Indirect heating boiler: device, principle of operation and connection diagrams. What is an indirect heating boiler and how does it work Scheme with two circulation pumps

To arrange supplies hot water operating from the heating system, put a double-circuit boiler. Its disadvantage is low productivity. Hot water is only enough for washing hands or dishes. For comfortable bathing, it is better to install an indirect heating boiler, the advantage of which is a storage tank.

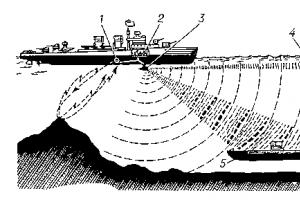

The basic principle of operation of an indirect heating boiler is to circulate the coolant through a heat exchanger connected to the heating system. The hot liquid is pumped by the pump. The internal circuit of the boiler is enclosed in a storage tank, where the water coming from the water supply cold water heats up from the energy of the coolant.

The circulation of the heating system has a vicious circle. Having given up energy, the coolant returns to the boiler through the pipes. The cycle is repeated while the pump and boiler are running. The rate of water heating inside the storage tank depends on the thickness of the coil pipe.

Design features

To better understand the work, it is necessary to study the device of the indirect heating device and understand how it differs from its counterparts.

The water heater is designed for indoor and outdoor heating systems. open type. The main difference is the energy source. If gas water heater works from bottled or main gas, and electrical appliance from the heating element, then the internal circuit of the indirect heating boiler consists of a coil. The coolant is the source of energy. The coil is equipped with an inlet and outlet for connection to the heating system.

There are bivalent water heaters with two heat exchangers, where a heat carrier is supplied to one coil from the heating system, and heat is supplied to the other circuit from the solar system or heat pump. If desired, the coils can be combined with fittings. It will turn out an indirect heating water heater with one circuit.

The heat exchanger is enclosed inside the storage tank, where the indirect heating of the water takes place. To connect to the water supply, the tank is similarly equipped with an inlet and outlet pipe. The shape of the storage tank is usually a cylinder, but there are rectangular models. So that the water inside the tank does not quickly cool down, it was enclosed in a decorative case, and the space between them was filled with thermal insulation.

A magnesium or titanium anode protects against scale formation. The heating element is installed inside the storage tank. The anode protects the metal parts of the boiler from galvanic corrosion and also reduces water hardness.

A thermostat is a regulator with which to reduce or increase the flow of coolant into the heat exchanger. The mechanism allows you to adjust the temperature of water heating.

When choosing a boiler for home use, it is better to give preference to a model where a heating element is additionally provided. The device combines indirect and electric water heater. The heater allows you to heat water in the summer when the heating system is not working. To regulate the heating of water from electricity, an additional thermostat and automation are installed.

Varieties

Most often, an indirect heating boiler with a coil is found on sale. However, there are models assembled according to the "tank in the tank" system. The principle of operation remained unchanged, only instead of a coil, an additional capacity acts as a heat exchanger. The advantage of the tank-in-tank system is the larger heating area. To connect the heating system pipe to the tank, an inlet and outlet pipe is similarly provided.

By type of installation, indirect water heaters are:

- Wall models are limited to a storage tank of up to 200 liters. The water heater is hung on steel brackets. The main requirement is a solid wall. A hollow plasterboard partition will not withstand a water tank.

- The floor water heater is designed for a large capacity. Household models are usually produced with a storage capacity of 250-300 liters. The floor boiler for industrial use can hold more than 1000 liters of water. Due to the large dimensions, a separate room is allocated for the water heater.

According to the type of tank location, an indirect boiler is:

- Horizontal models are roomy. It is more convenient to maintain the water level, but the water heater takes up a lot of space.

- Vertical models are smaller. The advantage of a water heater is its compactness and saving usable room space.

According to the material of manufacture of the storage tank, boilers are of three types:

- All cheap models are equipped with an enameled steel tank. After a couple of years, the protective layer is broken and a leak appears.

- Glass-ceramic tanks are one step higher in quality. The service life is increased, but they are also more expensive.

- Stainless steel tank is expensive. However, the service life is unlimited. The water heater will last for many years, if you do not come across a low-quality fake.

A variety of indirect water heaters allows the consumer to choose the optimal model in terms of shape, cost, and capacity.

