A hole in the plank floor. What and how to fix. Repair of an old concrete floor: from small to major

How to fix a hole in the floor from the boards? What about the hole punched in the plywood flooring? How to eliminate a deep pothole in a concrete screed or through hole V reinforced concrete slab overlap?

In the article we will try to answer these questions.

Causes

First, let's find out where a hole in the floor can come from.

Agree that the situation when the surface suddenly falls under your feet is quite unlikely.

- Falling heavy objects. Quite real situation for weightlifting halls and for industrial premises With wooden decks(which, however, is rather an exception).

Note: scaffolds in gyms usually assembled from a beam, strapped with staples. The platform is laid directly on the screed and covered with a hard rubber sheet. In general, if a fallen bar breaks through the floor, this indicates either a gross violation building codes, or about poor discipline of athletes training with large weights outside the platform.

- rotten boards. The picture is typical for houses built more than half a century ago. Harmless antiseptics were not yet available at that time, and creosote and impregnations based on petroleum products were not used in residential premises.

- cracked boards. Actually, in this case, we do not have a hole in the floor, but a gap.

- Defects in slabs and screeds due to flaws in their casting or laying. IN apartment buildings gaps between hollow core panels predominate in this category.

- Finally, holes are punched in ceilings for laying communications - during construction or overhaul. They, of course, also have to be sealed - for reasons of heat and sound insulation.

elimination

How to fix holes in a concrete floor? In the general case, it is quite logical to use the same concrete for this. More precisely, a cement-sand mixture.

Hollows in the screed

- The pothole is cleared of debris and dusted with a vacuum cleaner.

- If you have it on hand, it would be a great idea to prime the recess. This will improve adhesion to the cement-sand mortar.

- Then the pothole is filled with mortar; the surface is smoothed with a spatula, trowel or ordinary plank. The ratio of cement and sand suitable for these purposes is 1:3.

- With a large volume of potholes, you can use a backfill made of fragments of bricks, stones and rubble.

As you can see, there are no universal solutions for all occasions. Everything is determined by the cause of the problem.

You can learn a little more about floor repair from the video in this article. Good luck!

" width="640" height="360" frameborder="0" allowfullscreen="allowfullscreen">

Good afternoon. I have a hole in the floor around the riser after the repair. Rats constantly climb out of it, since I live on the first floor. Tell me what and most importantly how to close a hole in the concrete floor so that these rodents no longer enter the apartment.

This problem occurs in many residents of old houses that have basements. At the same time, it should immediately be noted that the use of toxic substances practically does not help. It is necessary to completely block the access of rodents to the apartment, which means that you need to close up a hole in the concrete floor using materials that rats cannot gnaw through.

Preparation

First of all, you should examine the room and determine if there are other openings through which rodents enter the room. The fact is that in some old houses the sunbed, which departs from the riser pipe, is located below the floor level. Therefore, there may be several holes, which are used by rats.

Usually access to the basements of such buildings is difficult or there is almost no approach to a specific place. Given this, it is necessary to work on expanding the hole so that it can be sealed from above. At the same time, it is very important to do this in such a way that a kind of funnel with a narrow neck to the bottom is formed. This will make it easier to seal holes in the concrete floor without worrying that the created plug will fall out after a certain time.

Advice! Since all work will be done near the pipes, you must be very careful not to damage them. Many homes have long had plastic plumbing systems that do not tolerate physical impact very well.

materials

To complete the work you will need:

- cement;

- sand;

- water;

- gravel;

- pieces of reinforcement or thick wire;

- small plywood, although glass can also be used in the case of rats.

It must be said right away that when deciding how to seal holes in a concrete floor, preference should be given to concrete solutions. The fact is that rats cannot gnaw through rubble, and in addition to glass, you can get the maximum result.

Reinforcement

At this stage, you need to lay plywood or glass on the bottom of the resulting funnel. This overlap will serve to hold the solution in the hole and perform the function of a kind of formwork.

Next, place the armature. Usually it is used only in cases where the hole in the floor is too large. It strengthens the cork and serves to connect with the floor slabs. If the floor is made of two panels, then it is installed in the space between them. Some masters prefer to use a reinforcing mesh. This is considered an ideal option, but it is not worth buying it only for such purposes.

