Expansion tank for heating. Features of choice

To extend the service life of heating equipment and compensate for the thermal expansion of the coolant, an expansion tank is installed in the heating system. Which expansion tank for heating to choose will be considered in this article.

Features and functions of the expansion tank for heating

With an increase in temperature in the heating system by 15 degrees, due to thermal expansion, the volume of the coolant increases by half a percent. The expansion tank compensates for this expansion, the excess heat transfer fluid enters the tank capacity. When the coolant cools down, the expansion tank mechanism pushes the missing liquid back into the system.

If a small water leak occurs, so that there is no decrease in the pressure level in the system, the expansion tank pushes the coolant out, thereby compensating for the losses.

If there is no expansion tank in a closed heating system, the expansion of the coolant leads to an increase in pressure, rapid wear of the heating system components, or breakage and rupture of pipes and taps.

The scope of use of the expansion tank for heating:

- heating system powered by heat pumps and solar collectors;

- autonomous heating system;

- independent heating system connected to the central heating;

- closed loop system.

Advantages of installing an expansion tank for heating:

- no water pollution;

- low cost;

- ensuring safety and reliability;

- no heat loss;

- the minimum amount of air in the system;

- pressure adjustment;

- the use of an expansion tank does not depend on the type and quality of the coolant;

- increasing the life of radiators, pipes, taps and the boiler.

Varieties of expansion tanks for heating

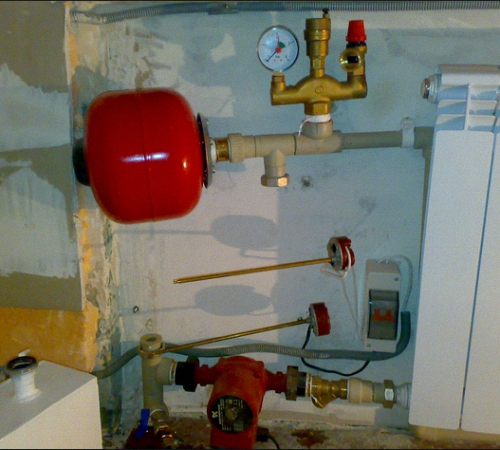

Photo expansion tank for heating:

Depending on the principle of work, there are:

- expansion tanks for open heating;

- closed heating expansion tanks.

Open type expansion tanks are less popular. Such devices are installed in systems where water circulation occurs without the use of a pump. The open expansion tank for heating contains a lid that can be easily opened when water needs to be added. The disadvantage of an expansion tank for open heating is the connection of the coolant with oxygen, which leads to the formation of corrosion in the heating system. In the absence of tightness in an open heating tank, water evaporates faster from the system, and it should be constantly added. The installation of an open expansion tank should be carried out at the highest point of the heating system, and this procedure is not always available.

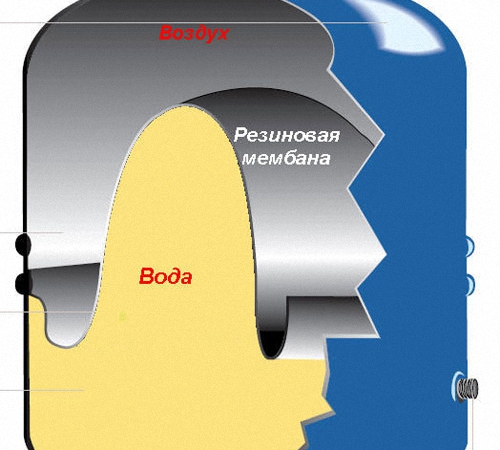

A closed or membrane expansion tank of the heating system is installed in a system where the movement of the coolant is provided by a pump. The closed-type expansion tank is made in the form of a steel tank without a lid, which has an internal partition in the form of a rubber membrane. One half serves to fill with coolant, and the second is air or nitrogen. The expansion tank is coated with powder-type paint in order to avoid mechanical damage to the walls of the vessel at a high temperature of the coolant. On one side, the membrane expansion tank is attached to the heating system using a fitting or flange, and the other side is used for air injection. The pressure in the heating expansion tank allows you to automatically adjust the flow of coolant into the system or back into the vessel.

