Old gas column. How to use? Gas column repair Neva

The gas water heater NEVA 3208 is convenient, simple and reliable. Despite the venerable age of most of the operated specimens, they quite regularly cope with their duties of heating water. But sometimes you want to clarify something in the instruction manual. And here comes the problem.

The original instructions are most often lost, and downloading the operating instructions on the Internet is Neva-3208 impossible. More modern columns Neva series 4000, 5000, Neva Lux 6000, boilers Neva Lux series 8000 - please, but there are no instructions for Neva 3208.

In the search, only fraudulent sites that require a cell phone number come across, but even there there is no instruction - only the name of the file. This is easy to check by trying to find a file on such a site with a name that obviously does not exist - for example, " qwerrasdfgfgh-$%#$@$". He will find it, and even say that it has been downloaded several thousand times! I hope that you do not fall for such tricks and do not enter your phone number on suspicious sites. And you can find the instruction manual for the gas column Neva-3208 here.

DEVICE WATER HEATING FLOW GAS HOUSEHOLD

NEVA-3208 GOST 19910-94

NEVA-3208-02 GOST 19910-94

OPERATION MANUAL 3208-00.000-02 RE

Dear buyer!

When purchasing the device, check the completeness and presentation of the device, and also require the trading organization to fill out coupons for warranty repairs

Before installation and operation of the device, it is necessary to carefully read the rules and requirements set forth in this operation manual, compliance with which will ensure long-term trouble-free and safe operation of the water heater.

Improper installation and operation may result in an accident or damage the machine.

1. GENERAL INSTRUCTIONS

1.1. Apparatus flow-through gas water heating household "NEVA-3208" (NEVA-3208-02) VPG-18-223-B11-R2 GOST 19910-94, hereinafter referred to as the "apparatus", is designed to heat water used for sanitary purposes (washing dishes , washing, bathing) in apartments, cottages, country houses.

1.2. The device is designed to operate on natural gas in accordance with GOST 5542-87 with a net calorific value of 35570+/-1780 kJ/m3 (8500+/-425 kcal/m3) or liquefied gas in accordance with GOST 20448-90 with a lower calorific value of 96250+/- 4810 kJ/m3 (23000+/-1150 kcal/m3).

When manufactured at the factory, the apparatus is configured for a specific type of gas, which is indicated on the label on the apparatus and in the “Certificate of Acceptance” section of this manual.

1.3. Installation, assembly, owner briefing, preventive maintenance, troubleshooting and repairs are carried out by gas operating organizations or other organizations licensed to this species activities. Section 13 must contain the mark and stamp of the organization that installed the apparatus.

1.4. Checking and cleaning the chimney, repairing and monitoring the water supply system are carried out by the owner of the device or the building management.

1.5. The owner is responsible for the safe operation of the machine and for keeping it in good condition.

2. TECHNICAL DATA

2.1. Rated thermal power 23.2 kW

2.2. Rated heat output 18.0 kW

2.3. Rated heat output of the pilot burner, not more than 0.35 kW

2.4 Nominal natural gas pressure 1274 Pa (130 mm w.c.)

2.5 Nominal pressure of liquefied gas 2940 Pa (300 mm w.c.)

2.6. Nominal consumption of natural gas 2.35 cubic meters. m/hour.

2.6. Nominal consumption of liquefied gas 0.87 cubic meters. m/hour.

2.7. Coefficient useful action at least 80%

2.8. Supply water pressure for normal operation of the device 50 ... 600 kPa

2.9. Water consumption when heated by 40 degrees (at rated power) 6.45 l / min

2.10. The temperature of the gas combustion products is not less than 110 degrees

2.11. Vacuum in the chimney not less than 2.0 Pa (0.2 mm w.c.), not more than 30.0 Pa (3.0 mm w.c.)

2.12. Ignition of the device "NEVA-3208" piezoelectric, device "NEVA-3208-02" - with a match

2.13. dimensions apparatus: height 680 mm, depth 278 mm, width 390 mm

2.14. The weight of the device is not more than 20 kg

3. SCOPE OF DELIVERY

3208-00.000 Apparatus "Neva-3208", or "NEVA-3208-02" 1 pc.

3208-00.000-02 RE Operating manual 1 copy.

3208-06.300 Package 1 pc.

3208-00.001 Handle 1 pc.

Wall fixing elements 1 set

3103-00.014 Gasket 4 pcs.

3204-00.013 Sleeve 1 pc.

4. SAFETY INSTRUCTIONS

4.1. The room where the device is installed must be constantly ventilated.

4.2. To avoid fire, do not place or hang flammable substances or materials on or near the device.

4.3. After stopping the operation of the device, it is necessary to disconnect it from the gas supply source.

4.4. To prevent the unit from defrosting during winter time(when installed in unheated rooms) it is necessary to drain the water from it.

4.5. In order to avoid accidents and damage to the device, consumers are PROHIBITED:

a) independently install and start the device into operation;

b) allow children to use the device, as well as persons who are not familiar with this instruction manual;

c) operate the device on a gas that does not correspond to that specified in the plate on the device and the "Acceptance Certificate" of this manual;

d) close the grate or gap in the lower part of the door or wall, intended for the inflow of air necessary for the combustion of gas;

e) use the device in the absence of draft in the chimney;

e) use a faulty device;

g) independently disassemble and repair the device;

h) make changes to the design of the device;

i) leave the working device unattended.

4.6. During normal operation of the apparatus and with a serviceable gas pipeline, the smell of gas should not be felt in the room.

If you smell gas in the room, you MUST:

a) immediately turn off the device;

b) close the gas valve located on the gas pipeline in front of the apparatus;

c) thoroughly ventilate the room;

d) immediately call the emergency service of the gas facilities by tel. 04.

Until the gas leak is eliminated, do not perform any work related to sparking: do not light a fire, do not turn on or off electrical appliances and electric lighting, do not smoke.

4.7. If abnormal operation of the device is detected, it is necessary to contact the gas management service and, until the malfunctions are eliminated, do not use the device.

4.8. Explosion or carbon monoxide poisoning or gas or carbon monoxide poisoning ( carbon monoxide) located in the products of incomplete combustion of gas.

The first signs of poisoning are: heaviness in the head, strong heartbeat, tinnitus, dizziness, general weakness, then nausea, vomiting, shortness of breath, impaired motor functions may appear. The victim may suddenly lose consciousness.

