Concrete area in front of the house. How to fill the yard with concrete with your own hands. Step by step painting instructions

Pouring concrete is considered a cheap way to help bring the area near the house in order. Although the procedure is not easy, if you follow the technology and sequence, you can do it without the help of a master. Concreting the courtyard of a private house will help solve the problem of an uneven surface.

Preparation for work

basis quality process is the pouring of an even screed that can withstand a mass of concrete. To do this, the site must be dug up and the surface leveled. If the soil is infertile, then soil should be added so that the shrinkage process occurs and the base is well compacted. To strengthen the pouring technology, large crushed stone is added. It creates a solid cushion for further work and protects the base from subsidence.

Before starting, you need to mark the boundaries of the future site for concreting and dig or bring soil there for leveling. After that, a backfill is created, which helps to create drainage and normal moisture absorption. Its basis is sand and gravel in equal proportions. The layer of sand should not be less than 5 cm. After falling asleep, tamping is done so that the surface is compacted and the base no longer sags. The process of leveling and tamping is carried out with a rule or a channel (for this, a comfortable handle is welded to the surface).

Masters advise to moisten the sand big amount water, then the mass will condense faster. After drying, a layer of crushed stone of a fine fraction is poured (5 cm, like sand). Large material is sometimes used, but its particles create gaps, which complicates the pouring process. After completing the preparatory phase, you can proceed to the next part.

Fill stage

First you need to prepare the necessary tools for the job. Since the mixture at high temperature hardens faster, preparatory stage must be done quickly. In the process of pouring concrete of the yard, you will need:

- shovel and drywall profile;

- level for leveling the base;

- rule or board for quick screeding and surface adjustment.

In order for the surface to be flawless, you need to choose desired shape and fix it. To do this, builders create formwork. Can be used wooden planks or other materials with a smooth surface and a solid base. The installation process takes place along the edges of the pour and creates a form for concrete. Wooden stakes are used for support. Wooden supports are also made between the side panels so that in the process the concrete does not violate the created shape and the formwork does not droop. Struts with a slight angle rest on the stakes so that wooden support withstood the weight of the loaded mass.

Concrete for pouring the yard can be ordered at the nearest concrete plant. In this case, before placing an order, you should carry out the entire complex preparatory work and be ready not only for the double price of the material compared to its independent mixing, but also for the most efficient production of a large volume of concrete. Due to the fact that this is not always acceptable, we will tell how to fill the yard with concrete with your own hands from start to finish, with the production of concrete in-house.

to fill the yard with concrete is quite within the power of each owner

Stages of work

- Site preparation. The concreting site is cleared of grass and its roots. If the ground on the site is dense, you can do nothing more. If the soil is loose, a pillow of crushed stone with a thickness of at least 15 centimeters is poured. The pillow is sprinkled with sand for buckling and compacted with a mechanical vibrotamper or a large-diameter log with handles;

- Formwork, curbstones or well-burnt red bricks are installed along the perimeter of the planned site at the rate of 50-60 mm concreting layer height plus 1.5-2.5 cm protrusion of the curb, formwork or brick above the concreting plane. Outside, the formwork is supported with pegs. A border or brick is installed in a trench on a cement mortar.

- Since the concrete will be kneaded on its own, it will not be possible to fill the entire area of \u200b\u200bthe yard at once a priori. Therefore, based on your capabilities and the thickness of the concreting layer, the concreting site should be divided into squares and beacons should be installed at the corners of the squares, which you will be guided by when pouring concrete. It is best to use plaster beacons (measuring pegs) and a system of twine stretched between the pegs with a spider. For ease of understanding and operation, we divide the area of the area to be filled with beacons into “maps” with sides of 1x1 meter. In this case, with the accepted pouring thickness of 5 cm, it will take 5-6 buckets of ready-made concrete to fill the “card” - the best option when kneading on a sheet of iron or in a small concrete mixer;

- The entire area of the pour, in order to avoid subsidence of concrete, is reinforced. For reinforcement, you can use a special steel mesh or “roll” yard illiquid assets into concrete: pieces of old steel wire, stamping, strips of steel, cut into strips of the hull of failed washing machines, refrigerators, air conditioners, etc.

