Mixer from a drill with your own hands. Construction mixer attachments: shapes and sizes

Both the mixer and the electric drill are far from essential items. Not everyone can afford to keep both at home. But even if you can boast of having an electric drill at home, most often it is the most powerful kilowatt machine, which is convenient for drilling walls. But drilling radio boards with it or repairing shoes will be hard, isn't it? Therefore, I had the idea to make a special nozzle for the mixer, with which you can now not only cook an omelette, but also a hole in hard to reach place drill.

The adapter for the drill is inserted into the socket of the “quick knife” nozzle. If you have a rubber joint between the mixer and the attachment, you will have to redo it too. For the effort that he is able to transmit is not enough even for the operation of a coffee grinder. A square is best for connecting, but a hexagon is also suitable.

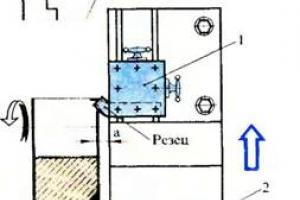

The drawing shows the dimensions of the details of the attachment for the MP-2E mixer manufactured by the Minsk Electrical Equipment Plant, but due to the similarity of all mixer models, the correction will be quite insignificant. I took the cartridge from a hand drill. You should not count on drills with a diameter of more than 5 mm even when drilling wood (after all, the power of the mixer motor does not exceed 100 W), so if you have a choice, the cartridge should be chosen as small as possible.

The scheme for making a drill from a mixer with your own hands

Parts 3 and 4 require fabrication on lathe; with no head right size for part 3, the hexagon groove will have to be milled. In the case of complete production of part 3, a slight improvement can be made, which is as follows. To exclude an additional friction surface between 3 and 4, make a selection for the hexagon with a slope of 5-6 degrees relative to the horizontal axis. This is necessary so that the head, sitting on the hexagon, engages with it when moving and is wedged by friction forces. In this case, there will be a small gap between the head and the sleeve, which will prevent additional heating of the assembly and the associated power loss.

Part 4 can be made from any structural steel, but if you can find a piece of polyethylene of the right size, the structure will only benefit. If structural steel is used, provision should be made for through hole in the shaft lubrication sleeve; the polyethylene sleeve should be lubricated with grease. Usually the chuck shaft is surface hardened and the MB thread should cut easily. The nozzle is assembled as follows. A sleeve is put on the chuck shaft, then the head is screwed on. The nozzle assembly is screwed to the mixer along the M3O thread.

The use of the attachment is also supported by the fact that the mixer, unlike most electric drills, has a smooth speed control, which creates additional convenience during work. By the way, maybe you have an old enlarger lying around? In the conditions of the Kodak victorious offensive, you will hardly need it already, and its tripod can be adapted for a drilling machine. A tripod with a gear rack from the Upa enlarger is especially convenient. The adjustment handwheel feeds the drill as smoothly as on drilling machine. If you have a low-power drill "Master", you can place it on a tripod as well.

Video instruction - how to make a drill from a mixer

A drill mixer is a great helper for any builder. Such devices are quite powerful engine and two ergonomic handles, which are necessary in order to hold the tool while mixing mortars and mixtures. This is a convenient mechanism that combines several important functions at once.

purpose

The construction sector of the industry does not stand still - every year new compositions appear that are used for the construction of structures, small and overhaul. Both glue and plaster and many other materials go on sale in the form of a powder, which must be diluted with water in order to make a full-fledged composition out of it.

In order for the components of the mixture to mix as well as possible and form a homogeneous operating weight you need to choose the right tool. For example, if you can mix wallpaper paste with an ordinary stick, then for cement mortars and putty which method will be ineffective, especially if you need a solution in large volumes.

Mixing building mixtures with improvised means, as a rule, does not give the desired quality of the working composition: many lumps form in it and a large percentage of dry matter remains, which could not get wet properly.

Many users in such situations resort to a puncher, which has the necessary rotation capability; however, experts do not recommend using this method, since the hammer is initially oriented to loads in a different plane without any influence of radial forces. Of course, it is possible to knead a small volume of the solution with it, but in large quantities you run the risk of simply damaging your tool, which, by the way, is quite expensive.

Great solution in this situation, it may be the purchase of a drill-mixer, which is optimal for mixing compositions in a volume of up to 15 liters in one go.

