Mixing unit for underfloor heating

When arranging any living space, considerable attention is paid to the issue related to floor insulation. In most cases, water insulation is used as a solution to this problem, in which the mixing unit for underfloor heating is a key element. If for radiator heating systems the most optimal temperature will be within 80-90 degrees Celsius, then for underfloor heating systems the temperature regime should be lower (about 35 degrees). Faucets for underfloor heating allow you to ensure the normal operation of low-temperature systems, lowering the temperature by mixing the return flow with the hot coolant.

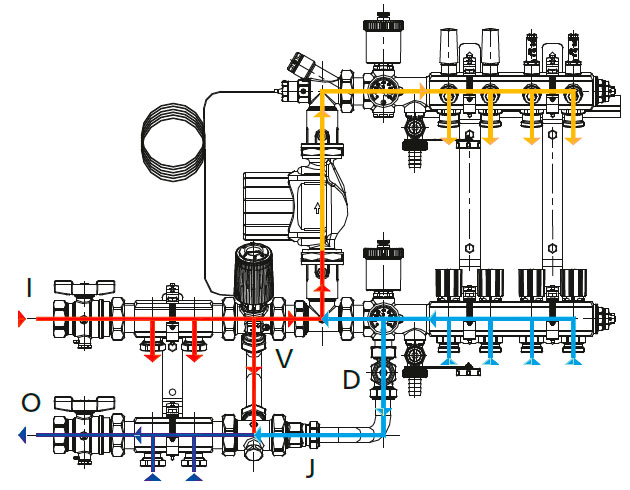

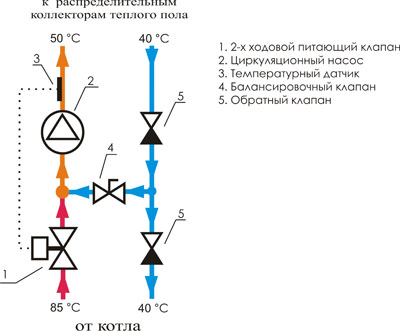

Devices of this action are great for connecting one distribution manifold. Naturally, they can be used as independent devices. Heat carriers are additionally equipped with a circulation pump, which is required to ensure forced circulation of fluid in the heating system. These devices, as a rule, have two-way and three-way supply valves that provide a constant addition of cold water from the return to the coolant.

Faucet for a warm water floor - the benefits of using

Underfloor heating equipped with a thermal mixer has many advantages that make this system more and more popular. We list the most important:

- Safety. Very often there are situations in which people forget about the high temperature of the heating devices, which causes severe burns. When using this system, such troubles are completely excluded.

- Hygiene. Caring for warm floors is not difficult, and thanks to constant heating, they dry out in the shortest possible time, which eliminates the possibility of the appearance of various fungi and mold.

Profitability. As a rule, when using underfloor heating, energy savings range from 30 to 50%.

- Durability. The only element in the system that is subject to the most significant wear is the pipe, which has a service life of at least 50 years.

- Outside temperature control - a two-way valve is equipped with an electric actuator connected to a thermostat. Adjustment of the heating level is carried out taking into account changes in the street temperature regime.

- Manual mode, in which the block is used without valves. The percentage of mixing in this situation is determined manually. Not recommended for use simultaneously with high temperature heat sources.

- Temperature limitation mode, which is ensured by installing a thermostatic head on the valve, equipped with a remote type sensor. The temperature regime of floor heating is limited by the mark set on the thermostatic head.

The purpose of the mixing unit for underfloor heating and the principle of its operation

A thermal mixer for underfloor heating is equipment designed for circulation and regulation of the heat carrier through the floor heating system. It includes two main elements:

- The circulation pump, thanks to which the liquid circulates in the underfloor heating circuit.

- A control valve that feeds the circuit with hot water to the temperature set on the coolant.

Mixing group for underfloor heating - types of collectors and their brief characteristics

First type

The basis of this device is the use of three-way mixing valves, the task of which is to mix hot water from the boiler and cold water from the return. The valves are usually equipped with servomotors, thanks to which it is possible to control thermostatic devices and weather-dependent controllers. This type of collector is considered the most optimal, but it has some disadvantages. First of all, it is worth noting the situation during which the valve, at the signal of the thermostat, can open completely and let hot water into the system, the temperature of which reaches 90 degrees Celsius.

A sharp temperature jump can provoke a rupture of the heating pipes, as the pressure in them becomes too high. It is also worth noting that three-way mixing valves have a high capacity, which is not very convenient, since any changes in the valve adjustment can significantly affect the floor temperature. Despite the mixing unit characterized by such shortcomings, a warm water floor of this type is considered simply indispensable in large heating systems.

Second type

With this type of mixer, two-way supply valves are used. Their main distinguishing feature is that the mixing of hot water with cold occurs constantly, which completely eliminates overheating of the warm floor. The two-way mixing valve has a low flow capacity, which ensures smooth and stable temperature control. They are not recommended to be installed in rooms with an area exceeding 200 sq.m.

Distribution mixing unit for underfloor heating

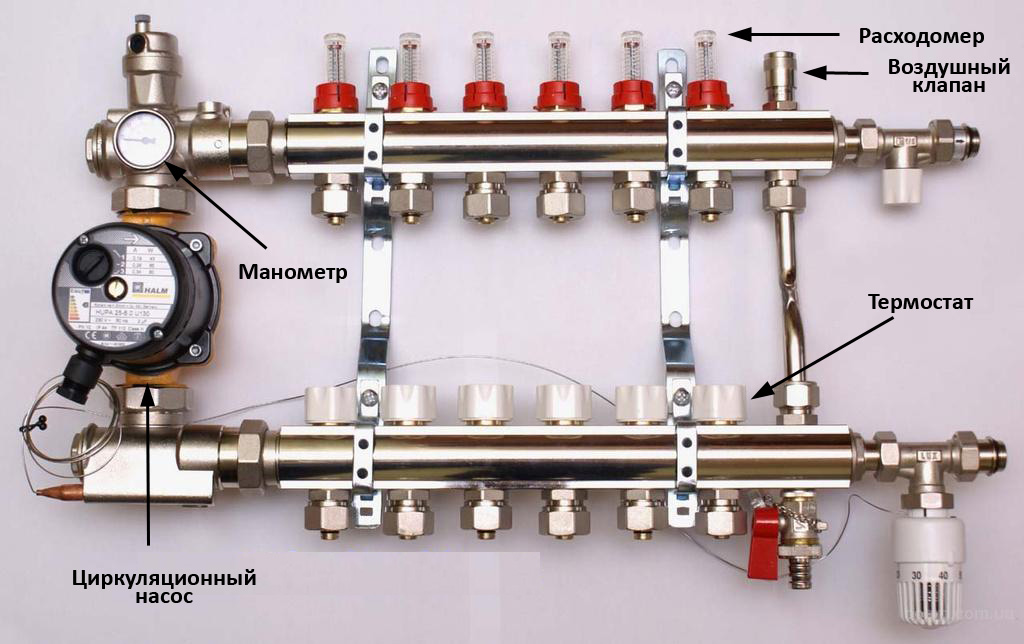

The collector for the water floor is an equally important element that is responsible for regulating the temperature of underfloor heating. Its main functions are to distribute the coolant along the heating circuits. Mandatory elements of the collector are flow meters and thermostatic valves.

Flow meters must be present without fail, since the length of the pipes in the system is different and, accordingly, water in short pipes without a flow meter can flow with less resistance. Thanks to the flow regulator, uniform circulation of the coolant throughout the system is ensured, and thermostatic regulators help regulate the temperature in individual circuits of the system.