Open-type expansion tank for heating - types, types, applications

1.

2.

3.

4.

5.

Expansion tanks for heat supply systems are installed to compensate for temperature changes in the volume of the coolant in closed heat supply systems. Even at school, in physics lessons, they study that water, when heated, significantly increases the specific volume, and since the circuit is closed, it needs to go somewhere. The tank will not only accept the excess liquid formed during heating, but also make up for its deficiency during cooling.

When there is no expansion device, in the event of an increase in temperature, the hydraulic pressure in the system increases and, since water is incompressible, the destruction of the heating structure becomes possible.

Features of the use of an expansion tank

The use of an expansion tank, such as in the photo, is justified by the fact that heating water by 10 degrees leads to an increase in its volume by 0.3%. Thus, when the temperature of the coolant in the system increases from 10-15°C to 80-95°C, then its volume will increase by about 2.4-2.8%. With the amount of liquid in the system equal to 100 - 300 liters, the difference can reach from 2.5 to 8 liters of water. And this is a considerable amount of coolant that cannot be hidden in pipes and radiators.An additional capacity is required, or rather an expansion tank of sufficient volume and a suitable type. During heating, excess water will be directed into it, and vice versa, a coolant will flow from the device into the system if the liquid is cooled.

The purpose of the expansion tank

An expansion device is required:- for temporary removal of excess coolant from the system when heating water and for drains when the maximum level of the tank is exceeded;

- to return the coolant to the heating system when it is cooled;

- to maintain the required hydrostatic pressure in the circuit by adjusting the volume of water;

- for the accumulation and removal of air and vapors from the liquid heat carrier, which begin to appear during its heating. So water contains a certain volume of air: it is up to 40 milligrams per liter. When the water warms up, almost 90% of this air is in the form of bubbles. The expansion tank removes excess air to the atmosphere.

Types of expansion tanks

Depending on the features of the design solution, these devices are of the following types:- open ;

- a closed expansion tank with a replaceable or non-replaceable (diaphragm) membrane (read: "").

Open expansion tanks

An open-type expansion tank for heating has advantages and disadvantages. These devices are mounted at the top point of the heating structure (main riser), as a rule, in the attic and they are a cylindrical or rectangular container of an open or semi-open type. Most often, the tank looks like a parallelepiped made of sheet steel and necessarily insulated from the surrounding air.The disadvantages that an open-type expansion tank for heating has are, first of all, its openness (contacts with atmospheric air) and large dimensions. Since the device is open or semi-open, there is a significant evaporation of water from the heating system, which means that constant monitoring of the level of the coolant is required. In case of its deficiency, fluid volumes should be replenished in a timely manner.

The presence of an open structure at the expansion tank leads to additional air inflow into the heating system, which causes increased corrosion of its individual elements. It should be noted that this type of device can now be found in residential buildings that have been in operation for more than a dozen years.

To mount an expansion tank for open-type heating and ensure its reliable thermal insulation, additional efforts and financial costs will be required, since it is necessary to strengthen the ceiling and purchase materials for insulation, etc.

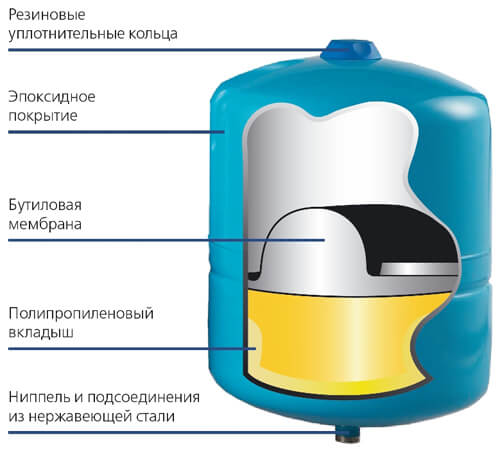

Closed expansion tanks

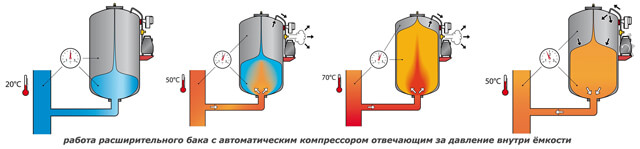

Closed for structures providing heat supply, it is a metal closed container having an oval or spherical shape. Inside the device there are two chambers delimited by a sealed membrane. One of them is intended for a liquid coolant, the second is air - it has a valve, the function of which is to maintain the pressure in the chamber at the desired level.When the first chamber is filled with a heat carrier, the membrane begins to sag and thereby an excess pressure is created in the air part of the tank. When this parameter reaches a certain level, the valve opens slightly and the air leaves the chamber.

Membrane-type expansion devices are produced in two design solutions:

- in a non-replaceable version - with a diaphragmatic membrane;

- in a replaceable version - flange-type tanks.

Initially, the second part of the closed expansion device is filled with air in such a way that it completely occupies 100% of its volume. In the process of heating the coolant, its excess enters the liquid chamber, and the air part is compressed at this time. It increases the pressure that regulates the volume of fluid in the heating system. Some manufacturers fill the air chamber with nitrogen at a pressure that is equal to the water pressure in the heating system.

A flanged-type membrane tank is equipped with a replaceable membrane, the neck of which is fixed to the heating structure with a slate with a pipe. Such an expansion device does not have contact of the coolant with the inner walls, since the liquid enters only into the membrane. For this reason, it makes no sense to use a special coating for the inside. If necessary, the membrane can be replaced with a new product.

It is convenient to mount an expansion tank of this type - it can be installed in the immediate vicinity of the heating boiler (modern small-capacity units are produced, including with built-in expansion devices).

Expansion tanks of closed type have the following advantages:

- the coolant in them does not come into contact with air. As a result, the liquid does not evaporate from them, and pipes and radiators do not oxidize;

- the probability of water overflowing over the edge of the device approaches zero (if an expansion tank for open-type heating is installed, this happens quite often);

- convenient installation almost anywhere (with the exception of the pipeline immediately after the pump);

- low probability of air congestion;

- safety during operation and reliability in operation at low financial costs.

- the volume of the device depends on the capacity of the heating system;

- when a high temperature is required for heat supply, a larger product is installed;

- the smaller the difference in height between the tank installation site and the highest point of the system, the smaller the capacity of the tank can be used.