How to make blocks at home. Various DIY building blocks. Business development and expansion

Cinder block is one of the most popular building materials. It is made by the method of vibrocompression from a concrete solution. A wide variety of buildings are being built from cinder blocks - from sheds and garages to residential buildings.

Planning to build something out of cinder blocks? Make them yourself! There is nothing complicated in the production technology of these concrete blocks. You need to thoroughly understand the order of work, find out the basic requirements and withstand the recipe.

The dimensions of the cinder block are standardized - 188 x 190 x 390 mm. Each block has holes. Usually there are 3 of them. For the manufacture of building elements, a mixture of cement grade not lower than M400, blast furnace slag and coarse sand is used. Often additional fillers and plasticizers are added.

It is possible to make blocks both manually using molds, and using equipment with the function of vibrocompression.

On average, one bag of cement is enough to make 36 blocks. The savings are obvious.

The cinder block must have the correct geometry. Even small irregularities will lead to a deterioration in the quality of the masonry. To get even blocks, the forms need to be filled not just to the brim, but with a small slide, because. during vibration, the concrete will slightly shake and settle.

Prices for different types of building blocks

Building blocks

How to prepare a solution?

There is no universal composition of the solution for the manufacture of cinder blocks - each master has his own unique recipe. In general, it is necessary to focus on the features of the composition of the slag.

| Components | Volume, l, per block | Dry block compressive strength, kg/cm2 | Frost resistance of the finished block, cycles | The coefficient of thermal conductivity of the finished cinder block |

|---|---|---|---|---|

| Slag up to 8 mm | 10 | 30-40 | 30 | 0.35-0,4 |

| Sand up to 3 mm | 1,8 | |||

| Cement | 2,75 | |||

| Water | 1,5 |

There is a standard "factory" recipe, you can focus on it. The proportions are as follows:

- slag - 7 parts;

- sand - 2 parts;

- cement - 1.5 parts;

- water - 1.5-3 parts. More details about determining the required amount of water will be discussed below.

Helpful advice! Previously, the standard dimensions of cinder blocks were given. However, for private development it is more convenient to use products with dimensions of 400x200x200 mm.

In addition to slag, such blocks can include ash, sawdust, gypsum, broken bricks, coal combustion products, gravel and other similar materials.

Pay special attention to determining the required volume of water. It must be added so much that the products do not spread after formation.

You can do a simple test. Throw a handful of the solution on the ground or other surface. If it crumbles, but when compressed back by hands, it reunites into a single mass - the consistency is optimal.

Making cinder blocks by hand

If not too large-scale construction is planned, blocks can be made without a vibropress.

We make a form

We collect the form with dimensions of 40x20x20 cm. If you wish, you can adjust the dimensions at your discretion. For the manufacture of molds, we use metal sheets or wooden boards.

The design is extremely simple: bottom and side walls. We fix the walls taking into account the selected width and length of the block. The height of the form faces must also correspond to the planned height of the building elements.

Helpful advice! You can make molds with cells for the simultaneous production of 4-6 blocks - very convenient. It is only necessary to increase the length and width of the outer faces and install partitions between them.

Prepare empty glass bottles. You will use them to create voids in blocks.

Pour blocks

Pour the solution evenly into the mold to the brim.

We place the bottles with the neck up in the poured mass. Level the surface of the fill, removing excess mortar.

We wait about 5 hours and get the bottles. We leave the cinder blocks in the forms for a day, after which we carefully take them out and lay them out on a horizontal surface in piles.

We leave the blocks to dry for a month. Only after the specified time, the material can be used for construction.

Helpful advice! During drying, cover the blocks with plastic wrap. It will protect products from cracking during the heat and will not let them get wet in case of rain.

We make cinder blocks on the machine

The machine allows you to significantly increase productivity. The equipment has a fairly simple design.

We assemble the machine

The main element of a home-made vibrocompression machine is a form (matrix) for cinder concrete mortar. By design, this form is metal box with internal elements in the form of voids. The void spacers can also be removable.

Work set includes the following materials and tools:

First step. We make a form according to the size of future blocks. Cut out from sheet steel side faces of the matrix. We will make the form immediately for 2 blocks. To do this, we cut out the inner central partition from steel and fix it in the box.

Second step. Determine the height of the elements for the design of voids.

Important! In accordance with the technology, the height of the voids should be such that the bottom wall has a thickness of 3 cm or more.

Third step. We cut off 6 pieces of pipe along the length of the restrictor cylinders to form voids.

Fourth step. We give the pipes a conical shape. To do this, we cut each piece of pipe longitudinally to the middle, crimp it with a vise and connect it using a welding machine. each cone on both ends.

Fifth step. We connect the limiters in a row along the long edge of the cinder block. We add along the edges of the row along a plate of 3 cm thickness with holes for fastening with eyes.

Sixth step. We make cuts in the middle of each such compartment. From the reverse side of the form we weld the eyes. They will allow temporary fastening of elements to create voids. A very convenient solution - it will be possible to remove the cylinders and make monolithic blocks.

