Dental unit with titles. Universal dental units. Dental tips. List of used literature

Instrument unit (UNIT) or dentist element- the basis of the dental apparatus. It includes manipulation tools: low-speed electric motors, electric and pneumatic micromotors, and turbine units. It is often completed with a lighting block for tools. The following instruments are installed on the doctor's block:

water-air gun, used for drying/wetting the mouth

turbine handpiece, used for therapeutic and orthopedic work

scaler, used to remove tartar

micromotor, used for processing crowns, prostheses and for distant teeth

Units are divided according to the type of tool supply:

- with top feed. The advantage of this type is the convenient return of the instruments to their place, the disadvantage is the small length of the sleeve, which is not always convenient for the doctor.

- with bottom feed. Unlike the previous type, there is a convenient sleeve length, which is comfortable for the dentist, but there is an inconvenient return of the instruments, the doctor needs to make sure that the instrument does not fall out.

Control block- important part dental unit It consists of pedals and a control panel that controls all systems of the installation.

The control pedals have the ability to control:

patient chair control

tool management

Modern installations use multi-key pedals. If the unit is used for a large number manipulation, it is extremely convenient.

assistant block, which includes:

Hydroblock, used to store and supply distilled water

Spit shell and glass shell, used to expel saliva and fluids into sewer pipe equipped with a flush system. The spittoon bowls are made of glass or ceramic. They are divided into 2 types: stationary and rotary.

Saliva ejector- used to remove saliva and fluids from oral cavity patient into the sewer

Vacuum cleaner- used to clean the aerosol mixture that is formed in the oral cavity when working with turbine handpieces

Lighting block- includes a lighting unit made of a halogen lamp and a bracket.

Dentist chair- an important block for the placement and comfort of the patient. There are hydraulic and electromechanical. Hydraulics are less reliable, but also have a lower cost.

Compressor- used to supply compressed air to tools.

Doctor's table- used for the convenience of the dentist, for placing instruments.

Dentist's chair- used for the convenience of placing a doctor. It differs from a regular chair in the presence of a latch that does not allow the chair to rotate after the doctor has taken a working position.

Assessing the complete set of the dental complex, three classes are distinguished: economic, medium and high. Economy class installations are equipped with the most necessary, while premium class installations include the maximum number of blocks and tools. Each clinic selects the unit according to the level of knowledge of doctors and their status.

But remember, every installation needs scheduled maintenance. The specialists of our company will be happy to help you with this issue.

Dentistry as a separate branch of medicine was formed in the 20s of the last century. At the same time, the first drills were produced, comparable in size to a perforator, and their sound resembled the roar of a bomber.

In the 21st century, medicine can afford not only compact drills, but also portable dental units that fit in a suitcase.

A dental unit is a complex of all the tools that are necessary for most dental procedures. The device of the dental unit includes:

- patient chair;

- tool table;

- instrument block;

- illuminator;

- for air supply;

- water and air heating unit;

- spittoon bowl.

Types of dental units

There are two types of such equipment:

- Stationary. All equipment is located on an area of 3-4 square meters. m and has a rigid attachment to the floor. These designs are distinguished by a large set of tools and instruments, but low mobility and bulkiness.

- Portable. The doctor's module does not have rigid connections with the patient's chair. Such equipment is compact and highly mobile.

Smart installation choice

When choosing any dental equipment, you should pay attention to the reliability and power of the tools that it comes with.

For example, the patient chair can be equipped with hydraulic or electric lifting mechanism. The first option has a low price, but is more prone to wear and, as a result, breakdowns.

Attention! Because of high cost clinics often prefer used equipment. But the fact is that it is sold without any warranty and service. It is better to purchase new equipment from an official supplier who will provide not only its setup, but also technical support and repairs.

When buying such equipment, it is important to give preference to trusted manufacturers: KaVo (Germany), Diplomat (Slovakia), Sirona (Germany), Darta (Russia), FONA (China, Slovakia), Azimut (China).

