How to clean and oil an antique wall clock? How to install a clock mechanism How to assemble a battery clock mechanism

Judging by the inscription on the watch itself, this is still a Japanese alarm clock, but we are not interested in the manufacturer, but in the details that can be taken from this inexpensive device :)

I disassemble this alarm clock not only to take the necessary parts from it, you can also assemble it from the pictures if you tried to fix it earlier) First, we remove the inner box with the clock from the transparent case.

Carefully remove the arrows.

On the back wall, you need to remove the clock adjustment knobs.

Now, on the four sides of the alarm clock, open the plastic latches. Be careful, latches break easily!

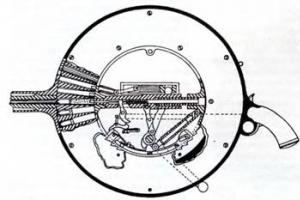

At the bottom of the watch is an electric motor, it consists of metal plates with a coil of copper wire and a permanent magnet combined with a small gear. This electric motor is powered by current pulses supplied from a microcircuit on the board.

Remove the top gears.

We take out the motor coil and the plastic partition. The coil wires are very thin and any inaccurate hand movement will lead to a wire break!

We remove the gears.

I don't need this alarm clock anymore, so I tore off the motor coil.

We bend the metal contacts of the alarm clock and take out the gear.

One by one, we tear off the contacts from the electrical board, they are attached to the plastic pins from the case.

On the board, a microcircuit is flooded, quartz, and a small speaker is placed on the wires. This board can be used as a security device or another device for giving an audible signal, I will talk about such schemes more than once on the pages of the site.

Do not rush to throw away the plastic box, there is a battery compartment left in it and it can also be used as a housing for a security device.

Alarm clock gears can be used for various crafts.

I recently told. Now I would like to talk about the wall.

Now it is probably impossible to find a house in which there would not be watches made in China or India. Wall Clock is such an element home comfort, which practically does not change its appearance. The only thing that wears out in them is the mechanism.

And it often happens that after several years of operation, the appearance is in perfect condition, and the watch either stops working, or hurries, lags behind, or, which is typical for smooth-running mechanisms, begin to literally “eat up” the batteries.

Throwing away such a watch is a pity, especially if they had a high purchase price or they are expensive as a memory. The most reasonable solution is to repair the wall clock with your own hands and replace the mechanism.

In the given example, we will replace the movement by rearranging it from another (new, but savagely broken) watch.

By the way, at any time point you can buy such a watch literally for a penny. At the same time, the advantage is that if the arrows from the "native" clock do not fit in diameter, you can easily install the arrows from the broken ones.

We unscrew the bolts of the mounting plate that holds the glass.

The clock from the Soviet times broke down, or rather the mechanism of the wall clock itself. I don't want to throw away the clock for my own reasons. Perhaps they fit the interior and there is no way to buy the same ones, or the clock is important as a gift for a long memory, but buying new ones is expensive or you don’t want to. In general, it will be faster and cheaper to completely replace a broken clockwork (which keeps time) than trying to fix it.

Then I decided to look for a clock mechanism for sale separately.

For some reason it seemed to me that the clock mechanism was expensive and made up a large

part of the cost of the watch. It turned out that the watch mechanism can be bought in bulk from 60

rubles! True, it is with a discrete course and noisy. Moreover, these mechanisms

standardized and have the same mounting dimensions. Find a store that

I would sell the watch mechanisms I needed at retail, it turned out to be difficult. IN

in the end, for 150 rubles I bought a silent mechanism with floating fur in the Bangood store Coupon(12% off) Code: BGHome

The old mechanism worked for 20 years.

New silent clock mechanism.

New silent clock mechanism.

s, everybody put it in old building hours, everything went well and the hands also came up, except for the second in my case.You can change the mechanism yourself, since now the repair of wall clocks has become very simple and cheap. I bought it, unscrewed the old one, put the new one in, and you're done.

s, everybody put it in old building hours, everything went well and the hands also came up, except for the second in my case.You can change the mechanism yourself, since now the repair of wall clocks has become very simple and cheap. I bought it, unscrewed the old one, put the new one in, and you're done.

Arrows packed in a separate bag

The task is to remove the old mechanism from the watch case. Then install the new mechanism. After that, install the arrows on the axis of the mechanism: the first is the hour, the second is the minute, the last is the second.

.

This mechanism is very quiet and takes several steps in a second. I am writing after a couple of months - it works perfectly, does not run away, does not knock, and does not interfere with sleep at night.