Positive and negative characteristics

Considering the pros and cons of indirect water heaters, we must dwell on the main advantage - energy savings. You will have to pay separately for the gas and electric boiler. The indirect water heater receives energy free of charge from a working heating system.

Other benefits stand out:

- Long service life. The heating of the heat exchanger does not form solid accumulations. Scale appears during the operation of the heating element, but it is not turned on all year round, but only in summer.

- A water heater with two heat exchangers or a tank-in-tank system is characterized by high performance.

- The model with an additionally installed heating element combines two important parameters: efficiency in winter, efficiency in summer.

- Having welding experience, an indirect water heater can be made independently.

The downside is the complexity and high cost of installation. The first heating of the container takes a long time, but then the water temperature is constantly maintained. In the absence of heating elements in the summer it is impossible to get hot water.

How to choose an indirect heating boiler

Do right choice a suitable indirect heating boiler model is a difficult task for a beginner. However, there is nothing overwhelming here, you just need to take into account a few important nuances:

- When choosing a water heater with indirect heating for an apartment or a private house, the first step is to determine the optimal volume of the storage tank. To hot water enough for all family members, they calculate taking into account the approximate consumption of 100 liters per day by one person.

- An indirect water heating boiler is economically beneficial for a family of four or more people. With this number of people, the approximate consumption of hot water is 1.5 l / min.

- Paying attention to the volume of the tank, take into account the heating time. Large capacity will take longer to heat up. It may be worth giving preference to a model with two heat exchangers or a tank-in-tank system.

- The composition of the thermal insulation determines how long the water will remain hot after the boiler is turned off. Cheap water heaters come with foam. Porous material poorly retains heat and quickly decomposes. The optimal thermal insulation is mineral wool or polyethylene foam.

- To make the right choice, you need to compare the power indirect water heater and heating boiler. If the latter is characterized by weak parameters, the boiler will become an unbearable load.

- When buying any model, be sure to pay attention to the presence of a thermostat, valve and other protection elements.

When with everyone important nuances the issue is resolved, you can pay attention to the form, design, manufacturer and other details.

Calculation of the volume of the storage tank

To make an approximate calculation of the volume of the storage tank, you can use a simple reading of the water meter. When the same number of people constantly arrive at the house, the daily consumption will have the same data.

A more accurate calculation of the volume is based on counting the water points, taking into account their purpose and the number of living family members. In order not to go into complex formulas, the hot water consumption is taken from the table.

Connection diagrams for the heating system

When choosing a connection scheme for an indirect boiler for heating water, the location of the device in the house, as well as the features of the heating system wiring, are taken into account.

A simple and commonly used scheme is based on connecting an indirect device through a three-way valve. As a result, two heating circuits are formed: heating and hot water. After the boiler, a circulation pump crashes in front of the valve.

If the need for hot water is small, a system diagram with two pumps is suitable. The indirect water heater and the boiler form two parallel heating circuits. Each line has its own pump. The scheme is suitable for country houses where hot water is rarely used.

The connection diagram is more complicated if the house has a “warm floor” system installed along with radiators. To distribute pressure across all lines, and together with indirect boiler there will be three of them, a hydraulic distributor is installed. The node normalizes the circulation of water through the "warm floor", water heater and radiators. Without distributor pump equipment will fail.

In indirect water heaters with recirculation, three nozzles come out of the body. Traditionally, two outputs are used to connect to the heating system. A looped circuit is led from the third branch pipe.

If the indirect water heating device does not have a third branch pipe, and recirculation must be done, then the return line circuit is connected to the cold water pipe and the recirculation pump is additionally inserted.

Recirculation allows you to get hot water at the outlet of the tap even before the liquid in the storage tank of the boiler is completely heated.

Popular Models

Choose suitable model always necessary according to technical specifications. As an aid, you can see the rating of indirect heating boilers, compiled taking into account consumer feedback.

Viessmann Vitocell-V 100 CVA-200

The model is equipped with a steel tank with an enamel coating with a capacity of 200 liters. Rapid heating of water is carried out by means of a heat exchanger with a total area of 1 m 2 . The temperature is controlled by a thermostat. The maximum allowable parameters: water heating - up to +95 ° C, inlet pressure - 10 atm.