Such devices are optimal both in everyday life and when carrying out professional repairs. Unlike a hammer drill and a conventional drill, they have a stronger bearing, in addition, the mechanism is equipped with a powerful gearbox, which is protected by a particularly durable metal case. Thanks to this set the device can work even at the lowest speed.

An important advantage is also the fact that such the construction mixer can simultaneously perform the function of drilling the surface, that is, in fact, it is a 2 in 1 device.

Types of structures and their characteristics

A drill mixer is used to carry out repair work in large volumes; the user, when mixing the solution, usually holds it in his hands, because the device has ergonomic handles that make the operation of the tool less laborious. If the engine of the device has a power of more than 1 kW, then a special gearbox is built into it: it is suitable for use not only at the very first speed, but also when switching from first to second.

The first is used to make thick dense mixtures, for example, mastic, and the second - for gypsum and cement. At the second speed it is also possible to stir paints and other liquids with a minimum torque.

In order to make work more comfortable, it is better to use tools that are supplemented with a speed stabilizer or inrush current limiters.

Such drills, as a rule, have a different configuration. Usually, they come with several types of nozzles, which can have several shapes.

- Right hand spiral mixing attachment- used for such solutions that have a very viscous structure. These include cement, concrete, as well as various kinds of plasters and glue. Such a nozzle kneads the solution, as if pushing it from the bottom up, the composition is mixed at the top, and then falls back.

- Left-handed spiral nozzle ideal for mixing paints and varnishes. Here the principle of operation is reversed: the mixture is pushed from top to bottom, where it is stirred and rises back.

- Screw nozzles allow you to mix light compositions.

- cross- a more specialized nozzle, it is used in cases where it is very important to prevent air from entering the container with the mixture.

Advantages and disadvantages

The main advantage of the drill-mixer is the possibility of its multifunctional use. On the one hand, the tool is referred to as a drill, therefore, in addition to mixing mortars, it can be used to form holes in surfaces different type, even the most hard and dense. On the other hand, a drill of this type belongs to the category of low-speed ones, therefore it cannot replace the drill by 100%, but at the same time, it is low speeds that make it possible to knead even the densest compositions.

Obviously, such a design cannot be used in industrial volumes, its power and design features not enough to cope with intensive use. But with the solution of small household tasks for minor repairs and finishing an apartment or a private house, she will cope in full.

Such a drill weighs much more than a conventional one: its mass is more than 3 kg, so frequent drilling with such a unit is associated with significant physical effort.

Principle of operation and features of use

Depending on the principle of operation, there are three types of tools:

- drill mixer;

- drill mixer with one whisk;

- device with two beaters.

A conventional electric drill-mixer is a low-speed, non-impact type. The power of this tool ranges from 500 to 2000 W, there are 2 comfortable handles, a rather large cartridge with a diameter of up to 16 mm.

Two-handed models are divided into options with a single whisk or two, the difference follows already from the name: mechanisms with two whisks mix even the most viscous mixture, they are equipped with a fairly powerful gearbox and can easily cope with solutions of a wide variety of consistency - from light to concrete.

Model Rating

The following brands are the most popular among consumers.

- Fiolent- this is a product Russian production, which is optimal for stirring the most dense and viscous formulations. The power of the device is 1100 W, and the speed is 600 rpm.

- Rebir- under this brand the most popular low-speed drills are issued. Individual models from this manufacturer have exceptional performance: power up to 2000 W and rotation speed up to 500 rpm.

- Interskol– offers a wide range of mixer drills with power up to 1050 watts. Such a tool is optimal for mixing any building mixtures, even concrete, and also for drilling: for example, if you place a special drill for wood in it, you can get a hole up to 1 m long in a matter of seconds.

- BISON- This is one of the most popular brands in the domestic market. The models presented in the assortment of this manufacturer have exceptional power parameters - up to 1200 W - and rotation speeds (up to 850 rpm).

- Makita is a well-known Japanese brand, which is in demand all over the world due to its quality and reliability. It is noteworthy that all models of this brand, in addition to excellent technical characteristics, are also distinguished by practicality, because they consume much less energy than competitors.

How to choose?

