Homemade brazier from a metal barrel - different design ideas, as well as a manufacturing method. Creating the simplest barbecue from a barrel according to a step-by-step plan Grill from a barrel of 200 liters

Having a summer cottage, most owners think about installing a barbecue. Besides good rest characterized by the preparation of barbecues and shish kebabs, you can’t do without a barbecue grill.

For kebabs, a simple barbecue made of a couple of bricks may be suitable, but you cannot cook a juicy barbecue on such a structure.

You can buy a ready-made brazier or make it yourself. The question is only with the choice of the type of barbecue, which can be mobile or stationary.

For the production of a stationary barbecue, concrete or brick is used. The mobile oven is made of metal.

Advantages and disadvantages of the design

The main advantages of this solution:

- easy to clean, repairable and low maintenance.

- It is convenient and safe to use it. Welding work can be carried out independently.

- The metal perfectly retains heat, as a result of which the meat is quickly and evenly fried. The cost of such a design is acceptable for any budget.

- Barbecue from the barrel is very convenient when transporting over short distances.

However, such a device is not resistant to corrosion, heats up quickly, so if precautions are not followed, burns can occur.

What advantages does it have? Learn how to make such a greenhouse with your own hands in our article.

What advantages does it have? Learn how to make such a greenhouse with your own hands in our article.

A good solution for giving is also a metal barbecue, the manufacturing instructions for which are in the full step-by-step version.

Required tools and materials

The main part of such a brazier is a metal barrel.

It should be noted that do not use barrels that were previously used for fuels and lubricants.

Also, for the manufacture of the original design, you need to prepare:

- door hinges;

- 4 rubber wheels for transportation of a brazier;

- steel corner from 45 mm;

- metal handle for the door;

- wire mesh.

The main tools for carrying out the work are the following:

- roulette;

- Bulgarian;

- welding machine;

- grinding and cutting disc;

- electric drill;

- jigsaw for metal;

- bolts;

- steel sheets.

Mangal can be made from old barrel any sizes. In addition to it, you can use the old gas bottle.

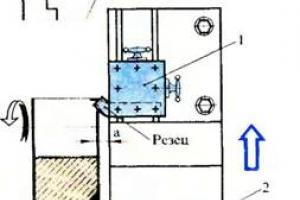

The photo shows an approximate scheme by which you can make a brazier from a barrel.

Manufacturing instructions

How to make a brazier from a barrel? The whole procedure takes place in several stages.

Preparatory stage - cutting

The production of the structure will not take much time, but will be saved cash that can be spent on the purchase of new equipment.

The barbecue model from the barrel can be produced in two variations - with or without a lid. The first model is made from two halves, and the second - from one.

Regardless of the option chosen, you should draw a schematic representation of the future design with detailed description all parameters and details. The drawing will be the main assistant in the process of work.

The second stage in the creation of the brazier is the preparation of all the constituent parts. First you need to cut the barrel with a grinder to the height of the container in half (for both versions).

But you can cut out only the upper part of the barrel, which will later become a lid.

The edges of the cut barrel are cleaned and freed from various irregularities. After preparing the barrel, you should decide on the parameters of the corner for framing the opening.

If you cut the barrel in half, attach door hinges to one part, connecting them to the main part of the container, you get a finished lid.

Frame manufacturing

First, cut the steel corner in half. The optimal height of the frame will be 1 m, and its width should correspond to the width metal container.

For the side of the frame, horizontal and vertical racks are required, which are arranged according to the following scheme:

- the horizontal top rack is installed from the top edge at a distance corresponding to the outer radius of the container;

- the lower horizontal rack is mounted at a height of about 20-25 cm from the edge of the vertical bottom.

All 4 posts must be laid out on a suitable surface and connected with a welding machine at an angle of 90º.

According to a similar scheme, you need to make the other half of the frame, as a result, both frames are combined into a common design, so they should be the same. The side parts are mounted with each other with steel corners.

This stage of work requires attention, because due to any error, the brazier will turn out to be uneven.

After the frame is made, wheels are attached to it. To make transportation more convenient, a convenient handle is attached to the frame.

A container should be placed on the frame so that the drain hole is at the back and top. It will play the role of a small exhaust pipe. inserted into the exhaust hole metal pipe the desired diameter.

