Embedded parts, their device, manufacture and applications. What are embedded details? Embedded parts are of two different types

Mortgage is a security that certifies the right of the pledgee to demand from the pledgor the fulfillment of the terms of the contract, in addition to which the mortgage was drawn up. In case of non-fulfillment of its conditions, it ensures the right of the pledgee to recover the pledge from the pledgor. The most common use of mortgages in Russia is mortgage lending. Until July 2018, when concluding a loan agreement, paper mortgages were used. This caused a number of problems for borrowers, since the process of returning mortgages after the full repayment of the loan was long-term.

Since July 1, 2018, an electronic mortgage has been introduced in Russia - an analogue of a paper mortgage in digital format. It has the same power as paper version, is compiled by filling out a special electronic form on the portal of public services or Rosreestr. The document is signed by the electronic signature of the pledger (and the debtor) and sent to Rosreestr, where it is certified by the signature of the state registrar. Then the document is transferred to the depository for storage. The details of the electronic mortgage are entered in the mortgage record. Thus, after the loan is repaid, the borrower will be able to receive the electronic mortgage back through an electronic appeal to Rosseistr.

Only a bank can earn on a mortgage in a mortgage, having received the mortgaged property in the property if the borrower cannot repay the debt. Individuals can earn on this instrument only if they themselves act as a pledgee. This may be practiced in private transactions with other individuals.

A mortgage is a registered security. Nominal, because it is issued, i.e. is drawn up by a specific person (debtor and pledgor) on specific name, namely, in the name of the creditor - pledgee.

In general, the mortgage should not be drawn up by the bank, but by the individual who took out a loan and pledged their property as collateral. If the property was pledged by a third party, then it also participates in the preparation of this document.

But in fact, everything is not so. The mortgage is drawn up by the bank, filling in all the required fields for the client. The borrower and the mortgagor need only sign the mortgage. But according to the law, it is considered that the borrower and the pledger made up the security.

The mortgage certifies at once 2 rights of its owner:

the right to demand repayment of the loan;

the right to foreclose on the property that is the subject of collateral (if the borrower pays the loan in bad faith).

According to the law, it is imperative not to forget to indicate 14 points in the mortgage, namely, the following information:

the word "mortgage";

about borrowers;

about pledgers;

about the creditor - mortgagee;

on the loan agreement (loan agreement);

on the amount of the loan, the amount of interest, the procedure for their calculation;

on the procedure for paying debt and interest;

about the real estate object - the subject of pledge;

on the value of real estate, confirmed by the conclusion of an independent appraiser;

on the right by virtue of which the real estate belongs to the pledgor, including information about the registration authority that registered this right;

on the presence / absence of encumbrances on real estate;

signatures of all borrowers and pledgers;

on mortgage registration;

on the date of issue of the mortgage.

The creditor may indicate in the mortgage and other information. Some banks, instead of including additional conditions in the mortgage, simply stitch together a copy of the loan agreement with the mortgage.

By the way, theoretically, some mortgage conditions can be posted on the Internet on the lender's website or published in the media with a circulation of at least 10,000 copies. Then, when making a mortgage, it simply indicates the source of the publication.

Mortgage procedure

The mortgage, as a rule, is drawn up on the day of the conclusion of the contract for the sale of an apartment and a loan agreement. Although it can be drawn up later, at any time until the loan is fully repaid.

The mortgage bond is transferred together with other documents under the sale and purchase transaction to the body for state registration of rights to real estate. All mortgage sheets must be numbered and stitched.

When the registration of rights to real estate is completed, an employee of the state registration authority puts on the mortgage information about the rights (property and mortgage), certifies this information with his signature and seal, and issues the mortgage to the creditor - the mortgagee, putting down in the mortgage also the date of its issue.

If a government agency made a mistake when filling out “its” information (and this happens, oddly enough, often), it must correct the error in an explicit form and certify its correction.

Mortgage sale

And so we got to the point, and for what, in fact, this additional document is required. After all, there is a loan agreement, there is a mortgage agreement (or a sale and purchase agreement with a mortgage in accordance with the law), isn't there a lot of everything?

Another document, namely, a mortgage, is needed to simplify the "sale" of the loan. It happens that the bank cannot keep your loan on its balance sheet and sells it to someone else, to another bank, for example. Or a refinancing company.

If there is no mortgage, then the loan sale transaction (or, to be more precise, the loan assignment transaction) is complex - you need to draw up an agreement on the assignment of rights under a loan agreement and an agreement on the assignment of rights under a mortgage agreement. And not just compose, but register them. And if there are a lot of loans for sale? A lot… Have you imagined? For each loan, at least 2 contracts must be drawn up in at least two copies. Then take all the contracts to Rosreestr for re-registration. In general, all this is difficult.