Drazice OKC 200 NTR

The water heater is presented in two models: with one and two heat exchangers. The container is similarly designed for 200 liters of water. However, heating is carried out faster due to the increased heat exchanger area - 1.45 m 2. The disadvantage is the lack of a heating element, which does not make it possible to obtain hot water in the summer.

Roda Kessel ILW 200B

The powerful device with a 200 l steel storage tank is equipped with a copper heat exchanger. Additionally, the model is equipped with a heating element, which allows you to get hot water in the summer when the heating is turned off. The temperature is controlled by a thermostat. The maximum limit is +65 o C.

This question is often asked by owners of private houses. Many rightly believe that if they already have installed system heating, which allows you to supply the house not only with heating, but also with hot water for household needs, then why spend money and install an indirect heating boiler? At first glance, the boiler device really looks like a waste of money. But it's not.

The indirect heating boiler has a very low heat loss coefficient.

What is an indirect heating boiler and why is it needed?

An indirect heating boiler is a water heater that allows you to provide uninterrupted supply of hot water to all households at the same time.

In addition, its design does not imply the presence of its own heat source. External heat sources are used as a heat carrier for an indirect heating boiler. They can be a heating boiler, central heating, etc.

So, why do we need an indirect water heating boiler? Let's take as an example a situation where the hostess decided to wash the dishes, and the host in the meantime decided to take a shower. In this case, both will face either a shortage of hot water, or a sharp drop in water temperature, which is also unpleasant. The device of this water heater will avoid such situations, since it will be able to compensate for the shortage of hot water.

How does an indirect heating boiler work

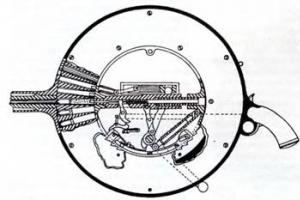

Externally, an indirect heating boiler looks like a large tank that has a cylindrical shape. And the design of the boiler itself consists of the following parts:

- boiler body;

- insulation;

- tank made of stainless steel;

- thermometer;

- heat exchanger;

- magnesium anode.

Due to the presence of a layer of insulation between the tank and the body of the boiler itself, the heat loss coefficient is 3-4ºС per day. The thermometer allows you to control the set temperature of the water in the tank. The heat exchanger is a spiral steel or brass tube, which is located inside the boiler itself. Very often this tube has a complex shape and is located closer to the bottom of the boiler. Manufacturers claim that it is thanks to this fact that uniform heating of water in the entire tank can be achieved. The magnesium anode is designed to protect the tank from galvanic corrosion. Almost all electrochemical reactions will affect the magnesium anode without affecting other parts of the water heater. Over time, this part of the water heater will have to be replaced, as it is subject to constant wear and tear.

Almost all new models of modern boilers have an alternative heat source. Such devices are also called combined. In the summer, when the heating season is over, boilers use either electricity or gas to heat water. There are also models on the market that are able to heat water due to sunlight.

The principle of operation of the device

The indirect heating boiler is not complicated, and the principle of its operation will be clear to anyone. A spiral-shaped tube, hollow inside, passes inside a large tank, most often it is called a coil. The coolant circulates continuously in the tube. Constant circulation is provided by a pump specially installed for this purpose, which, in turn, is equipped with an automatic control system. As soon as the water temperature reaches the set parameter, the pump turns off. Since the source of the heat carrier is a working heating system, at the time of heating the water in the boiler, a slight decrease in the temperature of the heating elements is possible. However, the water in the tank heats up quite quickly, so you can only notice a decrease in temperature for a short time with the help of a thermometer.

After the water in the tank reaches the desired temperature, it will remain so for a long time. Significantly reduce heat loss in the tank help modern insulating materials. As thermal insulation for boilers, polystyrene foam or polyurethane foam is perfect.

Each boiler has two inlet and outlet pipes, and they perform different tasks. The inlet pipe is connected to the heating boiler, where the coolant enters the coil through it, thereby heating the water in the tank. And the outlet pipe delivers already heated water directly to the place of its supply.

