How to make a knife sharpener. How to sharpen a knife to razor sharpness. Whetstones and whetstones

With the help of a knife, we cook food, cut food and perform other household chores. Therefore, it is very important that the blade of the knife always remains sharp. Theoretically, there is nothing complicated in sharpening knives, but in practice it turns out that not everyone can sharpen a blade well. To have an idea of how to sharpen knives and how to do it correctly, we advise you to read our article.

Before you start sharpening a knife, you need to find out what material it is made of. There are several types of knives:

- Carbon steel knives are the most affordable, made from an alloy of iron and carbon, easy to sharpen and stay sharp for a long time. Among the shortcomings, it can be noted - oxidation of the knife blade from interaction with food or an acidic environment, because of this, rust and stains appear on the knife, and the products acquire a metallic taste. Over time, after the formation of plaque on the blade, oxidation stops.

- Low carbon stainless steel knives are made from an alloy of iron, chromium, carbon and in some cases nickel or molybdenum. Stainless steel knives are inferior in hardness to carbon steel, so they dull quickly and require regular sharpening. The advantages include - resistance to corrosion.

- High carbon stainless steel knives are a higher class of knives, with a higher carbon content and additions of cobalt or vanadium. Due to the higher quality alloy, this species knives do not require frequent sharpening and are not subject to corrosion.

- Damascus steel knives are mainly made as edged weapons, but there are also kitchen options. Damascus steel knife is a multi-layered blade made of different alloys High Quality. The disadvantages include the high cost of knives.

- Ceramic knives have gained popularity due to their sharpness and ability to long time don't be dumb. But in addition to the advantages, ceramic knives have a significant disadvantage, which is their fragility when falling from a height and poor fracture resistance.

Sharpening tools

Touchstone (whetstone)

Whetstones are available with a different number of abrasive grains per square millimeter. Therefore, for rough sharpening and finishing grinding, it is necessary to use bars with a minimum and maximum abrasive content. In foreign-made whetstones, information about the number of abrasive grains is on their marking. Grinding bars of domestic production have to be chosen "by eye" or ask the seller which whetstone to use for primary and which for finishing sharpening.

Mechanical sharpener

Mechanical sharpeners are mainly used for sharpening kitchen knives. The sharpening process, although it happens quickly, but the quality leaves much to be desired. For this reason, for hunting and sporting knives, it is recommended to use other sharpening methods.

electric sharpener

Modern models of electric sharpeners allow you to achieve high quality sharpening, due to the built-in function, automatic detection of the angle of the blade. The electric sharpener is perfect for both domestic use and for sharpening knives in catering establishments. The lineup electric sharpeners are presented in a wide range, so the price may be different, but if you want your knives to always remain sharp, then buy more "advanced" and expensive models.

Musat

Musat - designed to maintain the sharpness of the edge of the knife. In shape, musat resembles a round file with a handle. Musats are included in knife sets, and many owners often confuse them with a tool for full-fledged sharpening of the blade. Please note that with the help of musat you will be able to maintain the sharpness of a sharpened knife, but if the knife is completely dull, it will not work to sharpen it with musat.

Sharpener "Lansky"

This sharpener is used for sharpening small and medium-sized knives. The design of the sharpener allows you to sharpen the blade at your chosen angle. Sharpener "Lansky" consists of a rod with a removable whetstone and two corners connected to each other. The corners simultaneously serve as a vise for the knife and a scale for selecting the sharpening angle. The sharpener also comes with ANSI marked whetstones in various grit sizes.

Sharpening and grinding machines

Sharpening machines are mainly used in production, for high-precision sharpening of blades of rotating shafts. In addition to high-precision machines, there are abrasive wheels with electric drive and rotating grinding discs. Sharpening knives on such machines should only be done by an experienced craftsman, because due to the speed of rotation of the circle or disk and high temperature heating, with any unsuccessful movement, the knife blade will become unusable.

Self-sharpening blades

Sharpening a knife with a whetstone

The sharpening of the blade, made by a whetstone, is considered the highest quality, of course, provided that it was produced by an experienced craftsman. To sharpen a knife on a whetstone, do the following:

- Place a whetstone with a low content of abrasive grains on a fixed surface. If the bar is small, it can be clamped in a vise.

- Holding the knife at an angle of 20-25 degrees with respect to the surface of the bar, start moving the knife along the whetstone with the cutting edge forward.

- Move the blade along the bar in such a way that during the movement it touches the surface of the whetstone, along its entire length.

- Try to keep the same blade angle while moving.

- After 2-3 strokes, turn the knife over and repeat the sharpening process on the other side of the blade.

- Thus, alternating sides, sharpen the knife until an edge (burr) appears along the edge of the blade.

- Change the rough sharpening stone for a grinding stone.

- Sand the knife blade until the edge is gone.

- Test the sharpness of a knife by cutting through a hemp rope that has been folded several times, or try cutting through a piece of paper.

How to sharpen a knife with a whetstone, see also the video:

Sharpening a hunting knife on a Lansky sharpener

Hunting knives are made of hard steel, so their initial sharpening requires whetstones with a low content of abrasive grains.

- Clamp the knife in the vise of the sharpener.

- Install a whetstone with a low content of abrasive grains on the shaft.

- Select the angle of the bar (for hunting knives it is usually between 20 and 30 degrees).

- Insert the rod into the desired hole.

- Lubricate the whetstone with the special oil included in the sharpener set.

- Start moving the bar along the blade of the knife, from the base to the tip.

- Turn the sharpener over and repeat the process on the other side of the knife.

- After the edge is formed, change the stone and do the final sanding.

- Since hunting knives are mainly made with a double-edged blade, after completing sharpening on one side, change the position of the knife in the vise and start the sharpening process on the other side.

- When finished sharpening, polish the knife blade with felt.

How to sharpen knives in a Lansky sharpener, see the video:

Sharpening scissors

Sharpening scissors must be done on a special grinding machine. Sharpening blades with the help of improvised (sandpaper, the edge of a glass, etc.) can temporarily improve the sharpness of scissors, but not for long. If you do not have the opportunity to sharpen scissors from a professional, then you can try to sharpen yourself on an abrasive stone. When sharpening, you need to follow a few simple rules:

- The sharpening stone should be fine-grained.

- The blade is sharpened over the entire surface of the edge at the same time.

- The angle of the blade must match the factory edge.

- The movement of the blade over the stone must be done from the screw to the tip.

- You need to sharpen scissors in disassembled form.

When sharpening scissors, do not rush, patience in this matter will be your ally.

How to quickly sharpen scissors, you can also see in the video:

Sharpening plane and chisel blades

Sharpening the blade of a planer and a chisel practically does not differ from each other. Therefore, the sharpening process described below applies to both tools:

- Set the chisel on the whetstone at an angle of 30-40 degrees.

- Holding the chisel with your hand, fingers free hand press the chamfer to the donkey.

- Start running the chisel over the grindstone until a burr forms on the smooth side of the chisel.

- Change the whetstone to a fine-grained one and do the final grinding of the chisel.

- Check the sharpness of the chisel blade by removing chips from the corner of the bar.

In addition to manual sharpening, the chisel can be sharpened on a machine with a rotating abrasive disc:

- Turn on the machine and let the disc reach full speed.

- Holding the chisel with both hands, lean its bevel against the grinding wheel.

- Be sure to observe the angle of the chisel, otherwise you will ruin the blade of the tool.

- Do not press the chisel with too much force and do not hold it too long on the disk, this will lead to overheating of the metal and destruction of the blade.

- While sharpening, wet the blade with water.

- The final grinding of the chisel blade is best done by hand, using a fine-grained bar or sandpaper.

Do not forget that when sharpening products on the machine, a lot of sparks and small particles are formed that can get into your eyes, so be sure to work with safety glasses. And in order not to injure your hands on a spinning disk, wear gloves.

