How to make a glass table: ideas, drawings with dimensions, step by step instructions, photos and videos. Glass table - an element of a stylish interior How to make a glass table

Designers in modern world reminiscent of naughty kids who got their hands on a 3D multifunctional construction set with a guidance system - if one exists. With the help of designers, earthlings suddenly found out that they live in a boring, gray environment and do not notice the bright opportunities provided by the achievements of progress. Some of their projects cause shivers and shock, while others - nervous laughter. For example, we would have made a glass table with our own hands without the participation of these figures at all - simply out of a sense of self-preservation.

Today we will consider the nuances of self-manufacturing glass tables.

Now there are two ways to reliably assemble glass structures of any complexity, but none of them provides for the presence of experimenters who are sick to the full head. Glass is a dangerous material in itself, so do not turn the master's everyday life into a horror movie.

Frame way to assemble a glass table

In general, in principle, if you decide to cut out the details of the glass table yourself, at home, only the frame method is suitable for you. It makes no sense to even take on the embodiment of a design or personal idea about open glass - it will come out obscene. The frame method is simple by definition:

Cut in furniture board hole right size and shapes, and then fix the raw glass in it with a glazing bead. Not too beautiful, and it will not be possible to install glass of normal thickness, but you can mount the countertop like a regular chipboard part.

Modern mechanical fasteners are diverse and give room for creative imagination, but they themselves are not always pleasing to the eye.

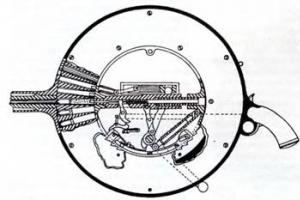

Mechanical fasteners for glass

The manufacture of a glass table using mechanical fasteners allows you to endlessly vary and even modify the assembled structures. The main difference from the second method is facet. Here it is needed.

Making a high-tech glass table

The hi-tech style, in which the most popular models of glass structures are made, implies a metal-glass combination, and without the use of clips protruding above the table top. Accessories can be purchased at construction or specialized stores.

Table assembled with special glue

It includes a variety of supports, legs, coupler and shelf combinations to give a decent look to any build – But! This requires special glue.

Adhesive for glass structures

When we researched the question "How to make a glass table with your own hands" - we stumbled over a small problem. The adhesive used to mount the mirrors is visible through the transparent glass surface and takes too long to dry - which is unacceptable in the absence of additional fasteners.

However, special types of glue helped to resolve this issue. Russian manufacturers have adopted the experience of Polish and German colleagues, and now they produce quite decent glue of two types: “glass-metal” and “glass-glass”. Like other types of special formulations, this one also has its own peculiarity - it polymerizes in ultraviolet rays with a length of 300-400 nm.

An ordinary UV lamp for warming up the ear / throat / nose is not suitable here - you need to find out the characteristics from the sellers of the equipment. In our region, we found a suitable device in a hardware store for only $26. The time sufficient for the final "drying" of the glue depends on the power of the lamp - the initial gluing took us about thirty seconds.

glass table detail

We really liked the quality of the glue - the connection is stronger than the material itself, that is, when you try to tear off the part, you will not break the glue, but break off a piece of glass.

If you decide to make a glass table with your own hands, take tempered glass 10-12 millimeters thick, and then you will need a bulldozer to dismantle the product. With the second assembly method, we decided to completely abandon additional fasteners and make desk in the waiting room, for which it is not a shame to put an attractive secretary.

Let's describe the detailing and assembly process of this table

The whole structure is glued tightly - only the monitor stand is movable. Detailing is simple to amazement:

- 1600x700 mm - countertop.

- 450x350 mm - the top of the monitor stand.

- 350x80 mm - 2 pcs. Monitor stand sides.

- 750x500 mm - 4 pcs. Sides of the table.

- 400x500 mm - 5 pcs. Shelves.

The thickness of the glass is 14 mm, the total weight of the table is about one and a half hundred kilograms, so there is no need to be afraid of thieves. Prestige - 11 points on a ten-point scale (the third secretary is going on maternity leave).

Attention! The ends of the joining parts must be perfectly even and without bevels - otherwise the design will come out crooked and unbalanced.

