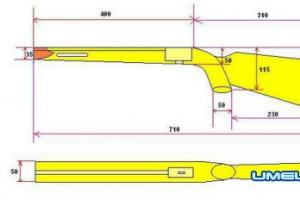

Fig. 99 tasks for graphic work 4. Practical and graphic work on drawing. Reinforcement task

- a) On the instructions of the teacher, build an axonometric projection of one of the details (Fig. 98). On the axonometric projection, apply the images of points A, B and C; label them. b) Answer the questions:

Rice. 98. Tasks for graphic work No. 4

- What types of parts are shown in the drawing?

- The combination of what geometric bodies formed each detail?

- Are there holes in the part? If so, what is the geometry of the hole?

- Find on each of the views all flat surfaces perpendicular to the frontal, and then to the horizontal projection planes.

- According to a visual representation of the details (Fig. 99), draw a drawing in the required number of views. Apply to all views and mark points A, B and C.

Rice. 99. Tasks for graphic work No. 4

§ 13. The procedure for constructing images in the drawings

13.1. A method for constructing images based on the analysis of the shape of an object. As you already know, most objects can be represented as a combination of geometric bodies. The investigator, in order to read and execute the drawings, you need to know. how these geometric bodies are depicted.

Now that you know how such geometric bodies are depicted in the drawing, and have learned how vertices, edges and faces are projected, it will be easier for you to read the drawings of objects.

Figure 100 shows a part of the machine - a counterweight. Let's analyze its shape. What geometric bodies known to you can be divided into? To answer this question, remember characteristics inherent in the images of these geometric bodies.

Rice. 100. Part projections

In Figure 101, a. one of them is highlighted in blue. What geometric body has such projections?

Projections in the form of rectangles are characteristic of a parallelepiped. Three projections and a visual image of the parallelepiped, highlighted in Figure 101, a in blue, are given in Figure 101, b.

In Figure 101, in in gray another geometric body is conventionally selected. What geometric body has such projections?

Rice. 101. Part shape analysis

You have met with such projections when considering images of a triangular prism. Three projections and a visual image of the prism, highlighted in gray in Figure 101, c, are given in Figure 101, d. Thus, the counterweight consists of a rectangular parallelepiped and a triangular prism.

But a part has been removed from the parallelepiped, the surface of which in Figure 101, e is conditionally highlighted in blue. What geometric body has such projections?

With projections in the form of a circle and two rectangles, you met when considering images of a cylinder. Therefore, the counterweight contains a cylinder-shaped hole, three projections and a visual representation of which are given in Figure 101. e.

Analysis of the shape of an object is necessary not only when reading, but also when making drawings. So, having determined the shape of which geometric bodies the parts of the counterweight shown in Figure 100 have, it is possible to establish an expedient sequence for constructing its drawing.

For example, a drawing of a counterweight is built like this:

- on all types, a parallelepiped is drawn, which is the base of the counterweight;

- a triangular prism is added to the parallelepiped;

- draw an element in the form of a cylinder. In the top and left views, it is shown with dashed lines, since the hole is invisible.

Draw a detail called a sleeve according to the description. It consists of a truncated cone and a regular quadrangular prism. The total length of the part is 60 mm. The diameter of one base of the cone is 30 mm, the other is 50 mm. The prism is attached to the larger base of the cone, which is located in the middle of its base measuring 50X50 mm. The height of the prism is 10 mm. A through cylindrical hole with a diameter of 20 mm was drilled along the axis of the bushing.

13.2. The sequence of building views on the detail drawing. Consider an example of constructing views of a part - a support (Fig. 102).

Rice. 102. Visual representation of the support

Before proceeding with the construction of images, it is necessary to clearly imagine the general initial geometric shape of the part (whether it will be a cube, a cylinder, a parallelepiped, or others). This form must be kept in mind when constructing views.

The general shape of the object shown in Figure 102 is a rectangular parallelepiped. It has rectangular cutouts and a cutout in the form of a triangular prism. Let's start depicting the part with its general shape - a parallelepiped (Fig. 103, a).

Rice. 103. The sequence of constructing views of the part

Projecting the parallelepiped on the planes V, H, W, we get rectangles on all three projection planes. On the frontal projection plane, the height and length of the part, i.e., dimensions 30 and 34, will be reflected. On the horizontal projection plane, the width and length of the part, i.e., dimensions 26 and 34. On the profile plane, the width and height, i. 26 and 30.

Each detail measurement is shown without distortion twice: height - on the frontal and profile planes, length - on the frontal and horizontal planes, width - on the horizontal and profile projection planes. However, you cannot apply the same dimension twice in a drawing.

All constructions will be done first with thin lines. Since the main view and the top view are symmetrical, they are marked with axes of symmetry.

Now we will show cutouts on the projections of the parallelepiped (Fig. 103, b). It is more expedient to show them first on the main view. To do this, set aside 12 mm to the left and right of the axis of symmetry and draw vertical lines through the points obtained. Then, at a distance of 14 mm from the upper edge of the part, draw segments of horizontal lines.

Let's build projections of these cutouts on other views. This can be done using communication lines. After that, in the top and left views, you need to show the segments that limit the projections of the cutouts.

In conclusion, the images are outlined with lines established by the standard, and dimensions are applied (Fig. 103, c).

- Name the sequence of actions that make up the process of constructing types of an object.

- What is the purpose of projective communication lines?

13.3. Construction of cutouts on geometric bodies. Figure 104 shows images of geometric bodies, the shape of which is complicated by various kinds of cutouts.

Rice. 104. Geometric bodies containing cutouts

Details of this form are widespread in technology. To draw or read their drawing, one must imagine the shape of the workpiece from which the part is obtained, and the shape of the cutout. Consider examples.

Example 1. Figure 105 shows a drawing of the gasket. What is the shape of the removed part? What was the shape of the piece?

Rice. 105. Gasket Shape Analysis

After analyzing the drawing of the gasket, we can conclude that it was obtained as a result of removing the fourth part of the cylinder from a rectangular parallelepiped (blank).

