Concrete from 16 20 decoding. Concrete class - new (C) and old (B) designations. Production of concrete mix

Displaying targets on the screen of the SPC SAM S-200

A little about the downed IL 20

Since I studied the S200V anti-aircraft missile system at a military school and served on it for many years, I can say the following: the Arabs could not confuse the F16 with the IL 20. This is the same as confusing a nail with a comb.

On the screen of the capture operator in the K2 cockpit of the S200V complex, the F16 looks like a nail, well, maybe like three nails together, then the IL20, because of the screws, gives a comb on the screen (there was even such a term in the ZRV). All propeller-driven aircraft provide such illumination. Let me explain: the primary, almost unprocessed reflected signal from the target comes to the screen of the indicator of the capture operator. All surfaces jet aircraft, from which the signal is reflected, are fixed. Therefore, the reflected signal is formed from several "brilliant points" of the aircraft, has approximately the same frequency and usually consists of two or three vertical lines standing side by side. From a propeller-driven aircraft, due to the Doppler effect (the propellers on it rotate and give different Doppler additions to the frequency of the reflected signal), the reflected signal in the form of vertical stripes occupies almost the entire screen. These are two types of reflected signals, visually well distinguishable. Any training for capture operators, and other members of the combat crew, begins with an explanation of precisely these differences. I am sure that our specialists, who prepared this Arab calculation, explained this to them. Moreover, in the K2 cockpit of the C200B complex there is a regular target simulator. It is on it that the training of l / s operators and the launch officer and the firing officer takes place. It provides simulation of all types of targets, and it perfectly simulates a propeller-driven aircraft.

It should be noted that the S200B system is quite difficult to operate and maintain. In order to launch a rocket, you need to perform a hell of a bunch of different operations. They must be clearly coordinated with both the K9 combat crew (the control point that gives permission to launch) and the K3 combat crew (from which the division’s launch complex is controlled. It is this crew that prepares the rocket for launch). An unprepared and untrained combat crew simply cannot do this. If they managed to launch a rocket, then they were clearly prepared and they simply could not have known the differences in marks from the target of propeller and jet aircraft.

I don't know if the "friend or foe" interrogator is used in Syria. But during my service, interrogators were not placed on equipment imported abroad. It was a top secret technique.

There is a version that the Syrian crew first captured, escorted and launched a missile at F16, and they made an anti-missile maneuver and our aircraft, with a clearly larger effective reflective surface, got into the antenna pattern. The missile automatically aimed at him, and an explosion occurred. Yes, this is possible, but only under one condition - it was necessary to “shine” the radar on our plane. If there was no reflected signal, then the rocket would have gone to self-destruction. This means that the Arabs accompanied our plane with a radar, and since they accompanied us, they saw the reflected signal from the target on the capture indicator. Moreover, when changing the target, the capture operator himself had to manually re-capture the new target for automatic tracking.

If in the process of pointing the missile at the target the type of the reflected signal has obviously changed, then any commander of the combat crew must react adequately - turn off the power. This is the learning of any calculation. When a target cruise missile launched from a Tu16 carrier is fired at a training ground, there is also an empirical opportunity to capture the carrier instead of the KRM. And in all the regulatory documents on live firing it is strictly stated that if the type of target changes, it is necessary to immediately stop tracking it. But the occurrence of such a scenario is very unlikely. The C200B radiation pattern, in missile guidance mode, has a width of 1.5 degrees. And, especially at short ranges, it is very difficult for a random aircraft to hit it.

In my opinion, the Arabs understood that they were escorting, and they launched the rocket consciously. But this is where corporate ethics comes into play. The worst thing for an air defense officer is to miss the target. When we took up combat duty, we were armed with a pistol. When we were young, we asked our commanders why we needed this. Wise people answered that if you miss the target, go and shoot yourself, you will save paper for prosecutors. It was clear to all anti-aircraft missile troops of the country's air defense forces that to remain with missiles at the launch site after an enemy air raid would secure a death sentence for themselves. Most likely, the Arabs adopted these principles, so they fired at what they saw. But I somehow hardly believe in the evil machinations of the Israeli Air Force. On the contrary, they are interested in military cooperation with us. And the fact that the Arabs place the most “interesting” objects for the Israelis in the immediate vicinity of the location of our troops is no news to anyone. So, the gentlemen from the Ministry of Defense should deal with their allies, and not mold us a new enemy.

