What you need to know about expansion tanks for heating systems?

Everyone who taught physics at school is well aware that water has one very unusual property - under certain conditions it can expand. An expansion tank for heating is a special container, the main task of which is to absorb excess volume of accumulated liquid. That's why you need an expander.

Heating systems have their own level of capacity. Given the fact that this system is closed, the appearance of an additional volume of water causes increased hydraulic pressure. Inaction in this case can lead to irreparable consequences, up to the failure of the devices.

To prevent such a development of events, expansion tanks for heating systems are used. The selection of a tank of the required size is carried out by specialists of design and installation organizations, depending on the type of heating and the amount of coolant circulating in it.

Tasks, functions and principle of operation

To understand the need to install such units, it is necessary to consider the functions that these expanders perform. An increase in the temperature inside the boiler for every 10 degrees Celsius leads to an increase in the volume of the heated liquid by approximately 0.3%.

The simplest mathematical calculations make it clear that bringing the coolant to the boiling point (100 degrees) will increase the total volume of water by approximately 3%. This is a fairly significant amount that can seriously affect the functioning of the entire system as a whole. Therefore, a special device is used to compensate for the thermal expansion of the liquid.

The device and principle of operation of the expander.

Thus, the expansion tank for heating performs several important functions at once:

- removal of excess volumes of water into the drain when a certain level of filling is reached;

- replenishment of water volumes when it leaks or when the temperature drops;

- maintaining the required level of hydrostatic pressure by adding or removing appropriate volumes of coolant;

- collection of air and water vapor that are released in the boiler when the temperature of the liquid rises.

In any heating system that uses ordinary water as a heat transfer fluid, a certain percentage of air is constantly present. According to experts, 1 liter of piped water contains 40 mg of air, which is in a dissolved state.

However, with increasing temperature, its solubility deteriorates somewhat, which leads to the release of about 90% in the form of air bubbles. Open-type tanks allow excess air to be vented to the atmosphere.

Flaws

With all the variety of functions performed, the expansion tank for heating has some negative qualities:

- large size, which can make it difficult to place them indoors;

- reduction in the resistance of various devices, pipes and radiators to corrosion;

- the walls of this heating equipment consume heat in certain quantities.

Depending on the design features, expansion tanks are divided into two main groups: open and closed. How to choose the one that suits you, consider further.

open

Relating to the first group, they are most often mounted in attics, that is, above the top point of the heating system. An open expansion tank is a rectangular or cylindrical container, for the production of which sheet steel is used. After their installation, it is necessary to make thermal insulation. No configuration is required before switching on.

Example: a circulation pipe is used to drain the liquid. A control pipe adjoins the sink, on which a shut-off valve is installed to regulate the water level in the tank. It should be noted the expansion pipe, through which the liquid enters directly into the tank. All these and other pipes are connected using special nozzles.

Open expanders have certain negative qualities.

For example, the owners of this auxiliary system will constantly have to replenish the volume of the liquid, since it has an increased volatility.

Before checking the coolant level, it is necessary to lift the protective cover of the open tank. In addition, additional monetary costs for its installation will be required, since the tank will have to be mounted at the top of the heating system.

It is also necessary to pre-insulate the place where the installation will be made. Due to the fact that the open expander operates at reduced pressure, it is somewhat difficult to control such a system.

And lastly, air enters the expandomat having the above device, which leads to an increased level of corrosion of the main elements.