To provide first aid, you must: take the victim to fresh air, unbutton clothing that restricts breathing, give a sniff ammonia, cover warmly, but do not let fall asleep and call a doctor.

If there is no breathing, immediately take the victim to a warm room with fresh air and perform artificial respiration, without stopping it until the doctor arrives.

5. DEVICE AND OPERATION OF THE DEVICE

5.1. Device device

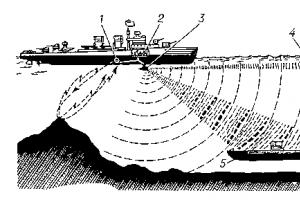

5.1.1. The apparatus (Fig. 1) of the wall type has rectangular shape formed by a removable lining 7.

5.1.2. All main elements of the device are mounted on a frame. On the front side of the cladding are: handle 2 for controlling the gas valve, button 3 for turning on the solenoid valve, viewing window 8 for observing the flame of the pilot and main burners.

5.1.3. The apparatus (Fig. 2) consists of a combustion chamber 1 (which includes a frame 3, a gas exhaust device 4 and a heat exchanger 2), a water-gas burner unit 5 (consisting of a main burner 6, an ignition burner 7, a gas cock 9, a water regulator 10, a valve electromagnetic 11) and tube 8, designed to turn off the water heater in the absence of draft in the chimney.

NOTE: Due to the fact that OJSC continues to work on further improvement of the design of the device, the purchased device may not fully match the description or image in the "Operation Manual" in individual elements.

5.2. Description of the device

5.2.1. The gas through the pipe 4 (Fig. 1) enters the solenoid valve 11 (Fig. 2), the button 3 (Fig. 1) of which is located to the right of the gas cock enable handle.

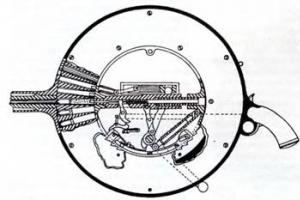

5.2.2. When the solenoid valve button is pressed and open” (to the “Ignition” position) (Fig. 3), the tap gas flows to the pilot burner. The thermocouple, heated by the flame of the pilot burner, transmits the EMF to the valve solenoid, which automatically holds the valve disc open and provides gas access to the gas cock.

5.2.3. When turning handle 2 (Fig. 1) clockwise, the gas valve 9 (Fig. 2) performs the sequence of switching on the pilot burner to the “Ignition” position (see Fig. 3), gas supply to the main burner in the “Apparatus on” position ( see Fig. 3) and regulates the amount of gas supplied to the main burner within the "High flame" - "Small flame" positions (see Fig. 3) to obtain the desired water temperature. In this case, the main burner lights up only when water flows through the device (when a hot water tap is opened).

5.2.4 Turning off the apparatus is done by turning the control knob counterclockwise to the stop, while the main and pilot burners are instantly extinguished. The electromagnetic plug valve will remain open until the thermocouple cools down (10...15 s).

5.2.5. To ensure smooth ignition of the main burner, the water regulator is provided with an ignition retarder, which acts as a throttle when water flows out of the supra-membrane cavity and slows down the upward movement of the membrane, and, consequently, the ignition speed of the main burner.

The device is equipped with safety devices that provide:

- gas access to the main burner only in the presence of a pilot flame and water flow

- shutting off the gas valve to the main burner in case the pilot burner goes out or the water flow stops,

- shutdown of the main and pilot burners in the absence of draft in the chimney.

1 - branch pipe, 2 - handle; 3 - button: 4 - gas supply pipe; 5 - hot water outlet pipe, 6 - inlet pipe cold water; 7 - facing, 8 - viewing window

Figure 1. Apparatus water-heating flowing gas household

1 - combustion chamber; 2 - heat exchanger; 3 - frame; 4 - gas outlet device; 5 - water gas burner block; 6 - main burner; 7 - ignition burner; 8 - thrust sensor tube; 9 - gas tap: 10 - water regulator; 11 - electromagnetic valve; 12 - thermocouple; 13 - piezo ignition (NEVA-3208); 14 - plate.

Figure 2. Apparatus water-heating flowing gas household (without cladding)

Figure 3. Positions of the gas cock control knob

6. INSTALLATION PROCEDURE

6.1. Installing the machine

6.1.1. The appliance must be installed in kitchens or other non-residential premises in accordance with the Gasification Project and SNiP 2.04.08.87

6.1.2. Installation and installation of the apparatus must be carried out by the operating organization of the gas facilities or other organizations licensed for this type of activity

6.1.3. The device is hung with holes (on the frame) on a special bracket mounted on the wall. Mounting holes of the apparatus are shown in Figure 4. It is recommended to install the apparatus in such a way that viewing window 8 (see Fig. 1) is at the level of the user's eyes.

6.1.4. Connecting dimensions of pipelines for gas supply, water supply and discharge, removal of combustion products through a chimney are shown in Figure 1

6.2. Water and gas connection

6.2.1 Connection should be made with pipes with DN 15 mm. When installing pipelines, it is recommended that you first connect to the water supply and discharge points, fill the heat exchanger and water system water and only then connect to the place of gas supply. Connection should not be accompanied by mutual tension of pipes and parts of the apparatus in order to avoid displacement or breakage of individual parts and parts of the apparatus and violation of the tightness of gas and water systems.

6.2.2. After installing the apparatus, the places of its connections with communications must be checked for tightness. The tightness of the water inlet and outlet connections is checked by opening the shut-off valve (see Fig. 4) of cold water (with closed water taps). Leakage at the joints is not allowed.

Check the tightness of the gas supply connection by opening a common valve on the gas pipeline with the handle of the device in the closed position (position "Apparatus off"). The check is carried out by washing the joints or special devices. Gas leakage is not allowed.

6.3. Installing a chimney to remove combustion products

For the apparatus, a system is necessarily provided for the removal of combustion products, going from the apparatus outside the building. Flue pipes must meet the following requirements:

- must be sealed and made of non-combustible and corrosion-resistant materials, such as: stainless steel, galvanized steel, enameled steel, aluminum, copper with a wall thickness of at least 0.5 mm;

- length connecting pipe should not be more than 3 m, there should not be more than three turns on the pipe, the slope of the horizontal section of the pipe should be at least 0.01 towards the water heater;

- the height of the vertical part of the pipe (from the water heater to the axis of the horizontal section) must be at least three diameters;

- The internal diameter of the flue pipes must be at least 125 mm.