The stand for the barrel can have various configurations:

- in the form of two semicircles in which the barrel will fit;

- a frame designed for the parameters of the barrel (the process of its manufacture is described above);

- a pair of crosses welded from a corner, having developed corners according to the size of the brazier.

Processing of the inner compartment

In the manufacture of mangal from metal barrel, work must be carried out both from the outside and from inside. Corners are welded in the inside of the container.

To make a brazier, you can weld 2 corners on the sides, and the remaining two in the center of the container.

For coals, a pair of corners placed on the side walls will suffice. They are located from the bottom at a height of about 10 cm. On such corners there is a metal mesh on which you can barbecue.

Barbecue with a lid can be used as a smokehouse, for which a chimney is mounted to the side.

For convenience, shelves-tables can be attached to the sides of the barrel. In this case, metal brackets should be welded to the barrel, where a metal or wooden coating is additionally attached.

According to the same scheme, you can make a brazier from an oxygen or gas cylinder. But keep in mind that their width will be smaller and suitable only for short skewers.

Surface treatment

To paint the brazier, you should purchase heat-resistant paint, since other types of coatings will not work here. After the paint has dried, the brazier will be ready for use.

You can think about the original finish of the structure, so that you end up with a unique design.

Paints that can be used for coloring

The following heat-resistant coatings are suitable for barbecue:

- Powder thermal paints. They are suitable for barbecue, but it is difficult to work with them on your own, because they need high-temperature firing.

- Silicone enamels. Coatings are resistant to temperatures up to 600ºC.

- Oxidation. This procedure is not simple, but it can be performed at home. The brazier bowl is treated with 5% sulfuric acid, boiled in a concentrated soap solution and boiled for 1.5 hours in a sodium hydroxide solution. After that, the brazier is treated with a non-stick layer that protects the metal from rust and corrosion.

It is easy to make a brazier from a barrel, but the only difficulty is the use of a welding machine.

Availability suburban area simply obliges to have a place and devices for a “tasty” rest on it. One of the most popular of them is the barbecue and barbecue grill, or both, combined in one installation. You can, of course, if there is an opportunity and the area allows, arrange a whole recreation complex with a stove and a gazebo. But, unfortunately, not everyone can afford it, and therefore resort to more available methods production of devices useful for recreation in the country. One of them is a barbecue made from a metal barrel. It is quite possible to make a barbecue from a barrel with your own hands.

This design can be of two types: open, without a lid, or with a lid-door.

The first of them, due to its design, allows you to cook not only shish kebab and barbecue, but can also have a grill function if you attach additional racks for the skewer to it.

To know how to build this work of engineering, and what is needed for this, you need to understand this in detail.

Materials and tools

Before you take on the manufacture of this useful summer cottage accessory, make sure you have all the tools you need for the job, which include:

- welding machine;

- grinder (grinder);

- cutting disc for metal;

- grinding disc;

- electric drill;

- electric jigsaw working on metal;

- wrenches, drills and screwdrivers;

- roulette.

Besides, you need to prepare the main and auxiliary materials from which the brazier will be made:

- metal barrel of any size. Basically choose a 200 l capacity, but it will depend on what size grill you want to have on the site;

- fixing bolts for connecting parts;

- metal corner for framing the edges of a cut barrel, with shelves 20 × 20 mm;

- pipe Ø 20 mm or square 20 × 20 - they are needed for the manufacture of legs and supporting brackets of the barrel;

- if a version with a lid is made, then window hinges and a handle to lift the lid will be needed;

- two metal gratings;

- for convenience in moving the brazier, you can attach wheels 2 or 4 pcs to the legs .

Manufacturing process

The process of making a brazier must begin with the development of a model that you would like to receive.

1. The first thing to do is to draw up a detailed drawing of the brazier according to a pre-drawn sketch. On the diagram, you need to put down all the dimensions - it will help you clearly follow the plan, without being distracted by additional fittings.

The blueprint looks like this. But the barrel stand can also have a different shape - choose the one that you like.

2. When the diagram with dimensions is ready, you can start preparing individual parts:

- cut a corner and pipes;

- prepare fasteners: hinges, screws and bolts of the right size.