Installation, repair and maintenance

Installation of a dental unit will not bring many problems if you strictly follow the instructions that are always included in the kit. The whole difficulty lies only in moving this structure, and it is caused by its mass - 200-250 kg.

Maintenance of equipment is carried out once a month and consists of computer diagnostics and technical inspection. This is done by professionals, because the wrong setting entails problems that can lead to a complete failure of the dental unit.

The cost of repairs depends on the nature of the damage. For the most minimal repair, the owner of the equipment will be forced to pay the master about 2000 rubles (and this is only for the work itself). Therefore, the purchase of new equipment, which will be under warranty, is more beneficial for the clinic.

Overview of the most popular models

Dental units "Darta" (Darta) are widely known in Russia, as they are produced in our country.

Darta 1600 M is one of the most popular models on the dental equipment market. Manufacturers have tried on the design and ensured ease of operation. Also, the developers themselves noted that when designing the unit, all the preferences of doctors and their assistants were taken into account. However, the Darta 1600 M is a bottom-feed device, and according to experts, this leads to the fact that the doctor has to make sure that the tip does not fall out of the socket. Also, this part is subject to imperceptible contamination.

Sirona Intego is the brainchild of a German company that was part of Siemens until 1997. The manufacturer himself calls this equipment the best in its class. And doctors note the convenience of working chairs and increased freedom of action. However, it is worth noting that Sirona is also more expensive than the products of its competitors.

Dental unit "Diplomat" (Diplomat Adept DA110A)- This is another popular model that has managed to establish itself in the market. Country of origin - Slovakia. Adept DA110A is a stationary device with bottom feed of tools. The equipment is compact and lightweight - depending on the variant - 50-70 kg. Experts speak positively about this model and the manufacturer as a whole due to the good balance between price and quality of the products offered.

Conclusion

Dental unit along with competent work the doctor is a major part of the successful operation of the clinic. Therefore, the selection of equipment must be approached thoroughly.

It is worth giving preference to manufacturers who have proven themselves in the market. It will be beneficial to purchase new equipment from an official representative of the company, which will provide warranty repairs and maintenance of the dental unit.

23755 0

dental unit This is a set of equipment designed to perform dental tasks.

The main component of the workplace (office) is a dental unit, which in some cases occupies an area of 4 m2 and can be used for:

Preparation of hard tissues of teeth in therapeutic and orthopedic dentistry;

- endodontic treatment of teeth;

- carrying out a number of outpatient and inpatient surgical dental operations;

- prosthetics for patients with removable and non-removable prostheses;

- performing orthodontic procedures.

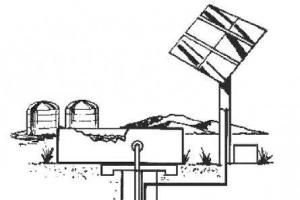

Modern dental unit(Fig. 7) is equipped with a turbine drill, electric drill, pneumatic drill, has a daylight lamp with adjustable illumination of the working field from 8000 to 28000 lux and other devices that allow the doctor and his assistant to work at the modern level. The tools of the pneumatic and turbine drill are air-water cooled.

In dental drills, three types of drives are used to transmit rotation from the motor to the handpiece:

Rigid multi-link gears with cords (hard sleeves);

- transmissions with flexible wire shafts (flexible sleeves);

- sleeveless transmissions using pneumatic or electric micromotors, which are directly attached to the dental handpiece or built into it.

Rice. 7. Dental unit

Currently, various drills with adjustable rotation speed are used in orthopedic dentistry, which is considered to be (V.N. Kopeikin):

Low (up to 10,000 rpm);

medium (from 25,000 to 50,000 rpm);

high (from 50,000 to 100,000 rpm);

very high (from 100,000 to 300,000 rpm);

ultra-high (over 300,000 rpm).