Other elements of the table should not have any sharp corners or cutting edges in principle - if you do not want to open a branch of a blood donation point.

Table assembly process

In this case, no tool is needed for assembly - except for a tape measure and a marker. All lines are marked on the outside of the connection - the surfaces to be bonded must be perfectly cleaned and degreased.

It is unrealistic to assemble the cabinets alone - you need an assistant who will irradiate the gluing place with a UV lamp while you hold the parts in the right position. We recommend wearing sunglasses - the eyes are not designed for such loads, although the process will not bring them much harm.

Glue the shelves to the sidewalls one at a time - until they grab, and only then irradiate until the final polymerization of the glue. Please note - it will not be possible to tear off and redo, so mark carefully. Also pay attention to the coincidence of the edges of the structure. Glue is applied to the end of the part, and not to the plane: Excess can be removed with a sharp knife, but this work will not bring pleasure.

There are many answers to the question: "How to make a glass table." But before asking this question, mark for yourself a few absolute truths:

- Glass does not tolerate negligence. The “And so it will do” option is good for misanthropes who wrote a will in favor of world peace (if they exist). Never use thin glass, especially in places where children are present. The cubs manage to split shop windows - what is some kind of table for them ?!

- You can see through it. Do not put a glass table in the living room, if your girlfriends have crooked legs - everyone present will lose their appetite.

- It's hard to see through it. This piece of furniture requires constant care. Fingerprints, dust, boogers or chewing gum stuck to the countertop will become public. If you do not intend to create an art object in this way, resign yourself to the need for constant cleaning.

Good luck to you.

Recently, furniture made of glass has become increasingly popular. And this is no coincidence, because this material is environmentally friendly and natural, allows you to give lightness, sophistication to the room and visually expand the space. Until recently, glass was used in the manufacture of furniture very rarely, as many people associated it with fragility. However, modern technologies for its production provide excellent strength to products, which makes it possible for interior items and furniture made of glass to withstand significant loads.

The first pieces of furniture made of glass were small tables. Today, glass is used to make shelves, coffee, serving and dining tables, bar counters, kitchen worktops, whatnots, cabinets, racks for equipment, etc. This was also made possible by combining glass with various materials: wood, plastic, metal. The only significant drawback of glass furniture is its cost. To produce a quality product, sometimes it is necessary to perform complex high-tech operations. In addition, glass products are usually made in small quantities according to the designer's sketches.

This also has a significant impact on the final cost. But if you are ready to become both a designer and a craftsman for your product, then its price will become quite acceptable. When choosing glass, it must be remembered that its thickness directly depends on the functional purpose of the future product. So, for the manufacture of a simple shelf, glass with a thickness of 5 mm is quite suitable, and for a table - at least 8 mm. For reference: a sheet of glass with a thickness of 15 mm with dimensions of 1 × 1 m can withstand a load of up to 100 kg.

Glass processing methods

Numerous types of processing of this material allow to significantly expand the scope of glass. First of all, it's cutting.

The main key to the success of such an operation as cutting glass is the glazier's table, which should not have deflections and bumps. Otherwise, the glass can simply burst, crack. Glass cutting can be done with a roller or diamond glass cutter, the main thing is that the tool used in

this, was not worn out.

The main sign of proper cutting is a characteristic hissing-crunchy sound. The glass cutter in action should not creak, squeak, bounce on the glass. The incision line must be carried out in one motion, without stopping and without going back. If you run the glass cutter twice along the same line, the resulting edge will crumble and chip off.

glass cutter

After making the notch line, the glass is tapped with reverse side with a special hammer or the handle of the glass cutter itself, and then break off with light pressure. To remove small fragments of glass remaining on the fault line, use the slots located on the handle of the glass cutter. After the element of the required size is cut out, its edges should be processed. This will give the edge a rounded and safe appearance. At home, this can be done with an emery bar, periodically wetting the glass with water. The direction of movement of the bar should be along the edge of the glass. In this case, there will be no chips.

To drill holes in glass, you will need a cylindrical diamond-coated glass crown, drills and plastic bottle with water. To avoid overheating of the glass during drilling, it is poured with water. If the glass is thick, it is drilled only halfway, then turned over and the part is drilled through.