You can also learn how to sharpen tools from the video:

Tips for quickly sharpening the blade with improvised means

Stone

To quickly sharpen a knife on a hike or on a picnic, you can use an ordinary cobblestone. Use any stone lying on the ground instead of a whetstone and run the blade of a knife along its surface. You will not achieve razor sharpness, but you will return the knife to working condition.

Second knife

It is quite possible to sharpen two knives at once, without sharpening stones and accessories. To do this, you need to take a knife in both hands and start sharpening the blade of one knife on the blade of another. After 5-10 minutes of this work, the knives will become sharper than before.

glass items

The blade of a knife can be sharpened slightly on the rough edge of glass or ceramic objects. For example, about the bottom of a glass or edge tiles. The main thing is that the surface is rough.

Leather belt

A leather belt is more suitable for finishing and razor sharpening a knife blade than for rough sharpening. But if there is nothing at hand except for the belt, then you can try to sharpen the knife on it. To do this, you need to give the belt a stretch and start to drive along it with a blade, you may not achieve strong sharpness, but you will polish the knife to a shine.

By learning how to sharpen knives and tools yourself, you will acquire a skill that will be useful to you throughout your life!

An electric grinder or, as the people say, emery, a great variety of everything that falls under the arm is collected, often they are made from engines from washing machines.

I also decided to make my own homemade machine for sharpening drills, knives, etc. I have a Chinese sharpener, but its quality 😥 well, you understand...

Making such a machine turned out to be one of the easiest things 🙂

Because:

- I had an extra motor at 1370 rpm and 370 watts.

- I did not order a nozzle for planting a grindstone on a shaft from a turner, such nozzles are sold on our market - it is enough to know the diameter of the motor shaft and you can purchase a nozzle for only 250 rubles + 200 rubles. for the grindstone.

Making a grinding machine with your own hands step 1

I installed an electrical box on the engine, placed a capacitor in it to start the engine, a toggle switch and a power supply for the lamp.

I used the toggle switch from a Soviet tube TV - it turns out to be a reliable thing, first I installed a modern beautiful Chinese toggle switch - when using it, the machine "stuttered" (worked with some jerks), and replacing the toggle switch with others of the same brand did not help until I installed the Soviet toggle switch.

For the sake of interest, I then installed these Chinese toggle switches on another engine, which also began to "stutter", it's a shame, I gave 100 rubles for 2 toggle switches. I just threw money in the trash...

Well, with a capacitor - everything is standard, I will not describe 101 times how to connect a three-phase motor to 220v - it's easy to find on Google, or in our article on.

Illumination for sharpening machine step 2

Check also these articles

For backlighting, I used an unnecessary LED table lamp from IKEA, I bought it for the house, but it was not useful anywhere, the lamp is powered by the mains through an adapter, which I dismantled and hid its board in a box on the engine.

Handpiece for lathe step 3

To attach the handrest, I used a furniture corner ground off at the right angle, then I attached a piece of a 32x32 corner to it, in which I sawed a groove and installed a handguard from a piece of steel 4 mm on it. Fixing the tool rest with a countersunk screw, thanks to the groove in the corner under the tool rest, the tool rest can be moved closer or further away from the whetstone. The corner is also attached to the casing with a screw, which allows you to adjust the angle of the handpiece relative to the grindstone.

Made a corner for fastening from a furniture suspension protective glass, for this I used a piece of plexiglass 6 mm thick.

The grindstone used 200x20 mm gray - I like these more in terms of rigidity, white ones are very crumbly. I know about the marking of stones, but I am not engaged in professional processing of steel in order to select a stone according to its parameters for a long time.

When installing the stone, I placed two washers made of cardboard, as required, so that when tightening the nuts, the whetstone does not burst.

About the safety of the DIY grinder

We read the theory - we know ...

The casing of my emery is not closed on one side - for safety it’s impossible, the casing should cover the stone as much as possible, but I decided for myself that sometimes it’s convenient for me to grind something on the side of the stone, although this is not recommended. And in general, I usually finish my machines gradually, I think that in the future, when I wish, I will still make a cover on the casing so that it closes the grindstone from all sides.

But, my machine also has safety advantages:

- the protective glass on Chinese machines is much thinner than what I used;

- the revolutions of the machine are 1380 rpm, although the grindstone is designed for 3000 rpm. in min. So my stone will have a very small chance of breaking.

What did I get

- I got an excellent home-made machine for sharpening drills, knives and other tools, the power of the machine is enough even for sharpening axes - checked;

- the speed of the machine is low, it grinds emery better at 3000 rpm, but mine works quietly and hard, I would say 🙂

Recommendation for choosing an engine for a homemade grinder

The engine is taken depending on your needs, if you are going to sharpen only awls, small knives, etc. on it, then an engine from washing machine from the USSR. Such engines usually have 1380 rpm. per min and 180-250 watts of power. Now there are also engines from modern automatic washing machines, but they are more difficult to connect - you need a special board, but you can adjust the speed on them.

For more confident work, it is better to take a 400W engine and 1380-3000 rpm. Such a sharpener will already be a good help in the workshop.

But if you want to work with large parts, sharpen crowbars, for example :), then you need to use an engine of the order of 750 watts or more and at 3000 rpm.

Photo of emery made by hand:

How to make a do-it-yourself knife sharpening machine at home and what materials / tools will help in this matter?

Knives in everyday life should always be sharp enough to comfortably perform their functions. When cooking and cutting food, they constantly become dull, as a result of which they need to be sharpened.

To perform this work, many different machines and devices have been invented, ranging from the usual whetstone to complex electric grinders. Using a simple bar is quite inconvenient and takes a long period of time. There are manual machines for doing this work.

Manual knife sharpeners

The grinding machines of the American company Lansky have slightly improved the usual sharpening with a bar. With the help of such a device, you can quite accurately adjust the angle of work with the blade, from 17 to 30 degrees.

Lansky sharpener during operation

A similar do-it-yourself knife sharpening machine can be made by any craftsman due to the simplicity of its design, as demonstrated in the video below.

Machines with fixed blades

These devices allow you to sharpen the knife much faster, because they allow you to apply more effort. Moreover, the efficiency due to the presence of a hard stop in the form of a table also rises several times.

SpitJack knife sharpening machine

As can be seen in the figure, in machines of this type, the sharpening bar moves along the fixed blade at a set angle. The sharpening angle is adjusted by changing the height of the bar attachment. Among the domestic analogues of such machines, one can mention the machine manufactured by the Ermak company.

Ermak sharpener

Machine tools with fixed sharpening surfaces

In devices of this type, there is no way to adjust the angle of sharpening yourself. Most often, several different angles for work are already installed on such a device. Using such machines, you just need to run the blade along the sharpening recess.

This recess consists of two planes, one or two of which is a sharpening bar. So in order to sharpen a kitchen appliance, it is enough just to run the knife over the sharpened surface several times.

Mechanical sharpener Chief's Choice

Electrical Devices for Knife Point

You can also mention professional tools that are used by most chefs, and it takes only a few seconds for the knife to become as sharp as possible again. These devices have an electric motor that rotates the grinding blades.

Such canvases are often made with diamond abrasives, and the engine power does not exceed 100-150 kW. Although, of course, there are more powerful machines for sharpening blades that are used in production.

We make a device for sharpening with our own hands

To make a do-it-yourself knife sharpening machine, you will need: a piece of laminate, a wooden rail, sandpaper, and two lamb bots. Instead of laminate, you can use chipboard or plywood.

To make a knife holder, you need to cut off a piece of laminate. So that the bar does not touch the holder when sharpening, you need to clean off its edge at an angle, using emery.