- product weight - in the range of 2.7-4.5 kg;

- power - 620-110 W;

- rotation speed - up to 1050 rpm;

- torque - 70 N / m.

In addition, when choosing suitable model pay attention to additional functions, which may be useful to you: soft start, auto-on mode, additional insulation of the case, overheating protection and others.

How to do it yourself?

If you wish, you can make a construction mixer with your own hands. For this, you need to use the most ordinary drill as a drive, and any product with a shank made in the form of a hexagon is suitable as a nozzle. Such a device is quite easily fixed in the drill chuck, the main thing is that the dimensions of this hexagon correspond to the minimum size of the chamber that can be placed in the chuck.

However, keep in mind that the motors and gearbox of a standard agitator are designed exclusively for a longitudinal surface, so only very small portions of the building mixture can be mixed with such a homemade tool.

In the next video, you will find the main features of mixer drills.

When carrying out various construction and repair work, it is very often necessary to mix several components to obtain a homogeneous composition of the mixture, whether it be various varnishes, paints, putties or sand-cement mortars. Preparing a quality mixture by hand is quite difficult. To carry out such work indispensable assistant there will be a construction mixer - a special device that will significantly reduce labor costs, save time and get a high-quality mixture.

Classification by design

Structurally, all mixing devices consist of a drive and a nozzle. An electric motor, a gearbox, a nozzle attachment system and controls (switch, speed switch) are installed in the drive housing. Nozzles are special devices that are fixed on the drive and with which the components of the mixture are mixed. By purpose and scope, modern construction mixers are divided into two classes:

- Drill mixers are dual-purpose devices. They are equipped with a cam chuck, which allows you to securely fix in it both nozzles for mixing building mixtures (with an appropriate shank diameter) and drills for arranging large diameter holes. Such a tool belongs to low-speed drills, therefore it cannot functionally replace a conventional electric drill. However, low rotational speeds and high torque make it possible to use them not only to mix a wide variety of solutions (up to heavy cement or sand and gravel), but also to use them for drilling large holes even in very hard materials.

- Construction electric mixers are highly specialized tools that are designed only for mixing various mixtures. The lineup of these devices is very diverse, you can even pick up a construction mixer that will successfully replace a household concrete mixer (and not inferior to it in performance, but significantly superior to it in terms of ease of transportation and variety of functionality). These devices are single-spindle (they provide for the installation of only one nozzle) and two-spindle (they install two nozzles at once, which rotate in opposite directions).

Of course, when using any construction mixer, you will need an appropriate container for mixing the components.

Varieties of mixers depending on power

Depending on the power, which is the main technical specification, which determines the scope, construction mixers (both highly specialized and drill-mixers) can be divided into three main groups:

Advice! When we choose a construction hand mixer, it is necessary to take into account not only its power, but also its weight. The more powerful the device, the heavier it is, which means that it will be more difficult to work with it.

Varieties of nozzle attachment systems

Construction mixers from various manufacturers are equipped with different devices to fix the nozzle:

- A chuck in which the shank is fixed with a special crimp key (like a conventional electric drill).

- Cam chuck of the QuickFix system (like a household screwdriver - crimping is carried out without the use of a special tool).

- Threaded connection of the shank to the mixer M12, M14 (much less often M21), using a conventional wrench which is included with the mixer.

- Cartridges SDS-plus and SDS-max (the design is similar to the fastening of drills in household rotary hammers).

- HEX system chucks (8, 10 or 12), for quick change and clamping of fixtures with hex shank with spring locking groove according to ISO 1173 E3.

Construction mixer attachments: shapes and sizes

The nozzle for an electric construction mixer is a bar, at one end of which there is a whisk for mixing, and at the other end there is a shank for attaching the nozzle to the drive. After you have decided on the composition of the mixture to be mixed, you can choose the shape of the whisk. And the bit shank standard should match your power tool.

Varieties of shanks for mixer nozzles

Now on sale there are a large number of nozzles for a mixer with shanks of various shapes:

- Ordinary hexagon, size 8, 9 or 10 mm. Such devices are designed for use in power tools that have a conventional cam chuck.

- Hexagonal (8, 10 or 12 mm) with a groove for spring fastening in HEX chucks (they can also be used in power tools with a conventional chuck).