Machine for cinder blocks compact (press from above)

Machine for cinder blocks compact (press from above)

Seventh step. Outside one of the transverse walls, we weld 4 bolts for the mounting holes of the vibration motor.

Eighth step. By welding, we attach an apron and blades along the edges from the loading side.

Ninth step. We prepare all structural elements for painting - we clean them and carefully polish them.

Tenth step. We do a press. It will look like a plate with holes that repeat the location of the holes in the block.

Important! The diameter of the holes on the plate should exceed the same parameter for the recesses in the block by about 0.5 cm.

We make the plate of this size and fix it in such a way that it can go deep into the box at the place where the limiters are installed by 5-7 cm.

In conclusion, it remains to weld the handles to the press, cover the structure with a primer mixture and mount the vibration motor.

An ordinary electric motor can be turned into a suitable vibration motor. To do this, it is necessary to weld eccentrics to the motor shafts. We won’t bother much - we’ll just weld the bolts so that their axes coincide. To regulate the frequency and strength of vibration, we wind the nuts onto the welded bolts.

Prices for machines for cinder blocks

Cinder block machine

Making blocks

Recommendations for the preparation of the solution were given above. You can use the standard recipe or modify it to your liking. The main thing is to get optimal viscosity. It can be determined "by eye" - a lump of the mixture must hold its shape steadily.

Before loading the mixture, lubricate the contact metal planes with oil. Due to this, the solution will not stick to the iron.

We put the finished mixture in the matrix and proceed to pressing.

We install the filled forms on the vibrating plate and let it compact the solution for 5-15 seconds. After the specified time, add more solution to the form, because. previously loaded will inevitably settle.

We repeat the process, only this time we do not turn off the vibrating plate until the clamp reaches the limiters. We remove the form until the machine stops.

We give the blocks 1-3 days for primary drying, carefully remove them from the blocks, lay them out on a flat horizontal surface and cover with plastic wrap. You can use the material for its intended purpose no earlier than a month later.

Successful work!

Video - Making cinder blocks with your own hands

For the manufacture of homemade blocks, only a few molds are required for casting them, as well as cement, sand and filler - slag or broken brick. Other types of fillers (gravel or crushed stone) will make the block very heavy, and in addition, a wall made of such material will heat up faster in summer and cool down in winter. If, however, expanded clay is used as a filler, then, although it has almost the same thermal insulation properties as broken brick and slag, it will cost several times more.

Forms for the manufacture of building concrete blocks

For self-production of building blocks at home, you will need special metal or wooden molds, the internal dimensions of which are different: 150 X 150 x 300 mm, 175 x 175 X 350 mm or 200 x 200 x 400 mm. With small blocks, it is more convenient to carry out masonry, and with large blocks, construction is carried out faster.

For the manufacture of a metal collapsible form for one block, four rectangular iron plates 3-4 mm thick are required (the height, width and length of the plates will depend on the chosen size of the form). Mounting grooves must be cut out on the sides of the plates, and handles must be welded to the end parts of the mold. For a four-block mold, you will need to make two rectangular plates and five smaller plates to separate future blocks in the mold.

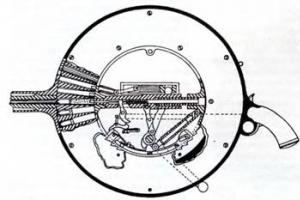

For the manufacture of concrete blocks with their own hands, compaction and the creation of bubbles in them are required, for this purpose it is necessary to make a special device. It will require one rectangular iron plate (according to the size of the mold), a small piece of wire rod with a cross section of 10 mm and three pipe cuts with a diameter of 50 mm and a length of 150 mm. At one end of each pipe, four triangular “teeth” must be cut to a depth of 50 mm. Then these teeth must be connected to each other so that a cone is obtained. The seams between the teeth must be carefully welded. Then, a wire rod handle must be welded to one of the planes of the plate, and pipe trimmings with a blunt end must be welded to the other.

Wooden collapsible form

Wooden collapsible form  Wooden collapsible form

Wooden collapsible form

To make a wooden collapsible form, you will need four trimming boards with a thickness of 35-50 mm (the dimensions will depend on the size of the selected form). Of course, wood is a weaker material for molding, so boards of high quality and strength are needed. All connections in the wooden mold must be secured with tie-down screws. Otherwise, the design of the wooden mold is the same as that of the metal one. Handles for the form can be made from a wire rod with a section of 10 mm, flattening its ends and drilling holes in them with a diameter of 6-8 mm.

To make building blocks with your own hands, you need to make a solution of cement, sand and aggregate (slag or broken brick) in a ratio of 1: 4: 6. When adding aggregate to the mortar, it is necessary to ensure that it is viscous and sticky, but does not turn out to be liquid or crumbly. Next, the solution is poured into molds, in which in hot weather it will solidify for 2 hours, and it will acquire the final strength in 1-1.5 days. In cool weather (+7 ... +18 C), the hardening and complete drying time increases by 3-5 times, and at temperatures below +7 ° C and during precipitation, it is not recommended to make blocks at all.