- We mark and cut off the upper part of the vertical stand, on which the bar will rest during sharpening. We choose an angle half that with which the knife will be sharpened, in our case it is 30 °. For kitchen appliances, it is better to use 10–15 °. In total, 2 such parts will be needed.

- In order to correctly calculate the length of the base and the height of the racks, you need to approximately make a design and markup. It should be borne in mind that the further installation of the transverse support will affect the height. After that, we cut off all the details, and clean their edges.

- Now we outline and drill holes in the base and the pressure plate at the same time for the bolts that fix the knife blade. When marking, it is important to maintain the distance of the holes from the edge of the base. This is necessary to ensure the versatility of the installation, since the knives have different blade widths. We fix the pressure plate with bolts.

- Vertical racks can be fixed with screws, but given that the load on them is small, it is better to use hot melt adhesive. In the same way we fix the horizontal crossbar. At this stage, the sharpener is already ready, it remains only to make a bar.

- To make a bar, cut a rail of suitable length. On one of its edges we glue emery with required size abrasive, in our case it is P1200. To improve the result, you can make several bars, with different grain sizes. The range P600 - P2000 is considered more optimal. To protect your hands from cuts, it is advisable to screw the handle on the top side of the rail.

- As a result, we get a functional and practical machine for sharpening kitchen knives. During operation, it rests with bolts on the edge of the table, which increases the comfort of use.

Video: how to make a knife sharpener from a piece of laminate?

Often, ordinary abrasive bars are used to sharpen knives at home. But their use requires special practice, since with the wrong angle for sharpening, the result will be disastrous. The blade will not have the proper sharpness, which will require additional processing.

Rules for sharpening knives

The layout of the bar relative to the blade

Before you start making a homemade device for sharpening knives, you need to familiarize yourself with the recommendations of experts. At the first stage, it is necessary to determine the angle between the working part of the blade and the bar. This can be done individually for each model.

The knife should be located strictly perpendicular to the direction of the bar. The angle in this case can be equal to half the sharpening. This is due to the fact that grooves are formed on the surface of the blade during processing. They appear due to the action of abrasive components. With the minimum graininess of the tools, they will be insignificant. But there will also be a small degree of impact on the knife.

In addition to this factor, when sharpening a knife with your own hands, you should consider:

- the average sharpening angle is 20-25 degrees;

- processing is performed from the beginning of the blade;

- to control the sharpening angle, you can paint over part of the blade with a marker. In this way, the actual area of influence can be controlled.

It should be remembered that the deformation along the entire length of the working blade will be non-uniform. Therefore, when doing sharpening with your own hands, the “report point” should be the bluntest part of the knife.

The resulting grooves due to the impact of the bar must be strictly perpendicular to the line of the knife. This is the main condition for proper sharpening.

The choice of whetstones for sharpening knives

Blades for sharpening knives

The main component of a homemade sharpening machine will be a bar. This is an abrasive material that, when exposed to the blade, thins it, increasing its sharpness. Therefore, before choosing a design, you should choose the right bars.

The main indicator of the bar is the grain size, but the dimensions should also be taken into account. Ideally, the length of the tool should be no less than the length of the knife. This will ensure uniform processing, reduce the likelihood of defects.

To sharpen knives with your own hands, you will need the following types of bars:

- high graininess. With their help, primary processing takes place, the shape of the blade is corrected;

- medium grit. They are designed to remove the grooves formed during the first operation;

- whetstone or leather belt rubbed with GOM paste. This stage is called polishing or finishing the blade.

The main task of drawing up a design diagram is the correct location of the bars. Therefore, we will consider several options for fixing them relative to the knife blade.

For sharpening ordinary kitchen knives, two types of whetstones will suffice - with high and medium grit. Additionally, they will need a donkey.

Simple version of the machine

Simple knife sharpening machine

The simplest version of the machine design is two pairs of wooden slats connected to each other with adjustable screws. A bar is attached between these components.

The main condition in the manufacture of this design is stability. During operation, it should not change its location on the desktop. For better fixation of the bar, it is recommended to provide support strips located between the wooden components.

Despite the ease of manufacture with your own hands, this machine has several disadvantages:

- the blade is set manually relative to the stone. During prolonged work, it is not always possible to control the sharpening angle;

- an additional fixing unit is required. Since the design must be stable, it is researched to fix it rigidly on the desktop;

- during operation, the screeds can loosen, thereby changing the location of the bar.

The main advantage of this scheme is the ease of fabrication. The design is suitable for sharpening kitchen knives at home. As additional components, you will need a touchstone.

The thickness of the wooden slats can be different. Actually for self-manufacturing such a design, you can use any improvised materials.

Manual sharpening machine with bar adjustment

Sharpening machine with the ability to adjust the position of the bar

To achieve the best result, it is recommended to take the drawings of factory tool models as a basis. Their difference from the instructions described above lies in the rigid fixation of the knife, but this will require great effort to manufacture.

The design consists of a support table on which the knife blade is attached. IN vertical position screw stand is installed. A strap with a slot is attached to it. The sharpening stone is mounted on a guide rod. The sharpening angle is changed by moving the slotted bar along the screw post.

Features of the operation of a machine of this type:

- sharpening angle is set with high accuracy. Its change depends on the thread pitch of the rack;

- instead of a bar, you can use sandpaper. For this, the base is made of plexiglass. A hole is made along it for installation on a guide rod. Sandpaper is glued to the surface of the plexiglass;

- the support base is best made wide. This will make it possible to fix it with clamps on any countertop.

The main problem with this design is the long adjustment of the sharpening angle. This can affect the speed of work if several types of knives are being processed. Each of them requires a long setup of the machine.

To increase the quality, you can use water or oil. They are applied to the abrasive surface, thereby reducing the impact of the chipped particles of the bar on the blade.

Sharpening machine with knife position adjustment

Alternative knife sharpening machine

An alternative manufacturing option for the machine is to change the position of the knife relative to the stone. In general, the design is in many ways similar to the one described above, but much easier to manufacture.

A movable fastening block for a pin with a stone is installed on the base. Two clamps are mounted on the same plane. One of them will be persistent, and the second - adjustable. By changing the distance between the clamps, you can adjust the angle of sharpening.

The main disadvantage of this design is the wear of the bar in one place. To solve this problem, it is recommended to make a long pin to adjust the position of the edge relative to the blade.

In addition to the above schemes, there are a lot of grinding machines that you can do yourself. When choosing the optimal model, one should proceed from the actual availability of improvised materials. It is also recommended to analyze factory machines. Often they are the basis for the manufacture of a unique design.

To get acquainted with the manufacturing features, it is recommended to watch the thematic video material, which describes in detail the machine for sharpening knives with your own hands:

Do-it-yourself knife sharpener drawings. Knife sharpener Lansky drawing. How to make a Lansky knife sharpener. I needed a knife sharpener. Mostly out of curiosity, what kind of animal it is and what it is with. I can sharpen any knife with my hands, but the convenience, and the need for which device in the household should be clarified. Searching the Internet, I found several suitable designs. The simplest and most famous of all was the LANSKY knife sharpener. Any person can sharpen a knife on such a device without special knowledge and skills. It is enough to understand the principle, but it is elementary and any knife will be razor sharp.

As it turned out, Lansky's sharpener is quite expensive pleasure. 1400 rubles minimum for basic set from a clamp, three stones and a jar of oil. The photo is shown below.

Cursed greed: They ask for a lot of money for a sharpener, and there are three pieces of iron bent at the knees, two screws, and a few pebbles. The hucksters are real. Additional sharpening stones can be purchased separately, but not up to them yet.

A sharpener seems to be needed, but I don’t want to pay money for it at all. Therefore, it must be done by yourself. I carefully examined the design of the Lansky sharpener, and came to the conclusion that there are no problems to make such a piece of iron at home from improvised materials.