If a water or sewer pipe enters the hole, then it must be protected from the loads that will occur when the concrete expands as a result of heating from climatic conditions. To do this, use a special damper tape, wrapping it around the pipe at the level of its passage through the ceiling.

Mortar and filling

Determining how to close a hole in a concrete floor, many begin to invent their own formulas for creating concrete and use various additives. In fact, everything is quite simple. We take three parts of sand, which we mix with one part of cement. Add a little water to the dry mixture so that the solution turns out to be thick sour cream in consistency.

Then, at the bottom of the hole, pour the finished mixture, with a layer of one centimeter. After that, we begin to lay out a layer of gravel, making the stones close to each other. Next, pour more mortar to cover the rubble. As a result, the solution should occupy half the depth of the hole.

Advice! It is very important to ensure that the mixture penetrates into all the gaps between the gravel. Some craftsmen use a small stick or thick wire to trample down the concrete. As a result, there should be no empty spaces or air bubbles.

Some masters, answering the question of how to close holes in a concrete floor, recommend pouring in one go. This saves a lot of time and allows you to get a monolithic cork. This solution is considered correct when working with thin floor slabs and shallow holes. If the hole is quite large, then the filling is carried out in two stages, so that the solution in its volume does not crack or shrink strongly.

Given this approach, you need to let the first layer harden. Usually it takes no more than a day. Since the final hardening does not need to wait.

Advice! If the filling will be carried out in several stages, then you should not immediately prepare a large amount of the solution. The rest will have to be thrown away, which will lead to an overrun of materials.

The second stage of pouring is carried out according to the principle of primary concreting. In this case, you can also put glass on the bottom of the pit to completely eliminate the possibility of rats entering the room. After that, a layer of mortar, crushed stone and mortar is poured again.

When the hole is filled flush with the floor, the mortar is leveled with a spatula, creating a smooth surface. It is worth noting that if the surface is covered with tiles or other coating, then the alignment is done on the same level with the screed.

On final stage on the floor, you can put tiles or the coating used in this room. Usually, after repairs, there are always small pieces that should not be thrown into the trash.

Bottom line: answering the question of how to close a hole in a concrete floor and at the same time block access to the room for rodents, we considered the option of making a concrete plug. At the same time, the composition of the solution includes crushed stone, which rats cannot bite through, and the presence of glass bridges completely eliminates this problem. However, it must be remembered that such work should be done only after the rodents have left the premises. Otherwise, they will remain in the apartment and will not be able to go to the basement on their own.

Tsugunov Anton Valerievich

Reading time: 5 minutes

When replacing floor covering apartment owners often have to deal with the need to repair the concrete floor, which can be both concrete and the floor slab itself. Despite the fact that concrete is a durable and reliable material, potholes and cracks can appear on it under the influence of various factors. To prevent further destruction, timely measures are needed, because from the state concrete base depends on the service life of the finish floor. Find out how to repair concrete pavement using special mixes for repairing concrete floors.

Causes of defects in concrete

Defects on the concrete floor can be formed for various reasons, which are primarily associated with violations in the process of its arrangement.

Cracks often appear due to missing, untimely cutting or incorrect calculation of the thickness of the joints in concrete floors, designed to prevent concrete stress during thermal expansion and shrinkage. Properly made temperature-shrinkage seam will avoid many problems.

Other causes of cracks include:

- a large amount of water in the solution when pouring a concrete screed or its lack;

- low-quality reinforcement;

- lack of base waterproofing.

Defects can form even with high-quality work done. Any coating is subject to natural wear and tear, it is negatively affected by excess moisture. Potholes appear due to physical influences. It is impossible to exclude the influence of external factors on the concrete floor. The weak point is the junction of the wall and the floor, cracks often appear there.

The type of damage must be determined. This will allow you to draw up a work plan and choose desired material. Often faced with the following varieties:

- small depressions, potholes;

- cracks of various sizes;

- the thinnest cracks and chips.

Repair should not be put off for a long time. The size of the defects may gradually increase, the concrete will begin to crumble and move away in pieces, which will complicate the sealing of problem areas.

The choice of mixture for the repair of concrete surfaces

Before you start repairing the floor in the apartment with your own hands, you need to prepare a mixture for restoring concrete surfaces and structures. In building stores, they are presented in large quantities. In order to choose the right brand of mixture, you need to determine the degree of damage to the concrete surface:

- First degree - there are shells, shrinkage cracks.