Example 2. Figure 106, a is a drawing of a plug. What is the form of its preparation? What resulted in the shape of the part?

Rice. 106. Building projections of a part with a cut

After analyzing the drawing, we can conclude that the part is made from a cylindrical billet. A notch is made in it, the shape of which is clear from Figure 106, b.

And how to build a cutout projection on the left view?

First, a rectangle is drawn - a view of the cylinder on the left, which is the original shape of the part. Then build the projection of the cutout. Its dimensions are known, therefore, points a", b" and a, b, which define the projections of the notch, can be considered as given.

The construction of profile projections a", b" of these points is shown by communication lines with arrows (Fig. 106, c).

Having set the shape of the cutout, it is easy to decide which lines in the view on the left should be outlined with solid thick main lines, which with dashed lines, and which should be deleted altogether.

- Look at the images in figure 107 and determine which shape of the parts are removed from the blanks to obtain details. Make technical drawings of these parts.

Rice. 107. Tasks for exercises

- Build the missing projections of points, lines and cutouts given by the teacher in the drawings you made earlier.

13.4. Construction of the third view. You will sometimes have to complete tasks in which you need to build a third one according to the two available types.

In Figure 108, you see an image of a bar with a cutout. Two views are given: front and top. It is required to build a view on the left. To do this, you must first imagine the shape of the depicted part.

Rice. 108. Drawing of a bar with a cutout

Comparing the views in the drawing, we conclude that the bar has the shape of a parallelepiped with a size of 10x35x20 mm. A cut is made in the parallelepiped rectangular shape, its size is 12x12x10 mm.

The view on the left, as you know, is placed at the same height as the main view to the right of it. We draw one horizontal line at the level of the lower base of the parallelepiped, and the other at the level of the upper base (Fig. 109, a). These lines limit the height of the view on the left. Draw a vertical line anywhere between them. It will be a projection of the rear face of the bar onto the profile projection plane. From it to the right, we set aside a segment equal to 20 mm, i.e., we limit the width of the bar, and draw another vertical line - the projection of the front face (Fig. 109, b).

Rice. 109. Construction of the third projection

Let us now show a cutout in the part in the left view. To do this, set aside to the left of the right vertical line, which is the projection of the front face of the bar, a segment of 12 mm and draw another vertical line (Fig. 109, c). After that, we delete all auxiliary construction lines and outline the drawing (Fig. 109, d).

The third projection can be built on the basis of the analysis of the geometric shape of the object. Let's see how it's done. In Figure 110, a two projections of the part are given. We need to build a third.

Rice. 110. Building a third projection from two data

Judging by these projections, the part is composed of a hexagonal prism, a parallelepiped and a cylinder. Mentally combining them into a single whole, imagine the shape of the part (Fig. 110, c).

We draw an auxiliary straight line on the drawing at an angle of 45 ° and proceed to the construction of the third projection. You know what the third projections of a hexagonal prism, a parallelepiped and a cylinder look like. We draw successively the third projection of each of these bodies, using communication lines and axes of symmetry (Fig. 110, b).

Note that in many cases it is not necessary to build a third projection on the drawing, since the rational execution of images involves the construction of only the necessary (minimum) number of views sufficient to identify the shape of the object. In this case, the construction of the third projection of the object is only an educational task.

- You are familiar with different ways construction of the third projection of the object. How do they differ from each other?

- What is the purpose of the constant line? How is it carried out?

- In the detail drawing (Fig. 111, a), the left view is not drawn - it does not show images of a semicircular cutout and a rectangular hole. On the instructions of the teacher, draw or transfer the drawing to tracing paper and complete it with the missing lines. What kind of lines (solid main or dashed) do you use for this purpose? Draw the missing lines also in figures 111, b, c, d.

Rice. 111. Tasks for drawing missing lines

- Redraw or transfer to tracing paper the data in Figure 112 of the projection and build profile projections of the details.

Rice. 112. Tasks for exercises

- Redraw or transfer to tracing paper the projections indicated to you in Figure 113 or 114 by the teacher. Build the missing projections in place of the question marks. Make technical drawings of the details.

Rice. 113. Tasks for exercises

Rice. 114. Tasks for exercises

2.1. The concept of ESKD standards. If every engineer or draftsman performed and designed the drawings in his own way, without observing uniform rules, then such drawings would not be understandable to others. To avoid this, the state standards of the Unified System for Design Documentation (ESKD) have been adopted and are in force in the USSR.

ESKD standards are regulatory documents that establish uniform rules for the implementation and execution of design documents in all industries. Design documents include drawings of parts, assembly drawings, diagrams, some text documents, etc.

Standards are set not only for design documents, but also for certain types of products manufactured by our enterprises. State standards (GOST) are mandatory for all enterprises and individuals.

Each standard is assigned its own number with the simultaneous indication of the year of its registration.

The standards are revised from time to time. Changes in standards are associated with the development of industry and the improvement of engineering graphics.

For the first time in our country, standards for drawings were introduced in 1928 under the name "Drawings for all types of mechanical engineering." Later they were replaced by new ones.

2.2. Formats. The main text of the drawing. Drawings and other design documents for industry and construction are performed on sheets of certain sizes.

For economical use of paper, ease of storing drawings and using them, the standard establishes certain sheet formats that are outlined with a thin line. At school, you will use a format whose sides are 297X210 mm. It is designated A4.

Each drawing must have a frame that limits its field (Fig. 18). The frame lines are solid thick main lines. They are carried out from above, to the right and from below at a distance of 5 mm from the outer frame, performed by a solid thin line along which the sheets are cut. On the left side - at a distance of 20 mm from it. This strip is left for filing drawings.

Rice. 18. Making an A4 sheet

In the drawings, the main inscription is placed in the lower right corner (see Fig. 18). Its form, dimensions and content are established by the standard. On educational school drawings, you will perform the main inscription in the form of a rectangle with sides of 22X145 mm (Fig. 19, a). A sample of the completed title block is shown in Figure 19, b.