6.3.3. The connection between the device and the flue pipe must be airtight. It is recommended to install the pipe according to the diagram in Figure 5.

6.4. After installation, installation and leak testing, the operation of the safety automation must be checked (clauses 5.2.5 and 5.2.6.).

Figure 4. Installation diagram of the device

1 - smoke pipe; 2 - branch pipe; 3 - heat-resistant seal

Figure 5. Scheme of connecting the flue pipe

7. ORDER OF WORK

7.1. Turning on the machine

7.1.1. To turn on the device, it is necessary (see Fig. 4)

a) open the common valve on the gas pipeline in front of the apparatus;

b) open the cold water shut-off valve (in front of the machine);

c) set the handle of the device to the "Ignition" position (see Fig. 3),

d) press the button of the solenoid valve 3 (see Fig. 1) and repeatedly press the piezo ignition button 13 (see Fig. 2) (or bring a lighted match to the pilot burner) until the flame appears on the pilot burner;

e) release the button of the solenoid valve after turning it on (after no more than 60 s), while the flame of the pilot burner should not go out.

WARNING: to avoid burns, do not bring your eyes too close to the viewing window.

At the first ignition or after a long period of non-use of the device, in order to remove air from the gas communications, repeat the indicated operations listed d and e.

f) open the gas cock to the main burner, to do this, turn the gas cock handle to the right until it stops ("Big flame" position). In this case, the pilot burner continues to burn, but the main burner is not yet ignited.

g) open the tap, and the main burner should ignite. The degree of water heating is adjusted by turning the handle of the apparatus within the "Big flame" - "Small flame" positions or by changing the flow rate of water passing through the apparatus.

7.2. Turning off the machine

7.2.1. At the end of use, turn off the device, observing the following sequence:

a) close the water taps (see Fig. 4);

b) turn knob 2 (see Fig. 1) to the "Appliance off" position (counterclockwise to the stop);

c) close the general valve on the gas pipeline;

d) Close the cold water shut-off valve.

8. MAINTENANCE

8.1. To ensure long-term trouble-free operation and maintain the performance of the machine, regular care, inspection and maintenance is required. Maintenance and inspection are the responsibility of the owner of the machine.

Maintenance is carried out at least once a year by specialists from the gas facilities or other organizations licensed for this type of activity.

8.2.1. The apparatus should be kept clean, for which it is necessary to regularly remove dust from the upper surface of the apparatus, and also to wipe the lining first with a damp and then with a dry cloth. In case of significant contamination, first wipe the lining with a wet cloth moistened with neutral detergent, and then with a dry cloth.

8.2.2. It is forbidden to use detergents of the strengthened action and containing abrasive particles, gasoline or other organic solvents for cleaning of a surface of facing and plastic details.

8.3. Inspection

Before switching on the device, you must:

a) check the absence of combustible objects near the device;

b) check for gas leakage (by characteristic smell) and water leakage (visually);

c) check the serviceability of the burners according to the combustion pattern:

the flame of the pilot burner should be elongated, not smoky and reach the main burner (flame deviation sharply upwards indicates clogging of the air supply channels to the burner);

The flame of the main burner should be blue, even and not have yellow smoky tongues indicating contamination of the outer surfaces of the nozzles and inlets of the burner sections.

In case of detection of gas and water leaks, as well as malfunction of the burners, it is necessary to carry out repairs and maintenance of the device.

8.4. Maintenance

8.4.1. During maintenance, the following work is performed:

- cleaning and flushing the heat exchanger from scale inside the pipes and from soot outside;

- cleaning and washing of water and gas filters;

- cleaning and flushing of the main and pilot burners;

- cleaning and lubricating the conical surface of the plug and the gas valve opening;

- cleaning and lubrication of seals and rods of water and gas blocks;

- checking the tightness of the gas and water systems of the apparatus;

- checking the operation of the safety automation, including the draft sensor, for which it is necessary to remove the chimney (see Fig. 1), turn on the device and with the gas cock fully open and maximum flow water, close the nozzle of the device with a metal sheet. After 10 ... 60 seconds, the device should turn off. After checking, install the flue pipe according to figure 5.

Work related to maintenance are not warranted by the manufacturer.

9. POSSIBLE FAULTS OF THE NEVA 3208 DEVICE AND METHODS FOR THEIR ELIMINATION

Fault name | Probable Cause | Elimination Methods |

The igniter is difficult to ignite or does not ignite at all | The presence of air in gas communications. | See section 7.1 Turning on the machine |

Clogged igniter nozzle | ||

Replace LPG bottle |

||

When the solenoid valve button is released (after a control time of 60 s), the igniter goes out. | Ignition burner flame fails to heat thermocouple | Call the gas service |

Broken electrical circuit thermocouple - solenoid valve | Check the contact of the thermocouple with the solenoid valve (clean the contacts if necessary) Check the tightness of the connection of the thermocouple with the solenoid valve, while remembering: the tightening torque must ensure reliable contact, but should not exceed 1.5 N.m (0.15 kg.m) in order to avoid damage to these units. |

|

The electromagnetic plug or thermocouple is out of order | Call the gas service |

|

The main burner does not ignite or is difficult to ignite when the hot water tap is opened. | Insufficient opening of the gas cock on the device or the general cock on the gas pipeline | Turn the handle of the device to the “Big flame” position and open the common valve on the gas pipeline completely |

Low gas pressure | Call the gas service |

|

Low tap water pressure | Temporarily not using the device |

|

Clogged water filter, torn membrane or broken water block plate | Call the gas service |

|

The main burner does not go out when the hot water tap is closed | Jamming of the stem of the gas or water block | Call the gas service |

The flame of the main burner is sluggish, elongated, with yellow smoky tongues | Dust deposits on the nozzles and internal surfaces of the main burner | Call the gas service |

After a short period of operation, the device turns off spontaneously. | No draft in the chimney | Clean the chimney. |

The supply of liquefied gas in the cylinder has run out | Replace LPG bottle. |

|

The faucet plug handle turns with considerable effort | Lubricant drying out | Call the gas service |

Ingress of contaminants | Call the gas service |

|

Low water flow at the outlet of the apparatus with normal water pressure in the pipeline | Presence of scale in the heat exchanger or in the hot water outlet pipe | Call the gas service |

Insufficient water heating | Large water consumption | |

Soot deposits on the heat exchanger fins or scale in the heat exchanger tubes | Call the gas service |

|

During operation of the device, there is increased noise from flowing water. | Large water consumption | Adjust the water flow to 6.45 l/min. |