Closed expansion tanks are divided into:

- interchangeable,

- non-replaceable.

Replaceable type expansion tanks are more expensive, but have a number of advantages:

- the possibility of replacing the membrane in case of damage or rupture;

- savings on pipes, since there is no need to install a closed expansion tank at the top of the heating system;

- ensuring minimal heat loss;

- since the coolant does not come into contact with the oxygen of the pipe and the entire system is protected from rust formation;

- vertical or horizontal arrangement of the membrane;

- exclusion of communication with the metal inner wall of the tank;

- easy replacement of the membrane is carried out through the flange of the expansion tank.

Non-replaceable expansion tanks, although they have a lower cost and do not allow membrane replacement. The membrane in the non-replaceable type expansion tank is located tightly and is firmly pressed against the inner surface of the tank wall. Damage to the membrane occurs only if the heating system is not started correctly, when the pressure rises quickly and exceeds the maximum allowable rate.

Depending on the type of membrane, expansion tanks are distinguished with:

- balloon membrane,

- diaphragmatic membrane.

An expansion tank with a balloon membrane is more reliable and has a larger volume. The coolant does not come into contact with the walls of the tank, which prevents the formation of corrosion.

The flat expansion tank for heating is equipped with a diaphragm-shaped partition wall, which cannot be replaced if damaged.

Selection of an expansion tank for heating

The size of the expansion tank for heating depends on such factors:

- type and capacity of the entire heating system;

- limiting value of the operating temperature of the coolant;

- ultimate pressure;

- the height at which the expansion tank is installed.

To determine the approximate volume of the expansion tank, you need to know the total volume of the entire heating system: pipelines, heating appliances and a heating boiler. From this volume, 10% should be calculated. For example, if the total volume of the heating system is 600 liters, then an expansion tank with a capacity of 60 liters should be selected.

3% of the volume of the expansion tank for heating falls on the reserve supply of coolant to compensate for possible leaks.

The exact calculation of the expansion tank for heating is carried out with the help of specialists or special online calculators.

Tips for choosing the right expansion tank:

1. After carrying out the calculations, care should be taken that the pressure surges in the heating system do not exceed the maximum units indicated in the technical data sheet of the device.

2. The calculation, as a result of which the volume of the expansion tank will be revealed, is better to increase by a couple of units. A larger expansion tank will not bring any negative consequences, and a smaller expansion tank can adversely affect the operation of the system.

3. Before installing the expansion tank, find out the parameters of the device in order to avoid problems with transporting the tank to the room.

4. If glycol mixtures are used as the heating medium, the preliminary calculation of the expansion tank should be increased by half.

5. With frequent operation of the safety valve, the installation and selection of the expansion tank was done incorrectly.

1. It is better to give preference to a membrane or closed expansion tank. Although such a tank is more expensive, a heating system in which a closed-type expansion tank is installed will last longer due to the lack of contact between the coolant and oxygen.

2. Pay attention to the material of the rubber baffle of the closed expansion tank. Manufacturers use natural butyl rubber or EPDM rubber for these purposes.

3. If the expansion tank is to be used in conjunction with a central heating system, the membrane rubber must be strong and resistant to high temperatures. Since central heating does not involve large pressure surges, but the temperature of the coolant is quite high.

4. A tank with a high elasticity of the membrane is suitable for a private heating system, since high pressure drops are typical for this type of heating system.

5. To use the expansion tank not only in the heating system, but also in the water supply system, the rubber for the membrane must be food grade so as not to lower the quality characteristics of the water.

6. When choosing between a replaceable and a non-replaceable membrane, it is better to give preference to the first option. Since if the non-replaceable membrane is damaged, the expansion tank must be completely changed.

7. Before buying an expansion tank, study the technical characteristics of the device, ask for quality certificates for the purchased products.