If slag is used for mortar together with cement, sand can be completely abandoned, and then the ratio of cement and slag should be 1: 6 or even 1: 8.

Before pouring the solution into the mold, it is necessary to moisten all its details, regardless of the material of manufacture, with water. You should work on a flat surface and fill the form with a solution of 2/3 or 3/4 of the volume (the exact amount is determined empirically after using a device for making voids).

After the block has completely hardened, it must be freed from parts of the form. The raw block must be left to dry completely, and the parts of the mold should be filled with water.

It is possible to make blocks directly at the construction site, i.e., fill on the spot. In this case, the dimensions of the mold for pouring can be increased to 330 x 300 x 600 mm. This will further speed up the construction process.

Consistency cement mortar and the filling method are the same as in the previous case. Can be welded in working structure several forms (3-4 forms are enough), and then the masonry will go even faster.

To cement mixture did not stick to the walls of the mold, before pouring, its inner cavity must be abundantly moistened with water or lubricated with used machine oil. After the mixture has set, the mold plates are peeled off from the walls of the block. In the process of erecting walls, it is necessary to verify the horizontal and vertical rows. In general, the laying of corners, the bandage between the blocks are fully consistent with the methods brickwork in half a brick.

Saman - a mixture of clay and straw, for making homemade blocks

Saman - a mixture of clay and straw, for making homemade blocks

The cheapest building material for self-made concrete blocks at home is adobe - a mixture of clay and straw. Cheapness is not the only advantage of adobe - it is a durable material with high thermal insulation properties, easy to "manufacture". For the manufacture of adobe blocks, collapsible metal or wooden molds are also used. It's better to make blocks small size, a maximum of 150 x 150 x 300 mm, since larger blocks are heavy and inconvenient to work with, and besides, voids cannot be made in them.

On a note!

Lack of adobe - instability to humidity. Before erecting walls from adobe, it is necessary to ensure reliable waterproofing of the foundation, and finished walls require plastering with cement-sand mortar, covering with any available polymer or metal mesh, and performing a fine finish.

Home production of concrete blocks for construction

The order of work in the construction and manufacture of concrete blocks is standard: first you need to choose a place, then make a foundation - here you need to build a slab foundation, you can use foundation slabs, connect communications, build walls, build a roof, install windows and doors and perform facing work and interior design summer kitchen.

The walls are laid out in half a brick, for a summer kitchen the thickness of the wall can be one brick - and that will be enough. As the laying progresses, it is necessary to align the walls vertically and horizontally, using a plumb line and a cord stretched horizontally from one corner of the house to another.

Home production of building blocks allows you to reduce the cost of laying openings with the subsequent installation of windows and doors. During construction, door and window openings must be made in the box of the building. It is necessary to establish the location of windows and doors at the planning stage. It is possible to leave openings of the required width in the process of laying walls in the places where doors and windows are installed, as well as insert wooden plugs, to which the stretcher boxes will then be attached. Wooden corks must be inserted in the second row relative to the bottom of the box and in the penultimate row relative to its upper part. At the top level of the box, a reinforced jumper 120 mm thick or a bar 70 mm thick should be installed. The ends of the jumper must be brought to the walls by 20 cm. If the planes of the next row of masonry and the upper part of the frame are at different levels, you will need to catch them up to the desired height using parts of the blocks and mortar, or assemble the formwork, tie the reinforcement and fill it with cement mortar.

After erecting the walls, the boxes should be installed on the places allotted for the windows and the door, having previously wedged the corners. Next, you need to align them horizontally and vertically, and only after that you can attach the side parts of the box to wooden corks using nails or screws. The remaining space between the walls, foundation, lintel and box must be filled around the perimeter with acrylic mounting foam.

The second way of arranging door and window openings is when door and window frames are installed in the right places, and then lined with blocks. Typically, this method is used for decorative masonry, when further wall decoration is not provided.

In this case, so that the door frame does not lead during the laying process, it is necessary to clamp it on both sides with blocks during the laying of the first row, after inserting the supports into the corners. After the second row, you need to align the box vertically and horizontally, fix it with nails or screws on the sides to the wall. It is also necessary to leave the outlet at 10 cm. Then, the solution must be applied to the outlets and clamped with a block of the next row, once again making sure that the box is level. The same must be done in the upper part of the door frame, as well as on the fourth and sixth rows with the window box. Jumpers are installed here in the same way as in the first method.

Building a house from blocks is moving faster than from bricks. You can buy them freely, but many make building blocks with their own hands.

Blocks in construction are used not only for the construction of walls. It also speeds up the use of building blocks for the foundation. Of course, these blocks must be very dense: 1.5 tons per 1 cubic meter. Making blocks with your own hands, if you look, is not such a super complicated matter.