The experience of using air turbines has revealed their positive and negative sides(Schletter P., Durov V.M., 1999).

These mechanisms carry serious problems that are related to:

With the imperfection of the rotor mechanism and the cooling system of the turbine of the old design (they create noise that is dangerous to hearing with a power of 99 decibels);

- the danger of excessive removal of hard tissues at high speeds of rotation of the instrument;

- high (up to 245 C) and detrimental to tooth tissues temperature in the preparation area;

- the formation of an aerosol cloud by the turbine tip, containing, in addition to water, microflora, fragments of hard tissues of the tooth and cutting tools, mucus and fragments of soft tissues;

- the possible retraction of this cloud into the mechanism at the time of shutdown and, accordingly, its release in the operating mode to another patient.

The doctor must be aware of these shortcomings and either avoid their manifestation or minimize them. It should be noted that turbine devices have advantages that distinguish them favorably from other installations:

1. There is no need to make a lot of effort, which greatly reduces side effect on the pulp and periodontal tissues;

2. The small size of abrasive tools prevents overheating of hard tissues by reducing the area of contact surfaces, also providing tool wear resistance;

3. Reducing discomfort compared to those observed when using old tools;

4. Reducing preparation time while improving its quality through the use of automated cooling systems (air or air-water).

Dental units can be classified:

1) according to the method of location in the office:

On stationary (see Fig. 7), rigidly fixed to the cabinet floor;

- portable (Fig. 8, a), in which the medical block-module does not have a rigid connection with the chair.

Therefore, a standard mobile complex on wheels and a stable stand with high-speed and low-speed instruments allow the most optimal positioning of it during a patient's appointment.

So, for example, an autonomous portable unit by Medica (Lithuania) makes it possible to modernize older dental units that do not have a turbine. Such a turbine attachment consists of a compressor, voltage stabilizer, water supply system (0.33 l water tank) and air (air pressure in the turbine 0.28-0.35 MPa). In Germany, a series of similar mobile turbine units Kavo Modular is produced with a different number of connected tips, an integrated compressor and a water tank;

2) by the number of attendants (only for a doctor; for the simultaneous work of a doctor and his assistant, i.e. the so-called principle of "four hands" work);

3) according to the method of arranging the instrumental block, there are, as a rule, three main options:

Rice. 8. Appearance portable unit (a) and mobile medical modules (6, B)

Mobile attachment trolleys, which are the most simplified and less expensive tool supply system. They can be moved based on the need for location, reliable in operation, aesthetically designed and can be automated;

- cabinet built-in brackets are suitable for rear and side feed of the tool. Arms are the most expensive and least mobile of all tool delivery systems and can be built into furniture. The patient, sitting down in a chair, does not see the instrument;

- a doctor's table mounted on a pantographic holder with instruments and a halogen lamp is less aesthetically pleasing and less stable than other types, but provides a large radius of action. Such a table can be easily moved in horizontal and vertical planes, which ensures its convenient location relative to the doctor and the patient, is equipped with micromotor speed and instrument cooling controls, has a large area for placing instruments and semi-finished prostheses, and is also equipped with a negatoscope for viewing x-rays;

4) according to the method of fastening hoses for handpieces (upper and lower supply);

5) by drive type:

Air for mounting on the handpiece sleeve:

. turbine;

. micromotor;

. with built-in air micromotors, which are installed on the air sleeve through a quick connector;

. special purpose (laser, for beam preparation;

. for endodontic work;

. for periodontal manipulations);

. for professional hygiene (removal of dental plaque; whitening with soda under pressure) and removal of artificial crowns and bridges due to the destruction of the cement layer;

. electric for installation on them of electric micromotors (brushed and brushless) and piezoelectric scalers.