But if there is a mortgage (and we remember that it certifies 2 (!) rights at once), it is enough to write on the mortgage “I transfer the rights to someone under such and such an agreement from such and such a date.” And that's it! You don't even need to register it. It is possible, but not necessary. Selling a mortgage is a simple transaction.

That is why the mortgage must immediately provide a place for marks on the transfer of rights to the mortgage to the new owner. And not one place, but several at once, because. credit can "roam" from one lender to another.

And you can further simplify the process of transferring a loan to a new owner by indicating in the mortgage that it will be held in a depository. Then the depository does everything, and you don't even need to write anything on the mortgage when transferring rights.

AnswerRecently, the term "embedded parts" is found more and more often. In general terms, such a part is a metal plate with reinforcement (anchor) welded to it. Options for plates, as well as fittings, can be very diverse.

Why is this needed and where are they placed?

Embedded parts make it possible to ensure a reliable connection of reinforced concrete structures (RCS), as well as RCC and metal structures. And this, in turn, significantly increases the overall reliability of a building or structure, simplifies installation and leads to other positive effects.

The laying of parts is carried out in a concrete structure (usually, at the production stage of the latter, but not necessarily). Moreover, this is done in such a way that the metal plate is in concrete, and the anchor comes out. Thanks to this anchor, the concrete block can be securely connected to another concrete block or to an element metal frame. In most cases, the connection of anchors is carried out by welding.

Hence, it is obvious that embedded parts increase the strength of prefabricated structures, allow certain elements to be rigidly fixed and, in general, significantly increase the reliability of the object. This is probably why modern monolithic construction is unthinkable without them.

Where are inserts used?

Wherever it is necessary to connect two or more reinforced concrete elements or metal structures. Among the most obvious areas of application, we note:

- Installation of block structures, such as wells, channels and tunnels;

- Installation of load-bearing or enclosing structures based on reinforced concrete structures;

- Installation of columns;

- Installation of external facades;

- Installation of bases for masts, cell towers and other high-rise structures;

- Hydraulic structures, including technical reservoirs and reservoirs;

- Arrangement of window and door openings;

- Creation of foundations for buildings based on metal frames;

- Installation of frames from a metal profile.

This is by no means a complete list, but it should already be clear that modern building implies the active use of embedded parts.

What are the insert options?

As you already understood, the general design is quite simple - a plate and an anchor. However, the plate can be made of various alloys, have different thicknesses and shapes. The number and type of anchors can also vary within a fairly wide range - it can be round or profile reinforcement of various diameters. In some cases, the anchor may be threaded, which makes it possible to adjust the connection.

In addition, embedded parts are open or closed type. In the first case, there is only one plate, in the second case, there is a plate on both sides of the anchor.

To give parts additional properties, they can have various coatings, for example, galvanization. This improves corrosion resistance and extends service life.

The technology for the production of embedded parts does not imply particular complexity:

- A metal sheet of the desired thickness is cut into plates of the desired shape;

- The required amount of reinforcement of a given type and length is welded to the plate;

- The finished part undergoes additional processing (galvanizing, painting, etc.).

The term "embedded elements" is increasingly used in Everyday life. Small metal plates welded to an anchor or rebar help to securely connect reinforced concrete structures among themselves, to ensure high-quality fastening of reinforced concrete structures with metal parts.

This allows you to increase the overall strength, simplifies the creation of structures. Most often, the laying of parts is carried out during the manufacture of reinforced concrete structures. In this case, the element is positioned in such a way that the plate is in the concrete, and the reinforcement or anchor remains outside. It is thanks to the presence of the fastener that an excellent connection between the reinforced concrete structures is achieved, which is often carried out by welding. Thus, embedded elements enhance the strength of the prefabricated structure, help to rigidly fix its individual parts, significantly increase the reliability and durability of the structure. You can order embedded parts on the page http://xn--37-7lcu.xn--p1ai/metalloprokat?code=00000000113000000000 .

Areas of use of embedded elements

The main scope of embedded parts is monolithic construction. At the same time, any structure in which it is required to connect reinforced concrete structures to each other, as well as to metal components, is unthinkable without the use of embedded elements. Here are the main areas of application of such products:

construction of block structures such as canals, wells, tunnels;

installation of enclosing, load-bearing structures based on reinforced concrete products;

creation of external facades;

construction of foundations for the construction of buildings based on metal frames;

installation of hydrotechnical facilities, including reservoirs, technical reservoirs.

Assortment of embedded parts

All embedded elements have two components - a plate and a fastener. However, the plates can be made of different alloys, vary in metal thickness, configuration. The type and number of anchors can also vary within fairly wide limits. Fastener can be made of round, as well as profile fittings of different sections. In some cases, the anchor can be equipped with a thread that allows you to adjust the connection.

Embedded elements can be open, as well as closed. The first option assumes the presence of one plate and one anchor. In the second case, two plates are located at both ends of the fastener.