If you have broken quartz Wall Clock or fed up with their loud ticking, the cheapest way to get workingsilent clock is to buy a separate clock mechanism and install it yourselfhim to the old building.You can also create on the basis of the clockwork

That's what doesn't bother anyone in the house because it's a clock, and all because it's on the wall. And there is always a benefit from them, serviceable ones show the time, faulty ones give comfort to the interior. They hang and hang. Until then, until the owners decide to change their place of residence. And then those of them who have the habit of sometimes stopping are thrown away. They give new ones for housewarming, but their quality is the same as that of the old ones. That's why I decided not to throw mine away.

This is a gift from the last housewarming party, they are 30 years old. They show the time exactly, but they have one fad - they work only with a fresh battery (you need to change it every four to five months, with two, even used ones, connected in parallel, it takes much more than a year.

The assembly is of high quality, for example, the motor rotor (drive gear) has an individual mount on the board

I disassemble, clean everything, wipe it with alcohol, solder the contacts and even solder the screws to the board that fasten the installation components on the other side. All in the hope that they will work with one, moreover, not the strongest battery.

Collected, tried - a miracle did not happen. Put two - go. Leave it as it is, I couldn't improve it.

And this is the mechanism of modern watches. China. They go on the condition that every few hours they need to be shaken.

I disassemble, I clean, mine. But this is not enough here. It is necessary to understand the reason for the unstable operation of the mechanism. Soon the fairy tale takes its toll, and in real time for several days I stared at the device of this mechanics and rummaged through the Internet.

In the virtual space, I found a clue to the cause of the malfunction, but a solution was proposed there that was almost delusional. I had to come up with my own. And so in the photo, the metal scriber indicates a recess in the plastic, into which the upper axis of the engine rotor (drive gear) should be inserted. It is made a little deeper than necessary and, accordingly, the rotor dangles there, which leads at a certain moment to stop the clock.

I definitely decided on the diameter of this recess, picked up the necessary drill (maybe even a slightly smaller diameter) and drilled through it. Then he took a piece of fishing line of a slightly larger diameter and, with the help of a fine skin, grinded off the diameter of the line just enough so that it entered the hole with some effort.

From the inside, I inserted a segment into the hole so that there was a very small recess for installing the rotor axis. Assembled the watch mechanism, installed the battery. The clock did not run, as the fishing line rested against the axis of the rotor. Then, with small pliers, turning this impromptu stopper (line) from side to side, pulled it out. Exactly enough so that the rotor axis is released and the clock starts running. The tip of the stopper was shortened with wire cutters almost flush

So, we have completed the first part. Got a few tools. The places where the instrument grows were explored. We have prepared a workplace for ourselves. And in general - while we were doing all this - we had a good walk in the air and got to know the haunts and surroundings better. The first part involved quite a lot of movement and attentiveness when hiking - you had to SEARCH. What to look for - FSE! Everything interesting and in our not yet trained eyes - which can be useful to us and unusual. Something like plush. What is the result:

Tool. Which? First screwdrivers, then tweezers. To them - a binocular loupe, brushes, Petri dishes and needles. Got some oil. Yes, even for sewing machines. Well, there is no other. We think we have nothing else. NO. All. We manage with this primitive set. But without it, it's not worth starting.

They collected carcasses of hours.

different. Old. Wrist. They simply collected mechanisms - for spare parts.

They took indiscriminately, everything that was cheaper than the cost of half a pack of cheap cigarettes. This is their price. Half a pack of Belomor or Prima. Trolleybus fare. They shouldn't cost more. Regardless of the state - whole-broken. There are only two criteria. The first - mandatory - not rusty. The second - desirable - to be assembled (all parts are in place) - regardless of integrity. Trash. Let's sort. What do we have?

Women's wrist.

- Star. Old. Barrel-shaped movement, caliber 18 mm. Allegedly, in prehistoric times, the French brought us and assembled the LIP plant. So it's all French.

- Dawn- Penza watch factory

-Gull- standard small mechanisms, quite old, but tenacious

- Glory- newer gears

Lots of other titles. All Soviet. THE USSR. Looks like the state took care of the working class - it produced watches. To not be late for work. Maybe.

Men's wrist watch.

- Victory. Moscow. Lighthouse. Many watches were produced under these names. We're not talking about hours. About mechanisms.

Basically 2 types of mechanisms.

- "high" mechanism - for example 1MCHZ - "Moscow". Central second hand. Most watches were assembled on its basis - up to the famous "Sport". They stopped when the crown was pulled out. Ersatz stopwatch. An older type of mechanism. We do not name the technical caliber - it makes no sense. It is still impossible to order parts for the caliber.