Since this text is still being read, let me make a few additions that I think are important.

The S200 was removed from the air defense of the Russian Federation, in my 1994. After 1991, as far as I know, there was practically no live firing at the firing range in Sary-Shagan (Priozersk). As a result: those chiefs of calculations and commanders of departments who at least once fired at the range from the C200 are now at least 50 years old. The commanders of batteries and divisions are 60-65 years old. I don't think people of that age were sent to Syria to learn how to calculate. My question is: who and how taught these Syrians, who were given a complex that was very difficult to maintain and operate? Main and main reason the defeat of one's aircraft is a complete loss by the command of the Air Force-Air Defense of control over the air situation and the actions of their units. Above the officer - shooting in the division (K2) there are still a whole bunch of different commanders, and on K9 (command post of a group of divisions) and on the command post of the regiment, and the central command post. They had to, they had to forbid shooting at our plane. With K9 - just do not give permission to launch.

The air defense of a “non-smoking person” itself must, must, understand who flies, where it flies and why it flies. If they don’t know how to do this, then they need to learn, and don’t look for extreme outsiders and dishonor the armed forces. But back in 2015, in my opinion, our generals boasted that they controlled the airspace within a radius of almost 600 km from our air base. But, for some reason, they themselves could not detect two F16s at a distance of 100 km. By the way, the S200V was able to shoot down not only the F16, but also shoot down the guided bombs they launched in flight. Back in the early 1980s, in Sary-Shagan, we successfully carried out firing at a multiple target, in which it was not the carrier that was destroyed, but the “cruise missile” that had separated from it. Moreover, the dimensions of this cruise target missile were very modest, it seems, much smaller than American guided bombs.

In principle, a missile launch, provided that the missile does not see the target, is possible. On the s200 there is a mode in which the rocket starts, and only after that it captures the target. It's called something like "shooting at a closed target." But, in my opinion, the radar of the complex should still accompany something. Although, probably, it can also accompany the target from the imitator. Then the capture operator gives AC3, then the ROC AS, and the launch off - on the closed target mode and gives the RP. (start permission). But, anyway, the RP command should come to the computer K2 from K9. In this case, the rocket starts, searches for a target in flight, does not find the target and takes it sharply upwards (86 degrees angle) and after a while produces a self-burst. From the ground, this can be seen in the same way as undermining the target.

When a rocket is blown up, a cloud of special balls is formed, I don’t remember now, roofing felts 35, roofing felts 55 thousand pieces, in the form of a toroid (donut) with a radius of 200 meters. If someone gets there, consider lost. There will be many holes in the case. Like a fool. On the screen of indicators of capture and ICO, you can only determine the type of target. Propeller, rocket, turbojet or jet aircraft. If the target abruptly changed its type, then the trained commander of the combat crew will immediately turn off the power and send the missile to self-destruct. It all depends on the calculation. I have another version: the Arabs could take the Il20 for a jammer. It gives a huge illumination on the screen. But one thing is clear, the command of both our Air Force and the Arab air defense forces have clearly lost control over the air situation and the actions of their units. A mess - it is expensive.

Here are the pictures. It looks like the half-blind will figure it out. But the pictures are perfect. In fact, a multi-rotor aircraft "litters" the entire screen.

The first half of September is over, but we continue to look for the most interesting events in Moscow in 2018.

- From 16 to 20 September

FROM 16 TO 20 SEPTEMBER

40. Concert Odnono

Odnono's music is much closer to spiritual mantras than to any of the "earthly" musical styles, although the last of the band's 10 albums, Betalab, has outlined a significant tilt towards "live" electronics with parts of ethnic instruments from various cultural traditions of the planet. On September 19, the team will return to the 16 Tons stage to once again become a beacon for everyone who seeks to become aware of themselves in this world. Start - at 20:00.