- Thread M12, M14 and 21X1.5. Attachments with such shanks can only be used in highly specialized mixers.

- Shanks designed for installation in SDS-plus chucks (can also be used in a simple hammer drill).

Sizes and shapes of whisk attachments for a mixer

Nozzles for hashing let out:

- Standard lengths 400 and 600 mm (for some, extensions 400 mm are provided - total length up to 1 m).

- The diameter of the whisk (the part intended for mixing) is from 80 to 220 mm.

The shape of the whisk is chosen depending on the mixture to be mixed. The main forms of whisks:

- Spiral. Such corollas are divided into right-handed, in which the spiral is twisted clockwise, and left-handed, in which the spiral is twisted counterclockwise. Right-hand whisks in the process of mixing raise the solution from the bottom up and are designed for heavy or thick mixtures (concrete, sand and gravel, bituminous). Left-handed spirals, on the contrary, while stirring, capture the mixture from above and lower it down. They are designed for mixing various paint and varnish compositions, various fluid mixtures and liquid fillers, since splashing does not occur during their use.

On a note! If the construction mixer is equipped with a reverse system that ensures the rotation of the whisk both clockwise and counterclockwise, then for various formulations mixtures, you can use only one nozzle (right-handed or left-handed).

- Whiskers with straight blades. Mixing occurs only in a horizontal plane, which prevents the capture of air and its ingress into the mixture. Suitable for mixing various compositions based on gypsum (air ingress is highly undesirable), mixtures for self-leveling floors and the like.

- Screw-shaped whisks (the screw is usually made of plastic). Mainly used for light liquid mixtures. Sometimes two screws are installed on the axle: the lower one, which lifts the components up, and the upper one, which prevents the mixture from splashing.

Important! IN technical description manufacturers indicate what type of mixture a particular whisk is intended for mixing, as well as the maximum recommended amount of solution for which it is designed.

Depending on the size, materials and purpose, the price of these accessories is in the range of 100÷1100 rubles.

homemade mixer

Making an electric mixer with your own hands is quite simple. To do this, you can use an ordinary household electric drill or a hammer drill as a drive. For a drill, fixtures with a shank in the form of a regular hexagon or HEX are suitable. Both of them are conveniently fixed in the cam chuck of a drill. The main thing is that the size of the hex (standard: 8, 10 and 12 mm) corresponds to the maximum size that can be inserted into the drill chuck.

Attention! For mixing solutions, only low-speed drills or devices with speed control can be used.

If you use a hammer drill as a drive (naturally, in shockless mode), then you need to buy nozzles with a shank designed for mounting in an SDS-plus chuck.

However, it should be noted that motors and gearboxes, both for electric drills and rotary hammers (even powerful ones), are designed only for longitudinal load. Therefore, a home-made mixer based on them is quite suitable for mixing light solutions and in small volumes. When mixing solutions, the drive experiences significant radial and horizontal loads, which can lead to overheating and failure of the electric motor. Therefore, it is better not to make a concrete mixer with your own hands from a drill or a puncher. Although their use is quite acceptable when mixing paints, thin putties and other light solutions.

In custody

When choosing a device for mixing mixtures, it is necessary to be guided by their composition and volume. Based on this, you can choose a construction mixer of sufficient power so as not to overpay for a too advanced unit. If you need a mini mixer for mixing concrete, then it is better to purchase a powerful semi-professional tool from a trusted manufacturer.

During repair and finishing works Oh, each of you has come across such a highly specialized tool as a construction mixer, and you all know very well that its indispensability is difficult to overestimate. You can use a hammer drill or a drill, but in the end, when the tool fails, every experimenter will understand that it was not very good. good idea. In this article we will not talk about mixers, the topic of our today's article is devoted to attachments for this indispensable finishing tool.

One or two nozzles?

When choosing a construction mixer, you can see that some models of this tool are equipped with two spindles, which allows you to put two rotating nozzles at once. The differences between them are obvious. Duplex mixers are designed to work with a large volume of finishing mix during continuous use. The advantages can be added to the speed of work, such a mixer will quickly make the mixture homogeneous. And, of course, it costs more, so if you don't intend to use the mixer every day, go for a single spindle mixer.

Nozzle attachment methods

There are four ways to attach attachments to a mixer, and they all have their advantages and disadvantages.

