Pumping and mixing unit for the boiler: we combine radiators and underfloor heating

How to combine a radiator heating system and a water heated floor? For one heating boiler. If possible, with video accompaniment.

Khalil (Orsk)

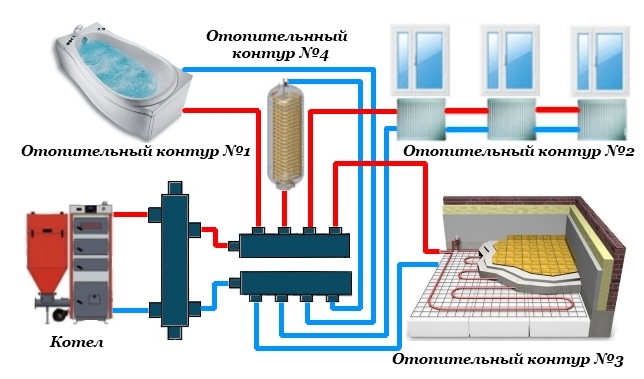

Hello Khalil! In order to simultaneously connect heating radiators and to the boiler, a collector assembly is required. It is bought in assembly (the price is 10-20 thousand rubles, depending on the heated area), or, if there is experience, they are assembled with their own hands.

For example, the price of a VALTEC COMBI pumping and mixing unit costs almost 15 thousand rubles. excluding collectors.

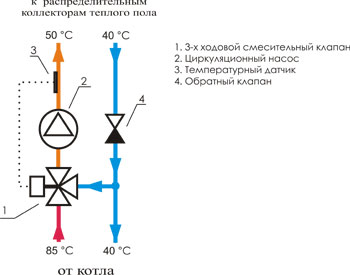

The boiler heats water usually up to 80-95°C, which is the optimum temperature for use in radiators. However, according to sanitary standards, the floor temperature should not exceed 30°C.

Exceeding this temperature can lead to an increased release of harmful substances from floor coverings, and in general it will be uncomfortable to walk on such a floor (see).

Considering the thickness of the floor screed and floor covering, the temperature of the heat carrier in the circuits is not higher than 55°C. That is why water for a warm floor is supplied through a mixing unit, it mixes a hot liquid with a cooler one (which has already passed through the system and has had time to cool down).

The scheme of the system is shown in the video:

System elements

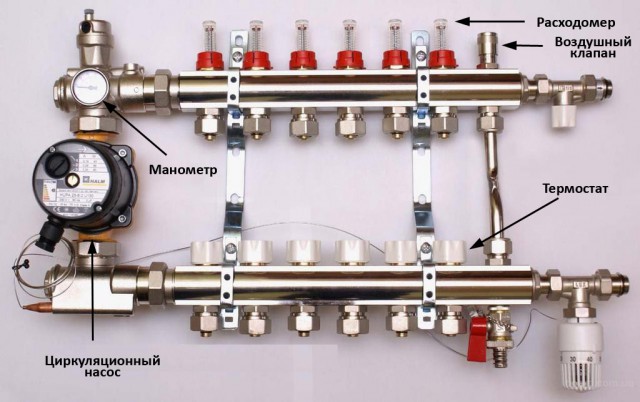

When the hot coolant reaches the collector, it rests against the safety valve. The thermal head determines the temperature of the liquid and if it exceeds the set values, the valve opens slightly and the cold and hot coolant are mixed.

In addition, if the contours are long, they often make a pump-mixing unit with their own hands. It is equipped with a circulation pump, which drives water through itself and increases the pressure in the system.

In addition to the main elements (two- or three-way valve and pump), there are additional parts in the assembly: a bypass (jumper), drainage and shut-off valves, an air outlet, and an expansion tank.

