Bathroom waterproofing under tiles: what is better to choose?

A bathroom in any home is the room with the highest level of humidity, it is in it that warm steam accumulates. The lack of quality will lead to the appearance of mold fungi and the appearance of an unpleasant odor. The most important action in the performance of facing work is waterproofing. What is better to choose will be prompted by an analysis of the options and their characteristics.

The use of high-quality and reliable materials for waterproofing will allow you to perform any tile finish design that will last a long time.This finishing method can protect against moisture and the appearance of wet spots. It also increases the life of floor and wall finishes and prevents damage to the concrete base. For the device in the bathroom, you will need the most moisture-proof and durable materials.

Bathroom waterproofing under tiles: which is better and which method is preferable?

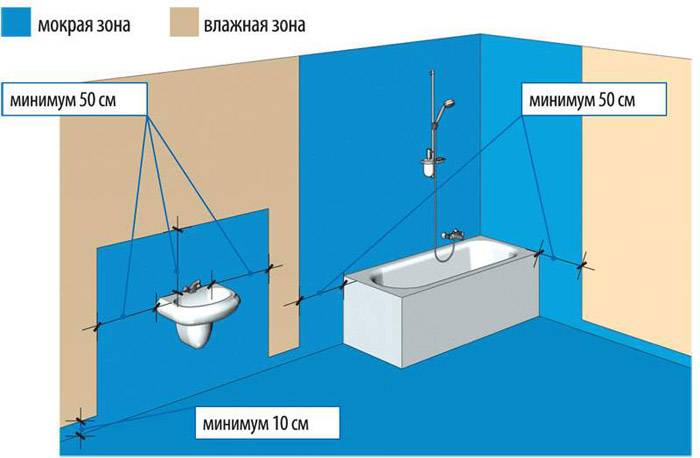

For sound waterproofing of floors in the bathroom, durable materials are required. On the basis of the floor, such a coating is made with a certain spade on the walls. When decorating walls, such protection is necessary in the area of \u200b\u200bthe washbasin, shower and other plumbing fixtures.

When choosing a waterproofing option, the following criteria should be considered:

- the bathroom does not require such strong waterproofing as the foundation;

- the price of material options, which can vary greatly;

- the technology of the installation process should not be too complicated.

Moisture protection mixtures are single-component, which are diluted with water, and two-component, which are created using a polymer emulsion.

Varieties of waterproofing the floor in the bathroom under the tile

When viewing the material for waterproofing the floor in the bathroom, it should be borne in mind that there are two main types. This is a coating, represented by mastics, various pastes and solutions. And the second - pasting consists of film coatings, roll type.

Helpful information! If the room is too low and the floor level cannot be raised, then impregnations are recommended, which are liquid formulations. They are distributed on the base and form a special film that protects against moisture.

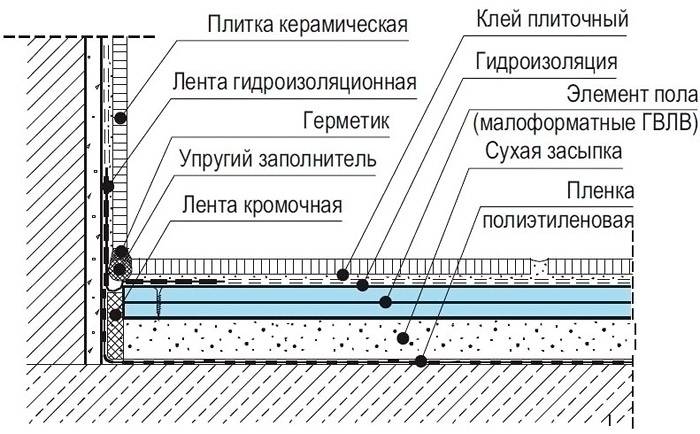

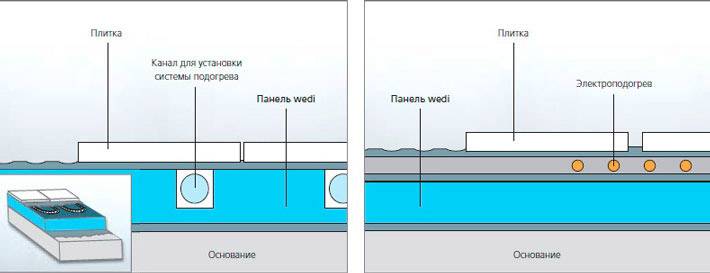

The diagram shows where the waterproofing layer passes.

The diagram shows where the waterproofing layer passes. Coating waterproofing

Moisture can be prevented by using waterproofing for the bathroom under. The following types of liquid coatings are used:

- cement-polymer products are a universal remedy. Such a mixture sets perfectly and is characterized by excellent adhesion;

- bitumen-polymer mastics are composed of special latex fillers, organic solvents and plasticizers;

- bituminous waterproofing is considered a budget option;

- modern materials include acrylic mastic.

Modern options are characterized by excellent waterproofing properties and provide full protection against moisture. The main advantage of such materials is the content of fillers and plasticizers in the composition, which give the material more elasticity and strength. Such a coating is characterized by the simplicity of the device, a long service life, and the floor does not need to be carefully leveled before processing.

The application of such waterproofing requires a special technique. Before work, you need to sweep the floor well. Then the base is primed using a roller. To prevent liquid from penetrating into the space between the floor and walls, they should be covered with a special sealed tape. Rollers are used to distribute the mastics over the entire area, and brushes are used for hard-to-reach areas.

Helpful advice! After applying the protective coating, leave time to dry. In this case, the room should be ventilated and ensure that dust does not penetrate the treated area. You can't step on the floor.