- M14. The most common type of attachment. On the vast majority of nozzles, you will see just such a mount. In fact, this is an ordinary clamping nut that completely copes with its task. I think that soon all manufacturers will produce nozzles with just such a mount.

- sds plus. Fastening for quick-release chuck, 10 mm in diameter. Usually it can be found on perforators. It should be noted that it perceives torque well, the nozzle is quickly inserted into the mixer. But many reproach him for the unreliability and the difficulty of repairing in the event of a breakdown.

- hex. Regular hex shank. Such cartridges are often found on drill mixers. With small volumes of work will cope with the tasks.

- Morse taper. Mounting in the form of a cone, the socket in the cartridge also resembles a cone. The most reliable fastening among all and at the same time it can be found only on expensive models of mixers. For example, the DeWALT DW 152 model costs about 22 thousand rubles, you are unlikely to consider this tool for purchase.

The shape of the working part and dimensions

Almost all nozzles for a construction mixer have the same size in length equal to 600 mm. And this is understandable, with such a length it will be convenient for a person to work with a mixer without fear for his back. If you wish, you can get all kinds of extension cords and knead the mixtures in a large barrel, although it is unlikely that such a crazy idea will come to someone's head. As for the diameter of the rod, this value is from 120 to 160 mm. But on the working part, we will dwell in more detail.

- Spiral. It can be in two versions: right-handed and left-handed. The first is designed to lift the mix up and is therefore suitable for heavy cement formulations such as tile adhesive. The left-hand one lowers the mixture down, eliminating splashing. Ideal for putties and all kinds of suspensions. If the mixer is equipped with a reverse, then the choice of spiral is reduced to a minimum. With one movement, you can make the spiral rotate both to the left and to the right.

- cross. With the help of such a nozzle, it is good to mix the mixture, where it is necessary to exclude the ingress of air. During the operation of the mixer, mixing takes place strictly in a horizontal plane. When working with sealants and gypsum mixtures, such a nozzle is simply irreplaceable.

- Screw. Designed for stirring more liquid mixtures such as varnishes and paints. The nozzle can have two screws, working with such a nozzle, the upper screw will push the mixture down, and the lower one, on the contrary, down. With such work, high-quality mixing is ensured, and there will be much less spatter.

There are many highly specialized attachments for various finishing mixes, but the above options will be enough for you to accurately select the attachment for the construction mixer. It is better to pay attention to the tool itself, there are much more selection criteria.

We will need from materials and tools:

1. Aluminum thick wire (In my case - 8mm)

2. Vise.

3. Large pliers or pliers.

4. Pipe ("gas") wrench.

5. "Bulgarian", chisel, hacksaw, or any other cutting tool to cut the wire.

I am currently building an extension to my house. Before erecting the roof of the extension, I decided to cultivate the pediment of the house, to which, in fact, the extension will adjoin. It turned out that the pediment needed to be painted. Since it was built of brick, I decided to do this with the help of a compressor and a spray gun, because it is quite troublesome to paint over deep masonry joints with a roller. I decided to use an acrylic-based facade water-dispersion paint. Went specially for construction market to buy two things - the paint itself and a mixer, which, holding it in a drill, can stir this paint when water is added to it. (For this method of application, the paint must be liquid). Arriving at the market, I chose the paint, bought it and drove off to the site.... I forgot about the mixer...

It turned out that I forgot not only about the mixer, but also about the primer - the surface to be painted must first be treated with a deep-penetrating primer....

Well... I had to go back. Again the construction market... I chose a primer and left. Having changed clothes and prepared the compressor, I remembered ..... that I forgot about the mixer again !!!)))))

What to do?.. Don't stir a twenty-liter bucket of paint by hand!... After thinking for a minute, I decided to get by with "improvised means". In the shed I found these pieces of thick aluminum wire:

We measure the length equal to the depth of the paint bucket, plus 10 centimeters, clamp it in a vise and bend it 90 degrees:

After that, we make another bend:

Further, grabbing with a pipe wrench (the vise is already too wide))), with the help of pliers we twist the wire into a spiral. I sawed off the excess with a grinder. (I could not photograph this process, because my hands were busy)))).

In the end, we got a great mixer, and did not have to spend money ...