The mixing unit must be installed before the contours of the warm floor, but it does not have to be right at the inlet. You can install the mixing unit in the basement, boiler room or any other room.

two way valve

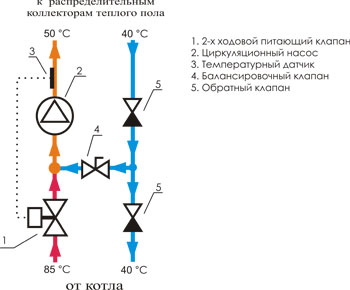

How the two-way valve works The thermostatic head on the two-way valve constantly controls the temperature at the inlet to the underfloor heating circuit. If necessary, it changes the position of the valve and thereby increases or decreases the water supply.

How the two-way valve works The thermostatic head on the two-way valve constantly controls the temperature at the inlet to the underfloor heating circuit. If necessary, it changes the position of the valve and thereby increases or decreases the water supply.

The circulation is designed so that the water goes in a circle, and the hot coolant is added when the temperature drops. Due to the low throughput, this option regulates the temperature smoothly and without sudden jumps.

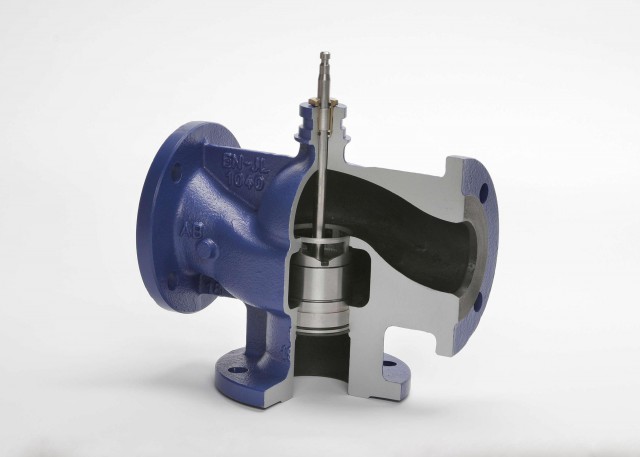

In most cases, they install just such a collector for a warm floor with their own hands. However, it is not suitable for rooms with a heating area of more than 200 square meters. m.  Sectional view of two-way control valve RV 113

Sectional view of two-way control valve RV 113

Three-way valve

The device of a three-way valve with a bypass This type is fundamentally different from the previous one. It mixes the return flow with the hot coolant inside. The valve has a damper, which is located perpendicularly between the supply and return. By changing its position, the ratio of warm and cold water is regulated. Often, controllers with servo drives are installed on such systems, which change the temperature automatically depending on the weather, the temperature in the house, etc.

The device of a three-way valve with a bypass This type is fundamentally different from the previous one. It mixes the return flow with the hot coolant inside. The valve has a damper, which is located perpendicularly between the supply and return. By changing its position, the ratio of warm and cold water is regulated. Often, controllers with servo drives are installed on such systems, which change the temperature automatically depending on the weather, the temperature in the house, etc.

Schemes of mixing units

Ready-made mixing units for air handling units can be viewed in the diagrams below.

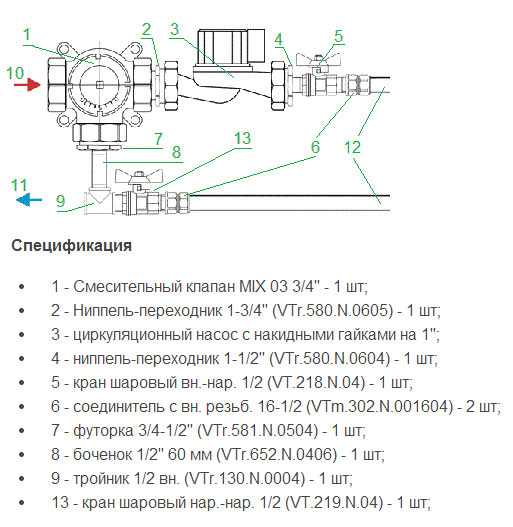

The first option is optimal for heating one room of 15-25 square meters. m. Manual temperature control. If you want to install automation, you can install the VT.M106.0.230 servo drive with a controller or thermostat.

- Connectors (No. 6) are connected to the pipes.