Rice. 19. The main inscription of the training drawing

Production drawings, performed on A4 sheets, are placed only vertically, and the main inscription on them is only along the short side. In drawings of other formats, the title block can be placed along both the long and short sides.

As an exception, on A4 training drawings, the main inscription is allowed to be placed both along the long and along the short side of the sheet.

Before starting the drawing, the sheet is applied to the drawing board. To do this, attach it with one button, for example, in the upper left corner. Then a T-square is placed on the board and the upper edge of the sheet is placed parallel to its edge, as shown in Figure 20. Pressing a sheet of paper to the board, attach it with buttons, first in the lower right corner, and then in the other corners.

Rice. 20. Preparing the sheet for work

The frame and columns of the main inscription are made with a solid thick line.

- What are the dimensions of an A4 sheet? At what distance from the outer frame should the drawing frame lines be drawn? Where is the title block placed on the drawing? Name its dimensions. Consider Figure 19 and list what information is indicated in it.

2.3. Lines. When making drawings, lines of various thicknesses and styles are used. Each of them has its own purpose.

Rice. 21. Drawing lines

Figure 21 shows an image of a part called a roller. As you can see, the detail drawing contains different lines. In order for the image to be clear to everyone, the state standard establishes the style of lines and indicates their main purpose for all drawings of industry and construction. In the lessons of technical and service labor, you have already used various lines. Let's remember them.

In conclusion, it should be noted that the thickness of lines of the same type should be the same for all images in a given drawing.

Information about the lines of the drawing is given on the first flyleaf.

- What is the purpose of a solid thick main line?

- What is a dashed line? Where is it used? What is the thickness of this line?

- Where is a dash-dot thin line used in a drawing? What is its thickness?

- In what cases is a solid thin line used in a drawing? How thick should it be?

- Which line shows the fold line on the scan?

In Figure 23 you see a picture of the part. Various lines are marked on it with the numbers 1,2, etc. Make a table in your workbook according to this sample and fill it out.

Rice. 23. Task for exercises

Graphic Work No. 1

Prepare an A4 sheet of drawing paper. Draw the frame and columns of the title block according to the dimensions indicated in Figure 19. Draw different lines, as shown in Figure 24. You can also choose a different arrangement of line groups on the sheet.

Rice. 24. Task for graphic work No. 1

The main inscription can be placed both along the short and along the long side of the sheet.

2.4. Drawing fonts. Sizes of letters and numbers of the drawing font. All inscriptions on the drawings must be made in drawing font (Fig. 25). The style of letters and numbers of the drawing font is established by the standard. The standard defines the height and width of letters and numbers, the thickness of stroke lines, the spacing between letters, words, and lines.

Rice. 25. Inscriptions on drawings

An example of building one of the letters in the auxiliary grid is shown in Figure 26.

Rice. 26. An example of building a letter

The font can be both slanted (about 75°) and non-slanted.

The standard specifies the following font sizes: 1.8 (not recommended, but allowed); 2.5; 3.5; 5; 7; 10; 14; 20; 28; 40. The size (h) of the font is taken as the value determined by the height of uppercase (capital) letters in millimeters. The height of the letter is measured perpendicular to the base of the line. The lower elements of the letters D, C, U and the upper element of the letter Y are performed due to the spaces between the lines.

The thickness (d) of the font line is determined depending on the height of the font. It is equal to 0.1h;. The width (g) of the letter is chosen to be 0.6h or 6d. The width of the letters A, D, Zh, M, F, X, C, SH, W, b, Y, Yu is 1 or 2d more than this value (including the lower and upper elements), and the width of the letters Г, 3, С is less than d.

The height of the lowercase letters roughly matches the height of the next smaller font size. Thus, the height of lowercase letters of size 10 is 7, of size 7 is 5, and so on. The width of most lowercase letters is 5d. The width of the letters a, m, c, b is 6d, the width of the letters w, t, f, w, u, s, u is 7d, and the letters h, c are 4d.

The distance between letters and numbers in words is taken equal to 0.2h or 2d, between words and numbers -0.6h or 6d. The distance between the lower lines of the lines is taken equal to 1.7h or 17d.

The standard also establishes another type of font - type A, narrower than just considered.

The height of letters and numbers in pencil drawings must be at least 3.5 mm.

The outline of the Latin alphabet according to GOST is shown in Figure 27.

Rice. 27. Latin script

How to write in cursive font. It is necessary to draw up drawings with inscriptions carefully. Indistinctly made inscriptions or carelessly applied figures of different numbers can be misunderstood when reading the drawing.

To learn how to write beautifully in a drawing font, first a grid is drawn for each letter (Fig. 28). After mastering the skills of writing letters and numbers, you can only draw the top and bottom lines of the line.

Rice. 28. Examples of inscriptions in drawing font

The contours of the letters are outlined with thin lines. After making sure that the letters are written correctly, circle them with a soft pencil.

For the letters G, D, I, I, L, M, P, T, X, C, W, W, only two auxiliary lines can be drawn at a distance equal to their height A.

For letters B, C, E, N. R, U, H, b, Y, b. Between two horizontal lines, one more should be added in the middle, but with which their middle elements perform. And for the letters 3, O, F, Yu, four lines are drawn, where the middle lines indicate the boundaries of the fillets.

To quickly make inscriptions in a drawing font, various stencils are sometimes used. You will fill in the main inscription in font 3.5, the name of the drawing in font 7 or 5.

- What is the font size?

- What is the width of the capital letters?

- What is the height of lowercase letters of size 14? What is their width?

- Complete a few inscriptions in the workbook for the teacher's assignment. You can, for example, write your last name, first name, home address.

- Fill in the main inscription on the sheet of graphic work No. 1 with the following text: drew (surname), checked (name of the teacher), school, class, drawing No. 1, the name of the work "Lines".

2.5. How to measure. To determine the size of the depicted product or any part of it, dimensions are applied to the drawing. Dimensions are divided into linear and angular. Linear dimensions characterize the length, width, thickness, height, diameter or radius of the measured part of the product. The angular dimension characterizes the magnitude of the angle.