- Concrete preparation. A very important stage, on which the strength and durability of concreting depends. Various sources publish different proportions of concrete. As practice shows, the most the best option concrete prepared in the following proportions is considered: 1 bucket of cement M400-M500, 3 buckets of crushed stone, 2 buckets of washed sand. You can knead the material in a concrete mixer or on a sheet of iron 2x1.5 meters with a shovel and a bayonet shovel.

- Laying concrete between the lighthouses. Concrete is laid out in buckets and the required thickness is leveled with a shovel and a rule. At the same time, they make sure that the concrete hides the tops of the lighthouses by 2-2.5 mm, no more.

- In order for there to be no puddles on the site, when pouring the “cards”, they try to ensure the slope of the site is 2-3 degrees (with a wooden lath and a building level), towards the optimal water drainage: site boundary, vegetable garden, garden, road, etc.

- Mandatory operation! After pouring a separate “card”, without waiting for the concrete to set, the so-called “iron-plating” of the upper layer is carried out. If you neglect this operation, then after a couple of years of operation, you will have to remove the concreting and redo everything. The essence and technology of ironing - sprinkle the surface of freshly poured concrete with dry cement with a layer of 2-3 mm, spray it with water until wet, and rub it into the body of the pour with a spatula, trowel or grout. Control - the surface of the concrete acquired a "raw" pleasant-looking greenish-blue color.

If there is such a need as concreting the courtyard of a private house, it is not always necessary to look for craftsmen and pay large sums for this. After studying technological process you can independently fill in not only the tracks, but also the platform for the car.

Purposes of concreting

To understand why a concrete yard is required, it is enough to understand the benefits that this provides:

- a platform in front of the house eliminates the appearance of dirt in inclement weather;

- the correct layout of the site helps to forget about puddles forever (the water in front of the house will not stagnate);

- there are no traces of vehicles on the surface with a hard coating;

- concreting is an alternative to fragile asphalt or expensive tiles;

- the platform protects from weeds;

- on a concrete surface it is easier to zone the space, place benches and flower beds;

- such an area is easier to keep clean.

The nuances of hand-made concreting

When laying concrete, it is necessary to take into account some features:

- In order for the solution to be of high quality, sand with a small content of clay impurities and large particles should be used. Check the quality of the sand by pouring it into a bucket filled with water. If the water remains clean after shaking, it can be used. Cloudy water indicates great content in the sand impurities of clay, silt.

- To strengthen the coating, a small amount of cement is applied to the hardening concrete and rubbed into the surface of the concrete composition.

- To prevent overheating and Negative influence rays of the sun, the coating is painted white.

- To reduce the moisture content in the solution, it is recommended to use coatings containing salts that have the ability to absorb moisture from the surrounding air.

- To prevent cracking of the coating at the joints, the prepared concrete mixture must be poured evenly and as quickly as possible.

- Concrete should not be shed with water as soon as it sets if reinforcing mixtures are used. This can lead to their detachment.

- When performing preparatory work, a slope should be provided along which precipitation will be discharged. For this purpose, when the concrete hardens, it is laid on it metal pipes squeezing them. After the solution hardens, the pipes are removed, and the grooves resulting from them will function as gutters.

A similar technology is used when equipping a house that does not have a basement, a garage, a basement or other outbuildings.

Preparatory work

Do-it-yourself concreting process begins with preparatory measures. When preparing the site, level the surface, clean upper layer soil.

Leveling and site preparation

They remove loose black soil with grassy roots to a depth of 5 to 15 cm. After removing the earth layer, they begin to prepare the site. A “cushion” is created from sand or gravel, which must be well compacted and poured with water. If the soil is super sandy or clayey, it can be left on.

The bedding is covered with plastic wrap and secured with adhesive tape. This will protect the concrete from rapid deterioration and will not allow grass to grow through the created concrete pavement. It will also not be able to flow until the concrete sets.

Cushioning and sealing

"Pillow" improves the quality of the concrete base. For its manufacture, sand or crushed stone is used, which is placed on top of the soil with a layer of 10-20 cm. The backfill performs the function of drainage.

A channel equipped with a handle is used to compact the sand. In some cases, a large amount of water is used, which is poured into the sand layer, and then left to shrink. A layer of crushed stone is placed on top of the sand layer and also compacted.

Most bottom layer foundation - pillow. It is designed to provide a solid and even surface for the device of the future foundation.

