Mixing unit for underfloor heating: selection and configuration

Water "warm" floor is a low-temperature heating system of a common line, through which the coolant is supplied to high-temperature radiators. Therefore, an additional element appears - a mixing unit for underfloor heating, designed to lower the temperature of the circulating water. Otherwise, excessive heating of the floor covering will cause discomfort during operation, the screeds will experience critical loads, which will reduce the life of the structure.

The standard heat carrier temperature for heating radiators at the outlet of the boiler is 95 - 90˚С. 85 - 70 degree heating registers are less commonly used. According to the current SNiP, SanPiN, a temperature of 50 - 35 ° C is considered comfortable for the operation of a floor covering. Therefore, water from the boiler must not be fed directly into the floor circuits. The issue of its lowering is relevant for water systems of any type. You can do without a mixing unit only when using a heat pump. The presence of any high-temperature consumer (shower, bath, wall-mounted radiators) will require the installation of a mixing unit.

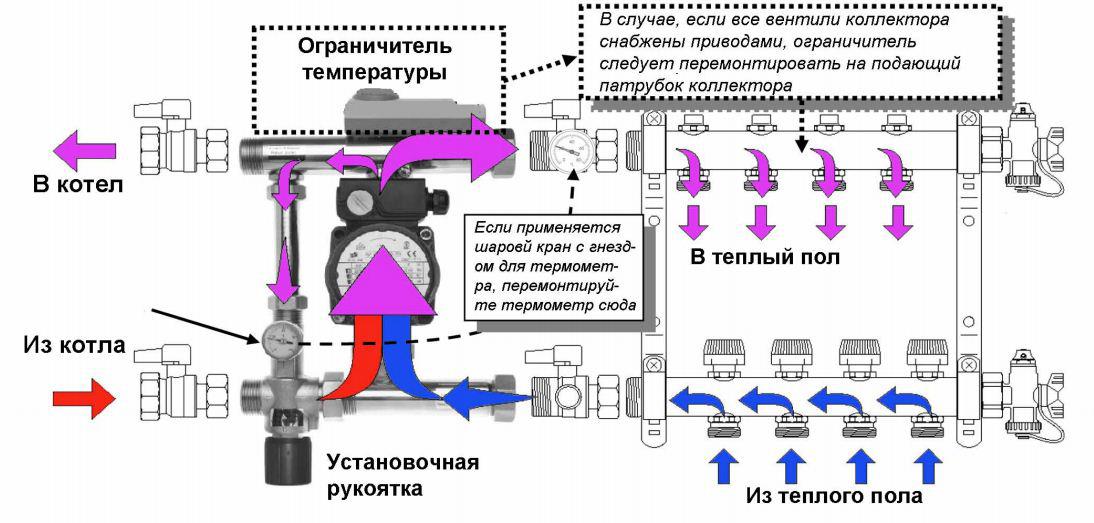

Appearance of the mixing unit for underfloor heating

The mixing unit for underfloor heating is mounted on a wall or in a niche in the same room where the heating circuits are laid. There are modifications with two, three way valves, popularly nicknamed "combs" for a similar shape. The nuances of the connection make installation inaccessible to the home master, a temperature calculation is required, therefore, ordering a service from a specialized company is preferable to increase the operational life and eliminate errors.

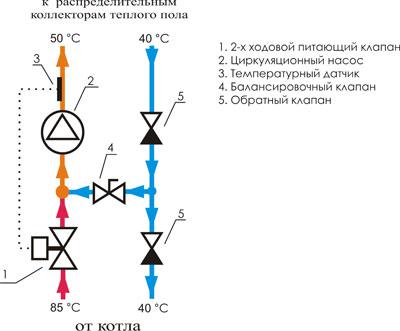

Scheme of operation of the mixing unit

Boiling water from the boiler reaches the room with heating circuits inside the screed, rests against the mixing unit for the warm floor, where the thermostat measures the temperature of the coolant. If the value is too high, the return valve opens, the liquid is mixed into the boiling water, which gave off thermal energy when passing through the pipes of one of the circuits. When the temperature set in the settings is reached, the main valve opens, water enters the system. There are two main schemes for including a node in the system, the choice depends on the operating conditions in a particular room.

In addition to temperature control, the collector "comb" ensures the normal circulation of the coolant. The node consists of the following elements:

- valve - provides outlet temperature control, periodically mixes cold water from the return

- pump - necessary for circulation with specified parameters to ensure uniform heating of the entire surface of the floor covering

- bypass - optionally mounted, protects equipment from overloads

- air sensors - control the content of O 2 in the coolant

- valves - shut-off, drainage, stabilize the operation of the circuits

To increase the artistic value of the interiors, the collector unit can be moved to the boiler room, the collector cabinet in a separate room. The second option is optimal if there is a warm floor in several rooms of the cottage / apartment. The most popular are three, two-way valves in various mounting schemes.

Two-way valve in the mixing unit

The main difference between the collector "comb" scheme with a two-way valve is the continuous supply from the return without shut-off valves. The mixing unit for the warm floor periodically mixes boiling water into it when the coolant cools below a predetermined level.

The valve is called a supply valve, it has a built-in liquid sensor-thermostat that cuts off / adds hot water as needed. Due to the stable temperature around the perimeter, the structure has a high service life:

- sharp jumps are smoothed out by a small valve capacity

- temperature control range negligible

- scheme has proven itself in practice

The only limitation is the excessive size of the contours. When heating more than 200 square meters, the drop in return temperature is too significant, mixing boiling water becomes ineffective.

Three-way valve in the mixing unit

Universal equipment is considered to be a mixing unit for underfloor heating with a three-way valve.