The principle of operation of the sharpener is very simple and can be seen in the picture. With the translational movements of the grinding stone, we form a smooth cutting edge on the blade of a knife fixed in the jaws of a special clamp. By successively changing the grinding stones with coarse grain to fine and very fine, we bring the knife to razor sharpness. stone movement

By rearranging the guide from the grinding stone in the holes in the terminals, you can get several sharp sharpening angles on the cutting edge. But since the cutting edge of the knife can be fixed at different distances from the jaws of the clamp, the sharpening angles float. And they are, in fact, close to necessary. This in turn affects the cut of the knife, but only slightly that the user does not notice the difference, so you can close your eyes to the floating of the angle.

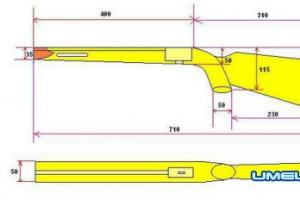

After rummaging through the bins of the Internet, I found drawings of clamping jaws. I redrawn it in a more readable form and converted all dimensions to millimeters, since the Lansky sharpener is made in the USA, and there, as you know, they use the inch system, not the metric system. Everything is pretty simple.

I drew in detail my own design of a clamp for a grindstone on a computer. And did the detailing. This design has a number of advantages. Sharpening stones can be different lengths, the pebble can work alternately with four sides, and not one like Lansky's branded stones, which affects the sharpening time. The greasy side of the whetstone can be quickly changed to a clean one, and the Lansky stones will have to be cleaned.

I bought a hairpin with an M6 thread in a store, it cost 20 rubles per meter rod, sawed off a 160 mm long hairpin with a hacksaw and processed the ends with a file, removing burrs.

The guide was made from an electrode for manual electric welding, I asked for it in the welding shop, they gave me several pieces without any problems. Also, electrodes can be bought on the construction market, they are sold by the piece, they cost mere pennies, they give 3-5 rubles apiece. The brand of the electrode is not important, the main thing is a straight, elastic, smooth and thin cylinder. He hammered the flux with a hammer and lightly cleaned it with sandpaper, removing burrs and flux residues. I bent the letter G with the help of pliers and sawed off the excess with a hacksaw, according to the drawing.

Taking advantage of his official position, he ran to the machine shop, rummaged in a box with scraps of metal, since there are a lot of scraps, found pieces of iron that were suitable in size, made of some kind of raw carbon steel, type steel 3. Sawed off to size with a hacksaw for metal, processed the burrs with a file, and marked the centers of the holes. Using a drilling machine, I drilled holes in the clamps and then cut the threads with a hand tap, remembering to add a drop of machine oil to the hole to reduce friction. I sawed the steps on the clamps with a hacksaw and adjusted them with a file, after which I polished the surfaces of the clamps on sandpaper.

I washed the glands in soapy water, thereby getting rid of the remnants of oil and shavings on the thread, dried it and heated it over the flame gas stove, zavoronil in liquid engine oil. Used for this event a "fishing rod" made from an electrode for manual welding and a piece of steel wire found in wire stocks. Clamps were used as "bait". Each detail was burnished separately. I cleaned the threads from oil residues with a long bolt and thoroughly washed the finished parts in soapy water.

I twisted together, according to the drawing, the clips and the hairpin, not forgetting to drop a drop of nail polish (I stole the vial from my wife), into the connection of the left clip and the hairpin. So that the hairpin does not spontaneously unwind, and eliminate play. After the varnish had dried, I inserted the donkey between the clamps, carefully tightened the nut and aligned the guide pin along the bottom plane of the stone.

At the nearest construction site, I found a piece of an ordinary metal corner with a shelf width of 90 mm and a thickness of 6 mm. However, such iron can be bought on the construction market or found at the nearest construction site. If you politely ask, they will saw off blanks to size for a small fee or "liquid" currency. Such goodness is also in bulk at construction waste dumps, at scrap metal collection points you can be asked to give way for a small amount of money, that is, finding suitable blanks is not a problem.

I redrawn the original dimensions of the Lansky sharpener for the corner 90x90x6 mm. Since I already had an M6 tap at my disposal, I replaced the thread in the original Lansky clamp with an M6 thread for my sharpener. The uniformity of the dimensions of fasteners reduces the cost of manufacturing the structure. In addition, there were small stocks of M6 screws for an Allen socket of a suitable size.

And I drew the entire assembly assembly and drew a 3D model of the sharpener in detail on a computer. Here's what happened

Having filed the corners with a grinder, processed the cuts with a file from burrs and cleaned the surfaces of paint with a metal brush and sandpaper. I leveled the planes from irregularities with a file and put sandpaper on a piece of chipboard and brought out the ideal plane. I marked and drilled holes in the horizontal shelves, according to the drawing. With the help of a grinder and a file, I grinded off the bevels on the sponges so as not to interfere with the movement of the grindstone. Carefully sanded the marks with sandpaper. I removed the radii in the corners with a file. I found a long bolt and an M10 wing nut in stocks of fasteners.

I marked and drilled holes in the vertical shelves. On the outer side of the corner, using a large-diameter drill, he removed large chamfers, and bored the holes with needle files to an elongated groove.

I scrolled the holes in the sponges and cut the M10 thread under the rack. The stand will serve as a large bolt with a nut. For this bolt, the entire system will be mounted in a desktop vise. A tightened nut on the strut will prevent the structure from turning and play.

Gathered everything together, fixed the knife, everything, you can use it.

After a few days of operation, I made minor adjustments to the design of the terminals. I drilled a couple of holes in the side planes and cut the M6 thread. Inserted spare screws into these holes. Knives come in different thicknesses, and the sharpener guide catches the screws. Having selected short screws from the stock of fasteners, he screwed them into place in the terminals. The stock pocket does not pull and is always at hand.

On occasion, I got hold of a wing nut with an M6 thread. With such a nut, it is more convenient and faster to tighten the grinding stones on the stud.

For complete set I will buy whetstones of various grain sizes. They are not expensive, from 20 to 50 rubles apiece, they are sold on any construction market or collapse. Again, you can use Lansky's branded stones.

It remains to find a suitable box for storing the sharpener. Gift tin and plastic boxes made of sweets or cookies, which are quite widely represented in pastry shops, are suitable for this role. Finding the right one isn't hard. Goodies to gobble up for the end of creating a sharpener, and the jar is in business. In order for the sharpener not to hit the walls in the jar, the stones do not deteriorate, it is useful to glue pieces of dense fabric or thin foam rubber onto the walls and bottom. Or cut grooves in a piece of plywood and pack all the iron and pebbles into them.

The sharpener is on my desk, and I spent the least amount of money, mostly on whetstones. We can say that I paid only for the donkeys, but for the M6 threaded stud.

I don’t see any point in paying our huckster-sellers. The sharpener is done for several hours, half a day maximum, and then only because the paint dries for a long time.

In online stores, which is much cheaper than in regular stores, the Lansky sharpener costs at least 1,400 rubles. And here is almost a useful device.

Of course, the Lansky sharpener has a number of drawbacks, such as a limited number of sharpening angles, which are slightly offset by the position of the cutting blade relative to the clamp, and the high cost of a branded product. These shortcomings are relatively easy to eliminate at home with an elementary plumbing tool, ingenuity and a little free time.

During the production of the clip, when the terminals were almost ready, I was presented with a real Lansky sharpener. So, in a homemade device, the need has disappeared. Thanks KonstP. Terrible revenge, for this irresponsible element, was in the form of a delicious dark beer.

During the production of the terminals, I came up with a simpler and more functional design of the knife clamp, but more on that in the next chapter of the Notes.

The surface finish of the terminals is far from perfect, since there was no task to set up a marafet. The product can be painted, since there is paint in the can.