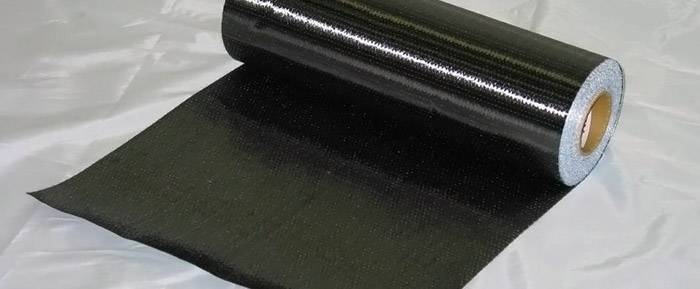

Pasting option

When deciding which bathroom waterproofing to choose for tiles and choosing what is best to use, it is worth trying the pasting type of moisture insulation. Roll-type materials are different. To create a built-up method, a gas burner is used, so it can only be used in a room where no one lives. For its laying, bitumen is melted, which emits a persistent odor. It is better to use self-adhesive and fiberglass reinforced waterproofing.

This type of insulation is produced in rolls.

This type of insulation is produced in rolls. This option is suitable for rooms of standard sizes and equipped with a ventilation system. Gluing waterproofing is considered a budget option, but requires some skills in the construction business. With this method, you need to pay attention to gluing the joints of the floor with the walls.

- a surface is prepared on which there should be no cracks, pits or tubercles;

- the surface is cleaned of debris and well primed with a bitumen primer;

- according to the measurements made, the material is cut. At the same time, it is worth making allowances for the walls of 20 cm;

- after laying the coating over the entire surface, you can walk with a roller to remove all bubbles;

- voids and joints must be treated with a bitumen-based sealant.

If pipes are installed before laying the tiles, they are covered with a special hermetic composition at the points of contact with the waterproofing layer. In this case, the pipes are placed in rubber sleeves. After installing the waterproofing, a screed is made.

Plaster variety

Stucco waterproofing of bathroom walls is popular. For this option, products with polymer components are used that improve the characteristics of materials. High-quality options include products of the Ceresit and Knauf brands, which are recommended for use in the bathroom. When choosing waterproofing, it is worth giving preference to the products of a particular company. Knauf contains synthesized latex, which gives the coating more elasticity.

Before distributing the mixture, the surface is cleaned and treated with a primer, and voids and joints are sealed with a special tape. Then the composition is prepared and distributed on the prepared basis. Plaster solutions are applied using rollers. After drying, another layer is distributed in the opposite direction.

Cast waterproofing

When planning how to make waterproofing in the bathroom, you should try the cast option. Installation is carried out by the method of cold or hot pouring.

As a material for hot waterproofing, asphalt concrete or bitumen is used. Such a coating is characterized by increased resistance to bending, reliability and elasticity. Filling is carried out on a previously prepared surface, where joints and seams were sealed. A similar method is used in private houses, and not in apartments.

The coating is carried out in several stages:

- the floor surface is cleaned, and the cracks are filled with a special sealant;

- the floor is dried with gas burners and;

- primer is made using hot bitumen;

- the area is allocated by the formwork design;

- the mass is warmed up for waterproofing; the hot solution is evenly poured out and distributed with a doctor blade.

Several layers of such filling can be used. For apartments, cast waterproofing of the bathroom under the tile is also used. What is best suited for this will be prompted by the advice of professionals. Cast coating can be cold applied. In this case, liquid glass or rubber is used.

Liquid rubber

One of the effective options for liquid waterproofing for the bathroom is liquid rubber. It is made from additives of polymer and bitumen. Calcium chloride is used as a fixing agent.

Durable coating is applied in different ways:

- filling equipment is made without any equipment, and allows you to fill small cracks;

- spraying is considered a more labor-intensive technique, since it requires a special device that helps to apply the solution under pressure;

- painting technique is carried out in the same way as the usual coating option.

After processing, a film is formed that protects the surface from moisture.

Overview of some types and costs

There are different materials for waterproofing a bathroom in a wooden house or in any other. An overview of the individual models can be used to select the best option.

| Image | Brand | Characteristics | Cost, rub. |

|

| 2 243 | |

|

| 1 040 | |

| 420 | ||

| Mastic creates a waterproof film. Solvent-free and odorless. | 2 600 | |

|

| 3 790 | |

|

| 580 | |

|

| 1 890 | |

|

| 5 340 |

Technology Features

A special approach is required for wood flooring. Wood quickly absorbs moisture, so it is necessary to isolate this coating well. In this case, a two-component waterproofing solution is used. To do this, liquid rubber is mixed with an activating component. The resulting composition is applied to the surface with a roller. After the layer dries, a second layer is applied.

When laying tiles, it must be remembered that the adhesive properties of such a floor are low, therefore, to increase adhesion, it is necessary to perform a screed with laying an armature mesh.

When using any waterproofing, preparatory work is first performed. Old paint is removed from the walls, floors are leveled and dust and debris are removed. Before laying waterproofing, you do not need to make perfectly smooth floors. Small irregularities will be covered by a layer of waterproofing. Alignment should be done with significant height differences. After clearing the surface, the floors are primed in several layers. The primer composition is distributed with a roller in even strokes.

Even with coating waterproofing, additional processing of corners, joints and pipe joints is required. In this case, all cracks and joints are eliminated with a sealed tape, and rubber plugs are put on the pipes. A similar type of moisture protection can be made independently. The dry mixture is diluted with water or a polymer emulsion. The finished mastic should resemble liquid plasticine.

The mastic dries within a day. During this time, do not walk on the floor, spill water or place any objects. After 24 hours, the final coating is laid.

High-quality waterproofing will allow you not to worry about the accumulation of moisture and leaks. High humidity will not harm such a finish. And even with a small flood - the water will not cause much damage.