Where to begin?

And the beginning of everything is the manufacture of forms.

Forms

On sale there are forms for building blocks with standard sizes. And at home you can make building blocks sizes that suit you. We take sheet metal, cut out the required shape of the workpiece from it and weld the shape. They also make molds from wood, they are good for adobe blocks. The bottom is not needed here. But the handles on the sides will come in handy, it’s more convenient to work with them.

Material for homemade building blocks

What makes DIY building blocks good is that they use material that you already have or you can easily purchase.

Basically, blocks are made on the basis of cement with different fillers, but craftsmen, like manufacturers, sometimes do without it. Depending on the material chosen, it is possible to manufacture home-made building blocks of the following types:

- cinder concrete;

- blocks based on liquid glass;

- adobe;

- chip concrete or arbolite.

How the filler is used:

- ash;

- slag;

- screenings;

- crushed stone;

- gypsum;

- perlite;

- expanded clay;

- sawdust;

- straw;

- broken brick and more.

Blocks without cement

The manufacture of building blocks using this technology is not available to everyone, because liquid glass is present in the mixture. Is it possible to negotiate with the nearest reinforced concrete plant and buy the main component there. The mix will be:

- two dozen parts of river sand;

- one and a half dozen parts of liquid glass;

- 4 parts of chalk;

- 3 parts of slaked lime;

- 2 parts kaolin.

Manufacturing process

- First, the sand is sifted;

- chalk is added;

- everything mixes well;

- slaked lime is introduced;

- kaolin or brick crushed to a state of powder;

- liquid glass.

The feedstock should be homogeneous, pasty. Before pouring this dough-like mass, moisten the molds from the inside. If you wish, you can add color to the building blocks. To do this, add:

- chalk of any color;

- powdered red brick.

Fillers are added to such blocks: slag, expanded clay, shavings. Their strength is high - they are much stronger than cement.

Expanded clay blocks

Expanded clay concrete blocks are one of the types of cinder blocks, where expanded clay serves as a filler.

Compound

- cement - 1 part;

- expanded clay - 5 parts;

- sand - 3 parts;

- water - about one part.

Technology

The manufacturing technology of expanded clay concrete building blocks is, in general, the same as any other:

- the starting material is placed in pre-lubricated molds;

- rammed;

- the form is removed after 10 minutes;

- the product remains in place;

- after 12 hours it is transferred to a place protected from precipitation and direct sunlight.

- in warm weather, the blocks will become hard after a little less than a month.

If you plan to make thick walls (about 0.5 m), then blocks are better with voids. To do this, inserts made of wood are inserted into the mold: round or square. And so that they can be taken out well, before inserting them, wrap them in roofing iron.

Advantages

- light weight;

- frost resistance;

- breathability;

- moisture resistance;

- strength;

- small cost.

A house made of expanded clay concrete blocks is built faster than a brick house, less mortar is needed for masonry.

adobe blocks

Components

For this type of block, the material is literally underfoot. All it takes is:

- clay;

- straw;

- river sand;

- water.

Selection features

In order for the characteristics of the building blocks to meet all the requirements, you need to know something about the features of the selection of components:

- It is better to prepare clay in the fall, cover it with a film and let it winter - this will improve its quality.

- Sand first sift, freeing from impurities.

- Straw can be taken to the field where wheat, rye or barley have just been harvested. If the straw remains from the harvest of the past year, then the quality will not be the same - after all, after lying down, it begins to sing.

How to determine the percentage of components

- clay - 1 cu. m;

- straw - 20 kg;

- sand - 25%.

In order not to spoil the entire batch of blocks, you need to make a small experimental batch. So we do it like this:

- we combine all the components in small quantities and write down the proportions;

- we make a batch;

- form a ball;

- leave in the sun to dry for about 1 hour;

- We throw it on the ground at a height of a meter and a half.

If all the components are matched in the right proportions, then the ball will remain intact. Added more sand than it should? It will break or crack. Not enough sand? The ball will float. So in a practical way, we select the most optimal option.

Preparation

To prepare the mixture for several dozen blocks at once, you need to make a recess in the ground: round with a diameter of about 2.5 m or rectangular 1.5x2.5 with a depth of half a meter. Line the bottom with polyethylene. Although some kind of ready-made container is also suitable: a trough or old bath. Then everything is as it was done in the old days: we put on high boots made of rubber and walk, mixing everything until smooth.

Manufacturing

- While the batch is in the manufacturing stage, we are preparing a platform for products: we select a flat sunny place;

- we bring the mixture with buckets;

- filling out forms;

- we compact;

- we remove the excess by drawing a board along the upper edges of the form;

- remove the form.

Finished blocks should dry. This usually takes several days. It is important that they do not get rain. Then they are transferred to a shelter and dried again. Will be ready in 10 days.

A house made of adobe blocks turns out to be very warm and comfortable. In addition, this construction material environmentally friendly, durable, fireproof. It is used for buildings no higher than 2 floors.