Summarizing all of the above, as an example of a modern stationary dental unit, we can name the Doctor model (Brazil):

With top suspension;

- carrying hydraulic seat;

- two swivel removable armrests and controls on both sides of the backrest;

- foot control;

- automatic return to the "zero" (initial) position;

- joint raising of the seat and simultaneous lowering of the back;

- a luminaire (three-position dimming 24 W, 150 W; maximum 25,000 lux);

- rotary hydroblock (spittoon and cup filler) of the antiseptic water supply system;

- doctor's block-module for three handpieces and an air-jet gun;

- assistant's block-module (air-jet gun, saliva ejector and ejector-type blood ejector).

Another stationary installation Laser-TL differs from the Doctor installation by lower suspension with a load-bearing hydraulic chair, two swivel removable armrests, foot and manual (on the right side of the backrest) control for 2 movements.

Rice. 9. Portable drill for surgical operations of the company "Esculap" C autonomous system cooling

It should be especially noted that at present, when designing dental units within the framework of the “all in one” concept, the achievements of information technologies (Planmek units, Finland) are used, which allow adding a display connected to a computer to the traditional configuration.

A drill for surgical manipulations should have a sufficiently large rotation speed range (from 1000 to 30,000 rpm) in order to dissect not only spongy, but also compact bone and tooth tissues. At the same time, prevention of bone damage from overheating when using cutters, burs is achieved in different ways:

Cooling of the rotating tool and contact with it bone tissue chilled sterile saline;

- a decrease in the speed of rotation of the cutting tool as its diameter increases;

- observance of the intermittent mode of operation without strong pressing of the instrument to the bone;

- use of sharp cutters, burs.

Given these requirements the best option is to equip the surgical room, the operating room with portable electric drills with a rotation speed of 1000 to 30,000 rpm, adjustable gear, having a reversible device (allows you to change the direction of rotation), and an autonomous unit for cooling the cutting instrument with saline solution (Fig. 9).

In the absence of a drill with an autonomous cooling system, you can use a universal dental unit (US-3O) or a portable electric drill and a standard medical system for intravenous administration of disposable fluid. In this case, the assistant regulates the supply of saline cooling during the operation.

Turbine drills should not be used for surgical procedures due to possible occurrence tissue emphysema.

Dental office

Under the editorship of Professor Trezubov V.N.

The dental unit consists of functional blocks , each of which has its own name. Depending on the configuration of the installation, the set of blocks may vary.

Drives

Drive unit - part of the dental unit, which serves to create and transfer energy from the unit to the handpiece.

Drive type:

1. Air– for installation on the handpiece sleeve:

Turbine

air micromotors;

· with built-in air micromotors, which are installed on the air sleeves through the connector;

for professional hygiene;

special purpose (for endodontic work).

2. Electrical- for installation on them

electric micromotors:

o brush;

o brushless;

Piezoelectric Skellers.

According to another classification for the transfer of rotation from the engine to

The handpiece uses three types of drives:

Rigid multi-link gears with cords - rigid sleeves;

gears with flexible wire shafts - flexible sleeves;

· sleeveless transfers using electric or pneumatic micromotors , which are directly attached to or integrated into the dental handpiece.

Flexible sleeve.

Flexible sleeve:

1 - leash; 2 - union nut; 3 - protective case; 4 - tip holder

The flexible sleeve can be bent in all directions during operation.

The flexible sleeve is now rarely used, mainly in drills with a rotation speed of up to 10,000 rpm. The main active part of the flexible hose is elastic long spiral , forming a rotating rod, flexible shaft 75 cm long. One (upper) end of this rod, with the help of a leash and a union nut, is attached to the motor shaft, which, rotating, sets in a circular motion a flexible shaft protected by tape armor and a protective spring. The continuation of the lower part of the elastic rod is a small length (10 cm) additional rod of increased flexibility, due to which the flexible sleeve is highly maneuverable. The elastic core of the drill sleeve is immersed in an outer protective case covered with a cloth or plastic tube. There is a tip holder at the free end of the sleeve.

Rigid sleeve.