Before you decide to buy a boiler, be sure to check the power of your heating system. After all, if you purchase a boiler with a large volume, there is a possibility that the heating system in your home simply will not cope with the task. Or heating will occur very slowly, and during this period the temperature of the heating devices will drop sharply, which will have an extremely negative effect on the comfort of people living in the house. You will also need to choose in advance which type of boiler you want to purchase: floor or wall. If you have a wall-mounted water heating system, then it is best to purchase a wall-mounted boiler. And vice versa. Experts advise purchasing a heating system and an indirect heating boiler from the same manufacturer. In this case, installation and installation will be easy and fast. And the results of their work will be effective and productive.

Advantages and disadvantages of the system

The main and main advantages of indirect heating boilers, in contrast to flow-type heaters, are:

- The ability to heat water in large quantities.

- Compensation for the emerging shortage of hot water during the peak load period. For example, when the hostess decided to wash the dishes and the host decided to take a shower. Thanks to the boiler, several people in the house can use hot water at once without causing discomfort to other users.

- The cost of water heated by an indirect heating boiler is extremely low. After all, no additional energy was spent for its production. An indirect heat source fully satisfied the need for heating water. IN winter period time, the use of a boiler becomes extremely important due to the high savings in energy spent on heating and heating.

- Compared to a flow type water heater, the use of an indirect heating boiler makes it possible to supply hot water in several directions at once.

- Possibility to use alternative heat sources (gas, electricity, sunlight etc.).

The disadvantages of indirect heating boilers include the following:

- High cost of equipment. Given the fact that in order to install an indirect heating boiler, it is necessary to first install a heating boiler, the installation of the first one places a heavy financial burden on the owners of a private house.

- In order to heat water in a container weighing 100 liters, it will take several hours. For this period of time, the heating temperature in all residential premises will be reduced.

- The whole structure takes up quite a lot of space. Usually, a heating boiler and an indirect heating boiler are installed in close proximity to each other. And since the dimensions of the equipment are rather big, sometimes a whole small room in the economic zone is allocated for them.

How to choose the right boiler?

The main criterion that you should be guided by when choosing a boiler is its capacity. In order to understand what should be the optimal mass of your water heater, you can use the average figures, and then multiply them by the number of people living in the house and round the resulting figure up.

So, statistics say that a person spends hot water per day on:

- washing - 6-16 l;

- washing dishes - 20-25 l;

- shower - 60-85 l;

- taking a bath - 160-180 liters.

For example, it will take about 40 minutes to heat water to the desired temperature in a 20-liter indirect heating boiler, and about 6 hours for a 200-liter boiler.

After you have decided on the required volume of the boiler, be sure to specify what material the coil is made of. In inexpensive boilers, the coil is made of steel and welded to the tank. And in models of a higher price category, the coil is removable and made of brass. Of course, a removable coil is more practical, since over time you can easily remove it and clean it from the scale that has accumulated in it.

Also, inexpensive models have a layer of glass-ceramic or enamel as a protective coating. However, such a coating is not entirely reliable, because constant temperature changes will occur inside the tank, which will eventually lead to microcracks and will no longer save the metal from corrosion. Therefore, when buying a boiler, choose a tank that is made of stainless steel, such a boiler will cost you more, but it will also last much longer.

The next thing you will need to pay attention to is the insulation material. In some models, foam rubber is used as a heater; this material is extremely unreliable and impractical. Polyurethane is best suited for these purposes. It is with such a heater that heat loss from the tank is practically excluded, which means that excess energy is not wasted to heat the water again.

In private houses, cottages, sports complexes and hotels, an indirect heating boiler is often used - the water heater functions without being connected to a centralized water supply. This equipment copes with the heating of large volumes of water, easily maintains the desired temperature and ensures uninterrupted supply of hot flow.

In a word, if you are looking for a budget water heater in a kit for a single-circuit boiler, consider installing it in the BKN house. And to simplify the task of choosing, we suggest that you familiarize yourself with the criteria for buying a boiler, the principle of its operation and connection diagrams.

An indirect heating boiler can only operate on resources from an external source, but a heating element can be connected to service the system in the warm season.

To ensure uninterrupted supply, a recirculation circuit is provided in the system - water will constantly move through the pipes, and when a tap is opened, a hot stream will flow at the points connected to the circuit.

An indirect heating boiler is usually installed next to the heating boiler, and this “duo” takes up a fairly large area, especially if both devices are floor-standing

Thus, the device allows you to significantly save on energy resources, but at the same time get no less comfort than when using a centralized hot water supply system.