Misaligned gaskets in the water block connection | Correct misalignment or replace gaskets. |

|

The main burner ignites with a "pop" and the ejection of the flame from the casing window | The ignition burner flame is small or deviates sharply upwards and does not reach the main burner (the nozzle is clogged or the air supply channel to the igniter is clogged with dust, the groove on the valve plug is partially clogged with grease, low gas pressure) | Call the gas service |

Ignition retarder not working | Call the gas service |

|

The igniter does not ignite from the piezo ignition (it ignites normally from a match) | No spark between spark plug and igniter | Check the connection of the wires of the piezoelectric generator to the candle and to the body of the device. |

Weak spark between spark plug and igniter | Set a gap of 5 mm between the spark plug electrode and the igniter. |

10. STORAGE RULES

10.1. The device must be stored and transported only in the position indicated on the handling signs.

10.2. The device must be stored indoors, which guarantees protection from atmospheric and other harmful influences at an air temperature of -50°C to +40°C and a relative humidity of not more than 98%.

10.3. When storing the apparatus for more than 12 months, the latter must be subjected to conservation in accordance with GOST 9.014

10.4. The openings of the inlet and outlet pipes must be closed with plugs or plugs.

10.5. Every 6 months of storage, the device must be subjected to a technical inspection, which checks for the absence of moisture and dust clogging of the components and parts of the device.

10.6. Apparatus should be stacked in no more than five tiers when stacked and transported.

11. ACCEPTANCE CERTIFICATE

The device is water-heating flowing gas household. NEVA - 3208 complies with GOST 19910-94 and is recognized as serviceable

12. WARRANTY

The manufacturer guarantees trouble-free operation of the device in the presence of project documentation for the installation of the apparatus and subject to the consumer observing the rules for storage, installation and operation established by this "Operation Manual".

Warranty period of operation of the device is 3 years from the date of sale through a retail network; 3 years from the date of receipt by the consumer (for off-market consumption);

12.3. Warranty repair of the apparatus is carried out by gas facilities, the manufacturer or other organizations licensed for this type of activity.

12.4. The average service life of the device is at least 12 years.

12.5. When purchasing the device, the buyer must receive the "Operation Manual" with the store's mark on the purchase and check for the presence of tear-off coupons for warranty repairs.

12.6. In the absence of a store stamp in the warranty cards with a mark of the date of sale of the device, the warranty period is calculated from the date of its release by the manufacturer.

12.7. When repairing the device, the warranty card and the spine to it are filled in by an employee of the gas industry or an organization licensed for this type of activity. The warranty card is withdrawn by an employee of the gas industry or an organization licensed for this type of activity. The spine of the warranty card remains in the instruction manual.

12.8. The manufacturer is not responsible for the malfunction of the device and does not guarantee its operation if the Consumer's claim is presented with evidence of:

a) non-compliance with the rules of installation and operation;

b) non-compliance with the rules of transportation and storage by the Consumer, trading and transport organizations;

Evidence can be presented both in the form of an opinion of an independent Expert, and in the form of an act drawn up by a representative of the Manufacturer and signed by the Consumer.

2016-10-29 Evgeny Fomenko

How to light an electronic ignition device

Before turning on the column, it is necessary to ensure that there is an inflow in the room fresh air because oxygen is burned during operation. All Neva devices are produced adjusted for a certain type and pressure of gas - natural G20, liquefied G30 with a corresponding pressure of 1.3 kPa and 2.9 kPa.

For example, let's consider how to light a Neva 4511 and Lux 5611 geyser with electronic ignition from LR20 batteries with a voltage of 1.5V (see the article in addition - why the Neva column does not light up). These devices have continuous hydraulic modulation of the flame. The front panel is equipped with a viewing window, gas and water adjustment knobs, and a digital display.

To turn on, install the batteries in the battery compartment, first make sure that the battery contacts of the battery compartment are not oxidized.

Open shut-off valves in front of the machine. Then turn the toggle switches to the minimum position. If ignition occurs for the first time, or after a long period of inactivity of the device, air must be removed from the system. This requires opening and closing the valve with water several times to continue ignition, since spark discharges last about seven seconds. After turning on, being careful not to get close to the viewing window, you need to make sure that the flame burns even, blue, without the yellow edges that appear if the burner is clogged.

The jet is adjusted using a knob, if the water supply has a low pressure, it should be set to the minimum position, while at the outlet of the device you will get a small, medium amount of water. If the pressure inside the line is high, and you need a large amount of water, the regulator should be set to the maximum value. If, at a low pressure, set the maximum value, then the column will go out, it can also go out if the tap is opened to a small flow. To make it light up again, you need to turn the regulator to the minimum position or increase the jet pressure.

You can adjust the temperature with the gas adjustment knob - the maximum position increases its flow rate and the temperature of the outlet jet, the minimum - vice versa. In addition, you can adjust the temperature of the outlet jet by changing its flow rate with a hot water valve - opening it more, the temperature will decrease, screwing it on, it will increase.

But it should be remembered that the temperature obtained is limited by the power of the device, with a high flow rate, especially in winter, it may have insufficient temperature.

When the jet adjustment toggle switch is set to the minimum position, and the gas regulator to the maximum position, the heat exchanger will overheat, the column will go out, as the overheating sensor will work. To turn on the device again, you need to close the hot water tap, then open it again. Use the toggle switches to reduce the gas flow or increase the water flow. Overheating of the heat exchanger leads to the formation of scale, noise during operation. This reduces the productivity of the device, reduces the output flow, therefore it is not recommended to dilute the hot jet with a cold one, as the service life of the device decreases. From user experience, you should not set the temperature above 60 degrees.

To turn off the unit, it is enough to close the valve, make sure that the main burner is extinguished. If it turns off for long time close the shut-off gas and water valves.

How to light a column with piezo ignition

Models of water heaters Neva 3208, 3212.4011 differ from models 4511.5611 in the type of ignition using a piezoelectric element.

To turn on the Neva 4011, you need to open the gas and water shut-off valves that are located in front of the device. Set the gas regulator knob (on the front panel) to the "Ignition" position, drown it to the limit. Holding with one hand, with the other hand press the piezo ignition button, which is located at the bottom of the device. In this case, a spark discharge should appear between the ignition plug and the pilot burner, which ignites the gas supplied to it.

