Do-it-yourself technology for assembling a mixing unit for underfloor heating - choosing and setting up a system

Many today install underfloor heating as an additional heating system. In apartments, as a rule, it is electric, and for private cottages it is more profitable to install a water floor. To equalize the temperature supplied to the inlet of the hot coolant, it is necessary to install an additional element, which is a mixing unit for a warm floor.

The scheme of the combined heating system of a private house may consist of:

- heating boiler;

- Contours of warm floors;

- Radiator circuit.

The temperature of the water heated by the boiler is 75-95 ° C, while sanitary standards set an indicator of 31 ° C, as the maximum comfortable temperature of the floor surface, for walking barefoot on it. Therefore, the direct flow of water into the floor circuits is unacceptable. This problem is solved by mounting the mixing unit.

The type of floor covering and the thickness of the screed should be taken into account. The water temperature in the pipes should be 35-55°C.

The thermomixer is used to mix hot and already chilled water from. Thanks to this, the heating circuit functions without deviations.

How the system works

How the system works A mixing unit for underfloor heating should be installed if the water heating boiler produces a high temperature of water, which is used for domestic needs and heating radiators.

How does a mixing unit work?

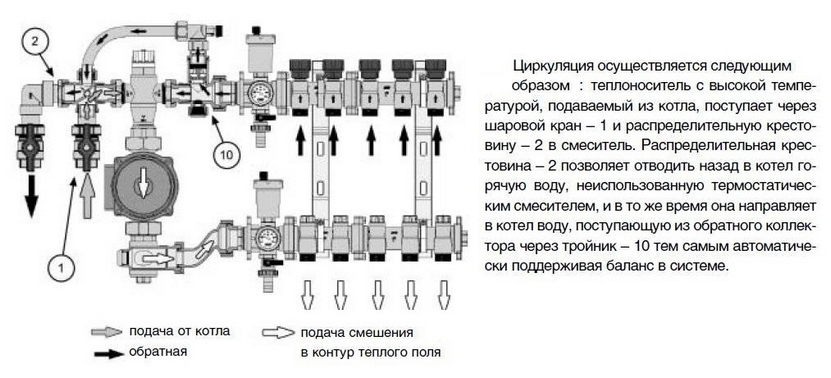

Before being distributed in the collector, the hot coolant enters the mixing system, where the thermostat measures its temperature. If the indicator exceeds the permissible value, then the safety valve opens and interferes with cold and hot water. When the liquid temperature reaches the desired value, the valve stops the supply of hot water.

As a rule, the mixing unit not only provides a comfortable temperature regime, but also serves to raise the pressure level in the circuit, which improves the circulation of the coolant. The scheme of the mixing unit includes:

- Safety valve;

- Circulation pump;

- bypass;

- Air outlets;

- Valves for stable functioning of circuits (cut-off, drainage).

The scheme of the mixing unit can have a different design. The most popular are schemes with two- and three-way valves.

Diagram with a two-way valve

A thermostat equipped with an infrared sensor is installed on the two-way valve (supply), which measures the temperature of the liquid entering the warm floors. The water in the mixing system moves in a circle, and the fuse head regulates the valve that opens or closes the hot water passage. This is the process of mixing liquids of different temperatures.

The three-way valve is not applicable for heating an area over 200 m2.

Three-way valve in the mixing scheme

The three-way valve is a versatile piece of equipment. It performs the functions of both a bypass valve and a bypass. Its peculiarity is that hot water interferes with the return inside the case. This type of unit is equipped with servo drives, thermostats, as well as weather-dependent controllers. The latter are able to check the temperature on the street with a frequency of 20 seconds. If the temperature of the water that enters the underfloor heating system does not correspond to the desired one, the valve automatically turns 45 ° in one direction or another.

The three-way design, however, is imperfect and has its drawbacks:

- The presence of excess pressure;

- Possibility of inlet of hot water;

- Large throughput, leading to significant fluctuations in the temperature of the coolant.

Sudden changes in pressure and temperature can cause rupture.

How to set up a mix node?

Connecting the mixing units is quite simple, so installation is quite feasible with your own hands if you have instructions. The first thing to do is to choose a place for the mixing unit.

The mixing group is mounted up to the contours of the underfloor heating system in a collector cabinet, in a boiler room or directly in the room.

If parts of the water floor are connected by means of flexible pipes, then the mixing unit is rigidly attached to the wall. It is necessary to provide free access to the parts of the mixing unit.

Collector cabinet and its equipment

Be sure to consider the type of material from which the pipes are made. They must withstand the temperature of the incoming coolant. If a water-glycol solution is used, galvanized pipes will not work.

Liquid must not be allowed to come into contact with parts of the mixing system that are energized.

After installation, the mixing system is connected to the coolant supply and return pipes and pressure, temperature and flow sensors are installed. These elements are either supplied with the assembly or assembled independently. After that, the thermal mixer is connected to the branch pipes of the outlets of the heating circuit.

Mixing unit connection diagram

Before connecting the circulation pump, grounding must be done. Optimum pressure loss parameters are ensured by means of a balancing valve on the bypass. This takes into account the losses in the non-return valve.

If the heating system is single-pipe, the bypass must always be in the open position. Then hot water in parts will pass to the radiators. With a two-pipe circuit, the bypass is closed. When the whole structure is assembled, it is connected with fittings to the circuits.

Mixing units Valtec

The mixing unit for underfloor heating valtec (Italy), thanks to fittings and automation, fits perfectly into the "smart home". Unlike other models, Valtek regulates the temperature of the coolant up to 60 degrees Celsius. Permissible pressure level - 10 bar.

The Valtec Combimix is a manifold block containing a thermostatic head and a separate immersion temperature sensor. In addition, the package includes:

- flowmeters;

- Automatic air vents;

- Water heating debugging valves;

- Drainage.

Equipment Valtec Combimix

The thermal mixer increases the rate of water circulation in the floor pipes and lowers the temperature to the set value. The Combi system is designed for a heat load of up to 20 kW.

The valtec underfloor heating mixing unit performs the function of mixing hot water from a water heating boiler with cold water from underfloor heating circuits. The liquid is moved by means of a circulation pump. The supply manifold receives water from the assembly, which then flows through the floor heating circuits. The temperature of the heat carrier decreases, heating the room, and then the water returns to the collector again. Cold liquid flows from the return pipe through the assembly, after which the cycle begins anew.

At the inlet of the unit there is a valve with a thermal head, which serves to set the temperature regime. An external temperature sensor is placed in front of the supply manifold. The degree of water heating is adjusted by hand on the scale of the thermal head. If the parameters increase, the valve closes automatically and hot water stops flowing into the unit. If the liquid has cooled down, the valve opens the way to the hot coolant. Thus, a constant temperature is ensured at the outlet of the unit.

The mixing unit is used not only in the water floor heating system, but also for heating open areas, walls, greenhouse soil.

Dear reader, leave your opinion about the article in the comments and share your experience and secrets of installing mixing units for underfloor heating.