Comparison of heating radiators for heat transfer

The real heat transfer of heating radiators of various types continues to be the subject of controversy that does not subside on various Internet sites and forums. Disputes are conducted in the context of which of them are the best in this indicator, which ultimately affects the choice of certain heating devices by users. Therefore, it makes sense to compare the thermal power of radiators of different types, evaluating their real heat transfer. What is said in the material presented to your attention.

You should always start with the technical passport that is attached to the product by the manufacturer. In it you will definitely find the data of interest, namely, the thermal power of one section or a panel radiator of a certain size. But do not rush to admire the excellent performance of aluminum or bimetallic batteries, the figure indicated in the passport is not final and requires adjustment, for which you need to calculate the heat transfer.

You can often hear such judgments: the power of aluminum radiators is the highest, because it is well known that the heat transfer of copper and aluminum is the best among other metals. Copper and aluminum have the best thermal conductivity, this is true, but heat transfer depends on many factors, which will be discussed later.

The heat transfer prescribed in the passport of the heater corresponds to the truth when the difference between the average temperature of the coolant ( t feed + t return line)/2 and in the room is equal to 70 °С. This is expressed using a formula:

(t feed + t return line)/2 - t air = 70 °С

For reference. In the documentation for products from different companies, this parameter can be denoted differently: dt, Δt or DT, and sometimes it is simply written “at a temperature difference of 70 ° C”.

What does it mean when the documentation for a bimetallic radiator says: the thermal power of one section is 200 W at DT = 70 ° C? The same formula will help you figure it out, you just need to substitute the known value of room temperature - 22 ° C into it and carry out the calculation in reverse order:

(t feed + t return) = (70 + 22) x 2 = 184 ° С

Knowing that the temperature difference in the supply and return pipelines should not be more than 20 ° C, it is necessary to determine their values as follows:

- t supply \u003d 184/2 + 10 \u003d 102 ° C;

- t return = 184/2 - 10 = 82 ° С.

Now it is clear that 1 section of the bimetallic radiator from the example will give off 200 W of heat, provided that there is water heated to 102 ° C in the supply pipe, and a comfortable temperature of 22 ° C is set in the room. The first condition is unrealistic to fulfill, since in modern boilers heating is limited to 80 ° C, which means that the battery will never be able to give off the declared 200 W of heat. Yes, and it is a rare case that the coolant in a private house is heated to such an extent, the usual maximum is 70 ° C, which corresponds to DT = 38-40 ° C.

Calculation procedure

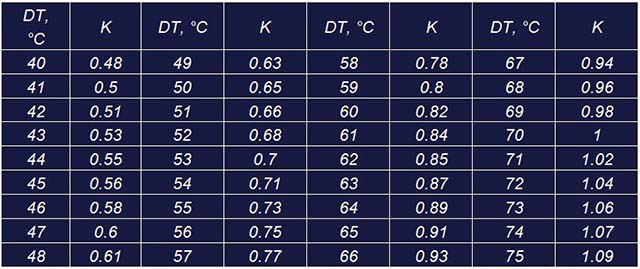

It turns out that the real power of the heating battery is much lower than stated in the passport, but for its selection it is necessary to understand how much. There is a simple way to do this: apply a reduction factor to the initial value of the heater's heat output. Below is a table where the values of the coefficients are written, by which it is necessary to multiply the nameplate heat transfer of the radiator, depending on the value of DT:

The algorithm for calculating the real heat transfer of heating devices for your individual conditions is as follows:

- Determine what should be the temperature in the house and the water in the system.

- Substitute these values into the formula and calculate your real Δt.

- Find the corresponding coefficient in the table.

- Multiply by it the passport value of the heat transfer of the radiator.

- Calculate the number of heaters needed to heat the room.

For the example above, the thermal power of 1 section of a bimetallic radiator will be 200 W x 0.48 = 96 W. Therefore, to heat a room with an area of 10 m2, you will need 1 thousand W of heat or 1000/96 = 10.4 = 11 sections (rounding always goes up).

The presented table and the calculation of the heat transfer of batteries should be used when the documentation indicates Δt equal to 70 ° C. But it happens that for different devices from some manufacturers, the radiator power is given at Δt = 50 ° С. Then you can’t use this method, it’s easier to dial the required number of sections according to the passport characteristic, just take their number with a one and a half margin.