The linear dimensions in the drawings are indicated in millimeters, but the designation of the unit of measure is not applied. Angular dimensions are indicated in degrees, minutes and seconds with the designation of the unit of measurement.

The total number of dimensions in the drawing should be the smallest, but sufficient for the manufacture and control of the product.

The rules for sizing are set by the standard. Some of them you already know. Let's remind them.

1. Dimensions in the drawings are indicated by dimensional numbers and dimension lines. To do this, first draw extension lines perpendicular to the segment, the size of which is indicated (Fig. 29, a). Then, at a distance of at least 10 mm from the contour of the part, a dimension line parallel to it is drawn. The dimension line is limited on both sides by arrows. What should be the arrow is shown in Figure 29, b. The extension lines extend beyond the ends of the arrows of the dimension line by 1...5 mm. Extension and dimension lines are drawn with a solid thin line. Above the dimension line, closer to its middle, a dimension number is applied.

Rice. 29. Drawing linear dimensions

2. If there are several dimension lines parallel to each other in the drawing, then a smaller size is applied closer to the image. So, in Figure 29, first the size 5 is applied, and then 26, so that the extension and dimension lines in the drawing do not intersect. The distance between parallel dimension lines must be at least 7 mm.

3. To indicate the diameter, a special sign is applied in front of the dimension number - a circle crossed out with a line (Fig. 30). If the dimension number does not fit inside the circle, it is taken out of the circle, as shown in Figure 30, c and d. The same is done when applying the size of a straight segment (see Fig. 29, c).

Rice. 30. Applying the size of circles

4. To designate the radius, a capital Latin letter R is written in front of the dimension number (Fig. 31, a). The dimension line to indicate the radius is drawn, as a rule, from the center of the arc and ends with an arrow on one side, resting on the point of the circular arc.

Rice. 31. Dimensioning Arcs and Angle

5. When specifying the size of the corner, the dimension line is drawn in the form of an arc of a circle with the center at the apex of the corner (Fig. 31, b).

6. Before the dimension number indicating the side of the square element, a "square" sign is applied (Fig. 32). In this case, the height of the sign is equal to the height of the digits.

Rice. 32. Drawing the size of the square

7. If the dimension line is located vertically or obliquely, then the dimension numbers are arranged as shown in Figures 29, c; thirty; 31.

8. If the part has several identical elements, then it is recommended to put the size of only one of them on the drawing, indicating the quantity. For example, the entry in the drawing “3 holes. 0 10" means that the part has three identical holes with a diameter of 10 mm.

9. When depicting flat parts in one projection, the thickness of the part is indicated, as shown in Figure 29, c. Please note that in front of the dimension number indicating the thickness of the part, there is a small Latin letter 5.

10. It is allowed to indicate the length of the part in a similar way (Fig. 33), but in this case they write a Latin letter before the size number l.

Rice. 33. Drawing the size of the length of the part

- In what units are linear dimensions expressed on engineering drawings?

- How thick should extension and dimension lines be?

- What distance is left between the image outline and the dimension lines? between dimension lines?

- How are dimensional numbers applied on inclined dimension lines?

- What signs and letters are applied before the size number when indicating the size of diameters and radii?

Rice. 34. Task for exercises

- Redraw in a workbook, maintaining proportions, the image of the part given in Figure 34, increasing it by 2 times. Apply required dimensions, specify the thickness of the part (it is 4 mm).

- Draw circles in the workbook with diameters of 40, 30, 20 and 10 mm. Enter their dimensions. Draw circular arcs with radii of 40, 30, 20 and 10 mm and dimension.

2.6. Scales. In practice, it is necessary to make images of very large parts, for example, parts of an aircraft, a ship, a car, and very small ones - parts of a clock mechanism, some instruments, etc. Images of large parts may not fit on sheets of a standard format. Small parts, which are barely visible to the naked eye, cannot be drawn in full size with the available drawing tools. Therefore, when drawing large parts, their image is reduced, and small ones are increased compared to the actual dimensions.

Scale is the ratio of the linear dimensions of the image of an object to the actual. The scale of the images and their designation in the drawings sets the standard.

Reduction scale-1:2; 1:2.5; 1:4; 1:5; 1:10 etc.

Natural size-1:1.

Magnification scale-2:1; 2.5:1; 4:1; 5:1; 10:1 etc.

The most desirable scale is 1:1. In this case, you do not need to recalculate the dimensions when rendering the image.

Scales are written as follows: M1:1; M1:2; M5:1, etc. If the scale is indicated on the drawing in the main inscription specially designed for this, then the letter M is not written before the scale designation.

It should be remembered that, no matter what scale the image is made, the dimensions in the drawing are applied to the actual ones, that is, those that the part should have in kind (Fig. 35).

The angular dimensions do not change when the image is reduced or enlarged.

- What is the scale for?

- What is called scale?

- What scales of increase are known to you, established by the standard? What scale of reduction do you know?

- What do the entries mean: М1:5; M1:1; M10:1?

Rice. 35. Drawing gasket, made in different scales

Graphic Work No. 2

Drawing "flat part"

Make drawings of the “Gasket” parts according to the existing halves of the images separated by the axis of symmetry (Fig. 36). Apply dimensions, indicate the thickness of the part (5 mm).

Do the work on an A4 sheet. Image scale 2:1.

Instructions for work. Figure 36 shows only half of the part image. You need to imagine how the part will look like in full, keeping in mind the symmetry, sketch its image on a separate sheet. Then you should proceed to the execution of the drawing.

A frame is drawn on an A4 sheet and space is allocated for the main inscription (22X145 mm). The center of the working field of the drawing is determined and the image is built from it.

First, axes of symmetry are drawn, a rectangle is built with thin lines, corresponding to the general shape of the part. After that, images of rectangular elements of the part are marked.

Rice. 36. Tasks for graphic work No. 2

Having determined the position of the centers of the circle and the semicircle, they are carried out. Apply the dimensions of the elements and overall, i.e., the largest in length and height, the dimensions of the part, indicate its thickness.