Sawdust concrete blocks (arobolit)

The technology for manufacturing blocks from sawdust concrete is similar to the manufacture of adobe blocks, but the components need not be mined, but purchased.

Components

Before you start manufacturing, you need to purchase:

- cement - M300 or higher;

- sand - a fraction no larger than 1.8 Mcr;

- not slaked lime;

- sawdust (softwood).

Preparing the Components

- sift sawdust;

- mix dry cement and sand;

- lime here and mix again;

- add sawdust and repeat the mixing procedure;

- pour water;

- In order for the components to adhere well to each other, we add calcium chloride or alumina sulfate;

- we control the quality of the mixture.

For quality control, roll the ball and squeeze it in the palms. If water flows, then there is too much of it in the mixture, if the ball crumbles, there is a lot of sawdust or sand.

Let's start manufacturing

- We line the form with plastic wrap;

- lay the mixture;

- rammer;

- without removing from the mold, leave to harden for 5 days;

- take it out of the mold and dry it further.

The drying process will take a long time - from 1.5 to 3 months: it all depends on the mass of the block.

Equipment

If the construction is to be large-scale, then it may make sense to invest in equipment for building blocks. For example: there is a mini-machine for the production of wood concrete RPB-1500 BL on sale. Its productivity is 1 sawdust block with dimensions of 19 x 19 x 39 cm per minute. Produced by a Russian manufacturer - the company INTEK.

Vibrating tables are widely used in the manufacture of building blocks. They allow you to solve the problem of ramming mixtures. The vibrating table consists of:

- movable table;

- engine;

- control panels;

- sometimes a transformer is included.

Compaction of the working mixture occurs under the influence of vibration created by the vibration motor.

Working cycle

- on the movable table we set the form;

- put in the mold half or completely dry mixture;

- start the engine;

- drying.

How to choose?

There are 3 types of vibrating plates capable of compacting material by weight:

- up to 75 kg;

- from 75 to 160 kg;

- from 160 kg.

Based on these indicators, you should choose the best vibrating table for yourself.

Manufacturers

They are released by:

- Russian company VPK;

- Stroymash LLC;

- plant "Red Poppy" in Yaroslavl and others.

Vibrating tables are also supplied by foreign manufacturers:

- Spain - Enar and Hervisa;

- Germany - Wacker;

- Italy - Batmatic;

- France - Paclite.

Cinder block is one of the most requested materials for the construction of walls of one-story buildings. It is distinguished by its low cost and the possibility of its independent production at home.

Cinder block - wall stone

This building material is intended for low-rise construction. There is an opinion that if cement of a “high” grade is included in the mixture, then a solid foundation for a bathhouse or a house can be made from home-made blocks. However, the foundation blocks must withstand huge loads, so the blocks should be purchased at the factory, and not made independently.

Cinder blocks are:

- hollow;

- corpulent.

Due to sufficient strength characteristics, solid cinder blocks are used for cladding and construction bearing walls, as well as partitions. At the same time, hollow products have good heat and sound insulation. Due to voids, raw materials are significantly saved, which means that the cost of production is much lower.

Cinder blocks are also used as an additional insulation in the construction of frames.

How to knead a solution to create a cinder block?

The name of the building material "cinder block" speaks for itself. This means that the main component of the solution will be the slag obtained in the blast furnace, which should be sieved through a special sifter (sieve).

We will need:

- 7 parts of the main filler (they will serve as slag);

- 2 shares of gravel having fractions of 5-15 mm;

- one and a half parts of cement (it is best to take the brand M 400, 500);

- about 3 parts water.

In addition to slag, other components can also act as the main element: clay, expanded clay, sand, gravel, crushed stone, gypsum and many others. It should be noted that if you have chosen blast-furnace slag as a filler, then other additives are prohibited to use. If you want to get a colored cinder block, then you can add chalk or red bricks brought to small crumbs into the solution (they should be crushed).

In addition, during the production of cinder blocks, make sure that the solution does not spread.

| Name of components | Qty components | Density, kg/m3 | Water absorption, % | Мрз, cycles not less than | Compressive strength, kg/cm2 |

|---|---|---|---|---|---|

| Cement, kg Sand, kg (m3) Crushed stone, kg (m3) Water, l (depending on the humidity of the components) | 500 900 (0,52) 900 (0,52) 100...200 | 2350 | 4 | 200 | 410 |

| Cement, kg Screenings, kg (m3) Sand, kg (m3) Water, l | 500 920 (0,54) 1150 (0,7) 100...200 | 2160 | 4,5 | 200 | 400 |

| Cement, kg Sand, kg (m3) Water, l | 600 1550 (0,9) 100...190 | 2200 | 5,3 | 200 | 436 |

Tip for obtaining durable blocks: a plasticizer must be added to the solution (you can buy it at any hardware store). Then you will get not only durable, but also frost-resistant and waterproof blocks.