The surface of glass or mirror can be either glossy or matte. For matting glass, a special paste is used (for example, "GlassMat"). By the way, applying it through a stencil, you can get a drawing or ornament on the workpiece. Glass processed in this way has a lower surface roughness than mechanically processed glass and a kind of “silky” surface.

The surface of glass or mirror can be either glossy or matte. For matting glass, a special paste is used (for example, "GlassMat"). By the way, applying it through a stencil, you can get a drawing or ornament on the workpiece. Glass processed in this way has a lower surface roughness than mechanically processed glass and a kind of “silky” surface.

If necessary, ordinary glass can be covered with a film for tinting car windows. So you get tinted glass, which will cost you much less than buying ready-made glass with a factory coating.

Shelves

glass shelves perfect solution for small spaces. They help to rationally use the space of the room, without visually reducing it. Also, glass shelves do not create shady areas on the walls, so that the room retains a feeling of lightness and airiness. For the manufacture of glass shelves, you will need a planed wooden beam with a section of 20 × 80-100 mm and glass with a thickness of at least 5 mm

- From glass, cut out rectangular blanks measuring 200 × 800 mm. Their number depends on how many sections your shelf will have. Finish the edges of the blanks.

- Saw cuts in each blank from the timber grooves of about 50mm. To do this, it is better to squeeze the bars together and make cuts simultaneously in both blanks. The shelves should slide into these slots with light force. If the grooves are too wide, strips of adhesive tape can be attached to the glass. The edges of the bars can be decorated at your discretion or simply sawed off at an angle of 45 degrees.

- Carefully attach the beams to the wall, while controlling their location. Insert the shelves into the slots. One or more shelves can be replaced with wooden or laminated chipboard - and then heavier objects can be placed on them

Coffee table

Glass coffee tables as an element of the interior fit easily into any design composition due to its unique features. So, for example, a glass tabletop can be given any shape, and the glass itself can be painted in almost any color.

Glass coffee table in height usually does not exceed the curbstone. Its legs are made of chrome-plated steel pipes or wood.

To make a coffee table with a glass top, you will need a chrome-plated pipe with a diameter of 50 mm, fittings for pipes, and glass with a thickness of at least 6 mm.

- Before proceeding for table making, sketch it. To do this, first plan in which part of the apartment it will be placed. and in what style should be done, to match room interior

- cut out of glass countertop necessary config. Finish the edges of the workpiece

- Saw off the required number of blanks for supports (legs) from the pipe. Depending on the design their table can be three or four.

- To the countertop using special glue (it is better to use UV - glue) when gluing the top supports. Connect each support with threadedstuds with thrust bushing cylindrical, installed in the upper part of each support.

- Insert thrust cylindrical bushings into the lower part of the supports. Screw into the support bushings flat or wheeled

You can make several coffee tables of different heights and combine them. The originality of this design lies in the fact that the entire contents of the lower shelf can be viewed without looking under the countertop.

Tiered coffee table

Cabinet for equipment

A glass cabinet for equipment does not clutter up the space and visually makes it freer, while a TV, DVD-meep or music

the center look elegant on her. Despite the fact that there is a huge selection of cabinets in stores, their cost is very significant. In addition, it can be difficult to find the right size and design to match your interior and equipment. You can solve these problems by making a glass cabinet with your own hands.

To make it, you will need a chrome pipe with a diameter of 50 mm, fittings for pipes, glass 10 mm thick for the top shelf and at least 5 mm for the bottom ones.

- Cut glass shelves required size. Process the edges of the workpieces

- Cut off the support parts from the pipe: four 150 mm long, four 550 mm long and four 50 mm long. Dimensions are approximate and can be changed to suit your project.

- Attach the top shelf to the supports with glue, as described earlier.

- Assemble the cabinet upside down. To do this, lay the top shelf of the cabinet with the glued top supports on a flat surface. Screw the threaded rods into the threaded holes of the upper supports. Fasten the support parts with a length of 150 mm to the studs.

- Secure the middle and bottom with break knots. To do this, drill holes with a diameter of 10 mm at the corners of the shelves.

Insert thrust cylindrical bushings into the lower part of the supports. Screw the flat supports into the bushings as described. - her. Holding the cabinet by its supports, carefully turn it over.

