportation. We will take the minimum price of 2500 rubles.

Delivery of lumber is another cost item

In total, at this stage you will need 67.5 + 5 + 2.5 = 75 thousand rubles. This amount is already beginning to worry some developers, because they thought that the price of lumber does not have a noticeable effect on the roof, during the calculations of profiled sheets they often did not take it into account.

Step 2 Roofing calculation. As we have already mentioned, the budget option of materials is being considered. During the calculations, the percentage of waste should be taken into account, and it will always be.

In our case, the roof area is 200 m2, taking into account the margin and complexity of the roof, you will have to buy approximately 232 m2 of profiled sheets.

Multiply the quantity by the price and get the amount of 69.6 thousand rubles.

To it must be added the cost of roofing fasteners (about 4 thousand rubles), as a result, an amount of about 74 thousand rubles is obtained.

As you can see, the cost of lumber for the truss system slightly exceeded the price of roofing. And at first it seemed that this amount would be about half as much and you could not pay much attention to it.

Step 3 waterproofing membrane. An unpleasant feature of metal coatings is the formation of a rather large amount of condensate on the underside of the sheets. To guarantee the durability of the roof, it is recommended to take it away, you will need a special membrane. Our roof requires three rolls of material with a total cost of 4.5 thousand rubles.

Prices for material for vapor barrier

Vapor barrier material

Step 4 Calculation of the quantity and cost of additional roof elements. It is necessary to calculate the cost of the ridge, cornice and wind slats, chimney bypass elements. The approximate amount is 16.5 thousand rubles.

Step 5 Now it's time to pay attention to one of the most significant expense items - the cost of services. construction companies. The price range is large, the minimum prices for which you can agree to build a simple gable roof, 500 rubles. per square meter. Our roof area is 200 square meters, the total cost of roofing works is 500 × 200 = 100 thousand rubles. They take separately for the bypass and sheathing of the pipe; together with the materials, this assembly will cost at least 10 thousand rubles. In total, you will have to pay 110 thousand rubles for the services of professional builders.

Now we can estimate that the approximate cost of the simplest gable roof with a budget version of roofing materials is within 280 thousand rubles.

Do you remember how much the calculations started with? From 60 thousand rubles. Inexperienced developers estimate the roof at this amount by eye. Keep in mind that in the calculations we did not take into account the cost of equipment and installation of a drainage system, snow retention. Roof not insulated skylights and individual outlets of ventilation and air conditioning systems.

Price drainage system about 48 thousand rubles, the price of the tape under the ridge is 11 thousand rubles, hemming the overhangs with spotlights is 33 thousand rubles, perforated tape to protect the ventilation ducts from large insects and birds is 4 thousand rubles. snow retainers 22 thousand rubles. In total, works that are insignificant in terms of volume require significant money - at least 118 thousand rubles. along with installation.

Prices for snow guards

Snow guard

What is the result

The complete construction of a roof from profiled sheets will cost about 398 thousand rubles, of which only 19% is the cost of metal plating. Most of the money will have to be paid for spotlights, gutters, tapes, films and other materials - 36%. Roofers will receive 27% of the total, and the truss system will cost 18%.

As you can see metal roof as a result, it requires the least finance from the construction estimate. But we calculated the cheapest and, accordingly, the lowest quality metal profile. Its service life does not exceed ten years. If you buy more expensive ones instead roof coverings the average price range, then the total cost will increase to 433 thousand rubles, and all the growth is only due to an increase in the price of roofing material. The actual increase in the estimate is only 9%. Now attention: the guaranteed service life of higher quality metal coatings increases by at least 1.5 times.

Conclusion. Only not very smart or very rich developers allow themselves to buy low-quality types of metal profiles for the roof.