Image gallery

The rate of water heating depends on the number of turns on its spiral. The principle of operation of this design of an indirect heating boiler is extremely simple: cold water enters the tank, and the coolant, moving along the coil, heats it up to the desired temperature.

But there are also devices designed according to the “tank in a tank” scheme, where two containers of different diameters are used instead of a spiral pipeline.

The system works like this: cold water enters a smaller tank, which is heated by a hot coolant circulating between the walls of the tanks.

In such devices, water becomes warm in a matter of minutes - a large heating area allows the equipment to operate efficiently in flow mode, guaranteeing an uninterrupted supply of hot flow.

A combined BKN for heating water can use energy from several sources at once or be equipped with a built-in heating element.

Varieties of boiler KN

By location:

- Wall- usually, this is a device small size with displacement up to 200 liters. Fastens with special brackets to any vertical surface, strong enough to support the weight of a fully filled tank (plasterboard partitions will definitely not work). It can be located high enough and not occupy the usable area of the room.

- Floor- a capacious boiler designed for a large number of consumers. True, for a device with a capacity exceeding 1000 l, it is recommended to allocate separate room– . But such a system is usually installed to serve large cottages, businesses, hotels and other institutions, for family use, you can get by with a device of 250-300 liters.

Tank shape:

- Horizontal- takes up a lot of space, but it is easier to maintain the desired water level in it without resorting to connecting pumps.

- Vertical- saves free space, but is very limited in capacity.

Depending on the nuances of use, layout features and the availability of free space, you can choose the optimal BKN model that will organically fit into the design of the room and provide your home with an uninterrupted supply of hot water.

What to look for when choosing a BKN

One of the main parameters that should be the decisive argument when buying a boiler is its capacity. To find out the required tank capacity, we advise you to focus on the number of people in your family.

- 80-100 l– 2 consumers;

- 100-120 l- 3 persons;

- 120-150 l– 4 users;

- 150-200 l– 5 consumers.

It is important to separate the concepts of "total tank capacity" and "working capacity", because the spiral pipe located inside the boiler occupies a significant area. Therefore, be sure to specify when buying how much water is actually placed in the device. IN technical specifications this nuance must be specified.

Also, in addition to the "total" recalculation of potential consumers, it is necessary to take into account both the frequency and volumes of water use. For example, if your family likes to soak in a warm bath, and not take a quick shower, the working capacity of the tank should be appropriate - at least 120 liters.

BKN is advantageous to use in combination with solid fuel or single-circuit gas boiler, but if the water flow is less than 1 l / min, a double-circuit boiler will cost less, which will take up much less space than an indirect heating system

Other important parameters:

- Power- the greater the water consumption, the higher the resource of the device should be. But at the same time, it is important that the power of the "indirect" does not exceed the capabilities of the heating system (or other external source of energy). For example, if the volume of the storage tank varies between 120-150 liters, the boiler power should be at least 23 kW, and for 160-200 liters 31-39 kW will already be needed.

- Heating time- a parameter depending on the volume of the tank and the number of turns on the coil (large or combined tanks can be equipped with several coils).

- tank material- for long-term use, boilers made of stainless steel or medical steel are best suited.

- thermal insulation- cheap models use foam rubber, which wears out quickly and transmits heat, so it is better to purchase a more expensive device where polyurethane was used.

- Control- the device will be able to work in automatic mode, if necessary, turning off and starting the flow of water, control heating using a temperature sensor.

When choosing the shape and size of the tank, it is also necessary to take into account that although theoretically the boiler can be installed in any room where there is access to the heating main, its optimal location is next to the boiler. So heat transfer is most efficient.

An indirect heating boiler can be made with your own hands. The instructions for manufacturing the unit are described in.

The nuances and schemes for connecting the boiler

As already mentioned, BKN uses energy from an external source to heat water. Therefore, before connecting to the coolant, it is important to choose a suitable scheme for mounting the device. Consider the most common options.

General principles for installing the device

It is necessary to mount the boiler on a prepared flat surface in the immediate vicinity of the boiler. Suspended models are mounted on concrete or brick wall, at the same level or slightly above the heating boiler.

For a floor-standing appliance, you should level the area reserved for the placement of the tank (if the floor is critically uneven, you can make a stand in the form of a podium).