Formwork preparation

The creation of formwork is required to give the necessary shape and even solidification of the screed. During its construction use:

- boards;

- pieces of chipboard;

- plastic panels;

- plywood sheets;

- slate sheets.

Formwork is installed around the site along a given contour. To connect the shields, nails or self-tapping screws are used. When installing the structure, the material is laid, propped up with pegs that are driven into the ground.

Usage plastic panels allows you to fill curly tracks, because the material is easily bent. This completes the preparation stage, you can proceed to the creation of a concrete coating.

Stages of concreting

The whole process of concreting consists of several stages:

- displaying lighthouses;

- reinforcement;

- pouring concrete mix;

- finishing processing.

Exposure of lighthouses

As beacons, it is allowed to use slats 2x4 cm, twine, a profile for working with drywall. To avoid the accumulation of rain and melt water on the site, the surface should be with a slight slope.

Beacons are placed in the transverse direction with respect to the site. With the help of a level, 2 beacons are installed along the edges, fixed with a cement-sand mortar.

After the concrete has set, cords (2-3 pieces) are pulled between the beacons and the rest of the beacons are installed along them.

Reinforcement

Reinforcement gives the screed stability and high strength. You can use building reinforcement, rods, pipe elements, steel wire.

Reinforcing the walkway in the yard will allow you to make a smaller layer of concrete.

It is better to take the reinforcing mesh ready-made (with a wire thickness of 6 mm and a mesh size of 10 mm). The finished mesh sheets are overlapped one on top of the other. The use of rebar will prevent cracks that can occur on concrete surfaces.

Solution preparation

To prepare the solution, several methods are used. To get concrete, mix the following components:

- cement;

- crushed stone;

- sand.

When mixing, it is required to observe the proportions: 3 parts of sand and 1 part of crushed stone are taken for 1 part of cement. There are other recipes (for 1 part of M400 or F200 cement, 2 parts of crushed stone and sand are taken), but in this case a vibrating screed is required, without it it will not be possible to properly level the concrete surface.

Mixing concrete begins with placing water in a concrete mixer. The recommended average ratio of cement and water is 1:1. Then the other ingredients are added to the water and mixed well until a homogeneous mass is obtained. When no sand is visible in the concrete mix, it is ready for use.

Pouring concrete

To facilitate the process of mixing the mixture, use a concrete mixer. If there are no auxiliary mechanisms, another method is used.

First, a solution is poured with a large amount of rubble and left without leveling. Then they are poured with a concrete mixture, in which there is almost no crushed stone. The thickness of the finishing layer can reach 2 cm. This option is economical, you can do without the use of expensive fixtures.

However, in order for the quality of concreting to be high, the entire site must be poured in 1 day. If it happens that the bottom layer managed to grab, then it will no longer be possible to tie the top one to it.

The concrete solution is unloaded with a shovel and distributed among the beacons (it must cover them). Excess concrete mix is removed using a flat rail, trying to make the surface as even as possible.

Finishing operations

The next step is to cover the surface with various impregnations. For the purpose of additional strengthening, a polymer layer is used. Mandatory topping treatment of the most stressed places is required:

- the edges;

- corners.

Polymer processing can be done in 2 ways:

- A dry reinforcing polymer mixture is poured onto fresh concrete.

- A slurry is prepared and poured into grooves (1 cm deep, prepared in advance) in the cured concrete.

Temperature joints

The technology provides for expansion joints that prevent damage to the coating in case of changing weather conditions. Under the influence of high or low temperatures the linear parameters of the material change (increase or decrease).

To do this, create technological gaps. At the pouring stage, small slats can be laid, and they must be removed before the concrete hardens. In some cases, strips of mortar are scraped off before solidification, using a construction tool for this.

If technological seams have not been created, after the concrete has completely hardened, they can be cut with a grinder.

How to take care of the surface

Properly dried, it becomes more durable. This process takes a long time. After water leaves the surface of the concrete, cleaning is performed, removing the existing sagging and tubercles, cover the coating with a film.

If the weather is hot, it is necessary to water it, otherwise, at a temperature of + 30 ° C, the concrete, which was kneaded on, loses about 50% of its strength.

The hardening process is fast, but it takes more time to gain basic strength. Therefore, you should not park a car or drop heavy objects on a recently concreted area.