The holding time is about 20 seconds, until the pilot burner lights up. Then the handle can be lowered. During initial start-up, the gas system must be bled of air. To do this, while holding the toggle switch, press and release the piezo ignition button several times.

Next, you need to switch the regulator to the “Turn on the main burner” mode. In this case, only the pilot burner is lit, the main one is ignited after the hot water valve is opened. If the tap is open, and the main one is not on, it is necessary to adjust the pressure with a water adjustment, or open it more strongly. You can turn off the column by turning off the water.

The inclusion of columns 3212, 3208 also begins by opening the shut-off valves. Next, fix the “Ignition” toggle switch opposite the risks, press the button of the solenoid valve. While holding the button (about 60 seconds), press the electric ignition button several times (or light it with a match if there is no button, as is the case with some models 3208) until a flame appears on the pilot burner.

After releasing the solenoid valve button, move the toggle switch all the way to the right, to the “Big flame” position, the pilot burner is working, the main burner has not yet ignited. When the tap is opened, the main one lights up. To turn off the device, you need to close the tap, turn the knob on the front panel counterclockwise until it stops, close the valves of the gas pipeline, water supply.

Video on ignition of the gas column Neva 3208:

Centralized hot water supply is certainly a convenient thing. But often, when moving into an apartment rented or purchased on the secondary housing market, we come across a strange unit - an old gas water heater. How is it safe to use?

A geyser, or, as it is officially called, a flowing gas water heater, appeared in our country with the beginning of mass housing construction in the 50s of the twentieth century. It was the installation of gas water heaters in apartments that made it possible to quickly solve the problem of hot water supply without the construction of expensive heating plants and pipeline networks.

How to determine the type of gas column?

First of all, let's define the terminology - we will call the old gas column, the design of which provides for a constantly burning ignition wick. The wick is ignited with a match or, in more modern models, with a spark from a hand-held piezoelectric igniter.

The gas water heaters installed in Stalinka and Khrushchev apartments overwhelmingly belong to two varieties - KGI-56 and similar in design L-1, L-2, L-3, GVA-1, GVA-3, early models of VPG. It is easy to distinguish them from each other by the control knobs.

Column KGI-56 (gas column of the Iskra plant, design of 1956) was widely used in the construction of multi-storey buildings in the 50-60s of the last century. It has a rectangular, slightly rounded body with an oval opening for ignition and two levers in the lower part of the body - the ignition burner switch-on lever and the main burner power control lever. In later modifications, a solenoid gas valve button is also installed on the front panel.

Columns of the L (Leningrad), GVA (automatic gas water heater), VPG (flowing gas water heater) series are structurally similar and have one rotary knob in the center and (optionally) an electromagnetic gas valve button.

HSV columns have become perhaps the most common in Russia and were produced in huge batches under various names (Neva 3208, Neva 3210, Neva 3212, Neva 3216, Darina 3010 and others).

The era of mass installation of gas water heaters in our country was short-lived - after 20-25 years, almost all new buildings were connected to hot water supply networks. The columns remained a hallmark of the "Stalin" and "Khrushchev". But their owners do not complain - this is Russia. And while the “lucky ones” with centralized hot water supply every summer for two or three weeks heat water in a basin on the stove, they calmly use hot water. Yes and cost geyser much cheaper than hot water from pipes.

And therefore, probably, the residents of new buildings pass horror stories to each other about an unknown and terrible device - a gas water heater. And it breaks in a day, and it takes a long time to kindle it, and it is dangerous to use it. Is it really?

Is it safe to use an old gas water heater?

A person who is accustomed to centralized hot water supply usually judges the safety of a geyser based on rumors and speculation of friends and acquaintances. Often, even these people have never seen a gas water heater, especially of an old design. Hence, terrible legends about almost daily explosions of gas water heaters multiply. It comes to the point that some families, living in a rented apartment and having a fully functional apparatus, heat hot water in a basin on the stove.

All these horror stories are greatly exaggerated. Any geyser, even if it was made half a century ago, has safety devices in its design. These devices include a water regulator, a flame sensor, and a draft sensor.

The main burner burns with a non-smoking blue or light yellow flame;

When the taps are closed at the taps or on the inlet pipe, the column goes out immediately, without delay;

The column allows you to adjust the temperature of hot water from barely warm to scalding hot;

The column does not turn off spontaneously during use.

If any of the above is not true, then the column must repair or, if repair is not profitable, replace with a new one.

Please note that 5-10 seconds after turning on the column from the tap, a few seconds can go very hot water, gradually replaced by water of the set temperature. Out of habit, you can get burned, but this is not a malfunction, but a design feature.

Is it possible to use a faulty geyser?

There can only be one answer to this question: absolutely not! And do not be convinced by people who successfully operate a geyser with minor or not very minor malfunctions.

The point here is this. Finding an old gas water heater from the 50s-70s in full working order is quite difficult. Most often, the flame control system turns out to be out of order - it and the new one did not differ in good reliability. Therefore, very often the gas valves in the columns are stuck open. Even the gas workers themselves did this, as it was tight with spare parts. It is easy to determine this - the gas valve button is not pressed or is pressed very easily. With some care, such a column works without problems.

Sometimes the water regulator is faulty. The author himself used a column with such a problem for several years. I had to open the water, and then light the column manually. When turning off, it was necessary to close the gas supply to the main burner and only then turn off the water. It was customary, and even then more than once, due to forgetfulness, it turned out to boil the column.

But for a person who is accustomed to using centralized hot water supply, this is unacceptable! Habits developed over the years are very difficult to change. You can bet on anything that on the first day you will boil a column with a faulty water regulator. Therefore, the device must be in perfect working order.

A gas water heater is a water heater that has excellent technical characteristics. Appliances this type of steel has become more in demand recently, however, in order to purchase and install a structure with your own hands, you will need to figure out how the device works and what advantages and disadvantages it has. The peculiarity of such columns is that they are needed in those houses and apartments where there is no hot water supply or it is often turned off.

Feature: Neva 4511

The gas column device is a device for heating water, and gas is required for its operation. The main criterion for choosing such installations is, of course, the characteristics of the product, as well as its cost and quality.

If you choose these settings for technical specifications, then you need to pay attention to such points as:

- Ignition type;

- Chimney type;

- Power;

- Safety;

- Dimensions;

- Additional functionality.

