Smooth ignition and attenuation of LEDs, scheme. Smooth ignition for LEDs Slow ignition and attenuation of LEDs the simplest circuit

In some cases, LED lamps or indicators are required to smoothly turn on and off. Naturally, the LED turns on instantly with normal power supply (unlike incandescent lamps), which requires the use of a small control circuit in this case. It is not complicated and in its simplest form it consists of only a dozen radio components, led by a couple of transistors.

Collection of circuit diagrams

First, there are well-known schemes from the Internet, and then a few personally collected and perfectly working. The first circuit is the simplest - when power is applied, the diode gradually increases the brightness (the transistor opens as the capacitor charges):

I made such a scheme for smoothly turning on and off the LEDs, the required current through the diode is selected by the resistor R7. And if you connect this breaker instead of a button, then the circuit itself will ignite and fade out, only with the resistor R3 you need to set the desired time interval.

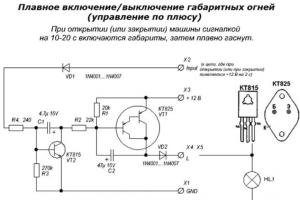

Here are two more schemes for smooth ignition and attenuation, which I also personally soldered:

All these designs are not related to network (from 220 V), but to ordinary low-voltage LED indicators. Industrial LED lamps with their unknown drivers, most often work unpredictably in different smooth controllers (or blink, or turn on abruptly anyway). So you need to control not the drivers, but directly the LEDs. Schemes provided by senya70.

In addition to a purely decorative function, for example, car interior lighting, the use of soft start, or ignition, is of fundamental practical importance for LEDs - a significant extension of the service life. Therefore, we will consider how to make a device for solving such a problem with your own hands, is it worth it to make it yourself or is it better to buy a ready-made one, what is required for this, and also what circuit options are available for amateur manufacturing.

The first question that arises when it is necessary to include a module for the smooth ignition of LEDs in the circuit is whether to make it yourself or buy it. Naturally, it is easier to purchase a ready-made block with the given parameters. However, this method of solving the problem has one serious disadvantage - the price. When making it yourself, the cost of such a device will decrease several times. In addition, the assembly process will not take much time. In addition, there are proven options for the device - it remains only to acquire the necessary components and equipment and connect them correctly, in accordance with the instructions.

Note! LED lighting is widely used in automobiles. For example, it can be daytime running lights and interior lighting. The inclusion of a soft ignition unit for LED lamps allows, in the first case, to significantly extend the life of the optics, and in the second case, to prevent the driver and passengers from being blinded by the abrupt switching on of a light bulb in the cabin, which makes the lighting system more visually comfortable.

What do you need

To correctly assemble a soft ignition module for LEDs, you will need a set of the following tools and materials:

- Soldering station and a set of consumables (solder, flux, etc.).

- Fragment of a textolite sheet for creating a board.

- Case for housing components.

- Necessary semiconductor elements - transistors, resistors, capacitors, diodes, ice crystals.

However, before proceeding with the independent manufacture of a soft start / attenuation unit for LEDs, you need to familiarize yourself with the principle of its operation.

The image shows a diagram of the simplest device model:

It has three work items:

- Resistor (R).

- Capacitor module (C).

- LED (HL).

A resistor-capacitor circuit based on the principle of RC-delay, in fact, controls the ignition parameters. So, the greater the value of resistance and capacitance, the longer the period or the more smoothly the ice element turns on, and vice versa.

Recommendation! At the moment, a huge number of soft ignition block circuits for 12V LEDs have been developed. All of them differ in a characteristic set of pluses, minuses, level of complexity and quality. There is no reason to manufacture devices with extensive boards on expensive components on your own. The easiest way is to make a module on a single transistor with a small strapping, sufficient for slow turning on and off the ice bulb.

Schemes of smooth switching on and off of LEDs

There are two popular and self-made options for soft ignition schemes for LEDs:

- The simplest.

- With the function of setting the start period.

Read also Dynamic monitor backlight: characteristics, scheme, settings

Consider what elements they consist of, what is the algorithm of their work and the main features.