Hard Sleeve:

1 – tip holder; 2 - the first knee; 3 - second knee; 4 - rods

The rigid sleeve is used in drills with a rotation speed of up to 30,000 rpm. It is intended for transfer of the rotating movement from the electric motor of installation to a handpiece. The sleeve consists of

· tip holder,

· first and second knee

· rod,

· string stretched over them.

In drills, with a bur rotation speed of up to 10,000 rpm,

no coolant is supplied to the cutting tool. At a rotation speed of up to 30,000 rpm, tubes are attached to the sleeve, through which water, air, or a mixture of them is supplied to the cutting tool to cool it. The rigid sleeve is mounted on a retractable rod designed to adjust the tension of the drive cord. The continuous cord is located in the grooves of 4 rollers located on the articulations of the extendable bar of the cranked sleeve. The presence of two grooves on the holder roller doubles the range of speed control of the cutting tool. The cord should be seamless, elastic and sufficiently tight. Otherwise, the motor roller slips and the speed of rotation of the drill drops.

Turbine sleeve.

The turbine sleeve is designed to carry compressed air and coolant mixture from the turbine unit to the turbine handpiece or pneumomotor.

The sleeve consists of rubber or PVC hose , inside which one or more rubber or PVC tubes are located, in addition, fibers can be located inside the sleeve (when using tips with backlight). Air and coolant are transferred through the main hose. On the one hand, the sleeve has a connector for connecting to the device, on the other - a connector for fixing the tip.

Dental chairs

The dental chair is a multifunctional complex with a wide range of treatment and diagnostic capabilities designed to perform all manipulations and operations in the dental practice. The simple but practical design of the chair facilitates the work of the doctor in any position.

Patient chair designed to accommodate the patient in the provision of dental care in stationary conditions of medical institutions. It consists of:

The base on which the seat is mounted with an angle-adjustable backrest;

armrests;

Headrest;

Mechanisms for lifting the seat and transforming the back.

On the back of the chair there is a control panel, including blocks: raising and lowering the seat; transformation of the backrest with a simultaneous change in the angle of inclination; automatic return to the chair to its original position.

Armchair headrest has height and tilt adjustment, as well as an additional "floating" pillow.

Chair armrests- rotary, if necessary, can be dismantled. The right armrest can be easily removed or moved. The chair lifting mechanism has an electrochemical drive and provides lifting of the upper part of the chair with a distributed load of up to 140 kg and a mass of attachments up to 50 kg from the extreme lower to the extreme upper position and vice versa. The lining details and covers of the backrest, seat and footboard of the chair are made of materials resistant to disinfectants and detergents. An adapter is mounted on the chair, which provides a suspension of the dental unit. All types of movements of the headrest and back of the chair are possible, however, programming is not provided, and the chair is either only foot-operated or only push-button from the back of the chair.

Ergonomic requirements presuppose the presence in modern dental chair:

· massive balanced base that allows you to maintain the patient's body in a horizontal and vertical positions;

· drive without noise and vibration, allowing for its automatic unfolding and folding (in programmable or manual mode);

· seat and back contour should provide the maximum possible support for the patient, ensuring anatomical conformity to his body and relaxation during manipulations;

· thin back , which will allow the doctor to move closer to the patient;

· back support should not be very long maximum width in the area of the shoulder blades, significantly tapering downwards, to reliably support the spine;

· armrests must either be easily moved from a horizontal to a vertical position, or removed and not be long;

· headrest , having a wide range of motion, should be easily and reliably fixed. A mechanism for changing the inclination of the headrest is necessary regardless of the position of the back;

· repositioning chairs (lifting, lowering, changing the angle of reclining the chair) should be carried out both from the operator’s seat and from the assistant’s. At the same time, foot (pedal) control is preferable in terms of compliance with the sanitary and epidemiological regime;

· materials , from which the chair is made, must withstand mandatory multiple treatments with antiseptics and disinfectants;

· color spectrum Desirable gentle tones.