Video - Installation of corrugated roofing

Anyone who starts building his own house immediately thinks about how much it will cost him in terms of financial costs. And this is the right approach. Purchase of building materials construction works, attracting transport and mechanisms - all this costs a lot of money. Let's add here the development of documentation (project and estimate). But experts assure that much of the above can be saved if it is reasonable to approach construction. For example, to conduct an accurate calculation of the amount of purchased building materials.

And since in this article we will be interested in the question of how to calculate corrugated roofing, we will consider it in terms of design features the roof itself. That is, what kind of roof according to the project should be built on your house.

Roof types

In construction today, eight types of roofs are used, on which corrugated board can be mounted:

- Shed;

- Gable, in which the slopes have the same size and shape;

- Gable with different slopes;

- Mansard roof;

- Tent;

- hip;

- Tri-slope;

- Mnogoskatnaya.

To make sure that such roofs exist, look at the photo below.

Why is it so important - the shape and number of rays. The thing is that each slope will be covered with corrugated board, which means that a separate calculation will have to be made for each of them. The first two positions do not count, because for a gable variant with the same slopes, the area of \u200b\u200beach will be equal. Therefore, the calculation of one will have to be doubled.

The most simple design roofs are shed, so the calculation of the required amount of corrugated board for it is easiest to do.

Calculation of profiled sheets for covering a pitched roof

Let's start with the fact that the sheets of roofing material themselves have two widths. This is basic and working. It is the working width that is taken into account, because the profiled sheet is overlapped on the roof relative to neighboring sheets, that is, its main width on the plane decreases. The deviations between the two indicators for different models of corrugated board are different, therefore, when making a calculation, it is necessary first of all to choose the type of profiled coating.

Attention! The greater the slope of the slope, the higher the roof, the larger the area that will have to be covered with profiled sheets.

In addition, it can be said that with such a high structure, the wind load also increases, but the snow load decreases, because snow does not linger on steep roofs.

But since shed roofs do not rise high, profiled sheets with a sufficiently large thickness are used for them so that they can withstand both snow and a person. But there is a certain minimum angle slope, which can be used under corrugated board. This is 12 °, so in any case it is written in GOST.

The angle of inclination will also affect the overlap of the two sheets with each other in the horizontal plane. So, for example, if the angle of the roof is up to 14 °, the overlap of two sheets will be 20-30 cm. The angle is 15-30 °, the overlap is 15-20 cm, the angle is more than 30 °, the overlap is 10-15 cm yes, at a low slope angle, the amount of roofing material increases.

All this, of course, additional indicators. The calculation is based on the area of \u200b\u200bthe slope. In fact, this is a rectangle, so calculating its area is not difficult. To do this, you need to measure the width and height, and multiply them together. After that, the area is divided by the area of \u200b\u200bthe sheet of corrugated board itself. To do this, its width (working) must be multiplied by the length of the panel. This is the area of the sheet. In the end, you will get an approximate amount.

In the event that the length of the corrugated board is equal to the height of the slope, then the calculation is simplified to a minimum. That is, the width of the roof slope must be divided by the working width of the profiled sheet. Of course, an integer in this mathematical calculation will not work, but it is worth rounding the final result to the nearest higher value. And this is waste, from which there is no escape in construction.

Attention! Do not forget that the corrugated board is laid on the roof with a small allowance of 30-50 cm, which forms the overhang of the structure.

This must be taken into account in the process of accurate calculations.

Calculation of corrugated sheets for triangular and trapezoidal slope

In some types of roofs there are slopes in the form of a triangle or trapezoid. The same principles for calculating the required amount of roofing material are used here, as in the previous case. That is, additional characteristics and conditions of the structure are taken into account. But here the area is determined by the purely geometric parameters of the ramp. So, we have a triangle, and its calculation formula:

S=1/2*a*h, where a is the side of the triangle, h is the height of the triangle lowered to that side.

And since the overhang is the base of the slope in the form of a triangle, which is easy to determine and measure. That height lowered to the overhang is equal to the height of the ramp itself. That is, it will be very simple to calculate the area of \u200b\u200bthe triangular roof slope. And this will help the usual calculator.