If we consider the quality of products, then it is worth considering the entire the lineup and it will be possible to find out that a huge number of such structures are on sale. most sought after and best model is Neva 4511, which has an unrealistic number positive feedback, and also there are all quality certificates and compliance with GOST standard.

Column Neva and its ignition

As already mentioned, there are an incredible number of models of gas water heaters and these can be: 3208, 4510, 4513, 3212, 5513, 3010 and more. The principle of operation and the connection diagram are almost the same. It is worth noting that the operation of a product called Neva requires ignition of the column, which means ignition of the gas.

There is equipment that differs in this criterion, and there are products with:

- Manual ignition;

- Piezo ignition;

- Electronic ignition;

- Microturbine ignition.

If the column is ignited manually, then this is an old model, since modern columns are automatic or Lux transit devices, which are not difficult to handle. The type of piezo ignition is similar to piezo electric stoves, in which to turn on the unit and ignite the gas, just press 1 button. This option can be found in modern devices, as it is very convenient and most importantly, it is safe to use products in residential premises. Electronic products are considered the most popular, but more expensive, but this does not affect their demand.

They have qualities such as:

- Reliability;

- Profitability;

- Ease of use.

Getting a spark is created in the same way as in cars, using a small battery, but batteries are most often used.

The Neva 4511 column is a model in which just such an ignition is installed.

There are also microturbine types of ignition, in which current is generated by means of a hydrodynamic generator, which is controlled by a water flow. In terms of cost, they are superior to all previous models, including HSV, Nomi, but they are the safest and provide good service.

Instructions for use of the geyser Neva 4511

Studying a document such as an instruction manual is the best opportunity to learn what actions are needed to avoid a problem in the operation of the device, and also not to harm yourself and the equipment. In other words, you need to familiarize yourself with the rules of safe operation. First of all, it is important to remember that gas water heaters are high-risk equipment and the likelihood of an accident is very high, which can harm sensors, in particular, an ionization sensor and human health. This element is responsible for shutting off the gas supply if the burner goes out.

In addition, each element that makes up the geyser must be serviceable.:

- Thermal sensors must be in good order, since they work at the moment when it stops, the ionization sensor is functioning.

- Thanks to the heating sensor, you can monitor the temperature in flow heater, as well as regulate the temperature of all equipment.

- A water pressure sensor is required for the main task of the device, in particular to turn on and off the gas supply if automatic water intake occurs.

- It is imperative to monitor the health of the sensor that controls the temperature difference in order to stop the operation of the burner in time and avoid the boiler from exploding.

It is strictly forbidden to use a column without a gas and water pressure sensor. It is with its help that you can control the flow of water and gas into the cavity of the column. If the water tap is open and it is turned off, the gas will not be supplied automatically, which is facilitated by the safety valve.

Description of the Neva geyser

Why do many make decisions such as purchasing equipment such as a gas water heater? Regardless of whether the installation will be old or new, it must be: high-quality, wear-resistant and correctly installed. In addition, you need to pay attention to how much power the structure has and how quickly it can heat water to heat the room. Naturally, if the house or apartment is large, then you need a device that will be able to heat it.

speakers gas type divided by power:

- 17-20 kW (small columns);

- 20-26 kW (medium speakers);

- 26-28 kW (large speakers).

With regards to the Neva column, in particular model 4511, it has a power consumption of 21 kW, however, it is capable of producing up to 11 liters per minute. To approximately determine liters per minute, it is enough to pay attention to the instruction manual. It is worth noting that the Neva 4511 model is perfect for two points of water intake, and if you need to connect to more points, a higher power setting is required.

Specifications: geyser Neva 3208

The service life of such a design as Neva Lux is quite long, however, in order for it to serve properly and not require repairs, as malfunctions will appear, it is necessary that the owner knows how to use the product.

Typically, this equipment does not require:

- Traction adjustment;

- Elimination of fistulas due to which the tank flows;

- Clean the radiator.

It is worth noting that the heater will not work if there is low pressure water in the pipes, and it is completely difficult to find the gas source from which the device operates, and therefore these moments can be called negative aspects designs.

A column called Neva 4511 can function even if the pressure is 0.2 atmospheres, but it is not advisable to use it for a long time.

If such an electric gas water heater does not work well, then the heat exchanger may need to be replaced. The heater has the peculiarity that you do not need to contact a service center to change this part.

How does a geyser work

The task of this type of water heater is to quickly respond to the opening of a hot water tap, as a result of which the burner turns on. For detailed description the principle of operation of such a device, it is enough to pay attention to the sequence of actions.

Namely:

- Initially, it is required to set fire to the igniter, which is located in the cavity of the viewing window directed towards the burner.

- After the tap is opened, water begins to flow into the DHW system, which increases the pressure in the pipes.

- Thanks to the water unit, the membrane is activated and the stem moves, which is connected to the valve installed on the gas pipe.

- Since the membrane of the water unit presses on the valve, it opens and the fuel supply to the main burner begins, which is ignited automatically from the igniter or from the electrode, depending on the design model.

- It is possible to adjust the flame manually by means of a special tap, which is displayed on the front panel.

- Water enters the heat exchanger cavity in the gas column, after which heating begins in the coil, which goes around the copper casing.

Turning on the device is not too difficult, and if configuration is required, then simply use the instruction manual. As soon as the water has reached the consumer and the tap is closed, after the membrane tap is closed, the stem is pulled on the frog, the gas supply valve is closed, and the burner goes out.

Gas column repair Neva

Experts do not recommend doing maintenance yourself, especially if you need to not only configure the equipment, but also disassemble it. Flowing geysers are needed so that the water does not stagnate, but flows, and the fact that it flows would be enough for consumer needs.

In this device, the solenoid valve often fails.

When the tap is opened, you can hear the click of the machine, which contributes to the ignition of the burner, but the gas does not flow. It is through the solenoid valve that gas is supplied to the burner. It is not difficult to replace it, just like heat exchangers. The diameter of the valve is standard, and the connection is not difficult to make. To purchase a spare part, you just need to know the model of your geyser or take an old faulty valve with you.

To remove and install equipment for heating water, it is best to contact specialists with extensive experience who can not only carry out all the necessary actions, but also provide a guarantee.

For the installation of a geyser, a special permit is required, since it is necessary to carry out power supply from a gas pipe, and this is possible only with special equipment. After that, you need to register the geyser as an object of gas consumption, especially if you are connecting to a central highway.