Outline the drawing with lines established by the standard: first - circles, then - horizontal and vertical lines. Fill in the main inscription and check the drawing.

The task “Complex cuts”

Special purpose

1. Studying the rules for making cuts in orthogonal projections established in accordance with GOST 2.305-68 (p. 3, p. 4).

2. Consolidation of skills in constructing sections of the surface by a plane.

The task is carried out on A3 format.

On the sheet, perform complex cuts provided for by the task. When performing a step cut, you need to redraw two views, then replacing one of them with a step cut. Apply dimensions. When performing a broken section, it is also necessary to redraw two views, then replace one of them with a broken section and apply dimensions. The recommended building scale is 1:1.

Task Instructions

1. Section of a surface by a plane.

2. Sections and sections, GOST 2.305-68 (p. 3, p. 4).

3. Rules for applying dimensions to drawings, GOST 2. 307-68.

In accordance with the examples of the task, shown in Fig. 2.2, and the initial data, complete your version of the task in thin lines. For each task option (from 1 to 30), the number of which is indicated in the upper left corner of the page, the initial data are given: for a stepped section, for a broken line section. After checking each drawing by the teacher, it is necessary to finish the drawings using standard line types. Fill in the main inscription, the name of the task and the scale.

Order of execution

- build two types of parts on A3 format Frame (from the task);

- build a view on the left;

- according to the given position of the secant planes, construct a stepped section in place of the front view;

- according to the given position of the secant planes, construct a stepped section in place of the left view;

- fill in the title block.

Consider the implementation of this task on the example shown in Figure 2.1.

Figure 2.2. for clarity, a three-dimensional model of the task detail is presented.

Figure 2.1 - An example of a task

Figure 2.2 - An example of a task. 3D model

- Examine the design of the part:

- the base of the part is a part of a cylinder with a diameter of 140 mm with cutouts;

- in the central part there is a hexagonal prism with a through hole.

- The main image is a complex section, the secant planes of which pass through the internal structural elements of the part.

Since the cut stepped, then to build it, it is necessary to mentally cut the part with two indicated planes (section A-A of the task, Figure 2.1 and 2.3) and combine them by parallel transfer into one.

After that, project onto a projection plane parallel to the cutting planes (Figure 2.4).

Figure 2.3 - Section A-A of the part model

Figure 2.4 - Section A-A in the detail drawing

- In place of the view on the left, make a stepped section B-B (Figure 2.5, 2.6). Since the position of the cutting planes is indicated in the top view, the result of the cut B–B will be rotated by 90°. When the section is located in the place of the view on the left, it is necessary to indicate the sign “rotated” - above the image.

Figure 2.5 - Section B–B of the part model

Figure 2.6 - Section B-B in the detail drawing

- Draw centerlines. Apply dimensions according to GOST 2.307-68.

Don't forget the size grouping rule!

An example of this task is shown in Figure 2.7.

2.3 Implementation example

Figure 2.7 - An example of performing control work No. 3 "Construction of a stepped section"

broken cut

- and A3 format to build two kinds of parts Frame (from the task);

- according to the given position of the secant planes, construct a broken section in place of the front view;

- build, if necessary, a left view;

- apply dimensions according to the rules for applying dimensions (GOST 2.307-2011);

- fill in the title block.

Consider the implementation of this task on the example shown in Figure 3.1.

In Figure 3.2. for clarity, a three-dimensional model of the task detail is presented.

Figure 3.1 - An example of a task

Figure 3.2 - An example of a task. 3D model

- Examine the design of the part:

- the base of the part is a segment of a cylinder with a radius of 95 mm with cutouts;

- in the central part - a cylinder with a diameter of 44 mm with a through hole.

- The main image is a complex section, the secant planes of which pass through all the internal structural elements of the part.

Exercise

Graphic work is performed on a sheet of graph paper or squared paper in A4 or A3 format according to a full-scale model issued by the teacher. Code in the main inscription: D.IG.–– 05.01.07, where D.IG. – design, engineering graphics; 05 - work number, 01 - version number, 07 - sheet number (after the title page).

An example of the task execution is given in Figure 41.

2. Determine the number of images (views, sections, sections, detail elements, given that their number should be minimal, but giving a complete picture of this detail).

3. Select on a sheet of paper the appropriate area for each image (while remembering that the area occupied by the images must be at least ¾ of the drawing field).

4. Draw images in thin lines.

5. Apply extension and dimension lines.

6. Measure the item.

7. Put down the required dimensions.

8. Fill in the main inscription and complete all other inscriptions on the drawing. When filling out the main inscription, it is necessary to indicate what material the part is made of. Designations of materials according to GOST in Appendix G.

9. Circle the visible contour lines.

Figure 41 - Sample work performance No. 5.

2.4 Graphic work No. 6 "Gear wheel"

Exercise

Graphic work is carried out on an A4 sheet according to a full-scale model issued by the teacher. When performing work, comply with the requirements of GOST 2.403-75 "Rules for the execution of drawings of spur gears". Code in the main inscription: D.IG.–– 06.01.08, where D.IG. – design, engineering graphics; 06 - work number, 01 - version number, 08 - sheet number (after the title page).

1. Guided by GOST 2.305-68, you need to choose the format of the drawing yourself.

2. Determine the number of images (full frontal section and instead of the view on the left, only the image of the hole for the shaft with the keyway).

3. Measure the item.

4. Calculate gear parameters.

5. Select on a sheet of paper the appropriate area for each image (while remembering that the area occupied by the images must be at least ¾ of the drawing field).

6. Draw images in thin lines.

7. Apply extension and dimension lines.

8. Put down the required dimensions.

9. Fill in the main inscription in form 1 (Appendix B) and complete all other inscriptions on the drawing;

10. Circle the visible contour lines.

On fig. 42 shows an example of a working drawing of a spur gear. The table of parameters for educational purposes is given in abbreviated form.

The table contains the following data:

module m;

number of teeth z;

dividing circle diameter.