Until September 20, the HERE on Taganka Gallery will host the exhibition “Here Will Be the City of Organism Varenye” by the Varenye Organism art group, which includes Onton Abstract, Mitya Urbi Sokolov, Konstantin Antonov.

“Here will be the city of Varenye of the body” - this is an attraction city, a simulator city, an interactive city and an adventure city. The exposition-manifesto of public art as a psychoactive urban landscape, contributing to the disclosure of hidden human potentials. "Here will be the city of Varenye of the organism" - a presentation of an archive of unrealized ideas, sketches and layouts of future projects of a group of artists.

The exhibition will feature printed computer graphics, art installations, video installations. These works, reminiscent of schemes, or complex synthetic multidimensional spaces, are virtual projects of "non-children's" playgrounds. They form a new landscape space in which the object acts as a simulator for a person. For authors, the idea of a useful experience that can be obtained from a work of art is important.

"Varenye organism" is a union of "artists-molecules", as the authors of the project call themselves. They transform everyday space into psychic space, turn cities into huge playgrounds. The Union of Artists even has a specific mission - to generate new synapses with the help of technological games and unusual behavior.

42. Exhibition "Finds of my street"

Until September 17 inclusive, the Museum of Moscow will host the exhibition “Finds of my street”. Its opening is timed to the Archaeologist's Day, which is celebrated on August 15.

Once again, in the halls of the museum, you can see unique historical objects discovered by archaeologists on the streets of Moscow recently, since the beginning of 2018. The exhibition of archaeological finds of the 2017 season "Secrets of Moscow Dungeons" at the July Moscow Urban Forum 2018 was named the best in the nomination "City Exhibitions".

“Finds of my street” is about 100 artifacts, evidence of various periods in the history of Moscow, which until recently were literally under our feet on Moscow streets. At the exhibition, guests will see objects Everyday life Muscovites from the Middle Ages to late XIX century. A significant part of the items was found on the territory of the districts of Moscow, which are well known not only by historians, but also by the general public - Zaryadye and Kadash.

The exposition will include tiles with unusual plots, examples of the art of medieval casters, ceramics, religious items. You can also see weapons, for example, a squeaker found almost on Red Square, or boots of phenomenal preservation, allowing you to see the smallest details the work of a tanner five centuries ago.

43. Show “Ural Pelmeni. Beach shizon»

Another humorous show "Ural dumplings" this time will raise the topic of vacations and the beach. A real rest in Russian is when you try to eat as much as possible on all inclusive; when you smear sour cream on a body burned in the sun; when you are not afraid to swim behind the buoys and carry home a suitcase of souvenirs no one needs. "Beach schison" is declared open.

44. Exhibition “Confabrics of the 17th century. Monuments of facial sewing»

As part of the project of displaying individual works from the museum's storerooms, the exhibition "Konfalons of the 17th century" will be held in the hall of one monument until September 21. It will feature two items that were once part of the temple set. Banners are church banners, without which not a single religious procession can do.

Compared with the numerous surviving embroidered covers and shrouds, Old Russian banners are a rarity; they are not often seen in museum halls. The exhibited banners are made of velvet, decorated with fringe along the edges and tassels along the lower blades. On both sides, images are embroidered with silk and metal, so-called "golden" threads, which are probably associated with the dedications of the thrones of the temple.

In this case, these are “Saint Alexy, the Man of God” and “The Tikhvin Icon of the Mother of God”, “The Conception of the Righteous Anna” and “The Calvary Cross”. Spectators will be able to admire the skill of ancient Russian embroiderers, see the various techniques used in facial sewing of the 17th century, and also discover some of the secrets associated with the existence of these wonderful works of art.

Construction is one of the most emerging areas V modern world, and every year experts create new types of building materials with a better set of characteristics than the previous ones. And if we talk about what is still used more often, then this, of course, is concrete products, a guarantee of strength and reliability for any structure.