When you are going to independently establish the process of creating cinder blocks, you should understand that there is no universal solution recipe. Each master, through trial and error, selects his own unique formula. If you are a beginner, you can resort to the standard.

Prices for plasticizer for concrete

plasticizer for concrete

Cinder block production methods

There are two ways to get such blocks on your site.

- With the help of formwork, that is, a form made of lumber or steel sheets.

- Based on the work of a special machine.

Video - Making a cinder block by hand

Video - Cinder block walking mobile machine

Video - Cinder block making machine

Tools and materials for the production of blocks:

- forms (wood or metal), or vibration machines;

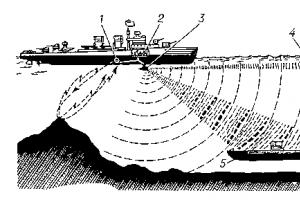

2,3,4 - pallet blanks. 5,6,7 - framing the matrix from below (corner 25x25). 8 - bar for fastening voids. 9 - void. 10 - the upper plug of the void. 11 - lower plug of the void

2,3,4 - pallet blanks. 5,6,7 - framing the matrix from below (corner 25x25). 8 - bar for fastening voids. 9 - void. 10 - the upper plug of the void. 11 - lower plug of the void

- concrete mixer;

- spatula for leveling;

- shovel for pouring mortar;

- solution.

Prices for cement-sand mixture

cement-sand mixture

Instructions for making your own mold

The design of the form has the following form: bottom and side walls. Between a pair of transverse boards or sheets of metal, you should fix the crossbars at the distance you need. Maintain a step corresponding to the size of the required cinder block.

Since it will be difficult to get the finished product out of the mold, the design of the container must be collapsible. For production efficiency, make formwork designed to receive 4-6 cinder blocks.

To make a mold in order to create cinder blocks, you will need:

- sheets of iron 3 mm thick;

- iron strips 5 mm (several pieces);

- cylinders, 4 cm in diameter;

- welding machine;

- Bulgarian;

- chalk for marking.

Prices for a welding machine

welding machine

Stages of manufacturing a single detachable metal mold

Step 1. We mark the sheet according to the size of the blocks: we need two longitudinal sides and two transverse ones. We cut our plates with a grinder.

The width of the longitudinal plate is 210 mm, the length is 450 mm, the transverse plate is 210 by 220 mm.

Step 2 Wings, 3.5 cm high, should be welded to the bottom of the mold for the cinder block so that the mold does not travel, and a handle to quickly release the poured solution from the mold.

Step 3 Notches are made along the contour of the transverse and longitudinal walls in order to hook the mold on the longitudinally installed walls.

Step 4. We collect our form.

Step 5. To create voids in the cinder block, we make hinged cylinders. They must be welded to a plate 3-4 mm thick, which should seem to penetrate the cylinders closer to the top. We make notches on the end walls of our container to hook them.

Video - Do-it-yourself mold for cinder blocks

Production of cinder blocks using a split mold

Forms have any dimensions. Standard sizes structures 90x190x188 mm, in private construction other sizes can be used, for example, 40x20x20 cm. In order to save material, it is better to use molds with cells of 4-6 blocks and cylinders (squares) to create cavities.

A metal self-made form (detachable) has the following appearance.

Consider the phased process of manufacturing cinder blocks.

Step 1. We mix the solution in a concrete mixer.

Step 2 Pour the mixture into our mold with a shovel. In this case, the mixture is thick. You can also use a liquid solution.

Step 3 Be sure to ensure that the solution fills the container evenly. To do this, we tamp the filled solution. We control the filling of the form to the brim. Aligning upper layer using a spatula.

Step 4 If the solution is dry, then a special lid should be used, the holes in which will block the bayonets in the mold. This device will help to compact our cinder block. For a liquid solution, such a cover is not used.

Step 5 We move our block to an open area for the purpose of further storage. After 30-40 minutes, remove the bottom, sides and top cover. For a better extraction of the cinder block, we will beat the walls and the longitudinal strip with the cylinders on top with an ordinary hammer.

Step 6 For complete drying, we need at least a day.

Production of cinder blocks using a vibrating machine

Step 1. We knead our solution, taking into account the proportions. Particular attention should be paid to the right amount of water, because the cinder blocks should not spread when you remove them from the mold.

kneading

In order to find out the correct consistency of the mixture, conduct a small test. Squeeze the solution in your hand: if it connects in it, and does not blur when it falls to the ground, this is a good and correct solution.

Step 2. We fill our form with a solution, with a slide.

Step 3 . We turn on the machine for 2-4 seconds, after which the loaded composition will be compacted. We level the mixture with our hands so that the iron pins (cylinders) are visible.

Step 4 If there is not enough mixture in the mold, it needs to be supplemented, the clamp is inserted and the vibrator is turned on again. The completion of the formation is evidenced by the sediment of the clamp on the limiters.

Step 5 . Our vibroform should again be switched on for 6-10 s.

Step 6 . We close the top with a lid with holes for the cylinders. And we make another ramming by raising and lowering the lid 4-5 times.