- The second degree is peeling of the surface, small chips.

- Third degree - cracks within 2 mm with a depth of not more than 40 mm.

- Fourth degree - cracks more than 2 mm, depth up to 10 cm.

- Fifth degree - large potholes and cracks, a depth of more than 20 cm.

The purpose of the repair mixture should be indicated on the packaging. Noteworthy are such manufacturers of mixtures for the restoration of concrete surfaces as Emaco, Birss, Ceresit, Bars.

You can use universal repair mixes, such as Ivsil Render.

Since the price of special thixotropic compounds containing reinforcing microfibers and polymers is quite high, the mixture can be prepared independently for a small amount of work. To do this, take 1 part of PVA glue and mix with 4 parts of water. In this solution with construction mixer or a special nozzle on the drill, knead the sand-cement mixture in a ratio of 1: 3.

Preparatory work

After choosing a material for repairing concrete floors, you should start repairing. First comes the preparatory stage:

- All foreign objects are removed from the room.

- Existing debris, concrete chips and dust are swept away. Potholes and cracks are thoroughly cleaned with a vacuum cleaner.

- Any dirt, rust, mold or old soil is removed with a stiff metal brush.

- For elimination greasy spots you need to use a special solution.

- The concrete floor is swept with a wet broom, then it needs to be dried.

- If the reinforcement is visible, then it should be cleaned with sandpaper and primed with a composition with anti-corrosion properties.

Areas of the concrete surface that have lost strength should be hammered and cleared. The rule also applies to the edges of problem areas.

Filling holes in concrete floor

Repair of concrete floors begins with the expansion and deepening of the pothole around the perimeter. It is better to use a grinder with a diamond disc for this.

- The cut is made 1 cm deeper than the defect. To the sides, the pothole expands by 2–3 cm. If necessary, these figures are increased.

- Using a perforator or a hammer with a chisel, a notch is made in place of the pothole, a rectangular recess should be obtained. If a perforator is used, then it is better for outsiders to move away.

- The recess is thoroughly cleaned with a vacuum cleaner and primed.

- You can close up the pothole after the soil has dried. The mixture is carefully leveled, it is pierced several times to remove air. You can use a metal pin or trowel. Level the surface using the rule.

The depth of the hole matters. If it is more than 5–6 cm, then the composition is poured in several layers. The maximum layer thickness is 2 cm.

- After hardening, they proceed to grinding. A building level will help to achieve an even concrete base.

Work is recommended to be carried out in a respirator, goggles and gloves. Windows must be left open during renovations. The floor can be covered with paint on concrete, which will serve as additional protection. It is selected specifically for residential premises. A floor repaired in this way will serve for a long time.

Crack Repair Rules

The process of sealing cracks in a concrete floor differs depending on their size.

- Small gaps expand in depth and width by 2–5 cm. For this, you can use a chisel or grinder.

- The recess is cleaned of pieces of concrete and dust, then processed.

- To repair cracks in the concrete floor, a home-made mixture based on PVA is used. It fills the crack and waits for shrinkage.

- A second coat is applied, dried and sanded.

In cases where the cut is accompanied by strong dusting, which indicates that the concrete is weakened, it is necessary to use only special thixotropic compounds.

Repairing cracks in concrete floors should not be put off for long. If they are deformable, then they need to be treated with special attention. You can determine their appearance using strips of paper. A few months before the repair, they are glued to cracks in the concrete floor. With shrinkage slots, the paper will remain intact, with deformation strips they will break, which indicates their expansion.

- Such a crack is sawn 5 cm deep and 3 cm wide.

- The edges of the cut are knocked off, a triangular notch is formed.

- After thorough cleaning, the recess is primed.

- Markers are inserted into the crack with a step of 3 m.

Markers are thin smooth metal rods. You can make them yourself from the spokes of a bicycle wheel.

- The crack is filled with a thixotropic compound; the use of home-made mixtures in such cases is not recommended.

- The concreted area after drying is polished.

- The marker rods are removed, a new expansion joint is cut out through the holes left after them.

- Dust is removed from the seam, and the Vilotherm cord or its equivalent is placed in it.

- The seam is finally sealed with a sealant based on silicone or polyurethane.