- The supply of hot coolant from the boiler is connected to output No. 10, and the return is connected to No. 11.

- The scheme can be supplemented with an automatic air vent.

It is best to connect the supply and return from the high-temperature circuit through an American tap.

The second version of the node is also suitable for heating 15-20 sq. m., but unlike the previous version, it has automatic adjustment, due to the installed thermal head with a remote sensor.

- To connect it, the mixing valve (No. 1) is mounted with a “+” sign in the direction of the American tap from the supply.

- The supply and return are connected to American women through connectors with external threads (No. 4 - inlet, No. 7 water outlet).

- The operation of the circulation pump (No. 18) is directed towards the mixing valve (No. 1).

- The underfloor heating circuits are connected to outputs numbered 12 and 22.

Pumping and mixing unit from Valtec

Pumping and mixing unit from Valtec

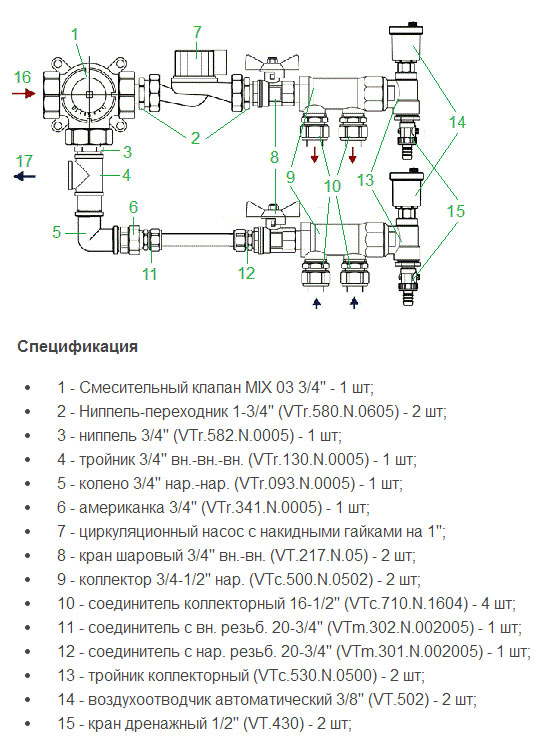

The third version of the collector unit is already suitable for 2-4 heating circuits with an area of 20-60 square meters. m. The diagram shows an example with manual control.

- To connect, the supply from the boiler is connected to terminal No. 16, and the return to terminal No. 17.

- For the system to work well, the length of the loops should be approximately the same.

- The diagram shows an option for two circuits, but if you need to connect three or four pieces, then the manifolds (9) are replaced with one adjustable manifold and one with ball valves (VTc.560n and VTc.580n).

The following scheme is also suitable for heating rooms up to 60 square meters. m., for 2-4 circuits, but it has automatic temperature control.

- The supply is connected through the upper American tap No. 3, and the return is connected to the lower tap.

- The pump must work towards mixing valve number 2.

- The valve itself is installed with a plus sign in the direction of supply from the boiler.

- The contours for the warm floor are attached to the collectors (12).

![]()

And the last scheme with auto-adjustment is suitable for a floor heating system for 3-12 circuits, up to 150 sq. m.

Specification:

- 1 mixing unit Combimix (VT.COMBI.0.180);

- 1 manifold assembly for the required number of outlets (VTc.594/VTc.596);

- circular pump 180 mm;

- 2 fittings (for each circuit) VT.4420.NE.16 of the Eurocone standard for connecting metal-plastic pipes.

The circulation of the coolant in such a collector is shown in the figure. The supply is connected to the upper outlet, the return to the lower. The operation of the pump is directed downward, so the lower manifold becomes the supply for the underfloor heating circuits (orange in the photo), and the upper one goes to the return line (blue).

A collector for a water-heated floor is usually installed in a manifold cabinet. They are both internal and external. Their standard depth is 12 cm, so not every node can fit, especially if large temperature sensors are installed. In this case, it is better to choose an internal cabinet, the depth of which is increased by deepening the back wall.