To provide embedded parts with a longer service life and additional resistance to corrosion, manufacturers use a variety of coatings, such as galvanization.

The manufacturing technology of embedded elements can be quite complex, despite the external simplicity of the product. For the production of such products, high-quality rolled metal of a given thickness is selected. Cutting is made in accordance with the shape of the plate, which can be a rhombus, trapezoid, rectangle or square. After that, the edges of the products are carefully processed, fasteners are welded. Finished parts are primed, coated with paint or galvanized.

The rock goes up to the sky. There is a crack on the rock. I want to climb and not get killed. Traditional insurance is carried out by mortgage elements. We begin the classification of embedded elements with the classification of the cracks themselves.

So, cracks are:

- vertical/horizontal/inclined

cracks are with pronounced narrowing and with parallel even walls

Well, finally, cracks come in different widths and different depths.

And there are also cavities in the rock. For each type of crack, any type of embedded elements is optimally suited.

Types of embedded elements.

There are not so many of them:

Stoppers

Stoppers are a truncated tetrahedral pyramid, usually with asymmetric and often curved edges, with a steel cable. Due to the asymmetric shape, the stoppers can be installed into the crack with a wide or narrow side. Stoppers are designed for relatively narrow cracks from 5 to 40 millimeters, with a pronounced narrowing. Microstoppers with a size of less than 5 mm can only be used as an artificial fulcrum (ITO). For installation, the stopper must be brought into the wide part of the crack and then wedged into the constriction. The narrowing should be on the side of the expected load. Stoppers are ideal for vertical and oblique cracks with a pronounced narrowing towards the bottom. Stoppers are also suitable for cracks expanding inward, including horizontal ones. Stoppers are easy to install and remove and are very reliable when used. correct installation. An important advantage of the stoppers is their low weight and volume. A set of ten stoppers of different sizes weighs only 450 grams and takes up very little space in a backpack.

Eccentrics (hexes)

Eccentrics, or they are also called "hexes", have the form of an asymmetric hexagonal prism. Due to its shape, the hexa can be installed in four different positions. Thus, one hexa spans a fairly large range of crack widths. Under load, the hexa tends to rotate around the central axis and thus firmly wedged in the crack. Cracks with a less pronounced narrowing are suitable for installing hexes than for stoppers. The minimum hex size is 11mm, which in fact partially overlaps the range of stoppers. However, for narrow cracks, stoppers are more convenient. The most relevant are hexes of large sizes. The maximum size is 91mm. Hexes are produced in two versions: with a guy from a sling or with a steel cable. The cable option may be more convenient to install and place on the leader harness, but this is a matter of habit. Just like stoppers, hexes are easy to install and remove, and very reliable. In terms of weight and volume, hexes are only slightly smaller than the corresponding size of a friend, but are much more convenient for transportation and placement on a harness.

Friends, camalots

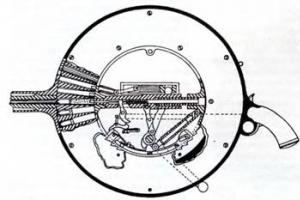

Friend consists of:

- four movable spring-loaded cams mounted on the same axis;

a flexible rod - a handle made of a steel cable covered with a plastic sheath (in some models - two rods), to which a guy is attached;

control bar with rods that drive the cam mechanism.

Camalots differ from friends in that the working cams are mounted on two separate axles, two cams per axle. This increases the reliability of the structure and somewhat increases the operating range along the width of the crack. During installation, all four cams can move independently of each other, which allows you to install friends in a crack with a complex wall surface shape. In addition, Omega Pacific offers "Link Cam" friends, in which each working cam is divided into three parts. This allows you to significantly increase the operating range and cover several numbers of ordinary friends with one friend.

Ideally, installing and removing friends is easy and convenient. He clenched his fists and inserted the device into the crack, released the fists and the device was securely wedged in the crack. To extract it, he clenched his fists and took out the friend. Beauty! But there are nuances...

Firstly, due to the mobility of the cams, a wide range of use of the friend is achieved. However, the friend cannot be used in extreme positions. If the friend is set in a position close to the extreme opening, it will most likely fly out under load. If the friend is installed completely compressed, it will be extremely problematic or impossible to pull it out. A common situation on a climbing route - the leader inserts the friend into a narrow deep crack, deeper for reliability. In the depths, the crack turns out to be narrower and the friend gets stuck. And then the second participant spends half an hour to extract the ill-fated device from the crack. And even after long fruitless attempts, he states that it is impossible to extract a friend.

Secondly, in order to extract the friend, it is necessary, as already mentioned, to compress the fists, and in order to compress the fists, it is necessary to move the friend a little forward. A little bit! However, if during installation the friend is inserted into the crack until it stops and it is not possible to move the friend forward, it will be problematic to remove the friend from the crack.

