Do-it-yourself mixing unit for underfloor heating

The purpose of the mixing unit is to adjust the temperature regime of the heated floor by mixing the liquid from the boiler and the return. It is not difficult to create a mixing unit for a warm floor with your own hands. However, with the device, certain actions should be strictly followed so that in the future the equipment does not break.

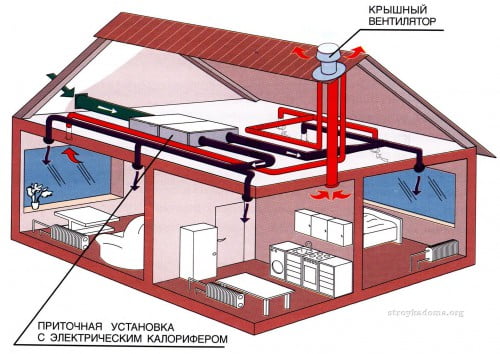

First of all, you need to find out how the mixing unit for underfloor heating works. It is used only for a water heating floor, since it has a mechanism similar to a radiator coolant. A typical heating scheme is built according to the following plan - a boiler that warms up the liquid, the contours of the heating floor and radiators.

The boiler heats the coolant to a temperature like in a radiator, usually it is 95C. Ideally, the temperature regime should not be more than 31C. There are several reasons for this, especially that the floor should not be very hot or cold to feel comfortable.

It is necessary to take into account:

- type and thickness of the finish coating;

- the height of the heating floor screed, in which the pipes are located.

Accordingly, the most suitable liquid temperature in the pipes should vary from 35°C to 55°C. However, in the boiler it is very high, and it is forbidden to direct such a temperature into the pipes. Therefore, in order to reduce it, a mixing unit is used at the beginning of the heating system. It is in it that mixing of water of high and low temperatures takes place. And the already cooled liquid is transferred to the floor tubes. By means of a mixer, the underfloor heating system functions correctly and without interference throughout the house.

Mixing unit for underfloor heating

Of course, there are warm floors that work without a mixing unit. But they are equipped with a water heating device that heats the coolant to the optimum temperature.

Mixing unit connection plan

The heating floor is connected to the boiler according to a certain scheme, which depends on the heating system:

- 1-pipe;

- 2-pipe.

A single-pipe heating system needs to constantly open the bypass, while a two-pipe heating system does not. The project can be both the most elementary and using a number of complementary elements.

Single pipe heating system

In any case, thermostats for the manifold group, devices for controlling the flow of water and valves are installed. Direct mixing can be performed on all outlets of the collector group, or before them.

How to make a mixing unit with your own hands

The cost of the mixing unit is quite high, so it is more profitable for many to make it with their own hands. In addition, it is not always possible to find a regulator with the required number of inputs. In this case, you should also purchase combs, which you can put on your own.

In order to assemble a mixing unit for a warm floor with your own hands, you will need:

- 2 or 3 way valve;

- special nuts;

- manual air vent;

- return valve;

- clamps;

- ball valve;

- circulation pump;

- tees;

- devices for determining temperature.

Mixing unit for underfloor heating

The first stage consists of the manufacture of the manifold. You can do this using 2 ways:

- solder from polypropylene tees;

- twist from tees.

In any case, the diameter of the elements should be ¾ inch. When soldering, the collector will cost more, since each branch of the comb must be equipped with an MPH, which has a rather big price. High-quality tees are considered the most suitable material. The most important thing is to choose them correctly. For a comb, products with 1 inner and 2 outer ends are ideal. They twist with each other only with the help of tow.

The second stage is to create a hydraulic arrow. You can do it even without using a 3-way valve. A standard adjusting valve, which is used for heating batteries, will also suffice. In addition to it, you will need 2 tees, as for combs, and 2 connecting nipples with threads outside and inside, the length of which should be 0.5 m. Assembly is carried out on tow. To do this, the nipples are screwed on both sides of the tap, and 1 tee is connected to them on each side.

The third stage is the construction of the pump. It is impossible to make a pump unit for a warm floor with your own hands, so they buy it. The pump is mounted at the bottom of the hydraulic arrow by means of detachable connections, which are sold in the kit. You can also install it instead of a hydraulic gun. It will act as its replacement, and functions just as well.

Pump unit for underfloor heating

The final stage is the connection with the combs of the hydraulic gun. It is best to make detachable connections. When the pump acts as a separate element, it is necessary to buy a pipe. Its length should be equal to that of the pump. It is mounted on the supply, and a collector is screwed to the pipe. It is for this reason that it is much more economical to use a pump instead of a hydraulic gun.

Then the comb is completed with adjustment valves, Mayevsky cranes or automatic devices for air discharge. Next, the mixer is placed in the allotted area of a special cabinet and connected to the heating system.

Do-it-yourself thermomixing unit for underfloor heating is connected by means of shut-off valves. Similarly, there is a connection between the node and the heating floor. The first end with a comb at the bottom, the second - to the top. In order to avoid confusion, a certain layout should be followed - the supply and return of one segment must be connected in series. In addition, the electrical supply is connected to the pump.

Thermal mixing unit for underfloor heating

Blend node setup

After the installation of the mixer is completed, it is time to check its performance. As a rule, adjustment takes a lot of time and effort than installing a mixer. However, harmonious calculation allows you to do this at minimal cost.

First of all, the servo is removed. This is done so that it does not affect the node during the configuration process. The bypass valve is set to the extreme position.

Important! A valve accidentally activated during the tuning process will cause the result to be incorrect. Accordingly, the mechanism must be given a position in which it will be in complete inactivity.

