How to make an electric underfloor heating with your own hands

Electric underfloor heating has gained real popularity. It provides not only additional comfort, but also saves the cost of the main space heating. Laying a warm electric floor with your own hands is easy.

Important! The modern market of finishing and building materials provides a huge range of floor heating to choose from. Each type of underfloor heating has detailed instructions, so its installation is not a problem. Most importantly, carefully study the requirements.

DIY electric floor

Do-it-yourself electric floor device has the following scheme:

- draft base;

- thermal insulation;

- warm floor;

- coupler;

- flooring.

Mounting materials

floor heating materials

To equip a warm electric floor, you need to stock up on a special set of equipment and raw materials:

- cement powder, sand and water;

- damper and mounting tape;

- putty and adhesive tape;

- spatula and mixer;

- waterproof and insulating material;

- cable and brackets;

- self-tapping screws;

- thermostat and sensors;

- gloves, adhesive mixture and flooring.

The room must be prepared before the arrangement of the warm floor. All plumbing fixtures should be removed, furniture removed, old flooring removed and construction debris removed. In addition, the floor is leveled using a cement mortar. Only on a perfectly dry and clean, scrupulously leveled surface, you can do the installation of an electric floor heating with your own hands.

Floor preparation

A damper tape is laid along the contour of the room to compensate for the possible expansion when the warm floor is heated. Then the markup is carried out, namely the outline of the areas on the surface, in the area where the heating elements will be. In this part, certain distances must be observed:

- from stationary heating devices - at least 10 cm;

- from the walls - at least 5 cm.

Distribution of heating elements

The first step is to create a wiring diagram on paper. Here it should be taken into account that the heating element is not mounted in those areas where household appliances and overall furniture will be located. Where the heating elements pass, it is necessary to provide an intermediate area without heat sources. This is explained by the feature of the electric floor heating.

The thermal elements of one circuit in comparison with the hydraulic system heat up equally. They can break if there is a restriction on thermal output, which can be provoked by pieces of furniture without legs. In addition, the furniture itself can deteriorate from heating.

As a result, the plan should look like an irregular configuration that fits into the configuration of the room. A warm floor will be laid out along the contour and inside such a figure. This is a flaw in the electric version of the floor, since rearranging pieces of furniture can adversely affect the functioning of the entire system.

For different rooms, it is advised to create separate electric floor circuits, which will have an individual power supply and regulators. Even if such rooms are demarcated symbolically. After planning on paper, you can start marking the floor itself.

Thermal insulation device

The most important stage of work is the thermal insulation of the surface. Qualitatively executed thermal insulation will make it possible to minimize heat losses, while electrical energy will be significantly saved.

thermal insulation

When choosing a thermal insulation material, the following factors should be considered:

- for rooms on the ground floor, loggias and balconies, it is best to use the most effective and massive heaters - like a cork substrate or extruded polystyrene foam 20-50 mm;

- for rooms of the second or more floors, which have good wall insulation and are equipped with double-glazed windows, foam foam can be used as a thermal insulation material. It is produced in rolls. Thanks to a special light layer of the thinnest foil, penofol shows excellent thermal conductivity. It's easy to post it. This is done using a self-adhesive layer of material.

Joints are sealed with construction tape. Then the coating is concreted. In order to create a high-quality concrete screed during the subsequent installation of an electric type of floor, it is necessary to put a special reinforcing mesh on the insulating layer.

Arrangement of a warm electric floor

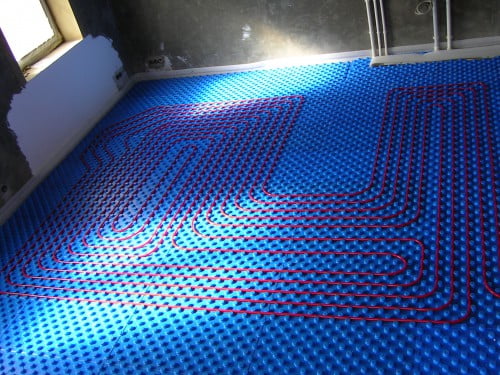

Underfloor heating installation

Installing an electric underfloor heating with your own hands needs to follow the instructions exactly. The cable is carefully laid along the marking lines. You can't categorically bend it. The cable is attached to the reinforcement mesh using clips or a special tape. The layout is carried out along the marked contours. During laying, the mats are cut in such a way that the cable is solid, and only the base is separated. By means of a special tape, the mats are attached to the thermal insulation.

The heating cable will be connected to the temperature sensor and the power cable only in a straight line. The connection area is covered with a corrugated pipe, and then laid out between the cables. The next step is to test the resistance of the cable. This is done by connecting to a thermostat.

Before connecting the floor, turn off the electricity in the room. It is first necessary to test the heating system and test it in different temperature conditions.

Floor screed

Laying an electric underfloor heating with your own hands involves closing it with a screed. This requires a concrete mixture. For independent use, it is recommended to buy a special mixture. Its packaging will indicate that it is intended for these events. The dry mixture is diluted according to the instructions. The thickness of the screed varies from 4 to 5 cm.

Underfloor heating screed

The mass is distributed with a spatula on top of the heating elements. Care should be taken to ensure that the mixture is laid under the cable body without pockets of air. Otherwise, the heating will be of poor quality. The finished screed needs to dry completely. After that, the laying of the floor covering is carried out. The technology depends on the materials used.

Calculation of a warm floor

For a clear understanding of the required power of an electric underfloor heating, a number of parameters should be taken into account:

- the role of a warm floor - if this is the only source of heat, then 220 W will be needed per square, and if additional comfort is needed, 150 W is enough for m 2;

- location and purpose of the room - in bathrooms and bedrooms they usually take 180-200 W / m 2, in the living room - 150 W / m 2, but if it has 2-3 external walls, then it is better to opt for a more powerful option;

- the type of room below - when there is another apartment there, then the calculated power is also suitable, but if this is a room without heating, then in addition to a thick heat-insulating layer, you need a warm floor with high power.

Important! After all the work has been done and the electrician is connected, the warm floor is checked for operability. You can not turn it on immediately at full power. You can do this after half a month / month.