Step 7 . Then, without turning off the machine, the form is removed - it is enough to take the machine to you.

Up to 500 cinder blocks can be produced per shift using a vibrating machine.

Step 8 . We dry the blocks for 5-10 days. The complete hardening of the resulting building materials will be completed after a month, while the humidity should be high and the air warm.

Step 9. After a day, the blocks can be transferred to storage places (they will not be broken), but they can only be placed together after a week. And if you still add a plasticizer to the solution, then after 6-8 hours they can be moved and stored.

Of course, it is not worth buying a vibrating machine for a single production, but special attention should be paid to tamping when creating cinder blocks (the quality of the product depends on this process). In this case, you can use a conventional grinding vibrator, on which it is enough to place our mold with the mixture.

Video - Production of cinder blocks using a vibrator

Features of storage of cinder blocks

The received products are stored in pyramidal piles, one hundred pieces at a time.

At the same time, they fit with small intervals. It is enough for you to dry the material for a couple of months, then you can start building a bathhouse, an extension or a barn.

What are the features of the production of cinder block?

In the production of cinder blocks, special attention should be paid to drying. So, for example, any dent or unevenness will spoil the building material. Another requirement for the quality of the material is the geometry. A large number of irregularities and flaws is a prerequisite for increased costs for finishing the erected walls. Therefore, in order for the product to turn out even, it is necessary to fill the form or vibroform to the brim. Do not skimp on pouring the solution with a slide, because the vibration will shake your mixture.

For better plasticity, when mixing the solution, do not forget to fill in the plasticizer at the rate of 5 g per block. This will save the product from possible cracks, increase strength and frost resistance. For building small bath You can knead the solution manually, but a concrete mixer will help speed up the process. It is enough for you to buy or borrow for a while a small unit with a capacity of 02-0.5 cubic meters. m.

Video - Homemade concrete mixer

Before preparing the mixture, the slag is moistened 5-6 hours before. This will allow you to better bind the grains of cement and fractions of the filler. It should be noted that if you are filling wooden or metal molds without the possibility of vibrating, the mixture should be watery.

Pros and cons of using cinder blocks

The advantages of cinder block should include:

- possibility of manufacturing suburban area or in a private house;

- drying of the material can take place both in an autoclave ( industrial production) as well as outdoors(when self-produced);

- a cinder block building carries minimal heat loss;

- the material is inexpensive;

- the construction of the building is carried out quickly, given the large size of the blocks;

- when mixing the solution, you can, by changing the proportions, give it certain qualities;

- You can produce a cinder block of any size.

Disadvantages of cinder block:

- low frost resistance, but with the use of a special additive they can be increased;

- there are doubts in terms of environmental friendliness, especially for products made on the basis of blast-furnace slag;

- As for the liquid absorption characteristics, the material has strong moisture absorption and requires special protective coatings;

- fragility (this material is clearly not suitable for the construction of skyscrapers).

- The blocks made with the addition of cement have the highest strength. The next place is occupied by blocks of lime.

- If small granules are replaced with part of the sifted sand, then the strength of the products will increase slightly.

- The combination of cement and lime (or clay) in a ratio of 3: 1 will save money, which will absolutely not win back on quality.

- Before you start pouring the solution, the molds should be cleaned and wiped. This will prevent the resulting blocks from sticking to the bottom and walls. For such rubbing, diesel fuel, used oil, or similar means are used.

- The density of the solution is a direct indicator of the rate of solidification. The thicker it is, the faster block can freeze. The main characteristics of the quality of cinder blocks depend not only on the production technology, but also on the choice of solution. Below are Various types mixtures, the use of which demonstrates certain characteristics imposed on the material.

Video - Cinder block. Instructions for a beginner

Every person wants to build own house or buy an apartment. Some people like to be as close as possible to nature, others are attracted by a noisy metropolis. To build a house on your own, you need to have a significant amount of Money. However, not everyone can afford to build their own building. In this case, you can make materials yourself. Moreover, elementary improvised means are often used for their production. How to make blocks yourself? This question is asked by a large number of novice builders who want to build a house.

For the production of blocks, soil is needed, located under the fertile layer. Naturally, the basis of this nature is the most accessible. It is known that such a tradition came from places that did not have big amount forest area. For the manufacture of blocks, people in those places used the method of molding, tamping or formwork, into which the soil was simply stuffed.

To make the blocks yourself, it is possible to use a mechanical device. With the help of electric tools, you can get a well-mixed mixture without using your own efforts. So the work is done quickly and efficiently.

For work you will need:

- sheets of metal;

- cement chipboard;

- cement;

- sand;

- expanded clay;

- roulette;

- pencil;

- tree;

- emery skin;

- hammer;

- nails;

- bucket;

- shovel;

- rule.

Building blocks are one of the most popular materials actively used in construction. With their help, you can build houses, garages, baths, outbuildings. The erected walls delight with warmth, solidity, and a good degree of sound absorption.