Some people notice small cobweb cracks on the floor, as in the next photo. Over time, they may become wider. When the concrete weakens in this part, they are cleaned and covered with soil. For embedding, you can prepare your own composition or use a store-bought one.

In order to lay a new floor covering, it is necessary that the floor itself be sanded and smooth. Along with repairing or replacing your floorboards, you will likely need to patch up cracks and holes in your plank floors, as well as clean up roughness and possibly dampness in cast-in-situ concrete floors. Any flaws left uncorrected can eventually affect the quality of the flooring and damage it.

Seal holes in wooden floors

Holes from buried nails and screws can be easily sealed with an elastic putty to wooden surfaces using a spatula for this. If you plan to leave your plank floor unfinished and rub it down with appropriate cleaners, try matching a putty or sealer to match the color of the wood the floorboards are made from; however, apply a layer of putty after each floor sanding cycle.

Deeper cavities can also be eliminated with elastic putty, however, if a knot has fallen out of the board, leaving behind a large round hole, insert a short wooden plug into it, after smearing it with glue, and then clean this place with a planer. Corks match the color of the floor or paint over after cutting them flush with the floor.

There are two main types of cracks you'll find in plank floors: gaps from cracked ends along the edges of the boards, and gaps between the boards themselves. Such cracks can most often be eliminated by pulling them together with nails: one nail must be hammered into each edge of the board near the end and further into the beam at an angle to its center. As the nails are driven in, these cracks should disappear.

Eliminating gaps between boards is more difficult. If they are not wide, you can use wood putty; however, for wider gaps, you will have to prepare thin slats and hammer them, after smearing with glue, into the resulting gaps. When the glue is dry, planer or sand the edges of the slats that protrude above the floor; if necessary, paint over the installed wedges.

If there are many wide gaps between the floorboards, the most The best decision- pick up all the boards in turn, starting from one side of the room and ending with the other. Special clamps will help you put the boards back together as they will press them against each other while you nail or screw them.

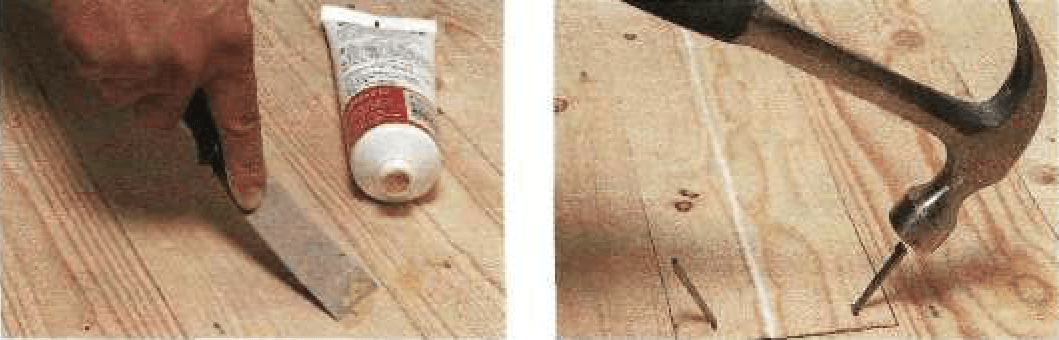

Seal gaps in the floor. To seal wide gaps, hammer glued slats between the boards. When the glue dries, use a planer to plan the edges of the slats that protrude above the floor.

Use a flexible wood putty to repair holes left by driving in nail or screw heads. When closing a crack at the end of a board, first fill it with glue, then pull it off by hammering nails near the end.

Leveling a wooden floor

Separate uneven areas floors can be sanded by hand - what you did after using putty - however, where there are depressions or a thick layer on the floorboards old paint, grease and mastic, the best way out is to borrow an industrial grinder and cycle the floor again. Start sanding the floor with a coarse sanding belt, then gradually move to a finer abrasive by guiding the machine across the boards. Finish sanding by running along the floorboards with a fine-grained emery cloth.

For hard-to-reach surfaces, also rent a special sander (if you do not have a belt sander), because Grinder does not capture areas of the floor located directly near the baseboards.

Sealing cracks and holes in monolithic concrete floors

Provided the screed is generally in good condition and dry, you may be able to repair cracks and holes using a quick setting repair mortar. Before this, all unbound particles must be removed from the slots, and the edges of the slots, if necessary, should be cleaned to provide a surface for the mortar to set. The edges of cracks and holes should be treated with a PVA (white) solution in combination of one part glue to five parts water to reduce the effect of the concrete's absorbent properties and help the solution soak into the floor.