And thirdly, friends have the unpleasant property of walking along cracks with parallel walls, for which they are actually intended. It happens like this. The leader inserted the friend into the crack in the correct position with the handle down and fastened the guy. If the line of further movement goes to the side, and this happens often, the rope pulls the friend to the side through the quickdraw, and turns the handle to a horizontal position. In this case, a pair of cams remains in place, and the second pair, located closer to the rope, moves around the first two cams and steps a little deeper into the crack. Then a slack is formed in the tension of the rope, and under the influence of gravity, the friend again turns the handle down, and now the first pair of cams takes a step a little deeper. During the work of the leader, the tension and loosening of the rope is repeated many times, and with each cycle the friend becomes deeper and deeper. There may be several results of such a walk. A friend can walk so deep that it will be impossible to reach the control bar, he can get stuck in a narrow place, taking an extreme position, he can rest against a wall.

In all these cases, extracting a friend will be problematic or impossible. On many popular routes, you can find friends and camalots wedged forever. Kamalots left forever not only violate the primordial beauty of the mountains, but also hurt the climber’s wallet, since the cost of an average kamalot is about three thousand rubles. And yet, as a result of walking, the friend can get into a wider place of the crack and simply fall out, which is not good at all. Therefore, if it is possible to install a stopper or an eccentric instead of a friend, I prefer more simple devices. If this is not possible, I carefully study the installation site for hidden traps, and fasten a long guy so that the rope does not pull the friend to the side when passing.

At the stage of pouring reinforced concrete structures, most of them require an embedded part, fully or partially sunk into concrete. These elements are joined (welding, threaded connections) separate parts of the prefabricated foundation or attach flights of stairs to it, Wall panels, ceilings, other enclosing structures.

What are mortgages for?

The foundations are made of concrete, it is very difficult to dock, attach two such products. Therefore, an embedded part is immersed in concrete, a thread, plate, and other seat remain on the surface. It is enough to weld these elements to each other in order to obtain complex spatial structures made of reinforced concrete. Mortgages are used for construction:

For the manufacture of mortgages, almost the entire range of rolled metal is used (circle, sheet, reinforcement, strip, channel, angle, bar).

Classification of embedded elements

To increase the strength, concrete structures are reinforced with wire meshes, rods of a periodic, constant section. These elements also apply to embedded parts of a closed type. The classification is based on:

Any embedded part must comply with GOST 10922-90, since they have a significant load. An anchor rod or reinforcement A-III - A-II class 25 - 8 mm in diameter is used for the foundation. If the temperature in the region of operation drops below 30 degrees, choose plates from VSt3ps6 steels. In other cases, VSt3kp2 steel is used.

Anti-corrosion treatment consists of galvanizing, galvanizing, painting. At small loads, stamped APs are usually laid in reinforced concrete products. With an increase in shearing, tearing forces, anchor rods welded to the plates are used.

Mortgage manufacturing technology

When designing metal elements inside the foundation, it is necessary to take into account the nuances:

Embedded part of a stamped type is made in accordance with the RS9903 album, developed by the leading designers of reinforced concrete: NIIZhB, MNIITEP. The sketches in the album allow you to use ready-made schemes the minimum possible reinforcement in the area of the location of the ZD.

The project should include the minimum possible sections of profiled steel, reinforcement. To do this, part of the effort is distributed to stops made of strip steel or short bars.

Welded joints

To increase the adhesion of stamped EPs inside the concrete parts of the foundation, 6 cm hooks with two or more ledges are created at the ends of the strips. The rods are connected to plates, shaped rolled products by welding in accordance with the requirements of GOST 19292:

- tee weld - manual or automatic submerged arc (in some cases zigzag, relief welding), roller welds, contact-embossed, semi-automatic in carbon dioxide environment

- inclined seam (joint) - submerged directly or at the end

- overlap joint - an extended seam, along two, one relief (manual arc, contact, respectively)

Relief spot welding is prohibited for APs used in concrete products experiencing vibration loads during operation (for example, flights of stairs).

Installation sites, application of embedded elements

The main operations for the construction of the foundation, other enclosing structures are:

For individual developers, the industry produces a range of embedded elements for a monolithic foundation. The simplest modification of the anchor for fastening wooden rack has the structure:

Mortgages for fastening gates, gates to fence posts are made independently:

- plate - used for hanging sections, wicket hinges

- corner - connects the plate with profile pipe pillar armored belt

Home-made embedded elements are usually not calculated, they are made from improvised materials, immersed in concrete without connection with the armored belt of structures. Most often, an individual developer uses mortgages in the following operations:

For more serious reinforced concrete structures, buildings, it is necessary to purchase factory products with embedded parts. All of them undergo flaw detection, laboratory tests for permissible loads, have accompanying documentation, and manufacturer's warranty obligations.