A simple scheme for smoothly turning off LEDs

Only at first glance, the smooth ignition scheme presented below may seem simplified. In fact, it is very reliable, inexpensive and has many advantages.

It is based on the following components:

- IRF540 is a field type transistor (VT1).

- Capacitive capacitor 220 mF, rated at 16 volts (C1).

- A chain of resistors for 12, 22 and 40 kilo-ohms (R1, R2, R3).

- Led-crystal.

The device operates on a 12 V DC power supply according to the following principle:

- When the circuit is energized, current begins to flow through block R2.

- Due to this, the C1 element is gradually charged (the capacitance rating increases), which in turn contributes to the slow opening of the VT module.

- The increasing potential at pin 1 (field gate) provokes the flow of current through R1, which contributes to the gradual opening of pin 2 (VT drain).

- As a result, the current passes to the source of the field unit and to the load and provides a smooth ignition of the LED.

The process of extinction of the ice element proceeds according to the opposite principle - after the power is removed (opening the "control plus"). In this case, the capacitor module, gradually discharging, transfers the capacitance potential to the blocks R1 and R2. The speed of the process is regulated by the value of the element R3.

The main element in the soft ignition system for LEDs is the MOSFET IRF540 transistor of the field n-channel type (as an option, you can use the Russian model KP540).

The remaining components are related to the strapping and are of secondary importance. Therefore, it would be useful to give here its main parameters:

- The drain current is within 23A.

- The polarity value is n.

- The drain-source voltage rating is 100V.

Important! Due to the fact that the speed of ignition and attenuation of the LED depends entirely on the value of the resistance R3, you can choose the required value to set a certain time for soft start and turn off the ice bulb. In this case, the selection rule is simple - the higher the resistance, the longer the ignition, and vice versa.

Improved version with the ability to set the time

Often there is a need to change the period of smooth ignition of the LEDs. The scheme discussed above does not provide such an opportunity. Therefore, two more semiconductor components need to be introduced into it - R4 and R5. With their help, you can set the resistance parameters and thereby control the ignition speed of the diodes.

On the Internet, there are many schemes for smooth ignition and attenuation of 12V powered LEDs that you can do yourself. All of them have their advantages and disadvantages, differ in the level of complexity and quality of the electronic circuit. As a rule, in most cases it makes no sense to build bulky boards with expensive parts. In order for the LED crystal to smoothly gain brightness at the moment of switching on and also smoothly go out at the moment of switching off, one MOS transistor with a small strapping is enough.

Scheme and principle of its operation

Let's consider one of the simplest options for the smooth switching on and off of LEDs controlled by a positive wire. In addition to the simplicity of execution, this simplest circuit has high reliability and low cost. At the initial moment of time, when the supply voltage is applied, current begins to flow through the resistor R2, and the capacitor C1 is charged. The voltage on the capacitor cannot change instantly, which contributes to the smooth opening of the transistor VT1. Increasing gate current (pin 1) passes through R1 and leads to an increase in the positive potential at the drain of the FET (pin 2). As a result, the load from the LEDs is smoothly turned on.

When the power is turned off, the electrical circuit breaks along the "control plus". The capacitor begins to discharge, giving energy to the resistors R3 and R1. The discharge rate is determined by the value of the resistor R3. The greater its resistance, the more accumulated energy will go into the transistor, which means that the decay process will last longer.

To be able to adjust the time of full on and off of the load, trimming resistors R4 and R5 can be added to the circuit. At the same time, for correct operation, it is recommended to use the circuit with resistors R2 and R3 of a small value.  Any of the circuits can be independently assembled on a small board.

Any of the circuits can be independently assembled on a small board.

Circuit elements

The main control element is a powerful n-channel MOS transistor IRF540, the drain current of which can reach 23A, and the drain-source voltage is 100V. The considered circuit solution does not provide for the operation of the transistor in limiting modes. Therefore, he does not need a radiator.

Instead of IRF540, you can use the domestic analogue of KP540.