Figure 42 - An example of the execution of the graphic work "Sketch of a gear wheel"

2.5 Graphic work No. 7 "Detailing of the assembly drawing".

Exercise

An example of the work performed is shown in Figure 43. Each task option consists of an assembly drawing, a specification for it, a description of the assembly unit and the name of the part included in the assembly unit for which it is necessary to perform the working drawing. Take the image of the assembly drawing for your option from Appendix D.

In the assignment, it is necessary to: make a working drawing of the specified part (sheet A3 or A4), set dimensions, perform the frontal diameter of the part (A3 or A4). Code in the main inscription: D.IG.–– 07.01.09.005, where D.IG. – design, engineering graphics; 07 - work number, 01 - option number, 09 - sheet number (after the title page), 005 - part number according to the specification.

Work Instructions

1. Reading the description of the depicted product and the drawing, establish the purpose, device and principle of operation of the product, types of connections used, understand the interaction of parts, determine the order of assembly and disassembly of the product. Present the shape of the part to be drawn.

2. Select the number of images (views, cuts, sections) of the part. The main image - on the frontal projection plane - should give the most complete idea of the shape and size of the depicted object.

3. Find out from the main inscription the scale of the depicted assembly unit. Drawings reproduced for educational purposes may not be to scale.

4. Select the scale for the part to be drawn. Small details are usually drawn larger, on a magnification scale. At the same time, keep in mind that you need to leave about the same amount of space on the dimension lines as the images take up.

5. Determine the required number of images of the parts to be performed, outline the main view and the necessary cuts. The location of the images of these parts on the working drawings should not necessarily be the same as on the assembly drawing. All views, sections, sections and other images are performed in accordance with GOST 2.305 - 68. Remember that the assembly drawing provides for some simplifications, such elements as chamfers and grooves are not shown on it. They must be shown on the working drawing. The dimensions of the grooves are taken from Appendix E. For very small parts of the part that require explanation, it is necessary to make a remote element.

6. Draw the required drawing with thin lines.

7. Apply dimensions.

8. Carefully review the completed drawing and carefully trace the lines of the visible contour with a thickness of 0.8 to 1.0 mm; lines of an invisible contour with a thickness of 0.4 to 0.5 mm; axial, remote, dimensional - from 0.2 to 0.3 mm (GOST 2.303-68).

9. Fill in the main inscription with a drawing font in form 1 (appendix B).

Figure 43 - Sample work performance No. 7

Introduction to the subject of drawing

The history of the emergence of graphic methods of images and drawing

Drawings in Rus' were made by "drawers", a mention of which can be found in the "Pushkar order" of Ivan IV.

Other images - drawings, were a view of the structure "from a bird's eye view"

At the end of the 12th century in Russia, large-scale images are introduced and dimensions are affixed. In the 18th century, Russian draftsmen and Tsar Peter I himself made drawings using the method of rectangular projections (the founder of the method is the French mathematician and engineer Gaspard Monge). By order of Peter I, the teaching of drawing was introduced in all technical educational institutions.

The entire history of the development of the drawing is inextricably linked with technical progress. At present, the drawing has become the main document of business communication in science, technology, production, design, and construction.

It is impossible to create and check a machine drawing without knowing the basics of the graphic language. Whom you will meet while studying the subject "Drawing"

Varieties of graphic images

Exercise: sign the names of the images.

The concept of GOSTs. Formats. Frame. Drawing lines.

Exercise 1

Graphic work No. 1

"Formats. Frame. Drawing lines»

Work examples

Test tasks for graphic work No. 1

Option number 1.

1. What designation according to GOST has a format of 210x297:

a) A1; b) A2; c) A4?

2. What is the thickness of the dash-dotted line if the solid main thick line in the drawing is 0.8 mm:

a) 1mm: b) 0.8 mm: c) 0.3 mm?

______________________________________________________________

Option number 2.

Choose and underline the correct answers to the questions.

1. Where is the main inscription located on the drawing:

a) in the lower left corner; b) in the lower right corner; c) in the upper right corner?

2. How much should the axial and center lines protrude beyond the image contour:

a) 3…5 mm; b) 5…10 mm4 c) 10…15 mm?

Option number 3.

Choose and underline the correct answers to the questions.

1. What arrangement of the A4 format is allowed by GOST:

A) vertical b) horizontal; c) vertical and horizontal?

2. . What is the thickness of a solid thin line if the solid main thick line in the drawing is 1 mm:

a) 0.3 mm: b) 0.8 mm: c) 0.5 mm?

Option number 4.

Choose and underline the correct answers to the questions.

1. At what distance from the edges of the sheet is the drawing frame drawn:

a) left, top, right and bottom - 5 mm each; b) left, top and bottom - 10 mm each, right - 25 mm; c) left - 20 mm, top, right and bottom - 5 mm each?

2. What type of line are axial and center lines in the drawings:

a) a solid thin line; b) dash-dotted line; c) dashed line?

Option number 5.

Choose and underline the correct answers to the questions.

1. What are the dimensions according to GOST in the A4 format:

a) 297x210 mm; b) 297x420 mm; c) 594x841 mm?

2. Depending on which line the line thicknesses of the drawing are selected:

a) dash-dotted line; b) a solid thin line; c) a solid main thick line?

Fonts (GOST 2304-81)

Font types:

Font sizes:

Practical tasks:

Calculations of parameters of drawing fonts

Test tasks

Option number 1.

Choose and underline the correct answers to the questions.

What value is taken for the font size:

a) the height of a lowercase letter; b) the height of the capital letter; c) the height of the gaps between the lines?

Option number 2.

Choose and underline the correct answers to the questions.

What is the height of the capital letter of rift #5:

a) 10 mm; b) 7 mm; c) 5 mm; d) 3.5 mm?

Option number 3.

Choose and underline the correct answers to the questions.

What is the height of lowercase letters with protruding elements c, e, b, r, f:

a) the height of the capital letter; b) the height of the lowercase letter; c) greater than the height of a capital letter?

Option number 4.

Choose and underline the correct answers to the questions.

Is there a difference between uppercase and lowercase letters? A, E, T, G, I:

a) are different b) do not differ; c) differ in the spelling of individual elements?