Do-it-yourself knife sharpeners: types and drawings

Every housewife sooner or later begins to dull the knives with which she cuts bread, vegetables or butchers meat. Using a dull knife is not only inconvenient, but also unsafe. At any time, it can break off the cut product and cause injury. Therefore, periodically the tool should be sharpened, using a special device for sharpening knives.

Every housewife sooner or later begins to dull the knives with which she cuts bread, vegetables or butchers meat. Using a dull knife is not only inconvenient, but also unsafe. At any time, it can break off the cut product and cause injury. Therefore, periodically the tool should be sharpened, using a special device for sharpening knives.

Such sharpeners in a wide range are available in stores. But for one reason or another, they do not always suit the consumer. In this case, you can make a device for sharpening knives with your own hands, having previously studied the types of stones for sharpening, the features of the tool and the proposed drawings.

Sharpening knives - prerequisites

For efficient and long-lasting knife operation the most important factor when sharpening it is blade angle. In the process of sharpening, it is necessary to restore the previously set angle, which will fully comply with technological standards and quickly, freely and efficiently cut the material.

For each blade, its optimal angle is selected:

- for a razor and a scalpel, the sharpening angle should be 10-15 degrees;

- knives for cutting bread, fruits and vegetables are sharpened at an angle of 15-20 degrees;

- multifunctional knives for various products are processed at an angle of 20–25 degrees;

- hunting and hiking knives - at an angle of 25-30 degrees;

- knives for cutting hard materials - at 30-40 degrees.

Without a special device, it is difficult to sharpen the blade at the right angle. Holding the knife with your hands, it is quite difficult to provide required angle of inclination cutting tool. To facilitate this process, there are special devices that you can make with your own hands. Their designs are quite simple, and the production itself will take not so much time.

DIY knife sharpeners

There are many types of sharpeners for knives, among which you can choose the one that best suits your needs.

There are many types of sharpeners for knives, among which you can choose the one that best suits your needs.

All devices consist of two parts:

- a bar of abrasive material;

- stop for attaching a knife.

As a bar, you can use ready-made special stones or make it yourself.

Sharpening stones - types and manufacture

On sale you can find several types of stones:

Aquatic tools. When working with them, water is used, which saves the surface of the stone.

Oil the stone resembles water in structure and shape, but its surface is the most oily.

Natural instruments are made from natural stones undergoing industrial processing.

artificial stones are made from non-natural components.

Rubber tools can also be found on sale, but working on them is not very convenient.

For self-production of an abrasive bar, you can use small plates of glass rectangular shape and a thickness of 4-5 mm. On the surface of the plates with the help of double-sided tape, you need to stick sandpaper of different grain sizes. The cost of such bars will turn out to be quite small, and sandpaper can be replaced at any time.

However, when using a glass bar, you should be very carefully tighten the nuts. otherwise the glass may crack. In addition, no water is used in its application, so the abrasive wears out quickly. For the same reason, when sharpening knives, fast movements should be avoided, which can lead to overheating of the material, and, therefore, to loss of blade properties.

Tool for sharpening wood blocks

It is enough just to make a sharpening tool from two wooden and two abrasive bars, which should be the same size.

For greater stability of the sharpener to its lower surface, it is recommended attach a piece of rubber .

Do-it-yourself sharpener from mounting brackets

The Lansky sharpener is taken as the basis for such a device, the drawings of which can be easily found on the Internet.

- metal plates measuring 4x11 centimeters;

- standard aluminum corners;

- metal rods about 15 centimeters long;

- a set of nuts and bolts;

- grinder with a vise or file;

- file.

Instead of a grinder, you can use a file, since this tool is only needed for grinding sharp corners from the corners and cleaning the places where the metal is cut.

Steps for making a sharpener:

- According to the drawing, markings are made for future holes in the plates.

- Holes are drilled and threaded into them.

- With the help of a file, all sharp corners and edges are rounded. This will allow you to comfortably use the made knife.

- Holes are made in the corner in accordance with the drawing.

- The hole for the spoke support is expanded with a needle file.

- The holes for the studs are threaded.

- The rods are inserted into the extreme holes and fixed with nuts of the appropriate diameter (M6).

- An M8 bolt is screwed into a wider hole, the length of which should be about 14 centimeters. A wing nut must first be screwed onto it, on top of which two ordinary nuts are screwed. The bolt in the structure will be used as a support post.

- Bolts are attached to the remaining holes, with which the knife will be clamped.

- Nuts are screwed onto the ends of the rods, a corner is strung, which is fixed with nuts. By lowering or raising the rods, it will be possible to adjust the sharpening angle.

- From a thin metal rod in the shape of the letter G, a rod with an M6 thread, two holders and a wing nut, a device is assembled that will hold the stone for sharpening. The end holder must be through hole under the needle

Such a device for sharpening knives has a fairly wide range of degrees of pressure angle and is most convenient to use.

Massive sharpener with stand

With your own hands, you can simulate a knife sharpener from Apex, the drawings of which are easy to find on the Internet. Such a knife sharpener is presented in the form of a stand, on which a platform is installed at an angle, and a support for the end of the nozzle in the form of a rod is placed on the side. This is a very convenient device with which you can sharpen any cutting tools with high quality.

Required materials and tools:

The angle of sharpening on such a device adjustable with bar and lamb. which fixes the part at the desired height.

Each of the described devices has its own advantages and disadvantages. When choosing a suitable option, you need to proceed from your needs and skills in such work that you will need to do with your own hands.

Knife sharpener - essential tool on the farm

IN household there are always cutting, sawing and planing tools. In the course of work, the sharpness is lost, and the blades have to be restored. You can give knives - planes to the workshop, but money is spent on this, and extra time is wasted. Therefore, home craftsmen prefer to sharpen the tool with their own hands.

Important! Only blades with a certain degree of hardening can be sharpened. If the cutting part has a hardness higher than 55 HRC, it cannot be sharpened with improvised tools.

You can buy a tool for sharpening knives or other household utensils in the store. Save time, but spend a lot of money - good sharpening is expensive.

By the way, there are different opinions about the name of the tool for sharpening knives. Emery, touchstone, whetstone, whetstone, musat ...

Can these definitions refer to the same object, or different products? About this, and how to make such a device yourself, we will tell in the article.

Since the advent of cutting objects (weapons, knives, axes), people have been looking for a way to restore the sharpness of the edge. In the Bronze and Copper Ages, it was easy.

Homemade knife sharpener made by hand. The knife cuts paper like a razor! Simple design available to make at home.

Soft metals were ruled by any stone. With the advent of steel blades, special rocks were used for sharpening, usually of volcanic origin.

Some of them are still used today: the American "Arkansas" and the Japanese "water stone". These are expensive devices, so most craftsmen use artificial emery.

A simple whetstone can sharpen both the knife and the cutting edge of the planer. However, the quality leaves much to be desired.

The golden rule of sharpening: Each blade has its own edge angle, and it should not change along the entire length.

This principle lies in the design of all grinding devices. By following this rule, you can independently manufacture such a device.

Do-it-yourself knife sharpening device - drawings, varieties

In order for the edge of the blade to be processed evenly, several conditions are necessary:

- Blade fixation, at the same time reliable, and without undue stress. Metal must not be damaged in a vice

- Setting a specific angle for the bar. When moving along the edge of the knife, the angle should not change

- Possibility to set different sharpening angles. You can process various tool, and some types of knives have a stepped structure.

Device for linear sharpening with a bar

For manufacturing you will need:

- Plywood or laminated chipboard

- Full length threaded steel stud, diameter 6-8 mm

- A bar of textolite or ebonite. Can be replaced with solid wood - beech, oak

- Aluminum plate 3-5mm thick

- Fasteners - bolts, nuts (wing nuts are better)

- Neodymium magnet from an old computer HDD.