The resistance R2 is responsible for the smooth ignition of the LEDs. Its value should be in the range of 30-68 kOhm and is selected during the setup process based on personal preferences. Instead, you can install a compact tuning multi-turn resistor at 67 kOhm. In this case, you can adjust the ignition time with a screwdriver.

The resistance R3 is responsible for the smooth fading of the LEDs. The optimal range of its values is 20–51 kOhm. Instead, you can also solder a trimmer to adjust the decay time. In series with trimming resistors R2 and R3, it is desirable to solder one constant resistance of a small value. They will always limit the current and prevent a short circuit if the trimmers are turned to zero.

The resistance R1 serves to set the gate current. For the IRF540 transistor, a rating of 10 kOhm is sufficient. The minimum capacitance of capacitor C1 should be 220 uF with a voltage limit of 16 V. The capacitance can be increased to 470 uF, which will simultaneously increase the time for full on and off. You can also take a capacitor for a higher voltage, but then you will have to increase the size of the printed circuit board.

minus control

The above translated schemes are great for use in a car. However, the complexity of some electrical circuits lies in the fact that some of the contacts are closed along the plus, and some - along the minus (common wire or case). To control the above circuit by minus power, it needs to be slightly modified. The transistor must be replaced with a p-channel one, for example IRF9540N. Connect the negative terminal of the capacitor to the common point of three resistors, and close the positive terminal to the source VT1. The modified circuit will be powered with reverse polarity, and the control positive contact will change to negative.

Read also

Recently I decided to assemble a circuit that would allow me to light up any LED strip (whether in a car or at home) smoothly. I did not reinvent the wheel, and decided to google a little. When searching on almost every site, I found circuits where the LED load is severely limited by the capabilities of the circuit.

I wanted the circuit to just smoothly raise the output voltage, so that the diodes flare up smoothly and the circuit was necessarily passive (it did not require additional power and would not consume current in standby mode) and would definitely be protected by a voltage regulator to increase the life of my backlight.

And since I haven’t learned how to etch the boards yet, I decided that first I need to master the simplest circuits and use ready-made circuit boards during installation, which, like the rest of the circuit components, can be purchased at any radio parts store.

In order to assemble a smooth ignition circuit for LEDs with stabilization, I needed to purchase the following components:

In general, a ready-made circuit board is a fairly convenient alternative to the so-called “LUT” method, where almost any circuit can be assembled using the Sprint-Layout program, a printer, and the same textolite. So, beginners should still first master a simpler option, which is much simpler and, most importantly, “forgives mistakes” and also does not require a soldering station.

Having slightly simplified the original scheme, I decided to redraw it:

I know that the transistor and the stabilizer are indicated differently in the diagrams, but it’s easier for me, and it will be clearer for you. And if, like me, you managed to take care of stabilization, then you need an even simpler scheme:

The same, but without the use of the KREN8B stabilizer.

R3 - 10K Ohm

R2 - 51K Ohm

R1 - from 50K to 100K ohm (the resistance of this resistor can control the speed of ignition of the LEDs).

C1 - from 200 to 400 microns F (you can choose other capacities, but you should not exceed 1000 microns F).

At that time, I needed two smooth ignition boards:

- for the already made highlighting of the legs.

- for smooth ignition of the dashboard.

Since I took care of the stabilization of the LEDs that illuminate my legs for a long time, I no longer needed Krenka in the ignition circuit.

Scheme of smooth ignition without a stabilizer.

For such a circuit, I used only 1.5 sq cm of the circuit board, which costs only 60 rubles.

Scheme of smooth ignition with a voltage stabilizer.

Dimensions 25 x 10 mm.

The advantages of this circuit is that the connected load depends only on the capabilities of the power supply (car battery), and on the IRF9540N field-effect transistor, which is very reliable (it makes it possible to connect 140W of load through itself at a current of up to 23A (information from the Internet). The circuit can withstand 10 meters of LED strip, but then the transistor will have to be cooled, since in this design it can be mounted on a field radiator (which of course will lead to an increase in the area of \u200b\u200bthe circuit).