Maintaining a moisture reserve is required not only during the formation of the solution, but also during further use.

Each owner of private housing construction is faced with the problem of landscaping the adjacent area. One of the simplest and most economical options is concreting the yard, which you can do yourself.

Preparatory work before pouring the yard with concrete mix

Before concreting begins, weak soil layers must be removed from the surface of the yard, after which the entire area is covered with a crushed stone layer with a thickness of about 200 mm. The rubble is carefully compacted. With strong soils, concreting can be carried out without additional crushed stone preparation.

The main activity of the Navigator company is . Here you can order concrete mixtures, crushed stone, sand from the manufacturer, fast and reliable delivery.

To maintain the horizon on uneven terrain, it is necessary to make a special device, since standard levels are unsuitable in this case.

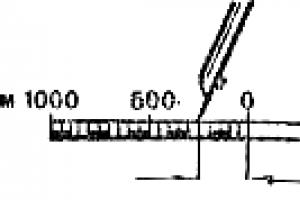

The device is conventionally called the "spider". For its manufacture, stakes are installed at the four corners of the yard, to which two parallel threads are tied. Two more must be tied perpendicularly to these threads, but in such a way that they can move. As a result, two movable threads are obtained, on the touch of which beacons are arranged.

Next, you need to correctly determine the plane of concreting. Its location depends on the direction in which it is planned to organize the flow of rainwater. The height of the plane above the level of the base is equal to the planned thickness of the concrete layer. In this case, it is sufficient to make a concrete layer 100 mm thick.

The plane is set by raising or lowering the threads to the desired height.

In order to set one of the sides to a horizontal position, a small special level is used, which, with the help of hooks, clings to the thread.

Calculation is an important stage in concreting the yard. Learn how to calculate the volume of concrete and its components!

How to determine the brand of concrete? reveals all the questions: what is the brand for strength, frost resistance and water resistance.

You can order or rent it from us.

Installation of beacons

After settling the position of the upper concreting plane, you can proceed with the installation of beacons. For this purpose, it is necessary to mix a small amount of concrete mixture.

In one row, concrete is applied by free-standing slides, into which the profile used to fasten drywall is pressed. This profile will be a beacon, the correctness of its location is checked by the threads of the "spider".

The threads should lightly touch the profile. The distance between the beacons is equal to the length of the rule with which the concrete will be leveled. It will take about a day for the beacons to dry.

The concrete layer will crack over time. Particularly vulnerable are the areas of contact between portions of the concrete mixture, poured not simultaneously, but after a certain time interval. Therefore, in order to preserve the integrity concrete pavement for a long time between the beacons, it is necessary to lay a reinforcing grid or a thick wire mesh.

The technology of self-preparation of concrete mix

To obtain high-quality concrete, it is mandatory to observe the proportions of its three main components - cement, sand and crushed stone. For one part of cement, you need to take three parts of sand and one part of crushed stone. The amount of water is determined by the following calculation - for a solution prepared in one bucket of cement, it will take 1.5-2 buckets. It is possible to change the quantitative ratio of the components. For example, you can take part of cement, two parts of sand and two parts of crushed stone. But in this case, it will be difficult to level the concrete solution without a special mechanism - a vibrating screed.

The readiness of concrete is determined by its color - no sand should stand out - and by the uniformity of the mixture.

Now you can start pouring concrete. With the help of shovels, the concrete is leveled between the lighthouses. The concrete mixture should be located slightly above the beacons. The rule is set to two beacons. With its help, when making reciprocating movements to the right and left, the concrete stretches towards itself.

This operation must be performed two or three times to completely remove excess concrete.

The device of the finishing layer of the concrete pavement of the yard

A day after the end of concreting, when the mixture hardens a little, it is necessary to clean the top layer, removing bumps and sagging. For these purposes, use a rule or silicate brick.

One of the ways to give the concrete surface additional strength and wear resistance is ironing, which is carried out after the cement has begun to thicken. This operation consists in sprinkling and rubbing a layer of pure cement into the concrete surface.

To obtain a durable high-quality concrete coating, a reinforcing polymer-cement topping coating is used. Ready-to-use dry mixture consists of highly active cement, modifying components, quartz fillers. Topping is used for the manufacture of monolithic floors of industrial buildings, warehouses, garages, and for road surfaces.