We assemble a frame from plywood, resting on the legs at an angle of 15 ° -20 °. In the part below, we twist a hairpin 30-40 cm long. For strength, you can fix the thread with glue or sealant.

We fix an aluminum plate in the middle of the working surface. First, we make a groove in it, according to the diameter of the fixing bolt. Why aluminum? In order not to damage the steel blade of the knife.

We make a lever for fixing emery. It is assembled from the rest of the hairpin. We cut out bar holders from two textolite bars. On one side, the stop is fixed with a nut.

From the side of the handle it is more convenient to make a spring-loaded block - for a quick change of emery.

We use home-made bars as the main element - we glue sandpaper with different grain sizes on an aluminum plate. Such devices are easily fixed in the lever.

The design feature is a hinge with two degrees of freedom. It is assembled from two identical textolite bars. One is screwed onto a vertical stud, and serves both as a horizontal rotary axis and as a lever support height regulator (this is how the sharpening angle is set).

The second bar, with a horizontal hole for the lever, is screwed to the first. This ensures free movement of the lever vertically.

The knife can be clamped with a plate, or mounted on a neodymium magnet. When removing the first layer with coarse emery, the blade should be firmly fixed.

For finishing, you can install the blade on a magnet and sharpen with little effort. The horseshoe of the magnet should be sunk flush with the table top, and glued with epoxy glue.

Homemade fixture ready to sharpen knives. We set the required angle of attack, and sharpen the edge with smooth movements along the blade.

The same principle is used in the device for sharpening knives on an electric grinder.

Electric emery not only speeds up work, but also allows you to get a high-quality concave blade edge profile. This is the so-called fuller sharpening. It will not work to get such a shape on a linear bar, therefore these two devices do not replace, but complement each other.

Important! If, when working with a manual sharpening device, you completely control the intensity of the process, then the high speed of rotation of the emery wheel can ruin the knife.

From friction, the metal on the tip heats up, hardening occurs. Steel loses its hardness and grinds with torn edges. Another problem is that a “released” knife quickly loses its sharpness. Therefore, the electric sharpener should be handled with care. Bring the blade for a short time, and take breaks to cool.

Do-it-yourself knife sharpener - video with explanations and an example of manufacturing

In this mode, it is difficult to maintain a constant angle, so fixing the knife is required.

The design is quite simple - along the axis of rotation of the emery there is a guide along which the carriage with the knife moves. The angle is maintained mechanically, and the force is determined by the operator.

The device is easy to do with your own hands - and it is not necessary to perform precise work on the processing of metal parts. The guide is made literally from the foot material.

On the workbench, next to the sharpener, guides are attached, with which you can change the distance from the knife stop to the rotating circle. This distance determines the angle of sharpening. The vertical rod must have a free movement up and down with a strong fixation of the position.

The knife is held horizontally, pressing against the stop. The force of contact with the emery is regulated directly during sharpening. The processing is symmetrical, you just change the side of the knife and sharpen at the same angle.

This method is only suitable for processing classic knives. Kitchen, hunting, tourist. Cutting planes of other tools require a different approach.

Design for sharpening knives, say jointer:

A specialized emery is used, with an end working surface. The guide for the carriage is placed at the bottom, away from the axis of rotation.

It is in this part of the disk that the abrasive is most effective. The guide with the cutting element is moved manually, the clamp is provided by the own weight of the knife.

Drawings of all structural elements are shown in the illustration.

This machine was used almost 100 years ago, and since then the technology has not changed. Ease of execution allows you to repeat the device in the home workshop. Any materials - metal, plastic, wood.

Instead of jointer cutting elements, it is possible to sharpen ice ax knives for winter fishing. Only the angle is more gentle. The scissor tool works the same way. The design (like the emery wheel) is significantly smaller in size.

To sharpen chisels and planer knives, you can also use electric emery and a fixing carriage. However, these tools are compact and can be handled by a mechanical fixture.

There are two equivalent ways - along the edge, and across. The processing quality is about the same, so you can not give preference to a particular device.

The factory product involves transverse straightening of the blade.

By analogy, we make a carriage from thick plywood. We use any rollers as guides, preferably in an amount of more than two. By moving the machine along the emery, you can give the tip of the chisel an ideal shape.

If you do not need serious sharpening, a simpler device is also suitable for small editing. Fasten a bar to the chisel with the required angle of inclination. Put emery and a piece of glass next to it. Apply soapy water to the glass.

The effectiveness of the device will pleasantly surprise you.

And for transverse sharpening - you can make an equally simple fixture. The guide is also a support. The blade is vertically mounted on the moving part. The only drawback is that the angle is fixed and is determined during manufacture.

True, unlike a knife, the deviation from the ideal is not so critical.

The same device is suitable for sharpening planer knives. Only because of the width of the blade, the process is quite laborious. Therefore, you can use an electric emery with an end working surface.

The emphasis is made from wooden block. It is only necessary to provide a change in angle. The clamp is provided by the operator, and it is possible to perform semicircular sharpening - carpenters will appreciate this option.

Of course, with the same apparatus it is convenient to tidy up the edge of the chisel. Given the high performance, you will restore the tool even after serious chipping.

Homemade tool for sharpening knives and tools from a grinder

When you again manually rub a knife on an old donkey, remember this article and create a home-made sharpener for your home workshop.

Homemade machine for sharpening knives with your own hands: diagram, instructions, manufacturing features

Every man in the house will benefit from a convenient do-it-yourself knife sharpening machine. Indeed, often the owner is judged by how sharp this kitchen tool is.

There are many techniques for sharpening knife blades. For example, for a process carried out at home, only a turning bar or ready-made fixtures with an angular gap shape will be sufficient.

To adjust expensive hunting knives, European manufacturers produce devices in the form of solid bars, which are based on a high-strength alloy.

This article will describe the manufacture of a machine for sharpening knives with your own hands.

Why do knives get dull?

What is the reason why a knife becomes dull when cutting? This can be explained by the fact that abrasive particles that are present in the material being cut have a negative effect on the cutting edge. For example, they are present on vegetables, paper. talking plain language, the blade is subject to gradual wear.

The next reason is the inability to keep the blade in the right position all the time. Any trembling of the hand causes the knife to tilt, which entails a lateral load.

sharpening technique

The sharpening technique consists in unified, but at the same time quite laborious methods. The main task is to eliminate damage to the blade. It should be noted that for many, such a procedure as sharpening knives provides a good mood and calm.

The basic rule in this process is to maintain a precisely set constant angle. Strength is not required here. The main thing is that the bar and the blade meet under certain angle. This is the basic rule of sharpening technique.

What needs to be done to maintain a constant angle?

In order for the angle to have a constant index, there are two ways. The first is to acquire the skill of sharpening. The angle indicator can be controlled using a conventional marker. They should paint over the carts and after several sharpening cycles, see how much the paint has survived. If it is worn unevenly, then the blade is not well processed.

If the knife being sharpened is decorative, then the blade should be sealed with adhesive tape so that only the edge for cutting remains open. Even if you unsuccessfully direct your hand, there will be no scratches on the blade.

It is also important that the direction of the blade along the bar is perpendicular to the edge at the points of contact. In fact, this is quite difficult to do. It is acceptable for the angle between the edge and the blade to be less than 90 degrees. But when directed along the cutting edge, this indicator is not suitable.

The abrasive particles of the bar can leave grooves on the blade that will never be sharpened, but will play a positive role when cutting. If the grooves are oriented along the cutting edge, then they will not be useful when cutting. The worst thing is that the cutting edge can break off altogether.

It is important that the bar is long. It should be one and a half or two blade lengths. It is acceptable that the diamond bar be somewhat shorter, as it grinds faster and better. Its width does not play a significant role. If it is wider, then it is more convenient to work on it and there is less chance of leading the blade beyond the device. This can damage its side surface or the blade.