During the first testing of the circuit, a short video was shot:

Initially, R1 was 60K Ohm and I didn’t like the fact that it took about 5-6 seconds to ignite to full brightness, later another 60K Ohm resistor was added to R1 and the ignition time decreased to 3 seconds, which was the most for highlighting the legs.

And since the ignition circuit for lighting the legs had to be connected to the break of the main power circuit, without thinking for a long time how to isolate it, I simply stuffed it into a piece of a bicycle chamber.

There are cases when it is necessary to smoothly turn on the LEDs used for lighting or backlighting, and in some cases turn off. Soft ignition may be required for various reasons.

Firstly, when turned on instantly, the light hits the eyes hard and makes us squint and squint, waiting for our eyes to get used to the new level of brightness. This effect is associated with the inertia of the eye accommodation process and, of course, takes place not only when LEDs are turned on, but also when any other light sources are turned on.

It's just that in the case of LEDs, it is aggravated by the fact that the radiating surface is very small. In scientific terms, the light source has a very large overall brightness.

Secondly, purely aesthetic goals can be pursued: you must admit that a light that smoothly lights up or goes out is beautiful. The LED power circuit needs to be improved properly. Consider two different ways to smoothly turn LEDs on and off.

Delay by RC circuit

The first thing that should come to mind for a person familiar with electrical engineering is the introduction of a delay by including an RC chain in the power circuit of the LEDs: a resistor and a capacitor. The scheme is shown in Fig.1. When voltage is applied to the input, the voltage on the capacitor, as it charges, will increase in a time approximately equal to 5τ, where τ=RC is the time constant. That is, in simple terms, the time the light is turned on will be determined by the product of the capacitance of the capacitor and the resistance of the resistor. Accordingly, the greater the capacitance and resistance, the longer the ignition of the LEDs will take. When the power is turned off, the capacitor will discharge to the LEDs. The time during which a smooth decay will occur will also be determined by τ, but in this case, instead of R, the product will include the dynamic resistance of the LEDs. For example, a 2200 uF capacitor and a 1 kΩ resistor would theoretically "stretch" the turn-on time by 2.2 seconds. Naturally, in practice, this value will differ from the calculated one both due to the spread of parameters (for electrolytic capacitors, the tolerances for the nominal value are usually very large) of the RC circuit, and due to the parameters of the LEDs themselves. We must not forget that the p-n junction will begin to open and emit light at a certain threshold value. The simplest scheme presented makes it possible to understand the principle of operation of this method well, but it is of little use for practical implementation. To obtain a working solution, we will improve it by introducing several additional elements (Fig. 2).  The circuit works as follows: when the power is turned on, the capacitor C1 is charged through the resistor R2, the transistor VT1, as the gate voltage changes, reduces the resistance of its channel, thereby increasing the current through the LED. Turning off the power will cause the capacitor to discharge through the LEDs and resistor R1.

The circuit works as follows: when the power is turned on, the capacitor C1 is charged through the resistor R2, the transistor VT1, as the gate voltage changes, reduces the resistance of its channel, thereby increasing the current through the LED. Turning off the power will cause the capacitor to discharge through the LEDs and resistor R1.

Let's turn on the "brains" ...

If the circuit should provide greater flexibility and functionality, for example, without changing the hardware, we want to get several operating modes and set the ignition and decay times more accurately, then it's time to include a microcontroller and an integrated LED driver with a control input in the circuit. The microcontroller is capable of counting the required time intervals with high accuracy and issuing commands to the control input of the driver in the form of PWM. Switching operating modes can be foreseen in advance and display the appropriate button for this. It is only necessary to formulate what we want to get and write the corresponding program. An example is the high power LED driver LDD-H, which is available with current ratings from 300 to 1000 mA and has a PWM input. The scheme for including specific drivers is usually given in those. manufacturer's description (data sheet). Unlike the previous method, the time to turn on and off will not depend on the spread of the parameters of the circuit elements, the ambient temperature, or the voltage drop across the LEDs. But you will have to pay for accuracy - this solution is more expensive.