For cooking cement mortar use PVA glue and water in the same ratio as the base; then cover the cracks with the resulting solution, and apply two or more layers to areas with large depressions. Level the surface with a spatula.

To help the freshly prepared mixture "grab" the edges of the crack, treat them with a brush with a solution of PVA (white). Apply a coat of quick setting repair mortar to cracks in the cast-in-situ concrete floor. Rub the solution on the damaged surface and leave it to harden. If the floor surface is excessively porous, apply an insulating layer consisting of a PVA adhesive solution with a brush.

Leveling monolithic concrete floors

It doesn't take much skill to create a smooth, flat surface, as the self-levelling floor compound does the job for you. There are two types of such a mixture: these are dry powders that must be diluted either in water or in a special latex (synthetic substance used for the production of adhesives, paints, foam rubber) emulsions.

Before you start pouring, clean the room, and also remove the doors and baseboards. Attach slats (shingles) to the entire length of the thresholds with nails to prevent unwanted spreading of the mixture. Treat all cracks and holes with a depth of more than 6 mm with a solution of PVA and water, as described earlier. Dilute the self-levelling compound in a bucket of water and pour it onto the floor, then level the resulting layer with a spatula or plaster trowel. Allow time for the mixture to settle. As soon as it dries - after at least 24 hours - you can install skirting boards and doors; however, make sure that the door does not touch the floor when you open it: you may need to slightly trim the bottom of it.

Dilute the self-levelling floor compound according to the manufacturer's instructions. Start pouring the floor with a mixture from the corner farthest from the door. Using a plastering trowel, level the layer of the mixture to a thickness of 3 mm.

To close the gaps in the floor between the boards, there are many options, you need to study them and choose the most suitable one. A wooden house is the most environmentally friendly and modern building for housing. It is pleasant and cozy to be in it, however, there are a number of problems that the owners of this building face, for example, gaps in the wooden flooring.

Good to know: how to close cracks in a wooden floor

Cracks can occur due to the drying of the tree. The tree dries for 10 years. Deformations of wood in off-season time are possible. In winter, wood swells, and in summer it dries and decreases in size. Visually, this cannot be detected, however, in the microcosm, under a microscope, you can see how the fibers in a tree change over time.

More possible reasons:

- Incorrect calculations of builders or incorrect installation of floorboards.

- Incorrectly prepared wood for operation - low-quality paints and varnishes.

- Bad ventilation.

- Insufficient floor fit.

- The appearance of mice and termites.

Do-it-yourself grouting of cracks in the floor is a very economical method, but it is not aesthetically pleasing and is used mainly in dilapidated housing or in the country

All cracks, depending on the size and location, are eliminated, you only need to pick up correct solution. There are many methods to eliminate gaps in wooden floor. Cracks up to 15 cm are filled with sealant. In this case, the sealant can be used in 2 types, it is a silicone or acrylic sealant for wood. Special sealants for wood differ in color, which allows you to eliminate joints and gaps as imperceptibly as possible.

Sealants have a number of advantages: resistance to moisture, favorable consumption in the process of sealing the gap and long operation after the elimination of defects in the floor.

You can fill the gap with wood putty. The choice can fall on acrylic-based, solvent-based, oil-based or polymeric, water-based. You can putty not only cracks and holes, but also irregularities on plywood or wood, as well as cracks. You can seal the gap with foam. However, it is necessary to eliminate cracks very carefully, without spraying foam. Excess foam can be removed only after it hardens.

Cracks are sealed with polyester paste. There can be both one and two-component options. Suitable for sealing gaps and seams up to 5 cm. Sealing gaps with improvised materials, such as slats, tow with paint, glass wool, grout from paste and paper, sawdust and own preparation of putty, is also relevant.

High-quality sealing of cracks in a wooden floor

Regardless of the size of the gap between the boards in the floor or in the parquet, before removing it, it is necessary to do a dry and wet cleaning, remove dust and clean the place of the gap, let it dry.

Termination options:

- If the gap in the wooden floor is up to 1 cm in size, then it can be sealed with a tourniquet, grout or filled with sealant.

- If from 1 cm to 3 cm, then a special putty is well suited.