Glass furniture in interior design thanks to play sun rays is able to enliven any environment and create a feeling of weightlessness, airiness, extraordinary comfort and coziness. Cabinets, tables and coffee tables, cabinets and other items made entirely of glass or combined with glass elements do not clutter up the space at all, but, on the contrary, visually expand it, which plays a significant role in the arrangement of small spaces. Thanks to the transparency and clarity of the designs, glass can be called a real find, allowing designers to implement a wide variety of ideas and solutions.

Video: Do-it-yourself glass luminous shelves

Do you want to diversify the interior without extra costs? A DIY glass table is a great idea. A unique product will update the interior of the room. Certainly, independent production furniture can not be called a simple matter, but the result is worth it. Yes, and such a product will cost much cheaper than purchased. Today's article - detailed description the process of making a table with a glass top.

Design features

The most popular are products with a monolithic countertop. But there are also transforming tables, with the possibility of extending the table top. The form may be different:

- Round.

- Oval.

- Rectangular.

- Square.

Glass can be ordinary, transparent, as well as frosted or tinted:

- The transparent design is the perfect solution for small spaces. It creates the impression of soaring, grace and lightness.

- The matte countertop often has a greenish tint. This is the natural color of the glass.

Important! Colored material attracts attention, first of all, with its unusualness and originality. For example, black glass is a great addition to a gothic or modern style. It will look great with chairs made of white metal or plastic.

For the manufacture of the underframe, most often, chrome-plated metal or wood is used. Wicker underframe, forged metal or durable high-quality plastic looks good. If the tabletop is made with a frame, then the frame must be made of the same material as the underframe.

DIY glass table - advantages and disadvantages

The advantages of glass tables include:

- Beautiful appearance. Such a product looks stylish and favorably transforms the interior.

Important! Particularly organic glass fits into the concept modern styles— Hi-tech and Minimalism.

- Practicality. Thanks to modern technologies, there are high-strength grades of glass. Furniture is also safe, where the glass is covered with a special film. Even if broken, the countertop does not crumble to smithereens. The fragments are firmly glued to the film.

- Persistence. The material is resistant to high humidity and significant temperature changes. It is chemically neutral with respect to aggressive substances. Glass does not absorb grease and dyes. This compares favorably with the usual countertops made of wood, MDF and chipboard.

However, there are also disadvantages:

- Fingerprints and traces of dirt are clearly visible on the surface.

- If you put dishes on it, then there is a rather loud noise.

Important! Compared to the advantages, these disadvantages are not critical at all:

- Fingerprints are invisible on the matte surface.

- The use of special caring compositions allows you to maintain products in perfect condition.

- The problem of noise is also quite solvable. It is enough to purchase special coasters for dishes.

DIY manufacturing technology

Consider how you can make a beautiful glass table yourself.

Preparation

First decide where new item furniture will stand as you are going to operate it. For example, as a coffee table or for eating. Take all the necessary measurements, draw the product to scale, indicating the location of the legs and the size of the tabletop.

To make a glass table with your own hands, you will need:

- Glass cutter - roller or diamond.

- Long metal ruler.

- Hammer with a rubber striker.

- Pliers equipped with rubber pads (for breaking glass).

- Bulgarian.

- File or emery bar.

- Turpentine or kerosene.

- Just glass. Which option to choose - transparent, textured, tinted or mirror, you decide.

Important! It is advisable to use high-strength hardened material for the manufacture of countertops, with a thickness of 0.6 to 1.2 cm.

The main thing is that the glass is dry and clean. It is best to dedust it with soft textiles and a soda solution. Such preparation will not be superfluous, because dirty glass can break away from the cut, and the tool quickly fails.

Cutting glass:

- Lay the prepared glass on a table or plywood sheet.

Important! Make sure that the material is adjacent to the surface with its entire plane.

- Place a thin rod (about 3 mm in diameter) under the cut line.

- Place a ruler on the glass so that it is 2-3 mm from the cut line.

- The optimal pressure force on the glass is 2 kg - this can be easily checked with conventional scales.