Option number 5.

Choose and underline the correct answers to the questions.

What does the height of the figures of the drawing font correspond to:

a) the height of the lowercase letter; b) the height of the capital letter; c) half the height of a capital letter?

Graphic Work No. 2

"Drawing of a flat part"

Cards - tasks

1 option

Option 2

3 option

4 option

Geometric constructions

Division of a circle into 5 and 10 parts

Dividing a circle into 4 and 8 parts

Division of a circle into 3, 6 and 12 parts

Dividing a segment into 9 parts

Fixing the material

According to the types, build a third. Scale 1:1

Option number 1

Option number 2

Option number 3

Option number 4

Fixing the material

Write your answers in your workbook:

Option number 1

Option number 2

Practical work No. 3

"Modeling by drawing".

Instructions for work

To make a model out of cardboard, first cut it out. Determine the dimensions of the workpiece according to the image of the part (Fig. 58). Mark (outline) cutouts. Cut them along the outlined outline. Remove the cut out parts and bend the model according to the drawing. To prevent the cardboard from straightening after bending, draw a line on the outside of the bend with some sharp object.

Wire for modeling must be used soft, of arbitrary length (10 - 20 mm).

Fixing the material

Option #1 Option #2

Fixing the material

In the workbook, draw a part drawing in 3 views. Apply dimensions.

Option #3 Option #4

Fixing the material

Card work

Fixing the material

Use colored pencils to complete the task on the card.

Amount (build-up)

clipping

Reinforcement task

Oval -

Algorithm for constructing an oval

1. Let's build an isometric projection of a square - a rhombus ABCD

2. Denote the points of intersection of the circle with the square 1 2 3 4

3. Draw a straight line from the top of the rhombus (D) to point 4 (3). We get the segment D4, which will be equal to the radius of the arc R.

4. Let's draw an arc that will connect points 3 and 4.

5. At the intersection of the segment B2 and AC, we get the point O1.

At the intersection of the segment D4 and AC, we get the point O2.

6. From the obtained centers O1 and O2 we draw arcs R1, which will connect points 2 and 3, 4 and 1.

Fixing the material

Perform a technical drawing of the part, two views of which are given in fig. 62

Graphic work No. 9

Detail sketch and technical drawing

1. What is called sketch?

Fixing the material

Tasks for exercises

Practical work No. 7

"Reading drawings"

Graphic dictation

"Drawing and technical drawing of the part according to the verbal description"

Option number 1

Frame is a combination of two parallelepipeds, of which the smaller one is placed with a large base in the center of the upper base of the other parallelepiped. A through stepped hole passes vertically through the centers of the parallelepipeds.

The total height of the part is 30 mm.

The height of the lower parallelepiped is 10 mm, the length is 70 mm, and the width is 50 mm.

The second parallelepiped is 50 mm long and 40 mm wide.

The diameter of the bottom step of the hole is 35 mm, the height is 10 mm; the diameter of the second stage is 20 mm.

Note:

Option number 2

Support is a rectangular parallelepiped, to the left (smallest) side of which is attached a half-cylinder, which has a common lower base with the parallelepiped. In the center of the upper (largest) face of the parallelepiped, along its long side, there is a prismatic groove. At the base of the part is through hole prismatic shape. Its axis coincides in the top view with the axis of the groove.

The height of the parallelepiped is 30 mm, the length is 65 mm, and the width is 40 mm.

Semi-cylinder height 15 mm, base R 20 mm.

The width of the prismatic groove is 20 mm, the depth is 15 mm.

Hole width 10 mm, length 60 mm. There is a hole at a distance of 15 mm from the right side of the support.

Note: when applying dimensions, consider the part as a whole.

Option number 3

Frame is a combination of a square prism and a truncated cone, which stands with a large base in the center of the upper base of the prism. A through stepped hole passes along the axis of the cone.

The total height of the part is 65 mm.

The height of the prism is 15 mm, the size of the sides of the base is 70x70 mm.

Cone height 50 mm, bottom base Ǿ 50 mm, top base Ǿ 30 mm.

The diameter of the lower part of the hole is 25 mm, the height is 40 mm.

The diameter of the upper part of the hole is 15 mm.

Note: when applying dimensions, consider the part as a whole.

Option number 4

Sleeve is a combination of two cylinders with a stepped through hole that runs along the axis of the part.

The total height of the part is 60 mm.

Height of lower cylinder 15 mm, base Ǿ 70 mm.

Second cylinder base Ǿ 45 mm.

Bottom hole Ǿ 50 mm, height 8 mm.

Upper part of hole Ǿ 30 mm.

Note: when applying dimensions, consider the part as a whole.

Option number 5

Base is a parallelepiped. In the center of the upper (largest) face of the parallelepiped, along its long side, there is a prismatic groove. There are two through cylindrical holes in the groove. The centers of the holes are spaced from the ends of the part at a distance of 25 mm.

The height of the parallelepiped is 30 mm, the length is 100 mm, and the width is 50 mm.

Groove depth 15 mm, width 30 mm.

Hole diameters 20 mm.

Note: when applying dimensions, consider the part as a whole.

Option number 6

Frame It is a cube, along the vertical axis of which there is a through hole: semi-conical at the top, and then turning into a stepped cylindrical one.

Cube edge 60 mm.

Semi-conical hole depth 35 mm, top base Ǿ 40 mm, bottom base Ǿ 20 mm.

The height of the bottom step of the hole is 20 mm, the base is Ǿ 50 mm. The diameter of the middle part of the hole is 20 mm.

Note: when applying dimensions, consider the part as a whole.

Option number 7

Support is a combination of a parallelepiped and a truncated cone. The large base of the cone is placed in the center of the upper base of the parallelepiped. Two prismatic cutouts run along the center of the smaller side faces of the parallelepiped. A cylindrical through hole Ǿ 15 mm was drilled along the axis of the cone.

The total height of the part is 60 mm.

The height of the parallelepiped is 15 mm, the length is 90 mm, and the width is 55 mm.