- If the gaps are very large, then it will work well polyurethane foam, wedges or slats.

The most common sealing of large gaps in a wooden floor is polyurethane foam.

The field of operations performed, it is better to cover the floor with sheets of plywood, the joints of which are also processed and leveled with putty. Small gaps or joints can be covered with putty made from glue and sawdust.

Sawdust is taken in a fine fraction, poured with boiling water and mixed until a homogeneous mass.

After the solution with sawdust has cooled down, PVA glue is added and applied with a spatula in the localization of the gap cleared of dirt and dust. After the surface of the sealed gap has been leveled to the floor level, it must be left for a couple of days so that the mixture can take and dry. After everything has dried out, the irregularities must be treated with an abrasive, and fire protection should be applied, and only then the selected paints and varnishes.

You need to know: how to close a hole from mice

There are mice in both rural and urban areas. If there are any gaps in the houses, then mice can easily enter the living quarters, they will not only harm human health, as they are carriers of leptosperosis, toxocariasis, streptobacillus and many others, which can be fatal, but also harm room, its decoration, can penetrate food.

A hole from mice, so that they do not gnaw through a new passage in a wooden floor at all, can be patched up with concrete mortar, after putting metal shavings there

The most proven options for sealing holes in the wall from mice are:

- glass wool embedment;

- Eliminate the defect with cement;

- Mounting foam also helps well, mice do not gnaw it, and tightly seal the hole.

The advice of experts comes down to broken glass, which are placed in the holes of mice.

How and how to seal the seams between plywood on the floor

On plywood flooring, you can often find seams and joints that need to be repaired. You need to know that the most important thing in choosing a putty is elasticity, since plywood consists of wood veneer, and the tree is subject to seasonal deformations. Over time, the plywood dries out, and the joints become more visible. It is also worth choosing a putty according to the color of the wood, as well as a special one, that is, for wooden material.

For sealing seams, are used:

- acrylic putty;

- Elastic sealant;

- hot glue;

- Sawdust with PVA and gypsum;

- Epoxy adhesive.

To seal the seams between the plywood on the floor, it is necessary to choose exactly the putty for wooden floors, since the other simply cannot withstand the load

It is worth considering that chipboard, plywood should be well fixed so that they do not walk and do not vibrate, then the selected putty (putty for wooden floors) will not crack and will hold tightly, closing the gap.

These works are also being done for plywood, on which linoleum will subsequently be laid.

It should also be covered with putty or better silicone sealant, dents in plywood and all joints, cracks. Plywood needs to be coated with an antiseptic. Before laying linoleum, it is necessary to pay attention to the evenness of the plywood and its cleanliness.

Types of putties for the floor from the boards

To date, there is a fairly wide selection of putties on wood. Before choosing a putty, you need to decide on the price, scope, type and brand.

Elastic putty for the floor does not require careful surface preparation, it is easy to apply and cover with other paints and putties

Putties are divided into types:

- Polymer putty, which is made on a water basis, therefore, does not emit chemicals into the atmosphere. It dries quickly enough, holds well and does not crack.

- Oil putty based on water, chalk and oils. It is one of the most reliable, however, after processing the gap, it takes a lot of time for it to dry completely.

- Acrylic putty is environmentally friendly and non-flammable, which is very important for wood.

- Solvent-based putty is ideal for parquet flooring, but is not the most environmentally friendly option.

- The putty is elastic, which is ideal for “floating” cracks and joints. It keeps its shape perfectly, has good adhesion to the surface.

- Pigmented wood putty, that is, various colors (white-birch, teak-mahogany, wenge-dark oak, beech-oak). It must be taken into account that often the color does not match the one declared on the package, you should require a demonstration of the goods or a stand with these putties.

- Putty for wooden floors, which is used to smooth out irregularities, various defects and cracks.

The main brands of putty manufacturers are Dulux, Parade, Semin, Varathane, Axton, Neomid, Forwood, Rainbow, Tytan, Master's Choice. We must not forget that putties differ in the main types: finishing, leveling, filling, universal, sealing. Putty is applied with a spatula of the selected size, by pressing it into the depth of the gap. After the putty dries, it is necessary to level the surface using abrasive products for wood.

How to close cracks in a wooden floor (video)

When cracks appear, it does not matter, any gap can be repaired with your own hands, and the wooden floor is easy to install and repair.