Cutting features

It is best to cut glass using a thin metal ruler. Highly qualified craftsmen cut the material by eye, according to the markings previously made with a marker or along the edge of the table.

Important! If you don't have great experience in glass cutting, it is better to practice on scraps first. This is not so difficult and will take a little time, but the chance of cutting the material perfectly will increase significantly. Try to draw only one cutting line.

Glass is broken off by hands in protective gloves. At the same time, position the glass so that the cutting line and the edge of the cutting table coincide. Press on the glass with a sharp movement, and it will break off along the cut line.

Important! If there are sharp edges or glass residue, remove them with rubber-backed pliers. For greater efficiency, place paper folded in several layers under the jaws of the pliers.

If the glass is curved, mark the stencil and pass the glass cutter along the line. Do the same for the round cut. To make unnecessary glass easier to break off, make special “rays” and break off in parts.

Edge processing

Even if you worked with the utmost care, sharp “teeth” and protrusions remain along the edge of the edge, which must be removed. Certainly, best option for processing the glass edge is a special machine. But manual processing is also quite effective:

- Work at the same time only in cotton mittens.

- Use a file or abrasive block to file the edges.

- Be sure to moisten the file with turpentine or kerosene.

- To make the edges even, evenly move the file or block along the edge.

- For grinding and polishing the edge, use a drill with nozzles or a grinder.

- Grinding speed should be low (1200-1700) rpm.

- Sandpaper grit varies from coarse to fine.

- Polishing - The final stage. Perform it with a felt circle, using a grinder or drill.

First of all, decide for yourself what type of table you want to make. It could be dinner table, bedside table or bedside table, and maybe a coffee table. In our case, we will make a small side table for the living room.

All further manufacturing work is best done in the yard or on the site next to the house.

Carefully consider your floor vase, its dimensions should be at least 40-45 centimeters in height and somewhere around 80-90 centimeters in diameter.

In any case, in every supermarket you can easily choose the product that fully meets the necessary requirements. Your vase can be made from clay, stone, ceramic, concrete, or plastic. However, if you like a plastic vase, then gravel or sea pebbles will need to be added to it to give stability. And if the vase is transparent, you will give the pedestal a rather original and colorful look.

In our case, we use round strained glass not less than 12 mm thick and about 110-115 centimeters in diameter. You can buy branded factory glass or look, say, in the garage for pieces of glass that are no longer needed, but are perfect for your needs. With this piece, you can go to the workshop, where the workers will cut it for you, or try to cope with this task yourself. Then ask the craftsmen to round the edge of the countertop on one or both sides, depending on your desire.

What glass is best for a table?

In principle, almost all known types of glass are suitable for making a table:

- smoky,

- transparent,

- tinted,

- Matte

- Colored glass that goes well with the overall interior of the room.

What are the safety rules for working with glass?

Of course, while working with such a complex material as glass, it is important for you not to get hurt and not harm your health.

If you decide to work with the glass yourself and cut it with a glass cutter, be sure to use safety glasses and wear thick work gloves.

When transporting glass from the store, make sure that it is properly packaged, always with foam inserts. They will protect the glass from splitting when shaking in the car.

How is the manufacturing process

Place a floor vase in the center of your living room seating area. It can be placed near the sofa or not far from the armchairs, in a word - in any place convenient for you.

Place the finished table top on the stand and adjust its position so that it lies exactly in the middle. After that, set it aside and apply silicone transparent glue. Spread the glue evenly over the neck of your vase, applying it in round balls, of which there should be at least six.

Then lay the countertop according to your marks. In order for the bonding points to be guaranteed to “grab”, put something heavy in the center on the glass. Let the glue dry completely before using the table.

Shards of glass can be placed on the bottom of the vase and illuminated, such as a Christmas garland. Then at night the garland will illuminate the fragments, which, with their reflections through the glass tabletop, will create a mysterious atmosphere in your living room.

Almost every person who at least once in his life has done something for his house with his own hands, over time, begins to feel the desire to make his efforts again. It's so nice to see the result of your work every day, especially if this craft becomes a noticeable accent in the interior of the house. Such an emphasis could be new table from glass. Some are wondering how to make a glass table with their own hands.

The glass table does not absorb moisture and grease, and is also very easy to clean.