8. Be sure to issue a warranty card.

9. The main conditions for the correct choice of an expansion tank are resistance to diffusion, temperature and pressure changes, durability, compliance with sanitary and hygienic standards, and the use of high-quality materials in the manufacture.

Manufacturers of expansion tanks for heating

1. Expansion tank for heating Wester (UK)

Peculiarities:

- made of high quality steel;

- do an excellent job of compensating for the expansion of the coolant;

- the membrane is made of EPDM;

- availability of a quality certificate;

- tanks are equipped with replaceable membranes;

- lack of contact of water with air;

- Wester expansion tanks are available in capacities from 8 to 2000 liters.

Expansion tank of the heating system price: from $ 18 for an expansion tank with a volume of 8 liters, up to $ 3600 for an expansion tank with a volume of 2000 liters.

2. Expansion tank Zilmet (Italy)

Peculiarities:

- designed for installation in an individual heating system;

- carbon steel - the basis for the metal body of the Zilmet expansion tank;

- the presence of a pneumatic valve inside the expansion tank;

- the minimum tank volume is 4 liters, and the maximum is 1000 liters;

- color scheme: red;

- operating temperature from 0 to +98 °C;

- the company produces expansion tanks for the heating system and for the water supply system;

- expansion tanks for heating are produced in two series: Cal PRO - expansion tanks for the heating system, OEM PRO - flat expansion tanks for boilers;

- price: from 30 to 2600 $.

![]()

3. Expansion tank of the Reflex heating system (Germany)

Peculiarities:

- high level of hydraulic stability;

- lack of air in the heating system;

- protection against pressure drops;

- variety of expansion tanks.

Varieties of expansion tanks Reflex:

- series N, NG - represents expansion tanks with irreplaceable membranes and polymer coating. The limiting operating temperature is 70 °C. The volume of the tank varies from 8 to 1000 liters;

- The S series represents white and red expansion tanks for use in the heating and water supply system. Temperature limit 70 °C. The minimum volume is 8 l, the maximum is 600 l;

- the G series represents expansion tanks only in red color which have a replaceable diaphragm and pneumomanometer.

Price: from 20 to 4000 $.

4. Expansion tank for heating Cimm (Italy)

Peculiarities:

- non-replaceable expansion tanks are produced for the heating system;

- for the manufacture of expansion tank membranes intended for installation in a water supply system;

- the minimum volume of expansion tanks is 6 liters, and the maximum is 1000 liters.

Varieties:

- The CP series represents flat expansion tanks with a volume of 6 to 18 liters, a maximum operating temperature of +90 °C;

- The ERE series is a membrane balloon expansion tank that can withstand a temperature of +100 °C.

5. Expansion tanks Gilex (Russia)

Peculiarities:

- purpose: removal of an additional volume of coolant;

- varieties: expansion tanks of open and closed type;

- volume from 6 to 300 l;

- models with a volume of more than 12 liters withstand a pressure of 6 atmospheres.

6. Expansion tank Flexcon (Netherlands)

Peculiarities:

- a variety of expansion tanks, according to the type of pressure in the system: expansion tanks for high, medium and low pressure;

- a reliable membrane that covers the walls of the tank;

- a special clamping ring is able to hold pressure, preventing the water level from dropping;

- minimal air ingress into the system;

- lack of water evaporation;

- application in heating systems with ethylene glycol mixtures;

- application: closed heating systems, air conditioning systems;

- operating temperature from -10 to 120 °C;

- volume from 6 to 12000 l.

Varieties:

- models of the C series are designed for heating systems with low pressure up to 3 bar, the maximum temperature for normal operation of the device is +70 ° C;

- the CE series is designed for medium pressure heating systems, maximum pressure 6 bar;

- the CE series for high pressure represents expansion tanks that can withstand pressures up to 10 bar;

- the PRO, M series is represented by collapsible expansion tanks for heating of vertical or horizontal design, with a maximum filling volume of 62% and an operating temperature of 70 °C.