Back to index

Varieties of building blocks

Any material of this type consists of cement, sand, water and fillers. Using certain ingredients, you can make a certain type of blocks:

Block laying sequence: a - single-row dressing system; b - multi-row dressing system; c, d - multi-row dressing system in a mixed way (numbers indicate the sequence of masonry).

- Cinder block, which is based on waste products from metallurgical enterprises. They are used in the construction of utility rooms. It is very convenient to lay such blocks. They are not capable of burning or freezing.

- Sawdust concrete belongs to more comfortable materials when laying. It can be easily cut, sawn, mounted. It has little weight. The sawdust itself acts as its component base. To prevent their natural decay and swelling, on the eve of the bookmark should be held in a solution of slaked lime.

- Block of gravel of various fractions. The named material has a large mass, which creates some difficulties during installation. It is a kind of concrete block.

- Expanded clay block, which has good thermal insulator properties. It is light weight, strong base and easy to install.

- Blocks with pine needle extracts, wood shavings, broken stone and crushed debris.

Back to index

Block production technique

Manufacturing with blockforms. Building blocks can be crafted using special machines for such production. On any such equipment, you can build 1, 2, 3 or more molds. A machine of this nature is represented by a vibrating table and vessels for shaping the blocks. Typical dimensions will be 190x190x390 cm. Removable partitions are provided here, with which you can make tiles of different sizes. There are devices for voids, which are 2 or 3 steel cylinders. A similar mechanism is simply laid in the block mold just before the concrete is poured. As soon as the solution hardens, these devices are removed. Finished block has hollow holes. The presented method of making molds significantly saves cement mortar.

It is not difficult to make the necessary samples on such equipment. In a container, a concrete mixer, a solution is prepared with a certain filler. In order for the finished product to be easily removed from the mold, the container must be lubricated with machine oil. After that, the cement mixture is poured into it.

Next, the vibrating table is turned on. After 2 minutes, the product is completely formed. During the vibration process, excess air is released from the concrete, as a result of which the composition is dense, as unnecessary water flows out of it. As soon as the product is formed, the surface should be smoothed with a spatula.

Now the block mold is moved to the place where the product will be dried. An open area with a roof or a special steaming chamber is well suited as such a site. Here it is important to follow the smoothness and horizontality of the surface. Removing the finished tile from this form will not be difficult. To do this, the lower base, resembling a layer of metal, is removed, and the side elements rise. The dried whole block remains in its place, it is not touched for several days. After the sustained time, the blocks are moved to any point.

Ground blocks. Blocks are made using a special machine. This is where the mould, molding powder and blower move. Moreover, vibrations and sounds during operation are excluded. There is no need to control the weight, measure the magnitude and check the pressure in the device.

Arbolite blocks. Wood concrete building blocks are lightweight materials made from wood chips, most often from coniferous species. It also contains sawdust, water, cement and chemical components.

The modern world dictates its own conditions and allows you to create such materials on your own. According to the requirements of state standards, wood concrete is made from wood particles, the dimensions of which must correspond to 40x10x5 mm. Numerical indicators of needles, leaves and bark are approximately 5-10%.

To make the desired composition, a significant amount of cement is required. And this will help to reduce the properties and retain heat. In this regard, wood chips are an important raw material.

Experienced builders often use shavings and sawdust in equal proportions. To avoid rotting, selected tiles must be aged for 3 months in the open air. Otherwise, block deformation will occur. Do not forget about the periodic tedding of this mass. If this is not possible, then it can be treated with zinc oxide. To prepare wood concrete, you need to take a concrete mixer.

Chips and sawdust are prepared independently using special machines or purchased commercially.

They are filled with water, to which liquid glass, calcium chloride (for quick hardening) and slaked lime are added as a disinfectant. Then the mixture is stirred in a concrete mixer with the addition of cement and some other components. After that, it is poured into molds. As such containers, you can make vessels from boards upholstered with linoleum. So it will be easier to pull out finished products.

Expanded clay blocks. For the production of such blocks, it is necessary to prepare a mold. To do this, a board is taken and a vessel is made from it in the form of the letter “G”. From the inside, it is coated with machine oil or wrapped in tin. In the end parts there should be closures that help the composition take the desired shape.

You can make expanded clay blocks with voids. This will significantly reduce the amount of material used, but such work is a little more difficult to do.

In addition to the container itself, you need to use tools such as:

- Master OK;

- shovel;

- buckets;

- mixing container;

- metal plate;

- water, sand, expanded clay.

To make the solution more elastic, experienced craftsmen add 1 tablespoon of washing powder.

casting rules. To give the mass the correct consistency and elasticity, mix all the ingredients and dilute them with water, defending it for a small amount of time. After that, the mass should be transferred to a metal plate and mixed well.

The resulting mass is put into a mold, and then into a special vessel that creates vibrations. After 2 days, her shutters open and she is released. After that, the building blocks are subjected to final hardening for 26 days.