Properties of concrete B 20

As we have already said, modern building hard to imagine without the participation of concrete different brands. The most popular both in civil and industrial buildings is concrete grade B 20. Preference is given to this artificially created material because of the ideal combination of its cost and quality. This is especially true for private construction, since the entire work process is carried out by hand.

Concrete B 20, which corresponds to grade 250 (according to new building codes marked as concrete C16 20) is produced at concrete plants and delivered to construction sites in special mixers. During transportation, the solution is continuously mixed and fed to the construction site without losing its properties.

Consider the main specifications concrete at 20:

- Set of compressive strength (20 MPa) after 28 days. A certain one is achieved by using components of a given quality.

Note!

Only full observance of the proportional ratio of ingredients in the composition of the mixture can give the maximum result.

Any slightest deviation leads to a loss of properties, experienced builders and designers are aware of this, so the stage of creating a mixture is clearly controlled.

- Frost resistance (designation F) of products and structures made of material of this class varies in the range F100, F150, F200. The number after the letter indicates the number of cycles of alternate freezing and thawing of the sample tested under laboratory conditions. To increase the frost resistance index, special additives are introduced into the concrete composition.

- The specific gravity of M250 concrete is about 2.3 tons per cubic meter. This figure characterizes the density of the product, and depends on the percentage of air inclusions and hardened mass, after evaporation of the water that is part of the mixture.

- Concrete grade C16 20 may have a water resistance in the range from W2 to W. The water permeability of the specimens is tested by exposing the test specimen to a water column under high pressure until the infiltration begins.

- Another indicator is the modulus of elasticity. To determine this characteristic, the mixture is subjected to heat treatment in autoclaves to reduce the curing time.

Grade C16 20 with a draft of a mixture cone up to 4 cm and a filler of a maximum fraction of 40 mm has an elastic modulus of 394 kgf / sq. cm and, accordingly:

- Fractions 80 mm - 424 kgf / sq. cm.

- Fractions 120 mm - 445 kgf / sq. cm), etc.

Application area

High physical and technical characteristics and advantages of B 20 concrete ensure its wide application in various areas of construction production and for various products:

- Construction of buildings of various scales, including large-sized ones. In the construction of high-rise buildings, the strength of structures that have to withstand serious loads is of great importance.

Important!

The use of one or another brand of concrete is strictly regulated by SNiP and GOST "Building materials", "Reinforced concrete structures".

Replacing the brand contrary to the recommendation of these documents is permissible only after agreement with the design organization and approval by the architectural control bodies.

- Manufactured under factory conditions designed for medium load.

For your information!

The construction of buildings and structures from prefabricated reinforced concrete significantly reduces construction time, but requires the use of specialized equipment.

- Arrangement of platforms, paths, blind area. Concrete B20 copes well with the aggressive effects of conditions environment and can withstand traffic loads.

Production of concrete mix

To create high-quality concrete of the appropriate brand, the process technology and the percentage of the ingredients of the mixture should be strictly observed.

Composition of concrete M 250

Cooking instructions concrete mix B20 gives the following calculation of the production composition per 1 m3 (1000 l):

- The main binder is cement - 360 kg.

- Fillers:

- Sand (humidity 5-6%) - 536 kg.

- Crushed stone (moisture content 1%) - 1141 kg.

- Water - 133l.

- Additives affecting frost resistance, plasticity, water resistance:

- Plasticizing C 3 - 3.085 kg (35% concentration).

- Plasticizing LST - 3.6 kg (20% concentration).

- Air-entraining START -0.72 kg (1% concentration).

building material cost

The price of concrete grade B20 directly depends on the additives introduced into the mixture and the quality of the coarse aggregate. Concrete on granite rubble will be more expensive than on gravel. The reputation of the manufacturer is also important. The latest equipment works at large concrete units and GOST standards are strictly observed.

On average, the cost of 1 m3 of concrete mix with indicators F150-200, W2-4 of well-known manufacturers (LLC Obrey, Garant Beton, BSU No. 5) will be 3400-3500 rubles.

Conclusion

We hope that the above information was useful to you, and we decide to remind you of a few important points. Firstly, in order to obtain high-quality products with proper strength, grades of at least 200 (for residential buildings) should be used.