- "low" mechanism - more modern. Side second hand.

Both in the first and in the second case, different factories produced a bunch of modifications of mechanisms - with improvements, simplifications, rac. Offers. There were also a bunch of types of exterior finishes. Satisfied the demanding consumer.

In addition - a full rainbow of other watch movements:

Slava - 2 types of movements, self-winding and non-self-winding. Somewhere on the Internet it was indicated - the prototype of the LIP-T-15. Again the French.

Complicated watch

With an alarm clock

Chronometer

For the blind

Our task is to learn how to disassemble and assemble. Then everyone will go their own way. One will only disassemble. Another will collect 50% and then - as they get bored or peacefully throw it in the trash (usually habits - vodka-dances will overpower), others - out of anger that it doesn’t work out - beat on the anvil with a hammer. Still others - they will calmly sort it out again, put it off for a couple of days and try again. This is a normal form of behavior for such an unusual hobby - precision mechanics.

Let's start with a simpler direction - men's watches. They are larger than women's. Better to be seen without a microscope. An example is a "low" Victory. It is the simplest for us. "High" is harder for the first time. The clock circuit is basically identical for all single-platinum watches. Therefore, you just need to understand and remember a few fairly simple schemes once. For the first workouts - just sketch what we are analyzing.

Frame:

Back cover.

There are several types of back covers. All the difference is in the manner of closing.

Slamming. A distinctive feature - usually, upon closer examination, you can find a flat into which a knife is driven in order to open it when pressed hard. In modern electronic consumer goods, a similar cover is often practiced, but with grooves, as it were, for unscrewing - a good joke. If you don’t know, then at least shoot yourself - you won’t be able to unscrew it.

Flat in the ring of glass. It's not a cover.

More modern solution- protrusion in the lid.

And this is where the knife comes in.

Screw, with a screw ring or threaded on the cover itself.

Or so - edges are visible along the edge of the lid.

We unscrew the first option either with the largest tailor's scissors (they are more rigid) or with the turned sponges of the old caliper. At flea markets, keys of this kind can often lie in ruins.

The corporate key (bought in the most common store for modellers - models of steam locomotives, cars, etc. in Germany) looks like this.

A rather rare option in Soviet watches is a bayonet. Turns a small angle and opens.

Bayonet lock on lid

So the clock was opened. What we see is dirt.

A lot of dirt. We immediately say that we will not deal with rusty watches. There is no chance. Nothing can be done - everything must be changed. Install new or sharpen new. It's too early for us.

The main parts of the mechanism

I - balance.

II - Wheel system

III - mainspring (maybe two - in Glory)

IV - ratchet - there can also be several types of them.

What we do first of all - while the mechanism is in the case - we lower the mainspring. If the head in the carcass is preserved and it can be turned (it has not been erased to the base), we try to turn it slightly towards the plant and look at the ratchet. It should turn slightly and slip a couple of teeth. This is what we need - with a needle we support it in the allotted state and, without jerks, let the crown turn and dissolve the spring, slightly releasing the crown between the fingers.

Immediately put in front of you at least 2 Petri dishes. Or white plates or dishes with a flat flat bottom. Diameter 15-20 cm. I use Petri dishes. They are easier to cover during breaks.

We take out the crown. To do this, press the latch with a needle.

We take out the mechanism from the case. Sometimes this is done towards the back cover. In our case, the opposite is true. The ring with glass is removed and the mechanism is removed from the side of the dial.

We remove the arrows

Minute, in general, simply - yes, even with a screwdriver

Hours and seconds are already a bit of an adventure. Tool - a piece was torn out of the relay (there was some kind of electric relay - there the material on the contact groups is exactly what we need - hard and thin. Bent - and there is the tool we need)

Turning the balance. The size (caliber) of the screwdriver must match the size of the screw.

The screw was unscrewed and how can this whole assembly be raised? - and it usually has special grooves into which you can stick a screwdriver and separate the balance plate from the base.

This is how we balance.

Everything is gradually laid out on Petri dishes.

Unscrew the screws of the mainspring block. There is one trick in the watch - if the screw has many grooves, then it is with a left-hand thread.

Under the dial - the node of the wheels of the arrows (I) and the node of the winding and transfer of the head from the position of the winding to the position of the transfer of the arrows (II) (scientifically called remontoir). We disassemble.

We remove the minute trib. This is the only node in the watch where force is required. We pull hard enough. If we jumped off - we will repeat. It always comes off with effort. The main thing is not to be afraid.