Making a machine for sharpening knives with your own hands

Homemade devices for sharpening knives are different designs. All that is required from the manufacturer is the availability the right material and tool skills.

The principle of operation of such a device as manual machine for sharpening knives with your own hands, is to hold the knife blade in a vertical position and drive it along a bar fixed at the right angle. This is much easier than placing the sharpener horizontally and holding the knife at just the right angle.

In order to make a do-it-yourself knife sharpening machine, you need a piece of laminate, a wooden rail, sandpaper and a pair of lamb bots. Chipboard or plywood can serve as a replacement for laminate

To make a knife holder, you need to cut off part of the material. So that the bar does not touch the holder when sharpening, it is necessary to clean its edge at an angle with emery.

It is necessary to mark and cut off the top of the vertical rack, which will serve as a support for the bar. The angle is chosen two times less than the one with which the knife will be sharpened. For kitchen knives, it is recommended to take an angle of 10-15 degrees.

A do-it-yourself knife sharpening machine, the drawings of which are obviously drawn up, involves the correct calculation of the length of the base of the racks. Please note that the subsequent installation of the transverse support will affect the height indicator. After that, all the details are cut off, and the edges are cleaned.

Holes are marked and drilled in the base and plate for pressing the bolts that fix the blade. When marking, the distance of the holes from the edge of the base is maintained. This is necessary for the versatility of the fixture, since all knives have their own width. The pressure plate is fixed with bolts.

Vertical posts are attached with screws. The moment that the load on the bottom is small is also taken into account. In this case, it is better to resort to using thermal glue. The horizontal bar is attached in exactly the same way. The grinder is almost ready. It remains to make a bar.

For its manufacture, a rail is cut desired length. Sandpaper with the desired size of abrasive is glued to one edge. To optimize the result, you can resort to the manufacture of several bars with different indicators grit. The range P600 - P2000 is considered the best. In order to protect your hands from cuts, you need to screw the handle on the top side of the rail.

The result is a homemade machine for sharpening knives with your own hands, characterized by high functionality and practicality. During operation, the device rests against the edge of the table, which is quite comfortable when using it.

A do-it-yourself knife sharpening machine can also be of a different type. In this case, it is based on the M8 threaded rod. Two large washers and nuts were used, which serve to hold a bar 200 mm long.

Heat shrink tubing covers the thread. A pair of paper clips hold the rail stand at the correct height. This ensures smooth adjustment of the sharpening angle. The base is a beam, the thickness of which is 40 mm. It is supported by hand.

How to sharpen planer knives with your own hands

Every owner who has a planer or jointer has probably faced the problem of sharpening their knives. Buying new ones from time to time is expensive. Knives can be easily sharpened by hand. In this case, specialized machines or grinding stones are used. If the planer is used constantly, then it would be better to make a machine for sharpening knives with your own hands.

Do-it-yourself planer knife sharpening machine

To sharpen the planer knife, special sharpening equipment is used. The machine for sharpening knives with your own hands has a compact size. It can be installed in the garage or on the plot.

Many are interested in how to make a machine for sharpening knives with their own hands. To make a device, you need to find certain parts. Perhaps these parts are lying around in your shed or garage. They can also be purchased online.

The machine for sharpening planer knives with your own hands consists of:

First of all, you should find a faceplate. This is the most important component of future equipment. It is she who is responsible for the sharpening process. Jointer knives are narrow, and the faceplate serves as a guarantor of complete and safe sharpening. This part will have to be bought new, but the rest can be used old.

It is better to purchase faceplates of German or American production. The average cost of a part is 25,000 rubles.

The next step is to find the engine, the power of which should be 1-1.5 kW. It is not necessary to buy it. Any will do, even old ones washing machine. But everyone will surely have a table, a casing and a vacuum cleaner.

The main steps in the manufacture of the device

When the table is selected, the engine is fixed directly below it. A faceplate is attached to the moving part. The engine must initially be equipped with a button that turns the unit on and off. It should be comfortable.

For reliable protection, the faceplate is covered with a casing square shape with one cut corner. It is this area that needs to be sharpened.

On the bottom surface of the table in the area of sharpening, a hole is made of the same diameter as that of a vacuum cleaner hose. The presence of a vacuum cleaner is not essential, but it is desirable to install it. It removes unnecessary dirt from blade processing.

What do you need to know?

Mounting the motor under the faceplate base is optional. You can make sure that the parts are connected by means of a belt. In this case, the design will be complex.

A do-it-yourself jointer knife sharpening machine is also suitable for saws and axes.

Ice screw sharpening

The sharp knives of the ice drill enable the fisherman to quickly make holes in the ice of reservoirs. However, over time, all cutting tools become dull and require sharpening.

For fishermen, a quality ice drill is a great pride. Often, true competitions are held on water bodies in terms of the speed of drilling ice holes. And victory does not always smile at young and strong fishermen who are armed with imported devices. There are times when seasoned fishermen equipped with simple Soviet-made tools are the winners in the competition. The reason for the high hole drilling speed lies in the good sharpening of the knives and the correct setting of the device. Beginner anglers, having bought new Swedish devices, do not even have time to blink an eye as their knives become blunt. The smallest grains of sand and pebbles in the ice contribute to the formation of chips and gouges on the blade.

Sharpening of devices is carried out by the most different ways. Many of our ancestors did not even know what a professional grinding machine. In most cases, sharpening was carried out using hand-made devices.

Homemade ice drill machine: what is needed to make it?

For the manufacture of such a device as a machine for sharpening ice drill knives with your own hands, you will need two strips of steel, the thickness of which is 4 mm, the width is 60 mm, and the length is 200 mm. A spring from a car is often used as a strip. But she is very hard to bend.

Progress

First you need to make the body of the device. The steel strips are bent in such a way that the chamfers of the knives pressed against the ends of the arc are not only parallel, but also in the same plane.

After making the arc from the same steel strip, the pressure plate is bent, which serves as a lock for the sharpened knives.

Holes for M12 or M14 bolts are drilled in the body and pressure plate. Having pulled the body and pressure plate together with a bolt and nut, we clamp the knives between them and check the strength of their fit to the surface of the end face of the emery circle.

If the knives are not located at the required angle (the chamfers do not fit exactly to the circle), then the device is modified by bending the body arc to the appropriate level. If the knives stand correctly, then the structure is disassembled, and stiffeners are welded to the arc of the body on both sides.

Sharpening knives is best done on an emery stone that rotates horizontally. In this case, when wetting the knives with water, the latter remains on the blade and stone longer, ensuring their safety. Dip your knives in the water more often. This will help prevent overheating of the steel.

Minus the device

The disadvantages of the device include the impossibility of sharpening knives with different angles of the cutting chamfer. But each manufacturer of ice drills offers its own models. In this case, a universal device will do.

Making a universal fixture for sharpening an ice drill

The universal design allows sharpening knives at any angle of the cutting edge. By smoothly changing the angle between the shoulders of the unit, on which the knives are fastened with screws, it is possible to fix the desired position of the knives in relation to the plane of the grindstone.

To manufacture this device, you need to find a door canopy with minimal play, as well as an M8 or M10 screw with its own nut. Holes are drilled in the shoulders of the canopy. Their diameter is 6-7 mm (for attaching knives to them with screws).

From a steel strip, the thickness of which is 3 mm, a fixing plate is made with a slot for the fixing screw. The plate and screw are welded to the shoulders of the canopy.

It happens that sharpening of knives is carried out, the location of the holes of which does not correspond to the holes in the canopy. In this case, additional holes are drilled in the shoulders for non-standard knives. In this case, the device has more versatility.

How are planer knives sharpened?