3. Next comes a rather complicated work with the main structural element - the barrel. It must be cut in one of two ways. Only part of the barrel can be cut out, which will then become the lid,

Only the future cover is cut out ...

or it is cut exactly in half (depending on the model chosen).

... or the barrel is cut lengthwise exactly in half

After the container is cut, all its edges are carefully processed with a grinding wheel so that no burrs remain on them.

Option one

- If the barrel is cut in half, its cut edges are framed with a metal corner - it is fixed by welding or screws.

- There is another option when the second half of the barrel is used as a lid. In this case, its edges are also tied with a corner.

- The two parts are fastened with hinges so that the lid can be freely closed and opened.

- To ensure that the lid does not fold back completely, On the one side make a movable mount.

- A metal handle is attached to the top. It is better to weld it in the same way as the corners.

- The hole for the cork, which is in each barrel, is quite suitable for fixing the chimney. The only thing to consider when cutting a container, if a lid is planned on it, the cork hole should be in its upper part or lid, approximately 30 degrees from the center. Subsequently, a pipe is screwed in or welded to remove smoke.

- In this model, if desired, it is quite possible to arrange racks on which the grill spit will be placed.

Varia NT Tue Oroy

- In the second option, when the barrel is not cut in half, but a square part is cut out of it, it does not require finishing with a corner, but the cut in this case must be neat and even. To do this, it is processed with a grinding disc. The cut out part - the lid is also attached to the main container with hinges.

- Special corner parts are attached to the lower cut edge of the barrel, on which gratings will be laid later.

Third option

In the third option, when only half of the barrel is used and there is no lid, a finishing corner will be needed. Grill attachments are also possible here.

4. Stand for a barrel can have a different shape:

- in the form of two semicircles, in which a round barbecue will lie;

- two crosspieces, welded from a corner, with turned corners along the diameter of the barrel;

- frame, also calculated according to its size.

- From above and in the middle, and if necessary, then from below they are fastened together with metal pieces of a corner or pipe.

- You need to choose from them exactly the one that seems easier for you to install. On the legs, four or two wheels are fixed for convenience. The mobile structure is easier to move around the site.

5. Then the barrel is installed and fixed on the finished stand using bolts or welding. Barrels or semi-barrels welded at the corners can serve for laying the grating. At a distance of 15-20 cm from the bottom of the tank, corners are welded on which the coal grate will be laid.

6. If you wish, you can arrange a convenient shelf-table on the side of the barbecue grill.

Brazier combined with a smokehouse

If you want to make a more complex design, which also includes the smokehouse function, and you have two metal barrels, you can try to make this option. In it, the most difficult thing will be connecting the two containers to each other and making a door at the bottom of the barrel for laying firewood.

Look at the attached video - this is a barbecue from a barrel with your own hands that any good host can do.

Video - barbecue and barbecue from a barrel, 2 in 1

Barbecue from a barrel can easily serve as a brazier for barbecue - for this you just need to remove the upper grate. It can also be used to prepare other favorite dishes. During the manufacturing process, you can independently invent and add additional functions, since this work requires a creative approach and gives a wide scope for imagination. Having this design on your site, you will be convinced of its usefulness and convenience.

But there are those who can not help but surprise. And this, perhaps, is barbecue from a barrel, which you can also make with your own hands!

In order to build such a homemade product, you will need some materials:

tin barrel;

specialized painting for the barbecue itself;

several hooks;

a specialized regulator, which is designed to be able to regulate the temperature process, directly, for a barbecue;

be sure to buy gloves and goggles in order to protect yourself from possible risks;

a grid designed for barbecue;

a grate made of that steel that will not succumb to the corrosion process;

bolt and nuts;

large pipes that are necessary for chimneys;

resperator;

steel and welding;

polished device;

hammer, and sandpaper;

felt-tip pen;

drill and drills.

Step 1

Before you start the main work, you need to make sure that your container is empty and most importantly, that there are absolutely no liquids in it, so as not to risk your life later, because such liquids can also be acids that tend to ignite.

Install the barrel so that it is convenient for you to remove old paint from it.

Then you need to attach two pieces tightly and weld.

Without fail, check how well your seams turned out. Consider the fact that there should simply be no gaps.

Step 3

In order to make the cuts on the barrel more accurate and symmetrical, draw small markings on it.