With regards to operation, it is advisable not to heat it to the maximum level, as this will only accelerate the process of salt and scale formation on the cavity of the heating element. It is important to take into account the hardness of the water used and choose a special tool that can soften it, which will significantly extend the life of all equipment.

The BaltGaz company produces: geysers Neva (Neva) and Neva Lux (NevaLux), shut-off and control valves, chimneys and all accessories necessary for connection. Water heaters operate in flow mode, designed for simultaneous connection of 1-3 points of water intake. Due to their compact dimensions, they are easy to install even in small rooms used as a boiler room.

The device and principle of operation of the speakers Neva and NevaLux

The BaltGaz line includes several flow-through gas boilers that differ in the principle of operation and features of the internal structure. All manufactured equipment can be divided into several groups:- Type of ignition - there are semi-automatic and automatic models. The first (4011, 5111) during operation use a constantly burning wick, ignited by a piezoelectric element. The second, with automatic ignition, are battery operated. The gas is ignited by a spark applied to the burner.

- Using modulation- gas instantaneous water heaters Neva and Neva Lux operate using hydraulic (5111, 5611) and electronic (6011,6014) changes in water heating power. There are models without automatic adjustment of the intensity of combustion.

The technical characteristics of water heaters manufactured by Baltgaz are described in detail in the following table:

Technical characteristics of flowing gas water heaters BaltGas |

|||||||||||

Power, kWt) | |||||||||||

Heating capacity (kW) | |||||||||||

Efficiency, not less than (%) | |||||||||||

Burner modulation | continuous hydraulic | continuous hydraulic | continuous electronic |

||||||||

piezoelectric | electronic |

||||||||||

natural/liquefied | natural / liquefied |

||||||||||

Gas pressure (natural/liquefied) (kPa) | |||||||||||

Gas consumption (natural/liquefied) (m³/h / kg/h) | |||||||||||

Chimney diameter (mm) | |||||||||||

Required vacuum in the chimney, not less than (Pa) | |||||||||||

Max. pressure water (kPa) | |||||||||||

Min. water flow (l/min) | |||||||||||

Min. pressure water (kPa) | |||||||||||

Heating water consumption at ∆t=25℃ (l/min) | |||||||||||

Number of draw points | |||||||||||

Dimensions (mm) | |||||||||||

Net weight | |||||||||||

Case color | white, silver | white, silver | white, silver |

||||||||

How to install a column Neva

When connecting gas water heater Neva is required to follow the manufacturer's recommendations, detailed in the instruction manual. Mistakes made during installation will void the warranty.Installation of the Neva column is carried out exclusively by qualified personnel (representatives of the service center or gas service) who have access to work and the appropriate license.

When connecting the column, follow a few basic recommendations:

The service life of the Neva gas flow boiler largely depends on compliance with the installation and operation rules, as well as regular maintenance. The period of use of the water heater is from 8-12 years.

How to turn on the Neva column

Automatic water heaters turn on by themselves. When the water supply tap is opened, the ignition unit gives a signal to produce a spark. The gas supplied to the burner ignites. After closing the water tap, the column is turned off.Semi-automatic flow boilers are distinguished by the fact that an ignition burner is used for ignition. To bring the column to a working state, you need to light the wick. To this end, in internal arrangement a piezoelectric element is provided. After ignition of the pilot burner, the water heater continues to operate in automatic mode.

You can adjust the Neva column using water flow and gas pressure regulators. If the device is provided with a modulating burner, the consumer sets the heating temperature, after which the electronics changes the intensity of combustion depending on the pressure in the pipeline and other operating parameters.

Columns Neva - malfunctions and their elimination

Water heaters Russian company BaltGaz mostly work without failures. IN automatic dispensers Batteries need to be changed every six months. Every 4-5 years, the membrane (rubber gasket) of the water unit fails. To repair the water unit, use a repair kit for the column, costing 80-200 rubles.Below are two tables. The first describes common error codes, their interpretation and troubleshooting methods. The second table shows breakdowns and repair methods, without reference to digital signals.

Error code | Decryption | Cause of failures | Solutions |

There is no spark. The temperature indicator does not light up. | Low pressure in the supply line. | Forcibly increase the water flow rate by connecting a booster pump. |

|

Batteries are dead or incorrectly inserted. | Replace elements. Check that the batteries are in the correct position. |

||

The contacts are oxidized, the electronic board is damaged. | Contacts are cleaned, dangerous connections are checked. * |

||

Broken water pressure sensor. | Change the sensor.* |

||

Water seal damaged. | Perform frog maintenance, replace gasket.* |

||

The control unit has failed. | Module replacement required.* |

||

Nagar prevents the production of a spark. | Carbon deposits are cleaned from the electrode, if necessary, adjust its location. * |

||

The column is disabled. | Gas is not supplied to the burner. | Contact Gorgaz. |

|

Shut-off valve closed, not fully (insufficiently) open | Open valve. |

||

The pressure in the line is insufficient for the normal operation of the column. | Contact Gorgaz. |

||

The supply of bottled gas has run out. | Install the filled bottle. |

||

The contacts of the control unit, the water pressure sensor, ionization and the solenoid valve of the wick are broken. | The connection is checked, if necessary, the supply cables are replaced, the contacts are cleaned. |

||

The ionization sensor is far from the flame. The wick or its candle is in contact with the details of the burner devices. | Set the position so that the electrode is in contact with the flame, but does not touch the wick.* |

||

The wick is clogged. | The jets of the pilot burner are cleaned, carbon deposits are removed.* |

||

Solenoid valve failed. | The knot is changed.* |

||

The gap between the electrode and the wick has become more or less than normal. | The gap between the electrode and the igniter is set within 4-5 mm. * |

||

The cable to the spark plug is loose. As a result of poor contact, a spark breaks through the burner collector. | Make sure the cable is snug.* |

||

Carbon deposits have accumulated on the electrode. | Perform maintenance.* |

||

The electromagnetic relay is triggered prematurely, even before receiving a signal from the flow sensor. | The relay has failed. | Assembly replacement.* |

|

The control unit needs to be replaced. | Assembly replacement.* |

||

The flame sensor is activated even before the burner is switched on. | Ignition is carried out using matches or any other extraneous source of fire. | Perform ignition correctly, in accordance with the instructions set out in the instructions. |

|

The electronic control unit has stopped working. | Replacement required.* |

||

There is no signal for water heating. | Poor contact of the cable connecting the control unit with the sensors. | Check the contact if you need to change the temperature sensor.* |