Closed

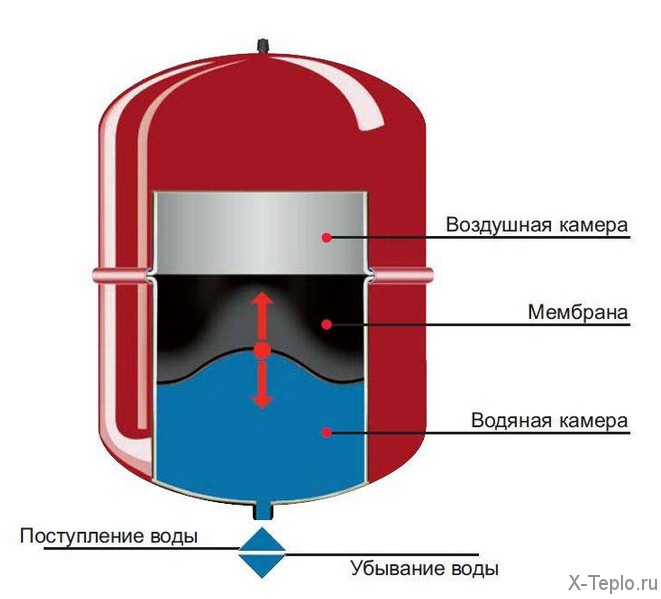

Let's move on to closed expansions. A closed tank is a special container made of metal, oval or spherical in shape. The peculiarity of this equipment is that inside it is divided into two chambers - air and liquid - using a sealed membrane. It is for this reason that such expandomats are called membranous.

The principle of operation of the tank is as follows: the air compartment is equipped with a valve, the task of which is to bleed air with a significant increase in the pressure level. Due to this, the coolant is able to fill the internal volume of the chamber. When the water pressure increases, the membrane made of heat-resistant rubber flexes and releases air from the compartment.

After the pressure is completely normalized, the membrane returns to its initial position, allowing air to flow back into the heating tank.

It is worth noting that membrane-type expansion tanks are available in various configurations. In some cases, the tank has one of the chambers filled with nitrogen under high pressure, while the other compartment is designed to be filled with water or other coolant. A feature of such a system is that the liquid chamber is connected to the heating system.

After that, the pressure in each of the compartments tends to be established at the initial level. The expansion tank of the closed type is set up at the factory, therefore, by purchasing this product, the buyer receives the product completely ready for use.

Mounting and positioning are also easy, but there may be a problem with the lack of free space, so if there is not enough free space, you can use a flat tank, the dimensions of which are optimized for installation in small spaces.

Depending on the type of membrane, there are two main types of closed tanks.

Expansomats with diaphragm non-replaceable membrane

To create a carbon body of this unit, a deep cold stamping method is used. The membrane is firmly fixed along the perimeter of the compartments. The inner surface of the body is covered with epoxy moisture-resistant paints that protect the surface from the harmful effects of water.

Enamel is used to cover the outer part of the case. In the initial stage, the vacuum tank is 100% filled with air, which, under high pressure, presses the membrane against the inner surface.

As the temperature inside the tank rises, the pressure begins to increase and the coolant begins to flow, which pushes the membrane in the opposite direction. At the same time, the air in the second compartment begins to compress.

Flanged with replaceable diaphragm

Such devices are manufactured in both horizontal and vertical versions. The key design features of the model include the fact that the coolant does not come into contact with the metal part of the expansion tank, since it is completely located inside the membrane.

As a result, it is not necessary to use a special coating to protect its surface from liquid exposure. In addition, it is possible, if necessary, to replace the membrane.

Often closed devices are mounted near the boilers. A second expansion tank can be installed in the heating system by placing it next to the boiler if the circuit also supports a hot water supply.

The main advantages of closed expanders

Depending on the power of the boiler, as well as on the volume of liquid used, the volume of the membrane tank for heating is slightly different.

Such equipment is recommended to be installed in country houses, since they have numerous positive qualities when compared with open tanks.

The coolant does not come into contact with air, as a result of which the liquid does not evaporate, for the same reason pipes and radiators are not oxidized by air, which increases their service life.

In closed tanks, the probability that the liquid will spill out of the limits is zero, so you don’t have to worry about finishing walls and floors. Installation can be carried out anywhere in the cottage, there is no chance of air jams, which in open devices occur as a result of increased pressure at the top point of the heating system.

There is also no need to feed the heating system with coolant. Conclusion - it is very easy to operate a membrane expansion tank.

Closed tanks mean economy, safety and reliability.

Installation

The expansion tank is installed in any part of the heating system, but it is preferable to install it in front of the forced circulation pump. Installation can be performed with both top and bottom connections.

If during the work it turns out that the designer made a mistake and the accepted volume of the tank is not enough to compensate for the thermal expansion of the liquid, instead of replacing the expandomat with a larger one, a second smaller tank is installed.

In the case of installation in a heating boiler system with a built-in expander, installation of a separate tank may not be required. Also, when considering various installation options, it should be remembered that in order to reduce heat loss, it is better to choose the mount in which the supply line will have the shortest length.