Topping is applied in industrial conditions with the help of special dosing trolleys; in private construction, hardening is done manually.

Work on the installation of the finishing layer begins at the moment when the depth of footprints left by shoes on the concrete surface does not exceed 4 mm. The first stage consists in uniform spreading of 70% of the total amount of the hardening mixture. After the darkening of the topping, which will absorb moisture from the surface of the concrete, it is necessary to start grouting. This operation must be carried out with trowels very carefully, making sure that concrete base dense and able to withstand vibrations. Otherwise, water separation may occur in the concrete.

After finishing the first grout, you need to start the second in a perpendicular direction.

If topping is applied in difficult conditions, then the first grout is carried out with a half of the entire mass of the mixture, the second and third - with a fourth part each. All grouts are carried out at right angles to the previous one.

Hardening of edges, corners and other hard-to-reach places

Particularly susceptible to abrasion and wear are the corners and edges of the site. Therefore, their treatment with hardening topping should be carried out carefully and carefully.

The edges of the plots can be strengthened in one of the following ways:

- Immediately after leveling the laid concrete mix, it is necessary to manually spread the hardening mix along the edges in a strip 100 mm wide. Consumption of dry mixture - half a kilogram per linear meter.

- After leveling the concrete along the edges, a strip of mortar is removed to a depth of 10 mm. A hard mixture of topping with water is laid on this place. The hardener must be compacted until it is completely combined with the base.

IN hard-to-reach places the hardener is rubbed by hand with wooden or metal floats.

If the hardening mixture has hardened, then in no case should water be added, as this will lead to delamination of the topping from the concrete element.

The use of hardeners when concreting the yard will not cause any particular difficulties in working with them, provided that the rules set out in the instructions are observed. And you can see how the concreting of the yard is carried out, you can on the video:

As part of landscaping suburban area includes the laying of convenient paths, the arrangement of check-in and car parking spaces, floors in gazebos, for the installation of barbecue facilities and coverage in other places. A reliable solution is concreting the courtyard of a private house. This is an affordable and inexpensive option, the work can be done independently without the involvement of expensive specialists.

Advantages of concrete pavements

- solid structure of a flat concrete surface, allowing the arrival of a heavy large-sized vehicle;

- reduction of weed germination and the formation of coating pollution;

- the ability to pour concrete into the yard with your own hands;

- ease of maintenance of concrete, in summer it is enough to water from garden hoses, and in winter it is easy to clear snow drifts;

- ease of passage through the site in rainy weather;

- problem-free framing of any decorative elements on the street, flower beds, small fountains, benches, tables, etc.;

- environmental friendliness of the coating without emission harmful substances during operation;

- durability, if the yard is poured with concrete correctly, in compliance with the requirements building codes and rules.

Some features of independent work

Filling the yard with concrete

Scope of work:

- Site preparation with cleaning of interfering elements, uprooting of shrubs and removal of roots.

- Excavation to the depth of the fertile layer with the removal of weeds and their roots. Compaction of the base with vibrorammers. The evenness of the bottom is controlled using a level or laser levels.

- Laying geotextile with an overlap on the edges of the pit.

- Installation of a 15 cm gravel-sand cushion with subsequent compaction.

- Installation of formwork from edged boards around the perimeter of the site and at the locations of decorative elements.

- Reinforcement of the site with a finished road mesh or viscous from individual rods. The protective layer is made with thickened concrete crackers.

- Installation of beacons with alignment using a laser level or a long rule with a horizontal level.

- Laying of concrete mix with leveling on lighthouses, observance of necessary slopes and arrangement of expansion joints. Compaction of concrete using vibrating screeds or platform vibrators.

- The next day, pulling out beacons and sealing furrows. Surface ironing.

- Formwork dismantling.

- Curing concrete.

Asphalt or concrete, which is better in the yard?

Asphalt will last up to 10 years, concrete - ≥ 20 years. Concrete is more expensive than asphalt, but its greater durability and ease of maintenance will equalize costs in about 5 years. It should be borne in mind that asphalt sites have lower strength characteristics that cannot withstand the arrivals of heavy equipment. And most importantly - environmental friendliness of the coating. In summer, the asphalt heats up with the release of fumes harmful to human health.

Conclusion: preference should be given to concrete sites.