When disassembling the switch transfer unit (remontoir), pay special attention to the spring.

She has a nasty property - to click and fly away in an indefinite direction. Against this, a simple trick is to cover (press) all of it lightly with just a finger and carefully “click out” with a needle from under the finger

Put everything in a petri dish

Now the longest and most accurate. Washing.

We take a shallow bowl. We pour gasoline there. And mine. Brush and toothpicks. To shine. No dirt left.

For small mechanisms - squirrel brush. Harder. For large mechanisms - alarm clocks, pocket watches - you can try soft art brushes for oil paints.

Dry: first put after gasoline on paper napkin. I usually take a heavy piece of cardboard and put a piece of paper towel on it. To not jump and jump. Select napkins and towels according to the criterion - the less villi - the better.

Let the gasoline soak in. Let's just put it. Then we take the parts with tweezers and blow air from a rubber pear (enema) to blow gasoline out of the holes. And so consistently all the elements of the clock that lie in a Petri dish or on an impromptu "dryer". Node by node. This is what is meant: if the platinum is unscrewed and with it - 3 screws - we put them together. We consider - "this is our node." In order not to confuse screws and parts. We put them in the same places in the Petri dish. Or better in a clean cup. Old - then wash and wipe. This is if we do not intend to collect quickly. Or we collect "from a sheet" - from a napkin. But this is with a certain experience, skill and speed of work. Balance. While there is no great experience, we do not understand. So we shove the platinum-spiral-balance block into a bath with gasoline and simply rinse it in gasoline for a long time. It is clear that this is wrong. It is necessary to disassemble everything, etc. - WE HAVE NO EXPERIENCE YET. Gutted for 5-10 hours, and then we will look at the balance. How he understands. Read books. And do according to wise books (if it is described in detail there).

Some note about the mainspring. We do nothing. Just wipe the outside with a paper towel. We clean the teeth with a brush. For now, we don't do anything. With disassembly, lubrication, assembly and replacement of the spring, we will have fun next time. No experience yet. It's difficult.

And now more intellectual work - to collect the resulting puzzle

Everything is done in the following order:

mainspring

Wheel system. Let's have some fun too. We placed the gears in the lower stones. They covered it with platinum, and then we need to move the upper platinum with tweezers in all directions until the upper axles of the gears do not hit the stones. A little tedious, but doable. Sometimes you can try to help the process with a thin needle to move the gears that you can get to. The main rule is NO VIOLENCE. Everything should be done without any effort whatsoever. Everything by itself “snaps” into place over time and the platinum noticeably “falls” down. The clock mechanism is a rather thin thing, the efforts are very small, the loss of efforts during operation is also very small, respectively - it cannot be assembled on tight landings - THEY CANNOT BE BY DEFINITION. If the upper platinum does not sit in place, the pinion has not sat in the stones. Or while we were moving it all - jumped out of the lower stone. We repeat once again - THERE CANNOT BE EFFORT! The criterion for the correct assembly may be the following: slightly turn the mainspring drum. SLIGHTLY ONLY - all gears should start turning. It's all - almost almost effortlessly on the clockwork drum.

Putting the anchor in place

We put the balance in place.

Lubricate the stones from above - from the side of the back cover. To do this, we use a homemade oil dosage.

We turn the mechanism over, lubricate all the stones from the side of the dial. We collect the mechanism of the crown.

Spring. Another adventure. We press it all with a wide screwdriver. We put the needle in place. Springs are probably the most foul thing in all this work. They jump. And we will suffer with them a) until we train our hands and b) until we collect carcasses of watches from which we will drag spare parts without a twinge of conscience.

They put it in place. We don't breathe. And suddenly it pops up.

Assemble arrow wheels. We put the minute tribe strongly on the gear axis. How? Yes, whatever comes to hand is approximately suitable. How we filmed and set. We rest. You will have to press the pins hard until it clicks.

Lubricate. What is there to lubricate - if you have assembled this puzzle - figured out - then you will also have to think about lubrication and lubricate it yourself. The basic rule is to lubricate only with oil dosage and to a minimum. All moving parts are lubricated. Plates must be dry. That's why it is a recess in the stones - so that the oil does not spread beyond its limits. We do not lubricate the stones of the anchor fork. It's early yet. A microscope is needed.

We put the dial.

We put the mechanism in the case.

Press the lock on the crown to put it in place. We start. Enjoy. DONE!!! YOURSELF!!!

Bogdan Yasinetsky