The cone base diameters are 40 mm (lower) and 30 mm (upper).

The length of the prismatic cutout is 20 mm, the width is 10 mm.

Note: when applying dimensions, consider the part as a whole.

Option number 8

Frame is a hollow rectangular parallelepiped. In the center of the upper and lower base of the case there are two conical lugs. A cylindrical through hole Ǿ 10 mm passes through the centers of the tides.

The total height of the part is 59 mm.

The height of the parallelepiped is 45 mm, the length is 90 mm, and the width is 40 mm. The thickness of the walls of the parallelepiped is 10 mm.

Cone height 7 mm, base Ǿ 30 mm and Ǿ 20 mm.

Note: when applying dimensions, consider the part as a whole.

Option number 9

Support is a combination of two cylinders with one common axle. A through hole runs along the axis: on top of a prismatic shape with a square base, and then a cylindrical shape.

The total height of the part is 50 mm.

Height of lower cylinder 10 mm, base Ǿ 70 mm. The base diameter of the second cylinder is 30 mm.

The height of the cylindrical hole is 25 mm, the base is Ǿ 24 mm.

The side of the base of the prism hole is 10 mm.

Note: when applying dimensions, consider the part as a whole.

Graphic work No. 11

"Drawing and visual representation of the part"

According to the axonometric projection, build a drawing of the part in the required number of views on a scale of 1: 1. Apply dimensions.

Graphic work No. 10

"Part sketch with construction elements"

Make a drawing of the part that has the parts removed according to the markup. The direction of projection for building the main view is indicated by an arrow.

Graphic work No. 8

"Drawing of a part with the transformation of its shape"

General concept on shape transformation. Linking a drawing to a markup

Graphic work

Making a drawing of an object in three views with the transformation of its shape (by removing part of the object)

Draw a technical drawing of the part by making notches of the same shape and size in the same place instead of the protrusions marked with arrows.

Task for logical thinking

Topic "Design drawings"

Crossword "Projection"

1. The point from which the projecting rays emanate during central projection.

2. What is obtained as a result of modeling.

3. Face of a cube.

4. Image resulting from projection.

5. In this axonometric projection, the axes are located at an angle of 120 ° to each other.

6. In Greek, this word means "double dimension."

7. Side view of the face, object.

8. Curve, isometric projection of a circle.

9. The image on the profile plane of projections is a view ...

Rebus on the topic "View"

Rebus

Crossword "Axonometry"

Vertically:

1. Translated from French, “front view”.

2. The concept in drawing on what the projection of a point or object is obtained.

3. The border between the halves of a symmetrical part in the drawing.

4. Geometric body.

5. Drawing tool.

6. Translated from Latin"throw, throw forward."

7. Geometric body.

8. The science of graphic images.

9. Unit of measure.

10. Translated from Greek"double dimension".

11. Translated from French, "side view."

12. In the drawing, “she” is thick, thin, wavy, etc.

Technical Dictionary of Drawing

| Term | Definition of a term or concept | |

| Axonometry | ||

| Algorithm | ||

| Analysis of the geometric shape of an object | ||

| Boss | ||

| Burtik | ||

| Shaft | ||

| Vertex | ||

| View | ||

| Main view | ||

| Additional type | ||

| view local | ||

| Screw | ||

| Sleeve | ||

| Dimension | ||

| screw | ||

| Fillet | ||

| geometric body | ||

| Horizontal | ||

| cooking | ||

| edge | ||

| Division of a circle | ||

| Division of the segment | ||

| Diameter | ||

| ESKD | ||

| Drawing tools | ||

| Tracing paper | ||

| Pencil | ||

| Drawing layout | ||

| Construction | ||

| Circuit | ||

| Cone | ||

| curved curves | ||

| Circular curves | ||

| Pattern | ||

| Rulers | ||

| Line - callout | ||

| Extended line | ||

| transition line | ||

| Dimensional line | ||

| Solid line | ||

| Dashed line | ||

| dash-dotted line | ||

| Lyska | ||

| Scale | ||

| Monge method | ||

| Polyhedron | ||

| Polygon | ||

| Modeling | ||

| Main inscription | ||

| Dimensioning | ||

| Drawing stroke | ||

| cliff | ||

| Oval | ||

| Ovoid | ||

| Circle | ||

| Circle in axonometric projection | ||

| Ornament | ||

| axonometric axes | ||

| Axis of rotation | ||

| Projection axis | ||

| Axis of symmetry | ||

| Hole | ||

| Groove | ||

| Keyway | ||

| Parallelepiped | ||

| Pyramid | ||

| Projection plane | ||

| Prism | ||

| Axonometric projections | ||

| Projection | ||

| Projection isometric rectangular | ||

| Projection frontal dimetric oblique | ||

| projection | ||

| groove | ||

| Scan | ||

| Size | ||

| Overall dimensions | ||

| Structural dimensions | ||

| Dimensions coordinating | ||

| Part feature dimensions | ||

| Gap | ||

| Drawing frame | ||

| Edge | ||

| Technical drawing | ||

| Symmetry | ||

| Pairing | ||

| Standard | ||

| Standardization | ||

| Arrows | ||

| Scheme | ||

| Thor | ||

| Pairing point | ||

| Protractor | ||

| squares | ||

| Simplifications and Conventions | ||

| Chamfer | ||

| Drawing formats | ||

| Frontal | ||

| projection center | ||

| Pairing Center | ||

| Cylinder | ||

| Compass | ||

| Drawing | ||

| Working drawing | ||

| Drawing | ||

| Dimensional number | ||

| Reading a drawing | ||

| Washer | ||

| Ball | ||

| Slot | ||

| Schaffing | ||

| Font | ||

| Hatching Axonometric hatching | ||

| Ellipse | ||

| Sketch | ||

Workbook

Practical and graphic works for drawing

The notebook was developed by a teacher of the highest category of drawing and fine arts Nesterova Anna Aleksandrovna, teacher of MBOU "Secondary School No. 1 of Lensk"

Introduction to the subject of drawing

Materials, accessories, drawing tools.