Step 4

Weld a few strips of steel to the edges of the sheet that you cut out. It is they who will not allow the lid to fall through when you close the barbecue.

Step 5

After these steps, you need to clean the barrel radically. For such purposes, you can use specialized oil-based products.

Step 6

The base of the barbecue should be made of rods.

As for the frame, it is in the form of a certain rectangle that will fold inward.

Step 7

To make a handle, you must apply, directly, welding.

Next, attach the handle to the barrel itself. And do not forget in the process of working to remove shavings from the metal.

Step 8

Finally, paint the barrel with a specialized paint that can withstand fairly high temperatures.

The article describes all the pros and cons that a brazier made on the basis of a metal container has. The stages of work on creating a structure, as well as the tools and materials necessary to create such a brazier at home, are listed.

Barbecue from a barrel in a few hours

Holidays in the country are most often associated with cooking barbecue in a pleasant company. Some have portable braziers in their arsenal, but most often, connoisseurs of tasty and juicy meat prefer to use more impressive devices. If there is no desire to make it out of concrete and brick, then it is quite possible to build your own brazier from a barrel in a few hours. What is the best way to do this? What improvised materials and tools will be needed in the process of making such a device?

Advantages and disadvantages

A brazier from a metal barrel has an undeniable advantage. With it, you can not only fry meat, but cook it correctly while maintaining juiciness and taste. Thanks to the large roasting pan, which warms up very well and evenly, the meat turns out tasty. Pluses are also:

- Ease of care, quick cleaning;

- Ability to transport over short distances;

- Profitability;

- Ability to self-repair if necessary;

- Uniform distribution of heat inside the brazier.

If you make a combined version, then it is quite possible to cook both a traditional barbecue on skewers and a juicy barbecue. Regular barbecue who understands, such tasty meat cannot be cooked.

The disadvantages of a barbecue from a barrel include:

- High susceptibility to corrosion. Therefore, it should be covered or hidden during bad weather.

- There is a possibility of getting a burn if safety precautions are not followed, since the entire surface of the barrel warms up quite strongly.

What is required for work

What is required for work

You can make a grill from an old metal barrel or even a gas cylinder. It is important to bear in mind that it is forbidden to use a container in which poisons, chemicals or fuel were cut. A 200 liter container will make a wonderful barbecue that can satisfy all the wishes of connoisseurs of delicious fried meat. Working with a gas cylinder is much more difficult. In order to make a brazier from a barrel with your own hands, you will need special tools and additional materials:

- Bulgarian with a circle for cutting and grinding;

- Welding machine;

- Jigsaw for metal;

- Steel corner with identical shelves not less than 45 mm;

- Grid for lattice;

- Metal door handle;

- Four wheels on a metal base (for transportation);

- Door hinges;

- bolts;

- Roulette.

Frame preparation

The first step is to make a frame that will securely hold the barbecue. The optimal height is 90 - 100 cm. For this, prepared metal corners at an angle of 90°. On one and the other side, two drains are installed, connected by a jumper. The height of the jumper should not exceed 25-30 centimeters from the ground to ensure reliable stability. Attach a wheel to each drain. It is important to ensure that there are no distortions of the frame, otherwise the barrel grill will not be as effective and of high quality.

Assembly process

How to make a brazier in a few hours? The main thing is to follow all the steps correctly and follow the recommendations. Making a barbecue from a barrel with your own hands consists of the following steps:

- In the side of the metal container, with the help of a grinder, a rectangular hole is cut out. Later it is used as a cover. The side walls must be at least 15 centimeters. In order to place 10 skewers, it is enough to have a capacity of 30 cm.

- Using a welding machine or bolts, it is necessary to fix the two parts of the barrel with loops. Weld a metal handle to the lid for ease of use.

- To properly equip inner part you need to weld plates or corners there. A brazier will be installed directly on them.

- To create draft and air circulation in the side parts of the barrel, it is necessary to make holes with an electric drill. The lid can also be perforated if the plan is to use the structure as a smokehouse in the future.

- The made brazier must be fixed on the frame. It is important that the drain hole of the container is at the top. This will be the exhaust hole. In the future, it is better to insert a piece of pipe into this hole.

If desired, you can cover the brazier from the barrel with heat-resistant paint with your own hands. This will allow the design to harmoniously fit into the landscape of the cottage or house.