Frequency and methods of pressure testing of the heating system

During the operation of the heating system of a residential building or office building, equipment malfunctions occur. To identify obvious and hidden defects, pressure testing of the heating system is carried out. Timed to coincide with the beginning of the heating season or done after the repair. In most cases, the work is carried out by a special organization that has the appropriate permission. In a private house, such tests can be carried out independently. However, before starting work, you must familiarize yourself with the rules for their implementation.

Pressurization of the heating system - what is it? Actions aimed at checking equipment and pipelines in order to confirm proper operation for their intended purpose define this concept. For this, hydraulic or pneumatic pressure tests are carried out. If the checks passed with a positive result, this means that the heating equipment is ready for further operation.

The current documents SP 60.13330.2012 (SNiP 41-01-2003) "Heating, ventilation and air conditioning" and the Rules for the technical operation of thermal power plants explain why pressure testing and the rules for its implementation are needed, and there is also a sample act on the results of inspections.

The frequency of checking the heating system for leaks

Depending on the tasks to be solved and the achievement of the expected results, the construction or operating organization determines the time when the heating system is pressure tested. It is customary to distinguish 3 types of work:

- Primary. It is carried out after the installation of equipment is completed until the pipelines are closed with insulation, screed, sheathing and other building materials. At this stage, the quality of the work performed is checked. All equipment is involved in the tests (heating stations, pipelines, instrumentation, etc.).

- Periodic (repeated). Pressure testing of the heating system of an apartment building is carried out before each heating period after the completion of all restoration work. The purpose of these tests is to confirm the working condition of equipment and pipelines and its readiness for the passage of the heating season.

- Extraordinary. Tests are mandatory carried out at the request of the supervisory authorities and after repairs associated with the replacement of equipment and welding. If it is possible to disable the defective area, then local pressure testing is carried out.

In an apartment building with individual heating, the decision on the timing and methods of testing is made by the tenant.

Crimping methods

In most cases, the heating system is tested for leaks with water. In private houses in which heating of a small volume and a pressure of not more than 2 kg / cm² is installed, testing with air (pneumatic tests) is allowed. The same applies to buildings that are not connected to the water supply and where heating operation is not planned in the near future.

Pressurization with water is carried out at an air temperature of at least +5 °C. The pressure is raised by a hand pump to a value exceeding the working one by 1.5 times. In this case, the parameters of hydrotesting of the installed equipment should be taken into account. The holding time under pressure should be sufficient to inspect the system, but not less than 30 minutes. A slight decrease in pressure gauge readings may be due to a change in temperature and is not critical during testing.

The types of pressure testing determine the scope of tests that should be sufficient to confirm the operability of the equipment. During the filling of pipelines with water, air must be removed through the ventilation of the batteries. It must be remembered that water does not compress. Therefore, the pressure rise is carried out slowly, with time delays.

How to crimp a water heating system with your own hands

Methods for checking the heating system in a private house depend on its design. In most cases, a scheme is used with an expansion tank equipped with an automatic pressure relief valve. In houses of earlier construction, the expander has an air vent, i.e. constant contact with the atmosphere. In this case, the pipelines and equipment are flushed, then the system is filled with coolant to the upper level in the expansion tank and the problem nodes are checked: welded and threaded joints, boiler fittings, etc.

If no defects are found, then part of the water drains to the average level in the expander and the system remains under hydrostatic pressure until it is put into operation. In this case, the act of hydrotesting is not drawn up.

When using a relief valve in the heating system, the pressure testing rules do not differ from checking the tightness of equipment in multi-storey buildings.

Work procedure

After installation of pipelines and installation of heating devices, before carrying out hidden work, heating pipelines are subject to mandatory pressure testing. This is due to the fact that after sealing a part of pipes for pouring or panels, it will no longer be possible to conduct their external inspection. In most cases, pressure testing of the heating system with air is carried out. This is due to temperature, the presence of water supply, the need for drainage of the coolant in winter, etc.