Attachments such as planers and thicknessers can often be seen in country houses. By means of them, raw lumber is brought to the desired state. Knives of these devices, like any others, become dull. If you use them often, then the best way out is to sharpen the knives for the planer with your own hands. For the manufacture of grinding equipment at home, you will need various materials: metal, aluminum or wood.

The knife holder can be made from a wooden block. Having made cuts at 45 degrees with a circular saw, you can sharpen knives with a band saw. grinder or a large bar. If the latter is not present, then sandpaper is attached to a smooth surface made of metal, wood, chipboard or glass.

Knife holders can be made from improvised materials. The optimal solution will use metal corners, which have an indicator of 90 degrees. When placing two knives on the sides, the sharpening angle of each will be equal to 45 degrees. Using screws, you can fix the knives with a second corner.

Celebrity Chefs Name Culinary Destinations Underestimated by Gourmets Looking for an unforgettable culinary experience? For them it is not necessary to go exactly to Paris. There are other directions as well.

Contrary to all stereotypes: a girl with a rare genetic disorder conquers the fashion world This girl's name is Melanie Gaidos, and she burst into the fashion world swiftly, shocking, inspiring and destroying stupid stereotypes.

9 Famous Women Who Have Fallen In Love With Women Showing interest in someone other than the opposite sex is not unusual. You can hardly surprise or shock someone if you admit it.

Unexpectedly: Husbands Want Their Wives To Do These 17 Things More Often If you want your relationship to become happier, you should do the things from this simple list more often.

How to look younger: the best haircuts for those over 30, 40, 50, 60 Girls in their 20s don't worry about the shape and length of their hair. It seems that youth was created for experiments on appearance and bold curls. However, already

11 Weird Signs That You're Good in Bed Do you also want to believe that you're giving your romantic partner pleasure in bed? At least you don't want to blush and apologize.

- Why you need a sharpener

- How do you sharpen a knife?

- Sharpening profiles

- Touchstone

- Knife sharpeners

- Knife sharpening machine

- Not only knives...

Interest in how to make a knife sharpener with your own hands arises for a reason. The consumer qualities of a hand cutting tool are enhanced by the use of modern materials and technologies for blade manufacturing and precise factory sharpening. At the same time, the price of the product is also growing, but it is becoming easier to spoil a fairly expensive thing with primitive sharpening. Therefore, various household appliances for sharpening knives are needed not only for convenience. To figure out why a knife sharpener is still needed and how to make it right, you have to start with the ideology and evolution of the knife.

Why you need a sharpener

A living relic of our days is a Finnish hunting knife. Not a bandit finca, sometimes of a bizarre shape, but a Finnish-type hunting knife, on the left in fig. Traditional hunting knives (center and left) are similar in shape to it, but the difference between them is very large.

The blade of a Finnish knife is forged from bloomery iron, which can be smelted right in your yard from swamp ore in a domnitsa furnace, without resorting to the blast furnace process, puddling, and other methods of converting cast iron into iron and steel. The viscosity of bloom iron is excellent, it is very difficult to break a blade from it. But the hardness is also low, somewhere around HRS55, the knife gets dull pretty quickly. Finnish hunters did not care: a blade of such hardness can be directed (sharpened) by beating on many natural stones, and there were always enough smoothed moraine boulders in Fennoscandia.

They sharpen the knife with a beating in much the same way as they beat off a scythe, only the touchstone is motionless, and the blade is moved. First, he is pulled along the donkey with the butt away from himself, then he is turned over and pulled with the butt towards him. The position of the cutting edge (RK) on the touchstone is always dragging; the movements are fast: shirk-shirk! On each movement, you need to keep the contact patch of the blade with the touchstone (see below), but the requirements for maintaining the angle of inclination are not so strict. Learning how to sharpen a knife with a bevel is not very difficult, and with some skill, you can also aim a smoothly running profile at the blade, see below. However, the Finnish knife is, in general, a dead end in the evolution of a cutting tool that has survived in special natural conditions.

A good knife has never been cheap, but in extreme situation the durability of the blade, combined with the toughness of the blade, became vital circumstances. Therefore, even in ancient times, knife blades learned to be hardened from the surface and cemented: the core remained viscous, not brittle, and a hard, hardened crust formed on the outside, see next. rice.:

It is still possible to direct a knife with a cemented blade with a beating, but a skill is needed that is not given to everyone. And the abrasive is already needed from a special breed of stone - lithographic grunstein shale. It is scarce in nature; grunstein is still considered a strategic raw material. There is no artificial grunstein and is not expected. Spoiling a cemented knife with an inept chop is as easy as shelling pears - a little somewhere, the cementation bark will be torn off to raw metal (this is not visible to the eye), the knife will only be thrown away, the blade will immediately become dull and will crumble.

Note: if you have an old slightly greenish scythe touchstone lying around somewhere, do not throw it away, it is a valuable rarity.

Knife blades don't need the toughness and toughness of hunting and camping knives, and they should cost a lot less. As a result, special steels and powder metallurgy are widely used in the production of home knives. The blade of the "eternal" kitchen knife is structured like a rodent cutter: in longitudinal layers, the hardness of which decreases from the core outwards. In any case, you have to sharpen the knife less often, but the beating is definitely excluded - the blade from it immediately crumbles.

How do you sharpen a knife?

For these reasons, the push-pull sharpening technology (push-pull sharpening or push-pull sharpening technique) has long been invented:

- The blade is pushed along the touchstone away from oneself with a twist, holding the butt towards oneself, the position of the RK is running (scraping);

- Then, without tearing the blade from the touchstone, they pull it with the butt towards themselves with a twist in reverse side, RK dragging position;

- The blade is turned over and repeat paragraphs. 1 and 2;

- Pp. 1-3 are repeated, in each cycle reducing the pressure, until the burr formed on the RC comes to naught (does not stick together).

Note: when they say or write “the burr will go away”, etc., this is not true. Metalheads have a slang word for slang; electricians have a “switch”. But in Russian, a burr and a switch are masculine.

Push-pull sharpening saves the blade, but requires high skill from the operator, because. during the sharpening process, a number of conditions must be continuously and precisely observed, see also fig. below:

- Maintain the angle of inclination of the blade to the touchstone, smoothly changing it in accordance with the curvature of the RK.

- Make sure that the tangent to the generatrix of the blade and the transverse axis of the contact patch of the RC with the touchstone coincide.

- Also make sure that the axis of the contact patch is always perpendicular to the longitudinal axis of the touchstone.

- Smoothly change the pressure on the blade as the area of the contact patch changes.

It is very difficult to meet all these conditions at the same time, completely symmetrically on the forward and reverse stroke of the blade along the touchstone, and a modern knife, as mentioned above, can be damaged by improper sharpening. Any household knife sharpener is just designed to save the grinder from continuous control of at least part of these conditions.

Note: for successful push-pull sharpening, the length of the whetstone (see below) must be at least 2 lengths of the knife blade from shank to tip.

Sharpening profiles

The profile of a knife blade is linked to the properties of the material and the structure of the blade, as well as to the properties of the materials for which the tool is intended to be processed. Sharpening on a simple blunt wedge (pos. 1 in the figure) gives a stable but rough blade: cutting resistance is high, and the knife tears quite viscous materials. A sharp wedge (pos. 2) quickly becomes dull or chipped; on viscous and / or fibrous materials, the cutting resistance may be greater than a blunt wedge due to the friction of the cut against the blade.

Ideal in all respects is an animated (smoothly escaping) profile, pos. 3. Experts are still arguing which generator is better - evolvent, hyperbola or exponential. But one thing is indisputable - it is difficult and expensive to make an ogival blade under production conditions, and it is impossible to direct it yourself. Therefore, knives with ogive sharpening are used only in special equipment, for example. microtomes - biological devices for obtaining the thinnest tissue sections.