For reference. Many manufacturers indicate heat transfer values under such conditions: t supply = 90 °С, t return = 70 °С, t air = 20 °C, which corresponds to Δt = 50 °C.

Thermal power comparison

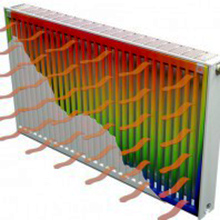

If you carefully studied the previous section, you should understand that heat transfer is greatly influenced by air and coolant temperatures, and these characteristics do not depend much on the radiator itself. But there is a third factor - the heat exchange surface area, and here the design and shape of the product plays a big role. Therefore, it is difficult to ideally compare a steel panel heater with a cast iron one, their surfaces are too different.

The fourth factor affecting heat transfer is the material from which the heater is made. Compare for yourself: 5 sections of the aluminum radiator GLOBAL VOX with a height of 600 mm will give 635 W at DT = 50 °С. Cast iron retro battery DIANA (GURATEC) of the same height and the same number of sections can only deliver 530 W under the same conditions (Δt = 50 °C). These data are published on the official websites of manufacturers.

Note. The characteristics of aluminum and bimetallic products in terms of thermal power are almost identical, there is no point in comparing them.

You can try to compare aluminum with a steel panel radiator, taking the nearest standard size that is suitable in size. The mentioned 5 GLOBAL aluminum sections 600 mm high have a total length of about 400 mm, which corresponds to the KERMI 600x400 steel panel. It turns out that even a three-row steel device (type 30) will give out only 572 W at Δt = 50 °C. But keep in mind that the depth of the GLOBAL VOX radiator is only 95 mm, and the KERMI panels are almost 160 mm. That is, the high heat transfer of aluminum makes itself felt, which is reflected in the dimensions.

In the conditions of an individual heating system of a private house, batteries of the same power, but made of different metals, will work differently. Therefore, the comparison is quite predictable:

- Bimetallic and aluminum products quickly warm up and cool down. Giving more heat over a period of time, they return colder water to the system.

- Steel panel radiators occupy a middle position, as they transfer heat not so intensively. But they are cheaper and easier to install.

- The most inert and expensive are cast iron heaters, they are characterized by a long warm-up and cool-down, which causes a slight delay in the automatic regulation of the coolant flow by thermostatic heads.

All of the above leads to a simple conclusion. It does not matter what material the radiator is made of, the main thing is that it is correctly selected in terms of power and suits the user in all respects. In general, for comparison, it does not hurt to get acquainted with all the nuances of the operation of a particular device, as well as where which one can be installed.

Comparison by other characteristics

One feature of battery operation - inertia - has already been mentioned above. But in order for the comparison of heating radiators to be correct, it must be done not only in terms of heat transfer, but also in other important parameters:

- working and maximum pressure;

- the amount of water contained;

- mass.

The operating pressure limit determines whether the heater can be installed in multi-storey buildings where the height of the water column can reach hundreds of meters. By the way, this restriction does not apply to private houses, where the pressure in the network is not high by definition. Comparing the capacity of radiators can give an idea of the total amount of water in the system that will need to be heated. Well, the mass of the product is important in determining the place and method of its attachment.

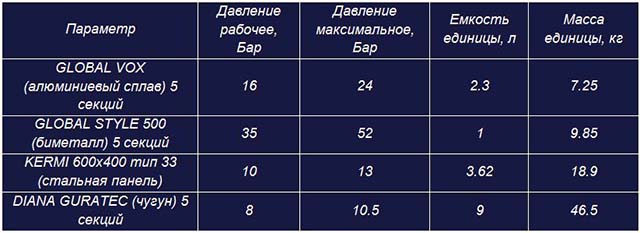

As an example, a comparison table of the characteristics of various heating radiators of the same size is shown below:

Note. In the table, a heater of 5 sections is taken as 1 unit, except for a steel one, which is a single panel.

Conclusion

If we compare a wider range of manufacturers, it will still turn out that in terms of heat transfer and other characteristics, aluminum radiators firmly hold the first place. Bimetallic ones will cost more, which is not always justified, since they are better only in terms of working pressure. Steel batteries are more of a budget option, but cast iron ones, on the contrary, are for connoisseurs. If you do not take into account the Soviet cast-iron "accordions" MC140, then retro radiators are the most expensive of all existing ones.

- Heading: