How to make a warm floor from polypropylene pipes

Many of us have faced heating problems: components are leaking, the need to replace the heating system in a private house, and so on. However, sooner or later we come to the conclusion that the most efficient heating system is the one that includes a warm floor. It is not only productive, but also very pleasant. Despite the terrible winter outside the window, you can safely move barefoot around the house, while feeling warm and cozy. What do I need to do? Install a warm floor with your own hands. Moreover, now there are enough various photo and video materials on this topic on the Web, so there will be no problems with the instructions.

Polypropylene pipes

And it’s worth starting with the base - polypropylene pipes. They are now known to many, have become an excellent replacement for traditional metal products. At the same time, they can be used in various environments: in mines, canals, under plaster or in the ground. Therefore, this material is well suited for underfloor heating. However, do not forget to take into account the ambient temperature. To install them, the air temperature should not be less than plus five degrees Celsius. Of course, this significantly limits the use of such material.

Such products have a too large bending radius - this is their main drawback. Thus, with a diameter of 16 mm, the product is laid with a minimum distance of 128 mm. This is not always convenient in terms of providing the necessary thermal power.

Pipes are connected using a special welding machine based on a thermal method. If you need to connect polypropylene products with metal, then flange and combined parts should be used.

Calculation of a warm "polypropylene" floor

To comply with the maximum temperature of the upper layer of the floor, polypropylene pipes are used - a warm floor is created in the room. At the same time, the water flow rate should be about 0.3 m / s so that the heat spreads smoothly over the heated area.

What determines the temperature of the warm floor:

- on the type of room: kitchen, bathroom, corridor, and so on;

- from the temperature of the room itself;

- from the final coating: carpet, laminate, tile and so on.

Often, an indicator of 45 degrees Celsius is taken as the average parameter.

Pipe calculation

It is impossible to make a warm floor without calculating the entire heating system, taking into account the area of \u200b\u200bthe heated room, the coolant pressure in the riser, and so on. Based on these characteristics, the pipe diameter is calculated.

Often, pipes 25, 20 and 16 mm in diameter are used for underfloor heating.

What are the consequences of making the wrong choice?

If the pipes are installed with a smaller diameter, the circulation of water in the system may be disturbed. To find out the pressure in the system, it is enough to measure it with a hydraulic pressure gauge.

When calculating the diameter of the pipes, you should also deal with their length. When making calculations, remember that the laying of the system starts from the walls with windows, since the cold air must be heated first. And after that, the heat should be distributed throughout the system.

Laying methods

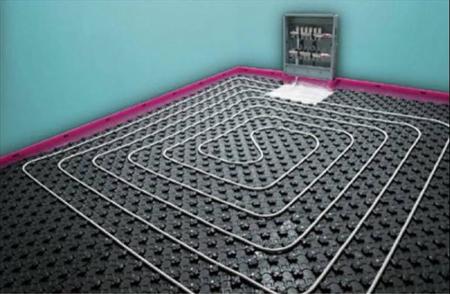

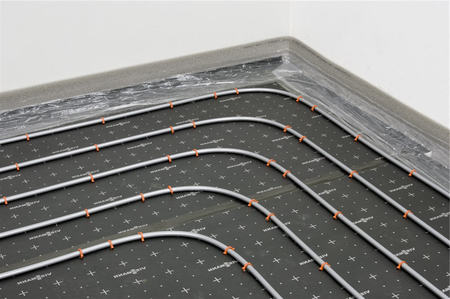

At the design stage, it is necessary to decide on the installation method: “shell” or “snake”.

"Shell" is most often used in our area. Although the design and installation of this method is more difficult than the second. The popularity of this method is due to the uniform distribution of heat over the floor surface. After all, hot supply and return slightly cooled pipes run in parallel. In this case, an average temperature is observed in any heated area, and the heating return point of the coolant is located in the middle of the pipe.

"Snake" can often be found in European homes. It is easier to calculate and install. Although there is no need to talk about the uniformity of heat distribution. As a result, during operation in some areas, the temperature may exceed the norm. Thus, with this method, heat losses increase, and the level of comfort of use decreases. Therefore, it is worth laying pipes with a “snake” if the temperature difference at the inlet and outlet is no more than five degrees.

Installation

According to the standards that must be taken into account when designing, the pipes should be located at a distance of about 20 cm from the walls, and the step is about 40 cm.

For laying the system, it is better to use coils, rather than separate pieces of material, since this will reduce the number of joints, and therefore save money.

In one circuit, the length of the heating element should not exceed 100 m. To release air, a valve is made at the highest point of the system.

Installation of "polypropylene" warm is carried out according to the principle of installing a pipeline. When laying, you need to monitor the material so as not to cause mechanical damage to it with a metal fastener.

Examination

After laying the system, it must be run at half power. Products must take their final form, and then a new layer is installed.

Is the game worth the candle?

Do-it-yourself installation of a warm floor is not difficult if you follow the recommendations given. Additionally, you can see the video and photo instructions. All this in the complex will allow you to create a high-quality and evenly heated floor heating that will delight all households and guests in the cold season.