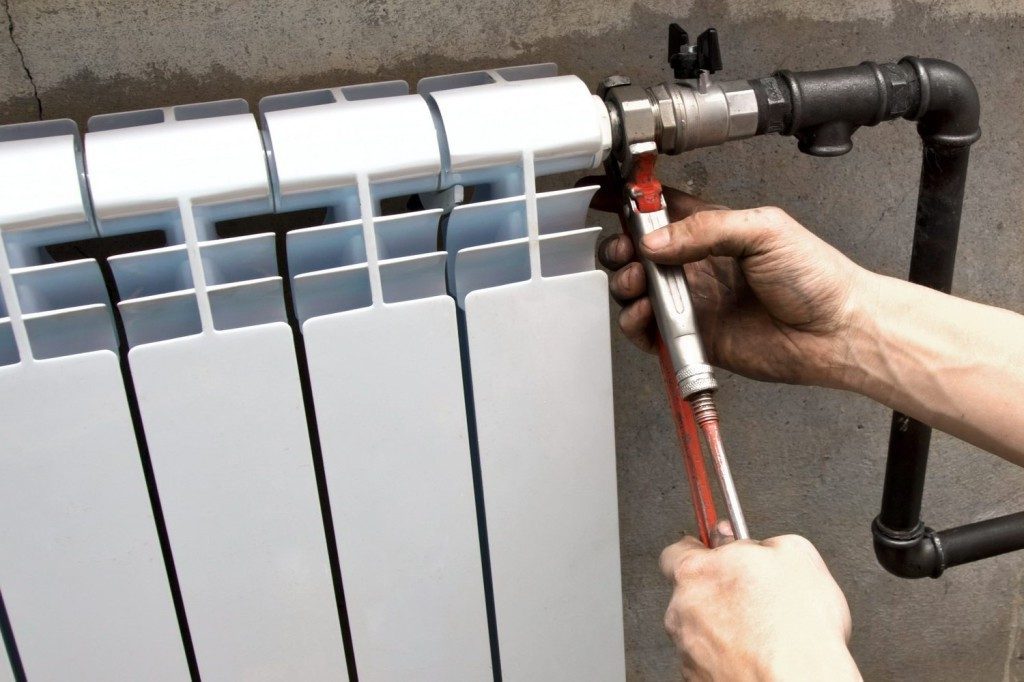

The pressure source is connected to the drain valve through a fitting or directly to the battery instead of the Mayevsky tap. Raise the pressure to the value of the relief valve (about 2 kg / cm²). Control of density of the equipment is carried out on the manometer. Inspection of the system is carried out after stabilization of the parameters.

The time the equipment is under pressure is not limited, but should be sufficient for a complete external inspection. In this state, the system can be left overnight. Defects are determined by the sound of the outgoing air. Suspicious connections are washed and the place of leakage is determined by the formation of bubbles. If the pressure gauge readings have not decreased by more than 0.1 kg / cm², then it is considered that the pressing is completed with a positive result.

Hydraulic tests of the heating system in a private house are carried out in the following order:

- Disconnect the boiler from the network, because. pressure will be released through the relief valve.

- Open air vents on radiators located in the rooms of the upper floors.

- Connect the pump to a drain valve located at the lowest point in the system.

- The pipelines are filled with a coolant with a temperature not exceeding +45 °C.

- After filling the pipelines, the air is re-bled through the air vents until water appears.

- When a pressure of 2 kg/cm² is reached, the drain valve is closed and the system is put on hold.

- They carry out an external inspection of pipelines, welded joints, soldering points (for plastic pipes), the condition of joints and fittings glands.

- After the test is completed, release the pressure. If you plan to use the heating system, then the water does not drain.

Hydrotesting is considered completed if no leaks or wetting of welded joints are detected, and the pressure gauge readings remain within the normal range. When carrying out periodic pressure testing, a local check of the unit on which repair work was carried out is allowed.

Crimping tool

In most cases, hydrotesting of heating equipment is carried out in cottages by supplying tap water. A pressure of 2 atm is sufficient to detect defects. If water has not yet been supplied to the house, then pressure can be created using a pressure tester. It is a positive displacement hand pump (piston or plunger) equipped with a pressure gauge and control valves. The coolant is manually poured into the existing container, from which it is pumped into the system.

The device is connected to the drain valve. After the heating system is completely filled and air is removed, the pressure tester creates the necessary pressure. The coolant is drained into the same container through a special drain valve. You can buy the device in the store, but you should remember that its price is high. To perform one-time work, it is easier to rent it.

For pneumatic testing, an automobile foot pump equipped with a pressure gauge is most often used. To connect to the system, a special comb is assembled, consisting of a pressure gauge and shut-off ball valves. All threaded connections must be securely sealed to prevent air leakage.

If it is not possible to rent a pressure tester, then a combined leak test is used. The system is filled with water and pressurized with air. In this case, the air pump is connected at the top point so that the system is less aired.

It must be remembered that hydropneumatic tests are works of increased danger. Therefore, it is necessary to strictly observe the safety rules when working with equipment under pressure.