Secondly, it is better to mix the solution with a concrete mixer, this allows you to reduce the time construction works and make the whole process easier for you (workers). In the presented videos in this article you will find Additional information on this topic.

Concrete is the most in-demand construction material without it, it is impossible to build a single structure, because it is concrete that is considered the basic basis of building art. Before using this product for its intended purpose, it is necessary to understand what the product is, how ready-mixed concrete differs from ordinary concrete, and what markings are inherent in it.

What is concrete

First, let's look at the difference between a factory mix and a commercial mix. If the concrete mixture was kneaded at the factory, and then was sold at facilities under construction, then such a product has the name of ready-mixed concrete. The difference between the factory mixture and the usual one is high quality first kind. This is confirmed by the available certificates.

Taking into account the strength index, the concrete class is denoted by the letter B and the numbers: B5; B7.5, B10 and so on. The number present in the formula indicates the pressure, expressed in MPa, that the presented products are able to withstand. For example, B10 is concrete, which in 95% of cases is able to withstand a pressure of 10 MPa.

What determines the brand of concrete? The brand of concrete implies the presence of letters and symbols: M50, M100, M150, M200 and so on. The number present in the formula indicates the compressive strength. It is obtained by the method of determining the average value from the results of testing samples. The compressive strength is obtained as the arithmetic mean of the 2 highest values in a series of 3 subjects. After the presented measures, a certain value is obtained, expressed in kgf / cm2, which shows the characteristics of the product brand in terms of compressive strength.

Table 1 - The use of concrete, taking into account the frost resistance group

| Frost resistance group | Designation | Scope of use |

| Low | less than F50 | Not very popular |

| Moderate | F50 - F150 | Frost resistance and water resistance of the material of this group has optimal performance. The presented products are widely used. |

| Increased | F150 - F300 | Thanks to high level frost resistance, such concrete can be used when laying the foundation in harsh climates. |

| high | F300 - F500 | This product can be used when laying the foundation with variable humidity. |

| Particularly high | over F500 | This high frost resistance is achieved through the injection of special additives. Involved in the construction of solid structures. |

Table 2 - The ratio between classes of concrete grades

| Strength grade of concrete | Concrete strength class (B) according to SNiP | Concrete strength class (C) according to SNB |

| M 50 | At 3.5 | – |

| M 75 | AT 5 | – |

| M 100 | At 7.5 | – |

| M 150 | AT 10 | From 8/10 |

| M 150 | At 12.5 | From 10/12.5 |

| M 200 | At 15 | From 12/15 |

| M 250 | IN 20 | From 16/20 |

| M 300 | At 22.5 | From 18/22.5 |

| M 350 | At 25 | From 20/25 |

| M 350 | At 27.5 | From 22/27.5 |

| M 400 | At 30 | From 25/30 |

| M 450 | At 35 | From 28/35 |

| M 500 | – | From 30/37 |

| M 550 | At 40 | From 32/40 |

| M 600 | At 45 | From 35/45 |

| M 700 | At 50 | C 40/50 |

| M 700 | At 55 | C 45/55 |

| M 800 | At 60 | C 50/60 |

| M 900 | At 65 | – |

| M 900 | At 70 | C60/70 |

| M 1000 | At 75 | C 60/75 |

The video talks about how to check concrete for quality and brand compliance:

Which water repellent is better to use for concrete is described

Concrete is a popular building material that is actively used today in the construction various designs. When choosing this product, you must focus on the formula that is indicated on the package. Only its correct decoding will allow you to accurately determine the technical characteristics of the selected product.

Many experts know that 16K20 was one of the most popular devices of this kind in the Soviet Union. The reasons for this popularity are the versatility and technical characteristics of the machine of this model.

Spheres of use and modification of the machine 16K20

You can download the passport of the 16K20 screw-cutting lathe in pdf format for free here:

Screw-cutting lathe model 16K20 belongs to the category of universal equipment for processing metal parts. Its characteristics, of course, do not allow it to replace milling equipment, but make it possible to use it to perform a whole list of specialized operations. Such operations, in particular, include threading various types(metric, inch, modular, pitch), drilling, countersinking and others.