|

The column does not ignite when the startup process is repeated seven times. | Insufficient gas pressure. | Open the gas valve completely. |

|

Contact Gorgaz, connect the filled cylinders. |

|||

Rinse filters.* |

|||

The flame controller is outside the combustion zone. | Adjust location.* |

||

The magnetic relay has stopped working. | Maintenance of modules.* |

||

The stem of the water assembly is sticking. | Serve the “frog”.* |

||

Carbon deposits have accumulated on the electrode. | Perform maintenance.* |

||

The boiler has switched off due to a signal from the draft sensor. The code is issued 2-5 minutes later, after the water heater is turned off. | Bad draft in the chimney. | Clean the chimney.* |

|

The traction sensor has failed. | Check the serviceability of the supply cables, clean the contacts. * |

||

The code flashes for a few minutes, the LO signal is displayed, immediately after that the water heater is turned off. After repeating the ignition process seven times, the E7 marker appears. | A short circuit occurs, turning off the water temperature sensor. | The short circuit is eliminated or the sensor is replaced. * |

|

The pressure to turn on the main burner is insufficient. | Flow rate less than 3.5 l/min. | Set the flow regulator to a higher value. |

|

Rinse the heat exchanger.* Contact your local utility company to clean the cold water system. |

|||

The temperature at the inlet to the column and at the outlet differ slightly. | Set a higher heating temperature. |

||

The water heater switches off spontaneously, error L0 appears. | Flame sensor set incorrectly. | Adjust the position of the sensor within 5±1 mm from the upper edge of the burner.* |

|

The boiler does not heat water to the specified temperature. | Incorrectly set water flow in relation to gas supply. | Reduce water flow rate or increase gas supply. |

|

Bad gas pressure. | Open the gas supply valve. |

||

Write an application to Gorgaz, install a filled cylinder. |

|||

Rinse or change filters.* |

|||

The heat exchanger is clogged, dust has accumulated on the radiator fins, as evidenced by a yellow flame. | Clean burner jets, column coil.* |

||

Scale has accumulated in the heat exchanger. | Flush the coil.* |

||

The "frog" or the control unit does not work. | Carry out maintenance, change the diaphragm, clean, lubricate the stem, install a new spring.* |

||

Ignition is carried out with a characteristic pop and flame out. | The fire of the wick is not deflected towards the burner. Pilot jets clogged. | Clean the wick, align it correctly with respect to the burner.* |

|

At normal pressure in the pipeline, at the outlet of the boiler, there is practically no water. | The heat exchanger is clogged, or the hot water supply pipe is clogged. | Rinse the radiator, remove scale.* |

|

Water filters are dirty. | Clean up.* |

||

The column is malfunctioning, there are strong differences in the temperature of heating hot water. | Flow rate incorrectly adjusted. | Enlarge flow. |

|

The water pressure in the pipeline is less than 30 kPa. | Contact the utilities. |

||

The water heater is connected to the water supply system with violations. | Fix violations.* |

||

After closing the DHW tap, the burner flame does not go out. | The “frog” stem is jammed. | Turn off the gas supply. Call the emergency service. |

* - Works are carried out by representatives of the service center or the Gas Service.

The following table lists common breakdowns, without reference to codes:

What caused | ||

The wick does not light the first time, or does not work at all. | The valve is closed. | Open valve. |

Pilot burner jet clogged. | Clean jets.* |

|

The gas tank has run out. | Install a full bottle. |

|

Breakdowns in the supply cable connecting the piezoelectric element and the burner. | Eliminate a broken contact in the supply cable.* |

|

The piezo ignition system does not work. | ||

The candle is out of order. | Replace assembly.* |

|

When the gas supply valve to the wick is released, the flame goes out. | Violation electrical circuit connecting a thermocouple - a relay - a solenoid valve. | Check the integrity of the cables, tighten the contacts.* In this case, the strength of the connection should not exceed 1.5 N/m (0.15 kg/m). Higher voltage will damage the module. |

The electrical circuit of the water-gas unit and its elements do not work. | Replace hardware.* |

|

The burner does not work, or does not start the first time. | Incorrectly set gas supply. | Set the controller to maximum. |

Insufficient gas pressure. | Application to Gorgaz. |

|

The pressure in the pipeline is insufficient. | Install a booster pump, contact the utility company. |

|

The “frog” does not work: the filters are clogged, the membrane has broken. | Replace gasket, wash filters.* |

|

The boiler turns on with a pop. | The burner nozzles are clogged, the wick is set incorrectly. | Perform wick maintenance.* |

Gas lights up yellow. | Dust has accumulated on the main burner. | Perform maintenance.* |

The column spontaneously turns off after 2-3 minutes of operation. | Bad traction (the controller gives a signal to turn off). | Perform chimney cleaning. Check the tightness of the chimney pipe joints.* |

The water assembly gasket is rough or ruptured. | Service and parts replacement required. |

|

The difference in water pressure at the supply and return of the water supply system before and after passing through the column radiator. | Scale has accumulated inside the coil. | Flush the radiator.* |

Water filters clogged. | ||

Weak heating. | Incorrectly set gas and water supply settings. | Set the heating temperature by changing the intensity of the gas supply to the burner |

Dust has accumulated on the burner, column radiator. | Clean the burner, remove soot from the radiator. Rinse pipes from scale.* |

|

The water supply unit is not working. | Replace module.* |

|

Insufficient gas pressure. | Contact the relevant service. |

|

During operation, the water heater makes a lot of noise. | Excessive water flow. | Reduce water flow rate. |

Distorted or worn gaskets. | Replace sealing rubbers.* |

|

The flame does not go out when the faucet is closed. | The water regulator has failed. | Repair of the water unit "frog" is required. Eliminate stem jamming, change the spring. |

* - do-it-yourself repairs are prohibited, the presence of a specialist is required.

How to clean the Neva column at home

In order for the Neva boiler to continue to work properly, every 2-3 years it is necessary to flush the heat exchanger, eliminating accumulated scale and soot. It will be possible to clean the Neva gas column at home even with poor water quality. Maintenance is carried out in several stages:- Remove the radiator- to pull out the heat exchanger of the Neva column, unscrew the casing, disconnect the water and gas. Dismantle the smoke exhaust unit. Pull out the radiator.

- Rinse and clean the heat exchanger- remove soot from the plates with a stiff brush and soapy water. To remove scale, the inner cavity of the coil is washed with special "chemistry" or citric acid.