It is clear that the value obtained in this way cannot solve the problem of determining the exact amount of corrugated board. It's all about configuration. Even in the highest place, the profiled sheet will not lie whole. It will have to be cut under the acute angle of the triangle. And these are additional expenses. True, some sheets will be cut in such a way that they can be used on the opposite side of the roof. And that's a little comforting. Therefore, experts believe that, when calculating the amount of corrugated board for a triangular roof, it is necessary to add up to 40% to the amount of material received.

As for the trapezoidal roof slopes, there will also be waste, but not as large as in the previous version. The area of a trapezoid is calculated by the formula:

S \u003d 1/2 x (a + b) x h, where "a" and "b" are the bases of the trapezoid, in our case the length of the overhang and ridge, and "h" is the height of the figure, that is, the width of the slope.

To close the plane of the trapezoidal slope completely, it is necessary to add 15% to the resulting number of sheets (this is for material waste).

Attention! Installation of corrugated board on a triangular and trapezoidal slope begins from the middle of the plane in the direction of the sides (ribs).

In principle, all these calculations are not as complicated as it might seem at first glance. And yet they are not for everyone. Therefore, on the Internet today you can use a program that works like a calculator. They are called that - an online calculator for calculating corrugated roofing. The necessary indicators are hammered into it, mainly dimensional, which determine the plane of the slope. As well as the planned brand of the corrugated board itself. And in the end, the calculator will give a fairly accurate number that can be used to purchase roofing material.

Calculator for calculating corrugated roofing - program features

There are a large number of programs on the Internet that are used by both simple country developers and professionals - architects and designers. For example, if you need to calculate the amount of corrugated board for the roof of a bathhouse, garage or a small country house, then you can use a simple program that is very easy to work with. Everyone will deal with it.

But if a large and complex building is planned on the site, with a figured roof, then the calculator in this case should be used difficult. Firstly, it will be very difficult to manually calculate such a roof. Secondly, a simple online calculator will not be able to do this either, the error will be too large. For such designs, a multifunctional program is needed. With its help, you can get not only the required amount of corrugated board, but also the layout of profiled sheets. In addition, it can be used both under a metal tile and under an ordinary tile. There are many advantages to such programs.

For example, calculator "Profi". It seems to be a serious name, but it is not difficult to work with it. True, it is necessary to be able to read the drawings, in this case the drawing of your house. Yes, and the estimate with its complex calculations will not be easy. But you can deal with it too.

The program calculator "Roof Profi" can:

- Develop a scheme for laying profiled sheets, taking into account all overlaps.

- Calculation of corrugated board and additional elements.

- You can change the values of the original data. You can access them except dimensional indicators, turn on specifications corrugated board, types of additional materials, the amount of overlap and even the price of products.

- You can lay the shape of the slopes from the proposed templates or draw it in any other program and transfer it to the calculator.

- Here, an estimate of the cost of corrugated board can be practically drawn up, if the prices of materials and the cost of contractors' services are correctly set.

To be honest, this is a small list of what can be done with this program. These are the main features. If you have not chosen the shape of the roof slope from the proposed templates, that is, you have drawn them yourself, then experts recommend drawing closed shapes. No broken lines or unfinished sections. The thing is that the calculator will calculate only geometric shapes. If you make even a small mistake, then the calculation, the layout of the profiled elements, and the estimate will be incorrect. Therefore, be very careful about the task of the initial data.

Generalization on the topic calculation of corrugated board

The calculation of corrugated roofing is an opportunity to save finances that are intended for the construction of a building (large or small). It's a necessary part preparatory phase. Today, not a single object under construction can do without it, whether it be a bathhouse or a huge Vacation home. To approach the calculations correctly means to determine the required amount of roofing material. That is, reduce its waste. Of course, not on all forms of roofs this waste will be minimal, but it is possible to reduce it with the right calculation. And this is savings.