The capabilities of this screw-cutting lathe are such that it can be used to process workpieces from both hot-rolled and cold-rolled steel. Before the appearance of this machine, the enterprises used the 1K62 equipment model, which is significantly inferior to it in all its characteristics. So, the advantages of the 16K20 screw-cutting lathe (compared to the previous model) include:

- operational safety;

- high reliability;

- the ability to process parts with high precision;

- simplicity and ease of maintenance;

- exceptional durability even with active use;

- high performance.

16K20 screw-cutting lathes are used at enterprises that produce products individually or in small batches, as well as in tool shops where such equipment can be used to perform both semi-finishing and finishing work.

From design features of this screw-cutting lathe, the following can be noted.

- The bed of the equipment is made in a box-shaped form and is installed on a massive monolithic base, which gives high rigidity to the entire structure. The accuracy of movement along the caliper frame and the movable tailstock is ensured by reliable guides that are heat treated and ground.

- Depending on the type of processing and configuration, the workpieces can be fixed in the chuck or clamped in the centers.

- The chisel holder is designed to securely hold the tool.

- To install the spindle, high-precision (precision) rolling bearings are used, which are necessary for the accuracy of its location and rotation.

- The design of the 16K20 screw-cutting lathe provides for a number of blocking and enclosing technical elements that ensure the safety of working on it.

- To ensure the accuracy of processing, the machine is equipped with rulers with sights, which can be used to control the longitudinal, as well as transverse movements tool.

- You can urgently turn off the supply of the caliper of the 16K20 machine using a special device installed on the apron of the machine.

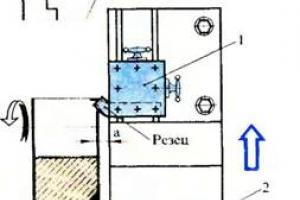

The 16K20 tool holder on the machine support looks like this:

Machine tool holder 16K20

Due to the versatility, reliability, ease of construction and maintenance of the 16K20 screw-cutting lathe, analogues of this equipment were produced at a number of domestic and foreign enterprises, where they were designated:

- MK6058 (6057, 6056) - Krasny Proletary Machine-Tool Plant in Moscow;

- 16V20P, 16V20 - Astrakhan Machine Tool Plant;

- ZhA-805 - Plant of automatic machine tools in Zhytomyr;

- 16B16 and modifications, Samat 400 - Srednevolzhsky machine-tool plant in Samara;

- GH-1840ZX ("Jet" - Switzerland), CU402 ("Vratsa" - Bulgaria), CD6140A ("Anhui Chizhou" - China), BJ1630G, CS6240, CS6240 ("Bochi" - China), CA6240B, CA6140A ("SMTCL" – China).

- KA-280 - Plant "Vercon" in Kyiv.

- 16VT20P, 16VT20 - Wistan plant in Vitebsk.

Technical capabilities and characteristics 16K20

16K20 screw-cutting lathes (as well as their analogues) are distinguished by the following characteristics.

- The spindle can rotate in the frequency range of 12.5-1600 rpm.

- It is allowed to machine parts with a maximum section of 310 mm above the recess, 400 mm above the bed and 220 mm above the support.

- Rapid movements in the transverse direction can be performed at a speed of 1.9 m/min, longitudinal - 3.8 m/min.

- The technical capabilities of the 16K20 screw-cutting lathe make it possible to obtain threads with various parameters on it. Their pitch can be in the range: 0.5–56 (modular and pitch), 0.5–112 threads per inch (inch), 0.5–112 mm for metric.

- The workpiece length can be up to 2000 mm.

- The number of longitudinal and transverse feeds is 22 and 24, respectively. The range of longitudinal feeds is 0.05–2.8 mm/rev, transverse - 0.025–1.4 mm/rev.

- The characteristics of the 16K20 machine allow processing workpieces weighing up to 1300 kg.

- For spindle rotation, you can choose one of 22 speeds (straight).