The process of its manufacture requires care and accuracy, but the end result is worth it. A little time, and you can proudly show your friends and relatives a new piece of furniture made by yourself. Consider how to make a glass table.

Pros and cons of a glass table

Advantages of glass table:

- suitable for any interior;

- hygienic;

- easy to care for;

- relatively light;

- does not absorb fat;

- glass can be treated with any cleaning agents.

These tables also have quite tangible disadvantages. Glass tops do not dampen sound, so the operation of the table is accompanied by characteristic sounds. In bright light, stains and prints become noticeable on the glass.

Back to index

How to make a glass table with your own hands

First you need to choose the shape, style and size of the table. It can be a regular high-tech rectangular glass table or oriental tale. It is necessary to decide what role it will play in the already existing interior. After all tasks are defined, it remains to prepare essential tool, materials and go!

To make a glass table you will need:

- glass cutter (it can be diamond or roller);

- pliers with rubber gaskets;

- metal ruler;

- rubber mallet;

- the material itself for making the table (it is better if its thickness is at least 6 mm).

Glass for the manufacture of the table, you can choose any. It can be transparent and matte, colorless and colored, smooth or textured and many more options.

But if you take ordinary transparent glass and then decorate it using any method, then you can get a unique piece of furniture at the output.

The choice of material for the manufacture of the underframe can only be limited by the imagination of the master. For these purposes, you can use wood, metal, plastic glass. In addition to the main tabletop, an additional shelf can also be included in the design of the table.

Back to index

cutting glass

In order to cut the countertop of the desired shape, it is necessary to apply its future contours to the glass. It is better to carry out these works on a special table so as not to transfer the workpiece from place to place and not expose it to the risk of being broken. First you need to practice on scraps of glass, then it will be a little easier to cut the countertop itself. The incision must be made with a metal ruler. The force of pressing on the glass cutter is determined by its sharpness. So, you do not need to press as hard on a diamond glass cutter as on a roller one.

Safety precautions must be observed when working with glass! Be sure to wear gloves to avoid injury to your hands.

After making the cut, you need to separate the edges of the glass. This can be done by hand or using pliers. In addition, the glass cutter has a special tool needed to break off a thin edge. As a result, we get a glass tabletop of the required size and shape.

The next stage of production is the processing of the glass edge. This can be done either manually or using a special machine. For manual processing of glass, you will need a file or an emery bar. When using a file, you will need a soaking liquid. It can be turpentine or kerosene. You need to work especially carefully. Movements should be uniform and smooth. After rough processing of the glass edge, it must be sanded and polished. This can be done with a drill or grinder using a special nozzle. For grinding the edges, successively reduce the grit of the emery wheel. Polish the surface with a special paste and felt.

Figure 1. To prevent damage to the pattern on the glass table, it must be applied from the back.

So, the base of the countertop is ready. Now you need to make a base. There may be many options here. It remains to attach the tabletop to the underframe.

Fastening is carried out using special suction cups and glue. In order to fix the suction cups on the legs, it is necessary to drill or cut holes in them. The glass is fixed to the suction cups with a special adhesive that dries under the influence of ultraviolet rays.

The glass table is ready. It remains to decorate it. Here are the most common options.

Back to index

Glass painting in stained glass technique

Materials:

- palette (it is better to use a piece of the same glass);

- stained glass paints;

- pattern stencil;

- contour paints;

- White paper;

- solvent;

- stationery knife;

- cotton wool;

- ammonia;

- water.

First you need to degrease the surface of the glass well. Then you need to fix a sample of the drawing and carefully transfer it to the glass using contour paint. If it turns out not very carefully, the excess can be removed with cotton wool. If the contour is thin, you can correct it using a cotton swab or a toothpick.

Figure 2. After painting, the picture must be covered with a layer of varnish.

After the contour is completely transferred, we remove the sample drawing and attach the glass to a sheet of white paper. We mix stained glass paints on the palette to get the necessary shades and apply it to the prepared sketch (Fig. 1).

Bubbles can be removed with a toothpick. The finished drawing needs to dry completely. To decorate the countertop, this technique is best applied from the underside of the glass (Fig. 2). For greater durability, the surface should be coated with a layer of varnish.