Then comes the turn of balancing the contours of the floor. First, the radiator circuit is closed, i.e. the balancing shut-off valve of the first line. The cover is removed from the valve and, using a hex wrench, it is turned to the end clockwise. The lines of the kennel are balanced by special valves. When the mixer has one line, then balancing is not necessary.

If necessary, it is carried out by the following actions. The regulators are opened to the maximum. The valve closes to the best size in the circuit where flow deviation is greatest.

According to this scheme, the heating line as a whole is regulated. When the flow data is lost when balancing the lines, they are re-adjusted. If the flow rate is not corrected with the valves open, increase the operating speed of the pump.

Pump mixing unit

Next, the pump mixing unit is connected with other heating elements of the system. Why open the balancing shut-off radiator valve, closed before starting the adjustment. Open it to an indicator corresponding to the optimal flow rate of the liquid.

The flow of water is controlled by means of special flow meters. Can also be adjusted via the return stroke in the floor system. Then comes the turn of the bypass valve. To begin with, the valve pressure is set. The parameter must have a value of no more than 10% of the highest pumping pressure. This maximum should correspond to the main features of the pump type. The valve is activated if the unit builds up pressure at the lowest flow rate.

Modifications and arrangement of mixers

Mixing units in standard configuration include:

- thermostatic and adjusting valve;

- thermostatic head;

- pump;

- temperature device.

In total, there are 2 types of mixer - with 2-way and 3-way valves. They mix cold and hot water for the heating floor, which forms its incessant circulation.

The 2-way valve is equipped with a thermal head with a sensor. The temperature is checked by the sensor in real time, and if necessary, it stops the flow of liquid from the boiler. Hot water is supplied only when it cools down while mixing with the return flow. Two-way valves are designed for rooms no larger than 200 m2.\

Three way valve

A three-way valve has more capacity than a two-way valve. In small rooms, it will not be able to let water into the general system if it is fully open. As a result, this can lead to sudden temperature fluctuations and rupture of the tubes. Thus, the 3-way valve is best suited for spacious and large rooms where systems with a large number of circuits are installed and environmental controllers are used.

The modern market offers models that differ in consumer type:

- for mounting to a personal standard manifold;

- as a group personal node for connecting a system with significant power.

In the latter case, it can be used to connect several systems with low power ratings, or those designed for high power with 2 to 12 outputs.

Outdoor temperature sensors

These devices are recommended for systems as an automated adjustment of the coolant according to weather conditions. For example, if it is cold outside, then a signal is given to increase the temperature of the coolant. When warming is observed, the sensor informs the system that it is possible to lower the temperature readings.

Temperature sensors

The design of the device involves a rotation of 90 degrees. And a special controller divides them into 20 sections, and monitors the condition of the conditions on the street. If the water temperature does not correspond to them, then the valve turns to the required number of divisions. Of course, you can do all this yourself, but with a weather temperature sensor it is much more convenient.

Advantages of a warm floor with a mixer

A heating floor with a mixing unit has a lot of advantages compared to other heating systems.

Comfort

It is possible due to the flow of heat energy due to radiation, but not convection. In addition, the floor surface and the room are uniformly heated. There are no cold bridges and hot batteries in the rooms. All this creates a comfortable and healthy atmosphere, respectively, there is no dust. The surface always remains dry, it does not form an environment for mold, mites and other harmful microorganisms.

Underfloor heating with mixer

economic benefit

Depending on the location of the pipes and the functioning of the heating system, you can save on space heating. It has been established that 30% less electrical energy is spent in residential apartments, provided that the ceiling has a standard height. Thus, the consumption of energy resources can reach 50%.

Safety

This is important for rooms where there are constantly people. The functioning of the heating floor allows you to avoid burns and other manifestations that may occur when using radiators or convectors.

Hygiene

The system of water floors with a mixer allows for the appropriate disinfection of the finish coat. The floor can be cleaned with various detergents, water. Such a heating system is perfectly suited for rooms with specific hygiene requirements. For example, a water floor with a mixing unit is suitable for kindergartens and hospitals.

Underfloor heating - comfort and convenience

Convenience

For a water heating floor, it is not necessary to install additional devices in a heated room. All the necessary elements are installed, as a rule, in pantries. Therefore, you can do a variety of layouts without allocating space for the unit.

Faucet installation features

The underfloor heating mixing unit is installed directly next to the heater. When the elements of the hydraulic system are connected with elastic pipes, the mixing unit needs to be firmly attached to the wall. In addition, before installation, it is necessary to allocate places so that there is free easy access to the elements of the mixer.

The control valve must be located in the area of the inlet to the heat carrier heater. In the process of selecting pipe materials, make sure that they will withstand the temperature of the incoming coolant. Therefore, it is advisable to buy polymer pipes. It is also worth remembering that galvanized pipe cannot be used for a glycol-water solution. It is better to use locking parts from bronze and brass, pipes from black steel, and a pump from cast iron. Manufacturers steel parts of the entire system are primed and painted from the outside.

Note! The place of installation and connection of the unit must be chosen taking into account air bubbles that may appear from the boiler circuit outlet. It is also required to completely exclude the possibility of water and condensed liquid getting on parts of the system under voltage.

Mixing unit control valve

Thus, it is advisable to select the mixing unit individually, to ensure maximum convenience in using the floor heating system.

It is quite possible to choose a system on your own, having previously studied all the connection diagrams. However, if the user does not understand anything at all about the nodes and the purpose of the parts, it is best to buy a ready-made design.

A cable heating floor can be installed in a room of any purpose, both in an industrial building, an office, and in a living room. For obus...