- The hole in the spindle has a diameter of 52 mm.

The kinematic diagram of the machine can be found in the photo below:

Kinematic diagram of the machine 16K20 (click to enlarge)

Depending on the length indicated in the equipment passport, the weight of the 16K20 machine can be:

- 3685 kg (for a model with a length of 3795 mm);

- 3225 kg (3195 mm);

- 3005 kg (2795 mm);

- 2835 kg (2505 mm).

The engine power of the hydraulic station and the main drive of the 16K20 machine (according to the passport and actual) is 11 kW. Accordingly, this indicator is taken as the power of this model.

To start the 16K20 screw-cutting lathe, the operator must press the button, with which the contactor coil closes electrical circuit. In addition to the main button, the machine device has a number of other elements through which the following equipment options are controlled:

- movement of the equipment support and carriage at high speeds (this option is controlled by the so-called push button);

- stop the rotation of the engine of the equipment;

- starting and stopping the coolant pump.

Schematic diagram of a 16K20 lathe (click to enlarge)

The handles located on the machine body serve to solve such tasks as:

- selection of the type of work performed: type of thread being cut and feed characteristics;

- quill fixation;

- friction clutch control;

- movement of the carriage and longitudinal movement of the sled;

- setting the thread pitch and feed value for its execution;

- turning off the feed box - for those cases where the thread is cut directly;

- choice of spindle rotation mode - number of revolutions;

- turning on and off the lead screw nut;

- intro start button circuit breaker;

- choice of thread cutting direction;

- selection of the mode for threading with normal or increased pitch.

On machines 16K20, a steady rest can be used, which is designed to prevent the workpiece from bending during operation, and also helps to fix it, thereby increasing the accuracy of processing. Lunette looks like this:

Adjustment and repair of the machine 16K20

The headstock is installed on the machine 16K20 and securely fixed on its frame during the assembly of equipment at the machine tool plant. However, it is often necessary to adjust this assembly during the operation of the equipment. To do this, first of all, you need to familiarize yourself with the description of the 16K20 screw-cutting lathe and the layout of its nodes, only then proceed to dismantle the feed box. After that, using the adjusting screw and focusing on special test grooves, adjust the position of the spindle along its longitudinal axis.

Some features of the 16K20 repair can be found in the video:

To perform the adjustment of the spindle bearings of the machine, it will not be enough to familiarize yourself with its description or photo, you should only trust the performance of such a task qualified fitters with relevant experience. Before the procedure, it is very important to check how stiff the spindle assembly meets the required parameters, for which a dynamometer and a jack are used. Having placed a jack under the spindle flange, a certain force is applied to the node, and its rigidity is determined by how much the node has deviated.

Although lathe 16K20 is not only versatile, but also very reliable equipment, the efficiency of its use and the accuracy of processing parts decrease over time. In order to long time to maintain this one in working condition and restore its factory specifications after active operation, it is necessary to perform a number of specific measures. These include inspection Maintenance, regular scheduled and major repairs.

Most often, the so-called minor repair of the 16K20 machine is performed, during which the following tasks are solved.

- The cutting head is cleaned and washed.

- The components of the screw-cutting lathe that are most prone to contamination are partially disassembled: the headstock, feed box, apron, etc. After disassembly, the elements of these components are inspected for damage and thoroughly washed.

- If scratches and nicks are found on the bed, tailstock, caliper and carriage, they are carefully cleaned.

- The operability and technical condition of gear couplings, buttons and control handles are checked, protective devices safety and blocking type.

- If signs of wear are noticed, then the bushings, elements for adjusting and fixing the tool holder are replaced.

- Scratches and burrs on clamping bars, adjusting wedges, splines and gears are carefully examined and, if necessary, cleaned.

- The lubrication unit is flushed and leaks in it are eliminated.

- The tightness and performance of the pneumatic components of the 16K20 machine are checked.

- The screw-cutting lathe is tested after the repair. At the same time, the following parameters are checked: the level of noise emitted by the machine during operation, the degree of its heating, the accuracy of processing parts and the degree of cleanliness of the machined surfaces.